A Reconfigurable Machine Tool Based on Reconfigurability

A reconfigurable and machine tool technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low cost, difficult RMT reconfiguration, waste of equipment and other resources, so as to reduce the cost of reconfiguration and achieve reliable High refactorability and refactoring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

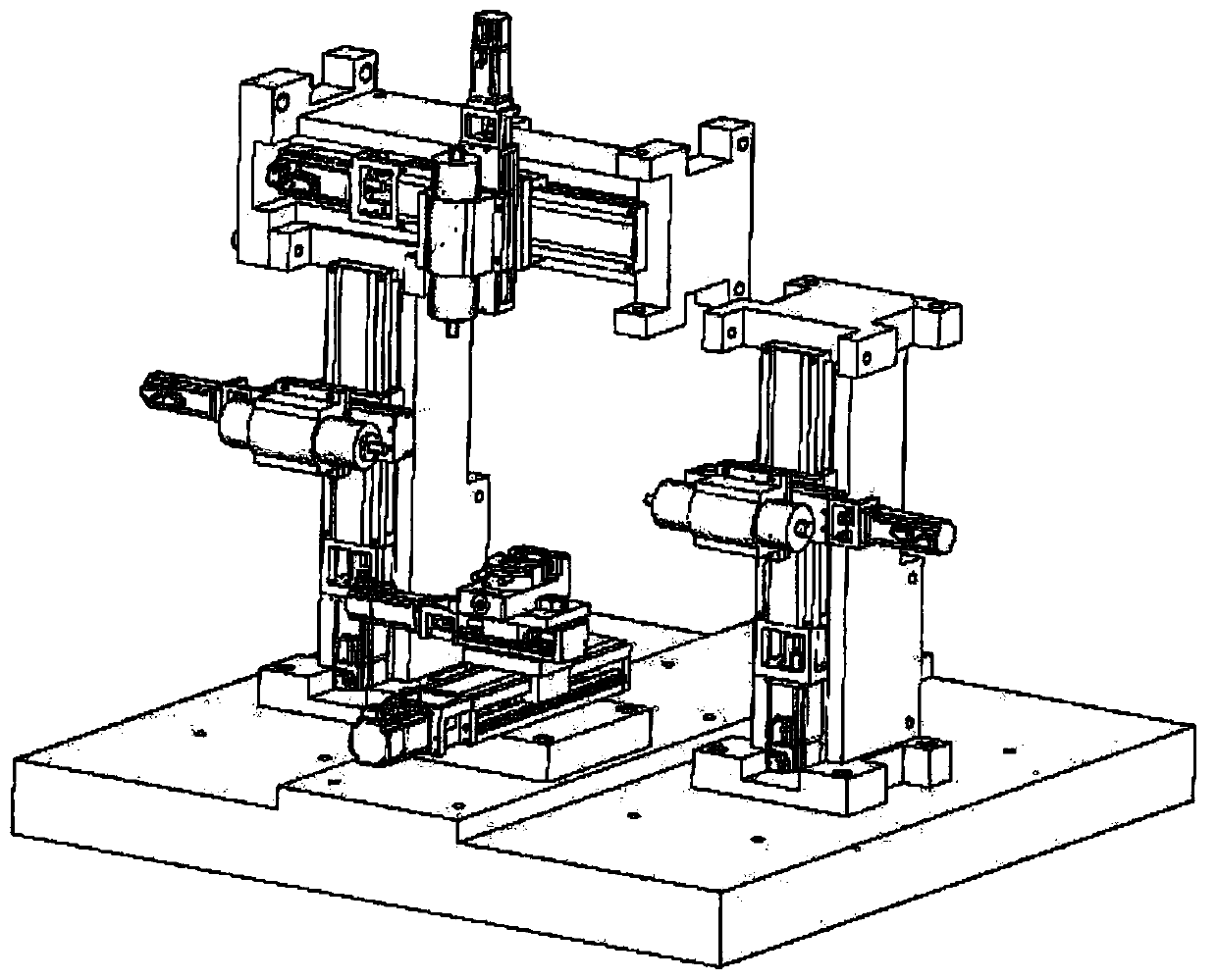

[0046]Based on the above design principles, the embodiment of the present invention provides a reconfigurable machine tool based on reconfigurability, its specific structure is as follows figure 1 As shown, the designed modules include bed module, functional arm module and workbench module.

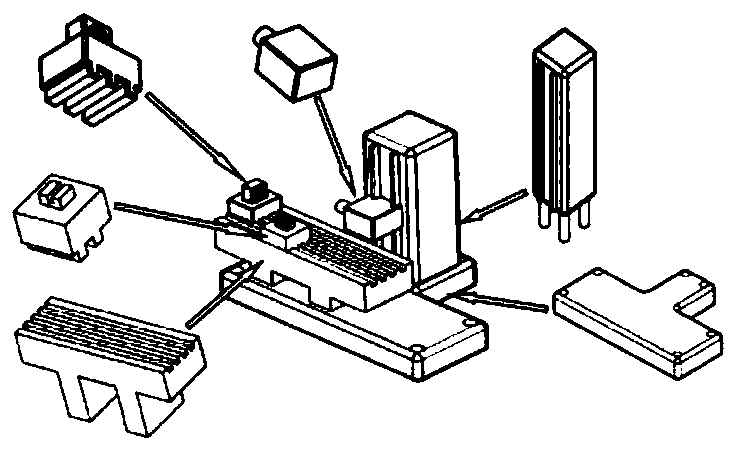

[0047] image 3 It shows the structure of the bed module. The bed module is a rectangular flat structure, which is divided into three areas by two parallel boundaries, which are respectively the installation area of the workbench module in the center and the first functional arm on both sides. The module installation area and the second functional arm module installation area; the positional relationship of the three areas is as follows image 3 shown.

[0048] according to image 3 , the three regions are equipped with pairs of threaded holes equidistantly distributed at a distance of l units, and each pair of threaded holes is composed of two threaded holes with a distance of l uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com