Method for pre-lithiating electrode material of lithium ion battery

A lithium-ion battery and electrode material technology, which is applied in the field of improving the first-week Coulombic efficiency of negative electrode materials, can solve problems such as poor practicability, difficult precise proportioning, and deformation of pole pieces, so as to reduce battery weight, reduce research and development costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

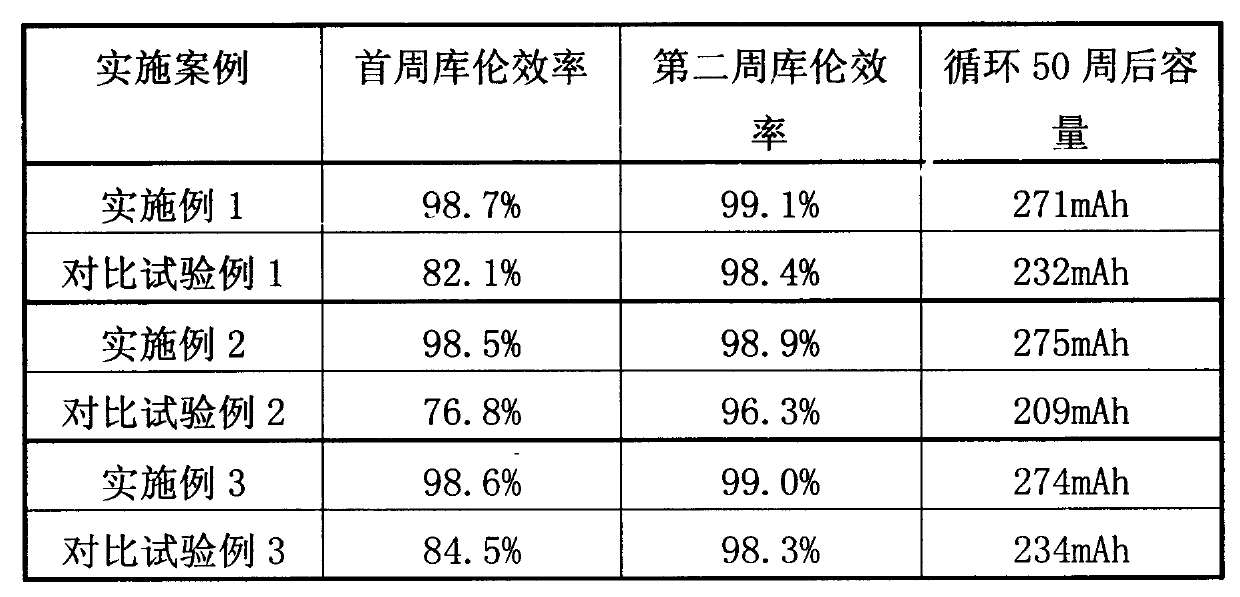

Embodiment 1

[0016] Take the natural graphite negative electrode material to make a pole piece and place it in the cathode cavity, and place it in a 6 In the EC / DMC electrolyte, lithium chloride aqueous solution is injected into the anode cavity. Charge and discharge equipment through an external circuit to control the charge and discharge potential and time.

[0017] 1. Stand still for 0.5h;

[0018] 2. Electrolyze with a current density of 100mA / g, and the voltage display is 3.1V;

[0019] 3. Power on for 20 minutes, then power off;

[0020] 4. Let stand for 10 minutes.

[0021] After the charge and discharge control is over, take out the pole piece and mix it with 2.0g LiCO 2 Assemble into a solid battery, let it stand for 1 hour, and test.

Embodiment 2

[0025] The carbon-coated graphite is used to make the negative electrode sheet, wherein the carbon is amorphous carbon from pitch cracking. Since amorphous carbon will irreversibly consume lithium ions in the first week, the graphite material has excellent cycle performance and capacity under normal conditions, with a capacity close to 372mAh / g, but the coulombic efficiency is low in the first week. The material is made into a pole piece and placed in the cathode chamber, which contains 1mol / L LiPF 6 In the EC / DMC electrolyte, the anode is injected with lithium carbonate aqueous solution, and the pole piece is connected to the positive and negative electrodes respectively through the external circuit charge and discharge equipment to control the charge and discharge.

[0026] 1. Stand still for 0.5h;

[0027] 2. Electrolyze with a current density of 100mA / g, and the voltage display is 3.05V;

[0028] 3. Power on for 40 minutes, then power off;

[0029] 4. Let stand for 10 m...

Embodiment 3

[0034] The silicon / carbon anode material produced by Betray Company was used to make pole pieces, the silicon content was 6wt.%, and the remaining components were amorphous carbon and graphite. After 50 cycles, the capacity was 480mAh / g. In the product description of this product, the first week Coulombic efficiency of this material is below 85%. The material is made into a pole piece and placed in the cathode cavity, which contains 1mol / L LiPF 6In the EC / DMC electrolyte, the anode is injected with lithium chloride aqueous solution, and the pole piece is connected to the positive and negative electrodes respectively through the external circuit charge and discharge equipment to control the charge and discharge.

[0035] 1. Stand still for 0.5h;

[0036] 2. Electrolyze with a current density of 150mA / g, and the voltage display is 3.15V;

[0037] 3. Power on for 20 minutes, then power off;

[0038] 4. Let stand for 10 minutes.

[0039] After the charge and discharge control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com