Halogen-free flame-retardant electric wire and cable sheath polymer material and uses thereof

A polymer material, wire and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of unsatisfactory flame resistance, and achieve the effect of simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

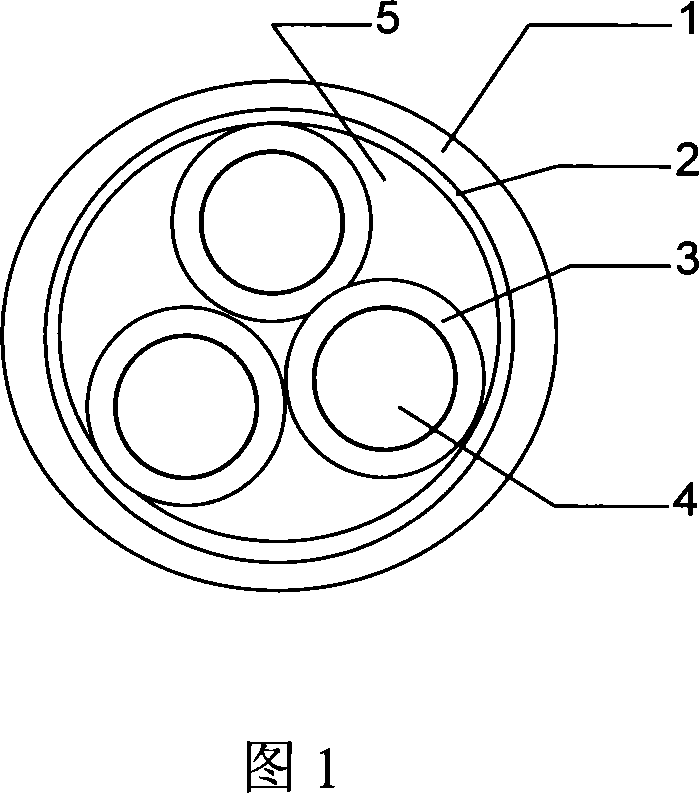

Image

Examples

Embodiment 1-8

[0037] 1. Preparation of halogen-free intumescent flame retardant

[0038] Phosphorus pentoxide (P 2 o 5 Content ≥ 98%) 43.47kg, add diammonium hydrogen phosphate (ammonium dihydrogen phosphate content ≥ 95%) 36.32kg simultaneously, stir and heat, and pass 20 minutes of 1 liter / min of ammonia, and keep the ammonia pressure at 0.2Mpa. When it rises to 250°C, it becomes a viscous syrupy liquid, and when kept at 250°C for 1 hour, it becomes a white solid powder. Pass 2 liters / min of nitrogen gas under stirring, cool to 50° C., pulverize and sieve to obtain compound (III). At -5°C, add 1000kg (III) to 3m 3 In 85% ethanol, stir for 30 minutes, add 0.2 kg of benzyltriphenylphosphine hydroxide activated by pyridine, add 230 kg of nitrogen-containing triazine polymer evenly under stirring, react for 3 hours, filter, dry, and pulverize to obtain JLS- PNP11217kg. The particle diameter is about 10 μm.

[0039] 2. Configure according to the proportions in Table 1, and the order of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com