Easy-peel highlighted silane crosslinking flame-retardant polyolefin insulation material, preparation method and application thereof

A technology of insulating materials and polyolefins, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of slightly matt, and achieve the effects of reduced consumption, excellent temperature resistance, and high temperature resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

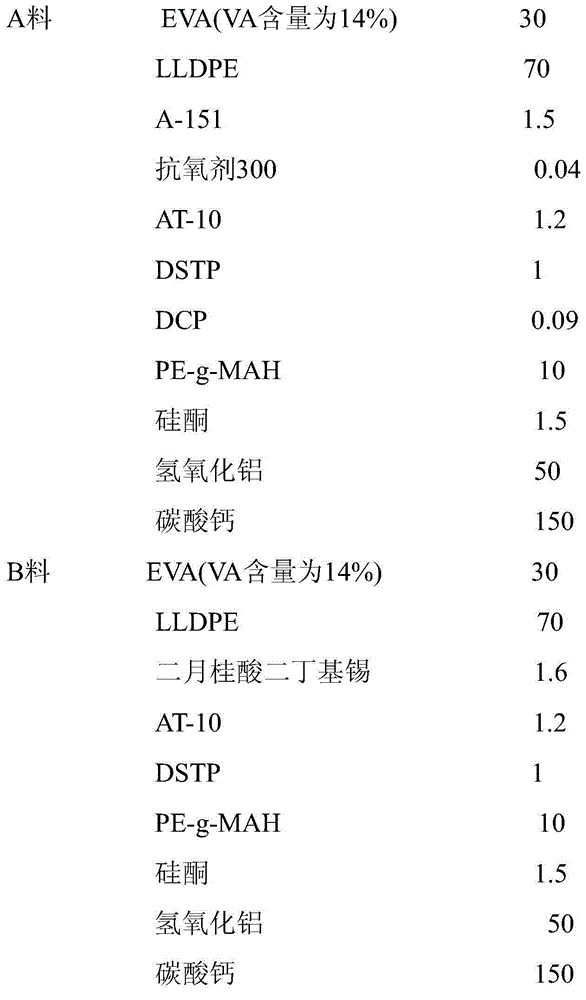

[0040] Example 1: The components and their parts by weight are as follows.

[0041]

[0042] All of the above components are commercially available from the market.

[0043] Firstly mix EVA (with 14% VA content), LLDPE, AT-10, DSTP, PE-g-MAH, silicone, aluminum hydroxide, and calcium carbonate on the internal mixer, and granulate them as A and B materials The public masterbatch. The silane coupling agent, antioxidant, and initiator are formulated into silane additives, the master batch is used to absorb the silane additives, and the obtained material A is vacuum-packed in an aluminum-plastic composite bag; the master batch is used to absorb dibutyl tin dilaurate, and aluminum-plastic The compound bag is packaged with material B.

[0044] Combine material A and material B (material A: material B=95:5 (weight ratio)) to obtain a polyolefin insulating material.

Embodiment 2

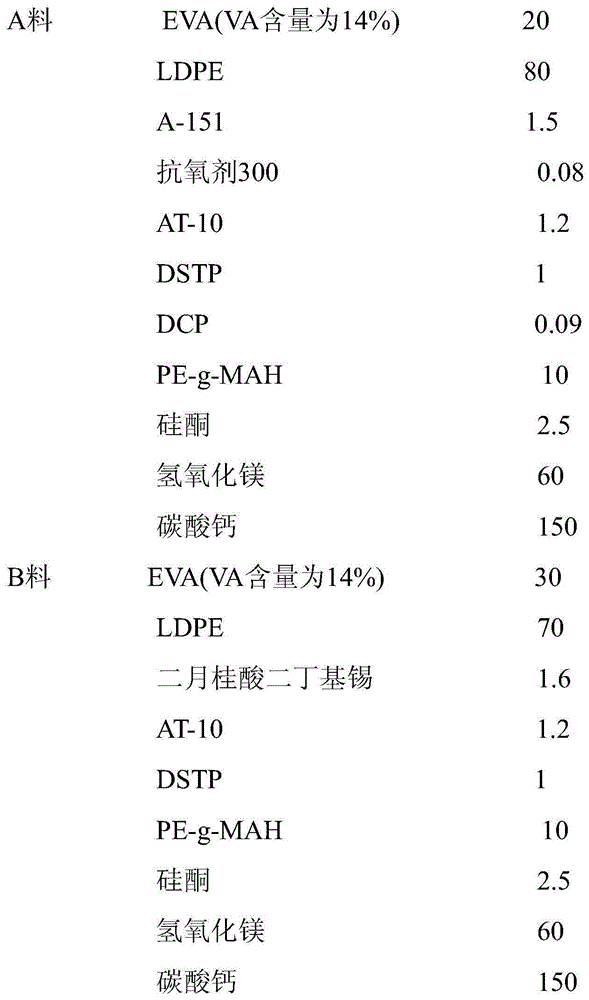

[0045] Example 2: The components and their parts by weight are as follows.

[0046]

[0047] A polyolefin insulating material was prepared according to the same method as in Example 1, wherein material A: material B=96:4 (weight ratio).

Embodiment 3

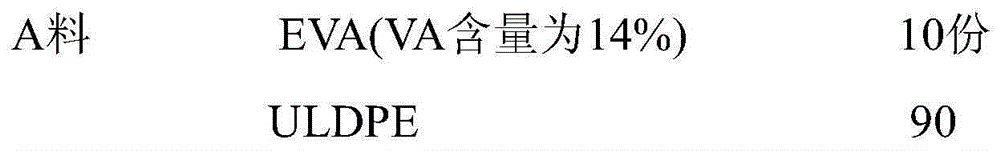

[0048] Example 3: The components and their parts by weight are as follows.

[0049]

[0050]

[0051] A polyolefin insulating material was prepared according to the same method as in Example 1, wherein material A: material B=95:5 (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com