Non-quenched and tempered steel used for welding and electroplating hydraulic rod and production method thereof

A technology of non-quenched and tempered steel and production method, applied in the field of non-quenched and tempered steel, can solve the problems of increasing heat treatment equipment investment and heat treatment process, hydraulic rod heat treatment deformation waste, etc., to achieve improved purity, good comprehensive mechanical properties, cutting process The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

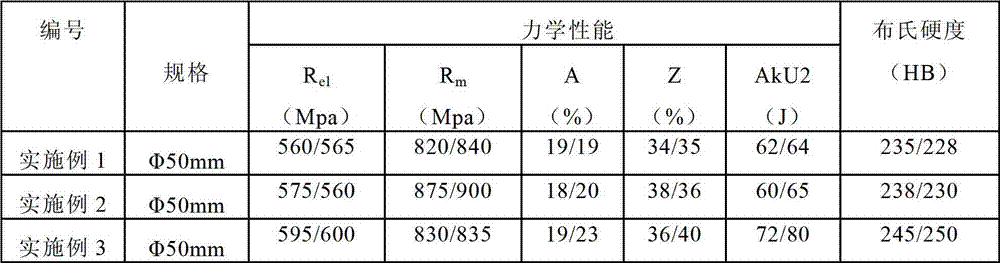

Embodiment 1

[0056] The composition and content of the non-quenched and tempered steel for welded electroplated hydraulic rods produced in this embodiment are shown in Table 1.

[0057] The specific production method is as follows: production by electric furnace continuous casting process, including primary smelting process, refining process, VD vacuum degassing process, continuous casting process and rolling process:

[0058] In the primary smelting process, electric furnace smelting is used, and the content of C at the control end point is 0.10wt%, the content of P is 0.009wt%, the content of Ni is 0.10wt%, the content of Cu is 0.09wt%, and the content of Mo is 0.05wt% %, and the tapping temperature of molten steel is 1645°C.

[0059] In the refining process, the LF furnace is used for refining, and the aluminum wire 2.1m / t steel is fed for deoxidation before a sample is taken for analysis; the silicon-calcium wire 1.6m / t steel is fed for calcium treatment before the steel is tapped in t...

Embodiment 2

[0064] The composition and content of the non-quenched and tempered steel for welded electroplated hydraulic rods produced in this embodiment are shown in Table 1.

[0065] The specific production method is as follows: production by electric furnace continuous casting process, including primary smelting process, refining process, VD vacuum degassing process, continuous casting process and rolling process:

[0066] In the primary smelting process, the electric furnace is used to smelt, and the content of C at the end point is 0.12wt%, the content of P is 0.010wt%, the content of Ni is 0.08wt%, the content of Cu is 0.05wt%, and the content of Mo is 0.03wt%. %, and the tapping temperature of molten steel is 1641°C.

[0067] In the refining process, the LF furnace is used for refining, and the aluminum wire 2.2m / t steel is fed for deoxidation before a sample is taken for analysis; the silicon-calcium wire 1.8m / t steel is fed for calcium treatment before the steel is tapped in the ...

Embodiment 3

[0072] The composition and content of the non-quenched and tempered steel for welded electroplated hydraulic rods produced in this embodiment are shown in Table 1.

[0073] The specific production method is as follows: production by electric furnace continuous casting process, including primary smelting process, refining process, VD vacuum degassing process, continuous casting process and rolling process:

[0074] In the primary smelting process, the electric furnace is used to smelt, and the content of C at the control end point is 0.12wt%, the content of P is 0.009wt%, the content of Ni is 0.03wt%, the content of Cu is 0.05wt%, and the content of Mo is 0.07wt% %, and the tapping temperature of molten steel is 1640°C.

[0075]In the refining process, the LF furnace is used for refining, and the aluminum wire 2.2m / t steel is fed for deoxidation before a sample is taken for analysis; the silicon-calcium wire 1.5m / t steel is fed for calcium treatment before the steel is tapped i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com