A kind of film thermistor and its preparation method and its resistance value adjustment method

A thin-film thermistor and film-throwing technology, which is applied in the manufacture of resistors, resistors, resistors with negative temperature coefficients, etc., can solve the problems of shortening the service life of thin-film resistors, high aging coefficient, and restricting development, and achieve resistance value Small, low aging coefficient, and the effect of improving aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

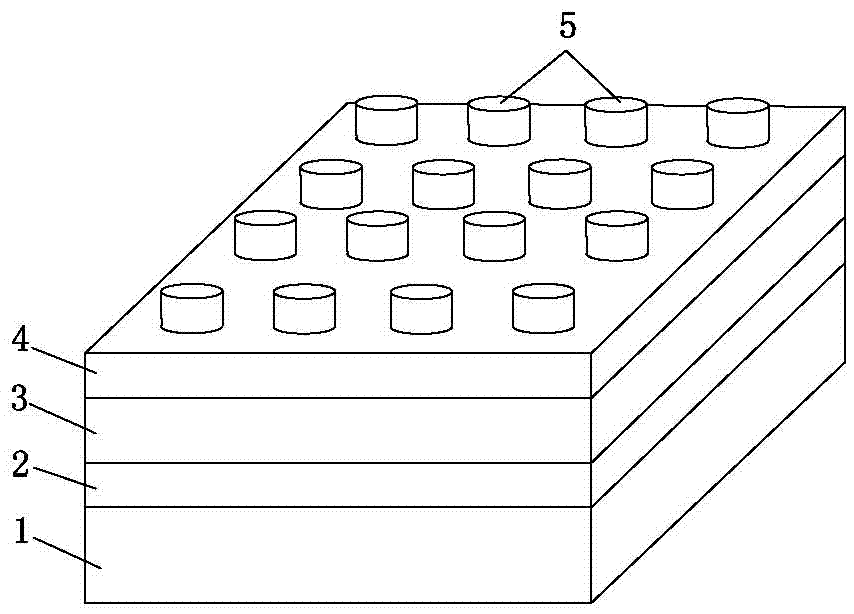

[0054] See figure 1 . A thin-film thermistor, comprising a substrate 1, a bottom layer of Mn-Co-Ni-Fe-O quaternary transition metal oxide film 2, and an intermediate layer of Mn-Co-Ni-Cu-O quaternary transition from bottom to top. Metal oxide film layer 3, top layer Mn-Co-Ni-O ternary transition metal oxide film layer 4 and electrode 5. In this embodiment, the substrate is Pt / TiO 2 / Ti / SiO 2 / Si substrate.

[0055] Among them, the bottom Mn-Co-Ni-Fe-O quaternary transition metal oxide film layer, the middle layer Mn-Co-Ni-Cu-O quaternary transition metal oxide film layer, the top layer Mn-Co-Ni-O three The primary transition metal oxide film layer has a three-layer structure, so that the thin film thermistor has the advantages of low resistance value and low aging coefficient.

Embodiment 2

[0057] See figure 1 . A thin-film thermistor, comprising a substrate 1, a bottom layer of Mn-Co-Ni-Fe-O quaternary transition metal oxide film 2, and an intermediate layer of Mn-Co-Ni-Cu-O quaternary transition from bottom to top. Metal oxide film layer 3, top layer Mn-Co-Ni-O ternary transition metal oxide film layer 4 and electrode 5. In this embodiment, the substrate is a Si substrate.

[0058] Among them, the bottom Mn-Co-Ni-Fe-O quaternary transition metal oxide film layer, the middle layer Mn-Co-Ni-Cu-O quaternary transition metal oxide film layer, the top layer Mn-Co-Ni-O three The primary transition metal oxide film layer has a three-layer structure, so that the thin film thermistor has the advantages of low resistance value and low aging coefficient.

Embodiment 3

[0060] See figure 1 . A thin-film thermistor, comprising a substrate 1, a bottom layer of Mn-Co-Ni-Fe-O quaternary transition metal oxide film 2, and an intermediate layer of Mn-Co-Ni-Cu-O quaternary transition from bottom to top. Metal oxide film layer 3, top layer Mn-Co-Ni-O ternary transition metal oxide film layer 4 and electrode 5. In this embodiment, the substrate is Al 2 o 3 substrate.

[0061] Among them, the bottom Mn-Co-Ni-Fe-O quaternary transition metal oxide film layer, the middle layer Mn-Co-Ni-Cu-O quaternary transition metal oxide film layer, the top layer Mn-Co-Ni-O three The primary transition metal oxide film layer has a three-layer structure, so that the thin film thermistor has the advantages of low resistance value and low aging coefficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com