Preparation method for resistor sheet used for overvoltage protector of urban rail transit

A technology for rail transit and resistance sheets, applied in overvoltage protection resistors, varistors and other directions, can solve the problems of large energy loss, high production cost, long diffusion time, etc., to achieve energy conservation and environmental protection costs, small aging coefficient, residual The effect of low pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

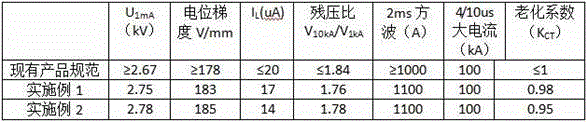

Examples

Embodiment 1

[0026] By mass percentage Bi 2 o 3 : 28.0wt%, NiO: 18.0wt%, Cr 2 o 3 : 1.0wt%, Sb 2 o 3 : 33.0wt%, Mn 3 o 4 : 6.0wt%, Co 3 o 4 : 11.0wt%, SiO 2 : 2.0wt%, containing Ag 2 O glass powder: 1.0wt% is used to prepare ZnO varistor compound additive powder. According to the ratio of the total mass of additive powder, the mass of deionized water, and the mass of agate balls is 1:1:2.5; add ammonium polyacrylate dispersant, the amount is 0.8% of the total mass of powder, and put it into a 10L polyurethane ball mill In the tank, use a tank-type ball mill for ball milling for 40 hours, and the speed is set to 415r / min.

[0027] The additive powder is dried, then pulverized with a pulverizer and sieved.

[0028] Thus, the ZnO varistor additive powder is prepared.

[0029] The composite additive prepared is according to additive: 14.00wt%, ZnO: 86.00wt%, adding Al(NO 3 ) 3 9H 2 O is added according to the weight ratio of 0.05% of the dry material for mixing and ball milling...

Embodiment 2

[0031] By mass percentage Bi 2 o 3 : 25.0wt%, NiO: 17.0wt%, Cr 2 o 3 : 1.0wt%, Sb 2 o 3 : 37.0wt%, Mn3O4: 6.0wt%, Co 3 o 4: 10.0wt%, SiO 2 : 3.0wt%, containing Ag 2 O glass powder: 1.0wt% to prepare ZnO varistor compound additive powder, according to the ratio of the total mass of the additive powder, the quality of deionized water, and the mass of agate balls is 1:1:2.5; add ammonium polyacrylate dispersion The dosage is 0.8% of the total mass of the powder, put it into a 10L polyurethane ball mill tank, and mill it with a tank ball mill for 40 hours, with the speed set at 415r / min.

[0032] The additives are dried, then pulverized with a pulverizer and sieved.

[0033] Thus, the compound additive powder for ZnO varistor sheet is prepared.

[0034] The composite additive prepared is according to additive: 14wt%, ZnO: 86.00wt%, adding Al(NO 3 ) 3 9H 2 O is added according to the weight ratio of 0.05% of the dry material for mixing and ball milling, and PVA (5% aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com