High-strength thin-specification steel plate with excellent shape and production method thereof

A production method and high-strength technology, applied in the field of iron and steel metallurgical materials, can solve the problems of reduced cooling rate, easy occurrence of buckling, poor impact toughness of steel plates, etc., and achieve the effects of optimizing rolling process conditions, simplifying production process and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

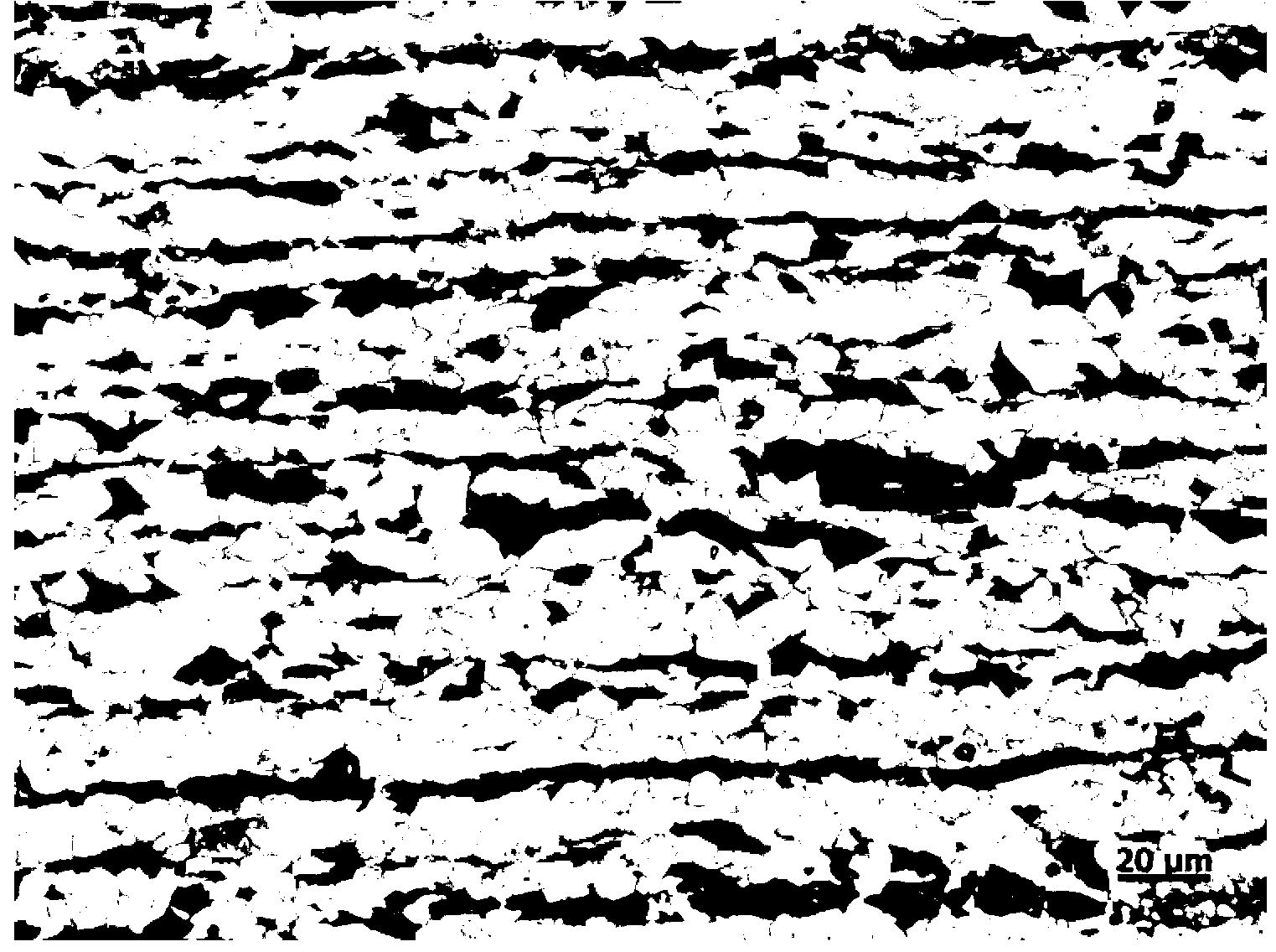

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples. Unless otherwise stated, the percentages used in the present invention are all percentages by weight.

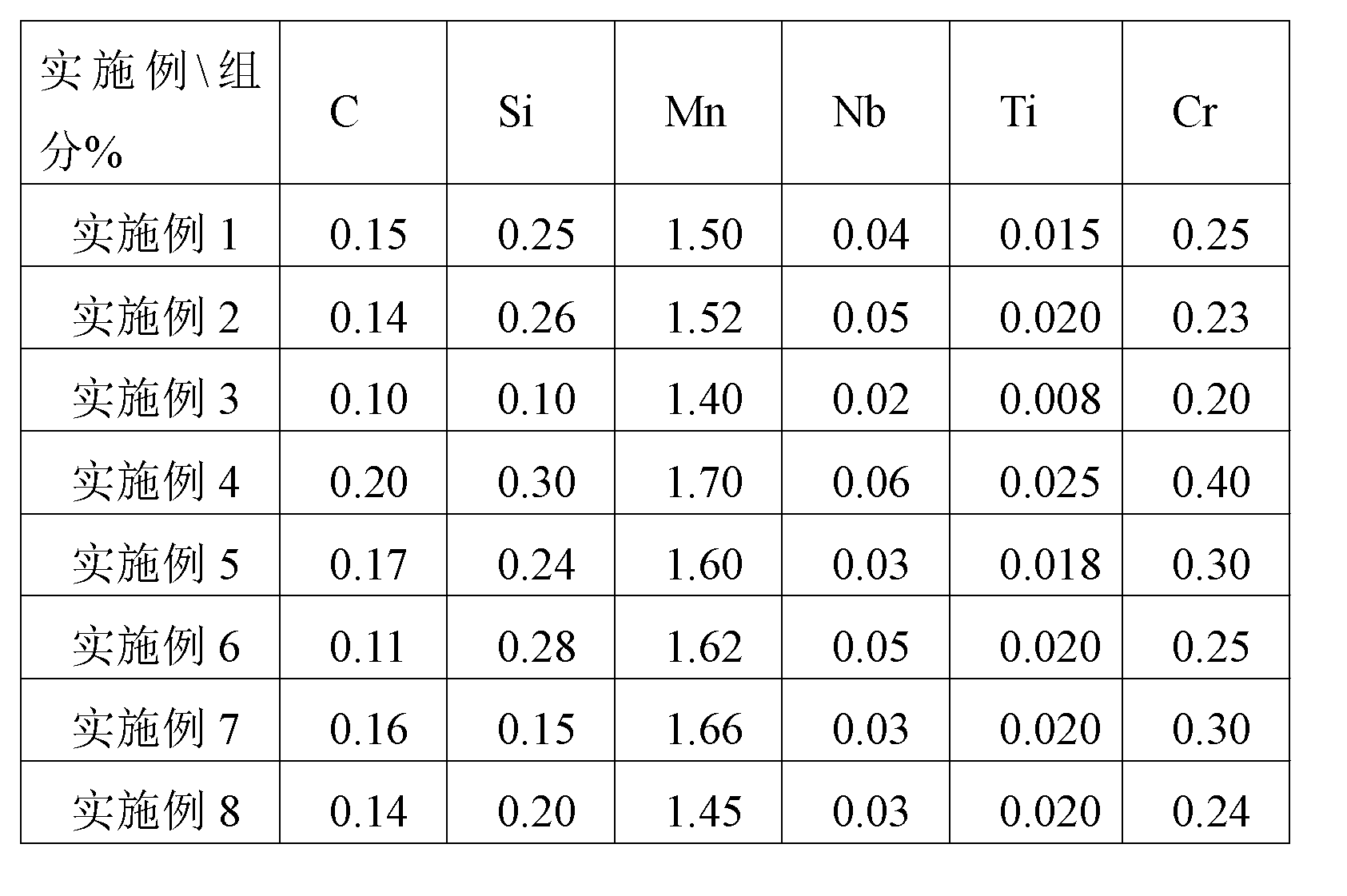

[0028] Table 1 lists the weight percentages of the chemical components of the high-strength thin-gauge steel plates with excellent shape in Examples 1-8 of the present invention, and the balance is Fe and unavoidable impurities.

[0029] Table 1

[0030]

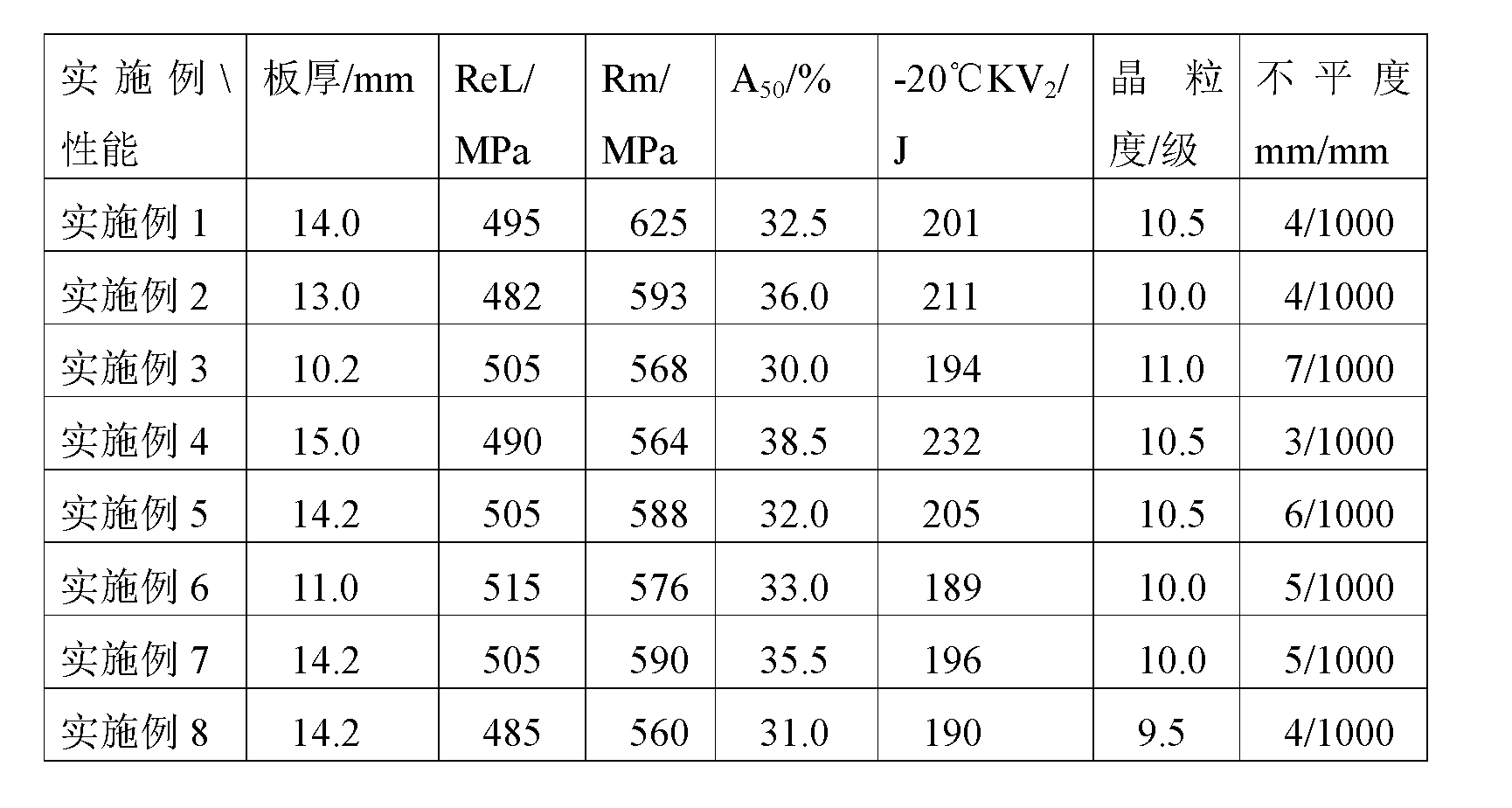

[0031] The production method of the high-strength thin-gauge steel plate with excellent plate shape as described in the above-mentioned embodiments 1-8 is as follows: smelting in a converter and continuous casting into a slab; heating the slab to 1150-1190° C.; , control the starting temperature of rough rolling to not be lower than 1080°C, control the reduction ratio of each pass to not be lower than 15%, the starting temperature of the finish rolling stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com