Aluminum-based dot matrix material based on 3D printing technology and preparation method thereof

A 3D printing and lattice-based technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of residual oxidation inclusions and gaps in the matrix, and the decline in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

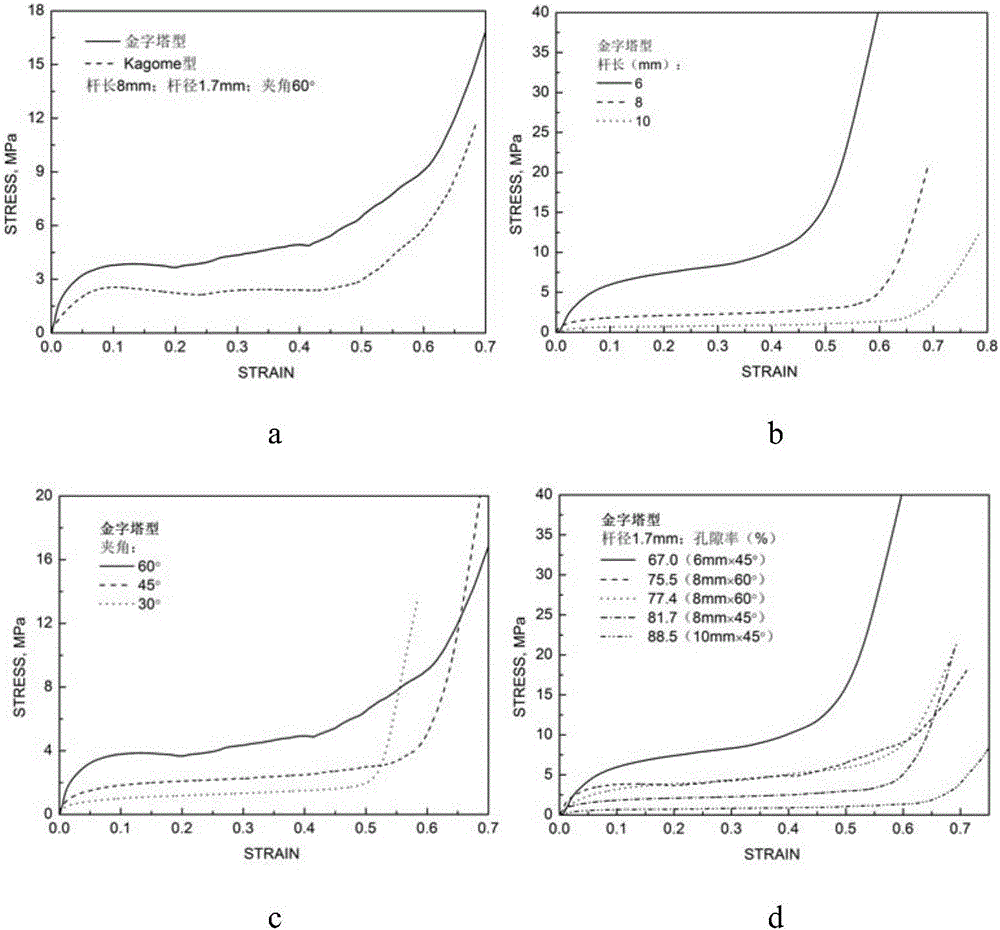

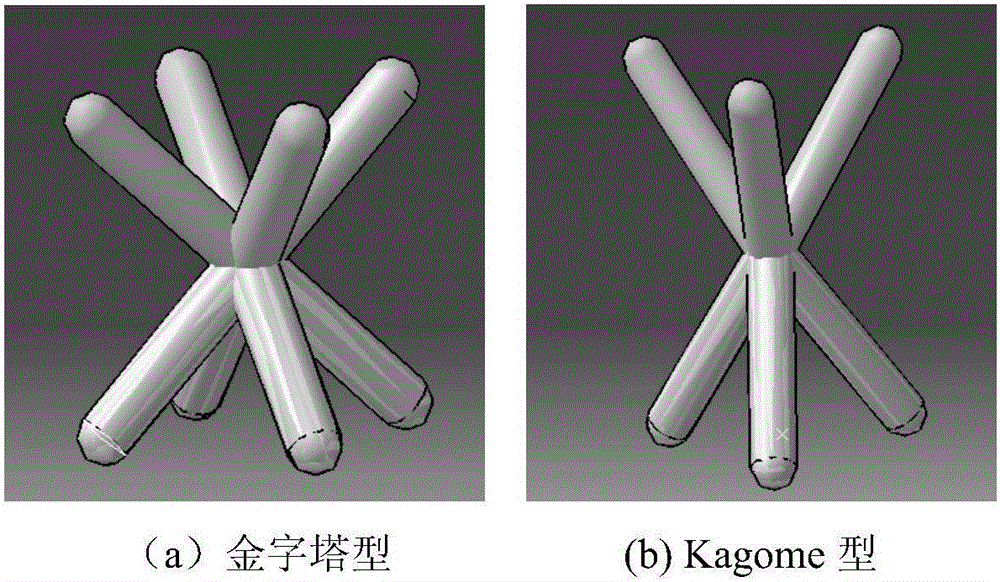

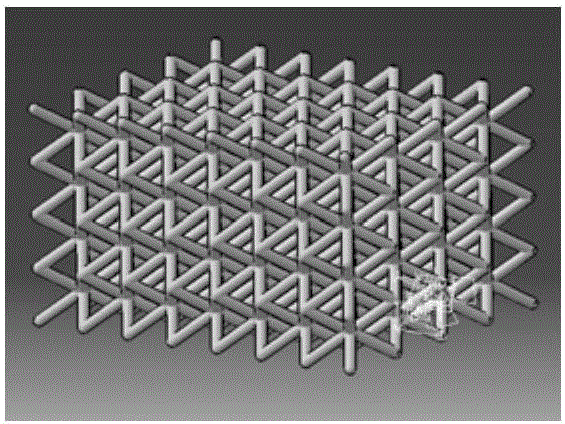

[0035] Aluminum-based lattice material based on 3D printing technology: substrate: L3 industrial pure aluminum; unit cell: pyramid type; rod diameter: 1.7mm; rod length: 6mm; rod / projection surface angle: 45°; rod cross-sectional shape: round ; Unit cell number: 4 layers; Unit cell number per layer: 60.

[0036] The preparation method is as follows:

[0037] (1)Using CATIA software to design unit cell structure, including pyramid configuration, rod element diameter, length, rod / projection surface angle, rod cross-sectional shape, number of unit cells per layer and number of lattice layers, etc., and then obtained by mirroring The corresponding topology.

[0038] (2) Using polypropylene (PP) plastic powder as raw material, the dot matrix model is printed by laser selective melting method.

[0039] (3) The gypsum powder and auxiliary materials are added with water to prepare a slurry with appropriate viscosity, which is poured into a polypropylene lattice model. After drying at 50°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com