Preparation method of nodular cast iron

A technology for ductile iron and molten iron, which is applied in the field of ductile iron preparation, can solve the problems of lowering performance of castings, slow cooling speed, and distortion of graphite in the center of castings, and achieves the effects of low production cost, short production cycle and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

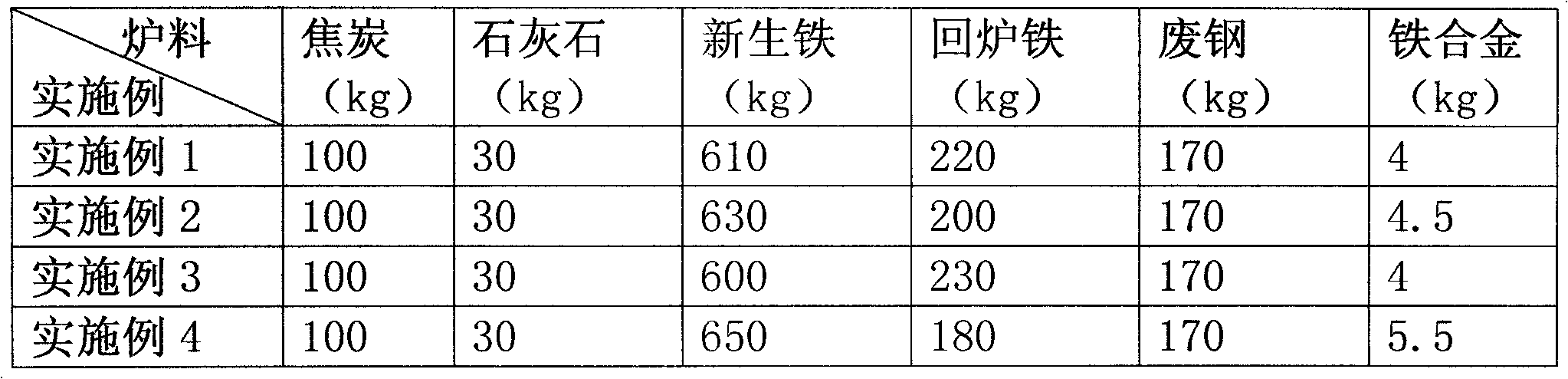

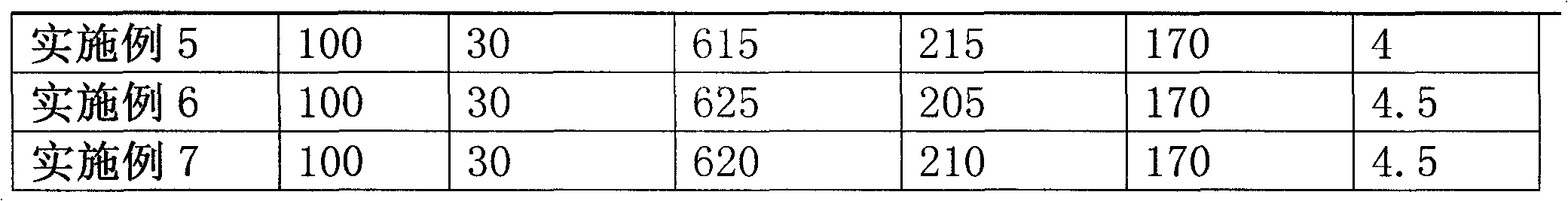

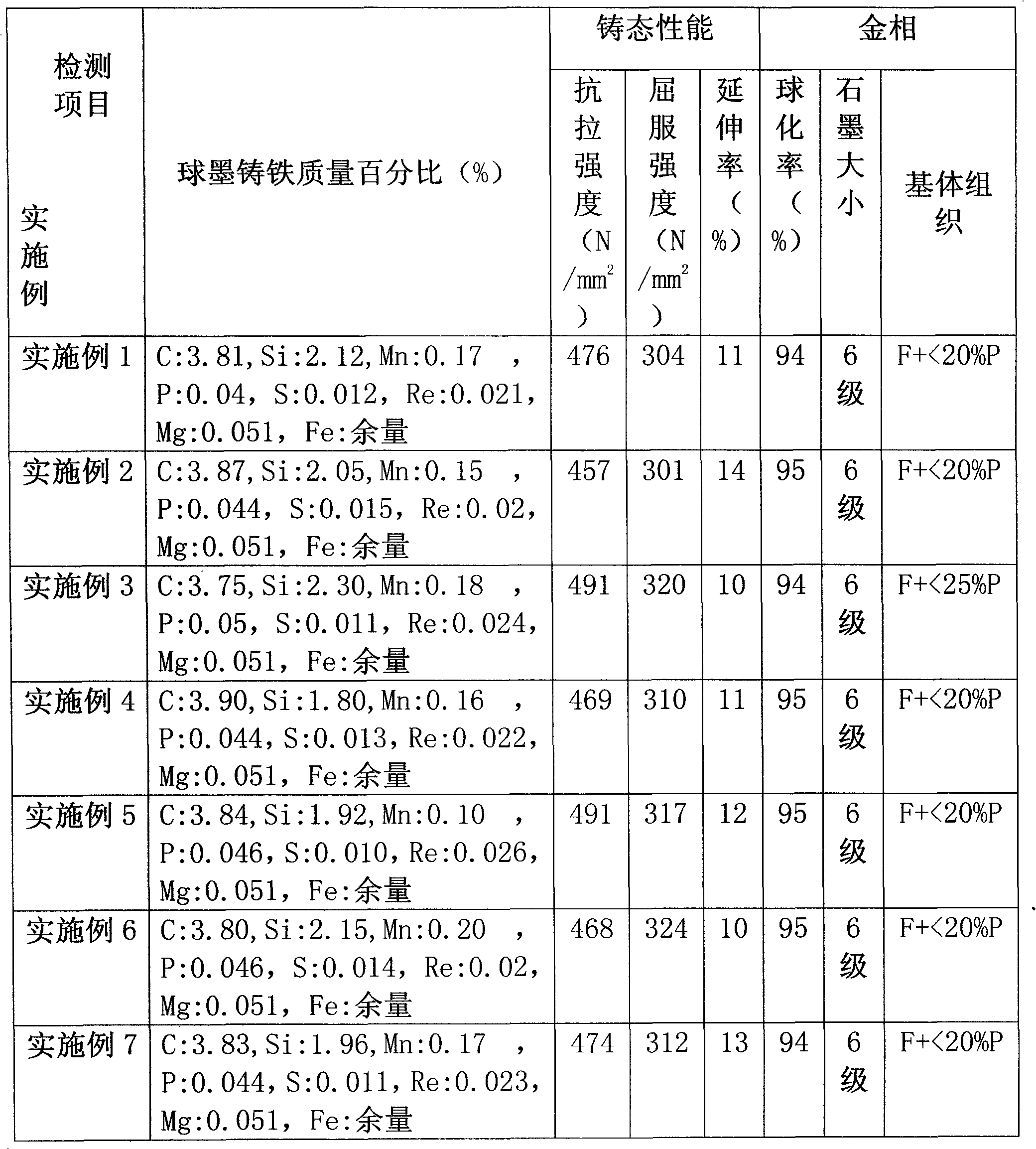

[0019] The percentage by weight of the nodular cast iron to be prepared in the present invention is: C: 3.75%-3.90%, Si: 1.8%-2.3%, Mn: 0.1%-0.2%, P: 0.04%-0.05%, S<0.015%, Re: 0.02%-0.026%, Mg: 0.04%-0.06%, the balance is Fe and unavoidable trace elements.

[0020] The above-mentioned preparation method of nodular cast iron includes a raw material smelting step, a spheroidizing treatment step and an inoculation treatment step.

[0021] (1) Raw material smelting

[0022] Each element in the ductile iron of the present invention is taken from coke, limestone, fresh iron, returned furnace iron, scrap steel and ferroalloy, and the mass ratio of each raw material is: 1: 0.3: (6.0-6.25): (1.8-2.2): 1.7: (0.04 -0.015). After weighing the raw materials, put the above-mentioned raw materials into the cupola. The cupola is preheated for 20 minutes and then the blast smelting starts. The molten iron temperature is 1450°C-1500°C. After the raw material is smelted into a liquid state, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com