Low-cost high-strength and high-toughness bridge steel and preparation method thereof

A high-strength, high-toughness, low-cost technology, which is applied in the manufacture of steel box girders and long-span bridge steel structures, and in the field of metallurgy, can solve the problems of high production costs and achieve low production costs, simple production processes, and small additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

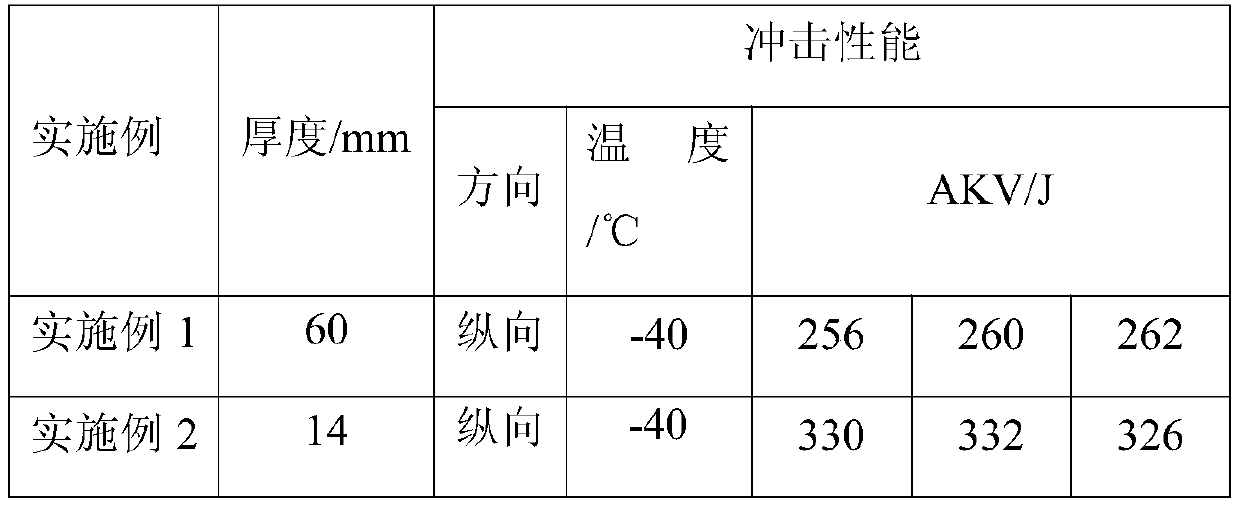

Embodiment 1

[0027] The chemical composition of high-strength and high-toughness bridge steel with a thickness of 60mm is as follows: C: 0.12%, Si: 0.25%, Mn: 1.55%, P: 0.010%, S: 0.002%, Al: 0.030%, Nb: 0.030%, V: 0.040%, Ti: 0.018%, the rest is Fe and unavoidable impurities. The preparation process is as follows: molten iron pretreatment → BOF steelmaking → LF refining → RH vacuum treatment → continuous casting → slow cooling → slab inspection, cleaning, judgment → heating → descaling → rolling → water cooling → flaw detection → spray printing logo → Cutting and sampling → storage.

[0028] The slab is slowly cooled to below 300°C, the thickness of the slab is 300mm, and the steel is tapped at 1170°C through a regenerative heating furnace.

[0029] The heating process adopts a three-stage heating process. The first stage: the temperature of the preheating stage is set at 800°C; Heating 2-2 section temperature is set at 1200°C; the third section: the temperature of the furnace gas in th...

Embodiment 2

[0032] The chemical composition of high-strength and high-toughness bridge steel with a thickness of 14mm is as follows: C: 0.10%, Si: 0.10%, Mn: 1.60%, P: 0.013%, S: 0.003%, Al: 0.045%, Nb: 0.010%, Ti: 0.025 %, the rest is Fe and unavoidable impurities. The preparation process is as follows: molten iron pretreatment → BOF steelmaking → LF refining → RH vacuum treatment → continuous casting → slow cooling → slab inspection, cleaning, judgment → heating → descaling → rolling → water cooling → flaw detection → spray printing logo → Cutting and sampling → storage.

[0033] The slab is slowly cooled to below 300°C, the thickness of the slab is 200mm, and the steel is tapped at 1150°C through a regenerative heating furnace.

[0034] The heating process adopts a three-stage heating process. The first stage: the temperature of the preheating stage is set at 700°C; The heating stage 2-2 temperature is set at 1230°C; the third stage: the temperature of the furnace gas in the soaking ...

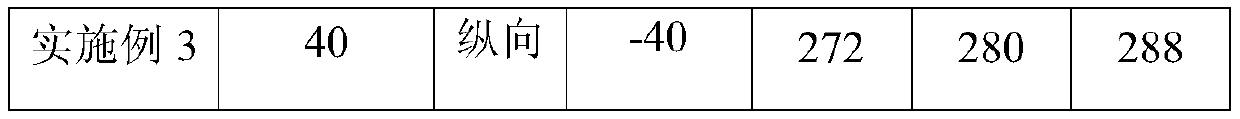

Embodiment 3

[0037] The chemical composition of 40mm high-strength and high-toughness bridge steel steel is as follows: C: 0.13%, Si: 0.35%, Mn: 1.30%, P: 0.015%, S: 0.005%, Al: 0.015%, Nb: 0.035%, V: 0.015 %, Ti: 0.010%, the rest is Fe and unavoidable impurities. The preparation process is as follows: molten iron pretreatment → BOF steelmaking → LF refining → RH vacuum treatment → continuous casting → slow cooling → slab inspection, cleaning, judgment → heating → descaling → rolling → water cooling → flaw detection → spray printing logo → Cutting and sampling → storage.

[0038]The slab is slowly cooled to below 300°C, the thickness of the slab is 300mm, and the steel is tapped at 1180°C through a regenerative heating furnace.

[0039] The heating process adopts a three-stage heating process. The first stage: the temperature of the preheating stage is set at 850°C; Heating 2-2 section temperature is set at 1180°C; the third section: the temperature of the furnace gas in the soaking sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com