Blended yarn with natural bamboo fiber and anti-pilling polyester fiber and production process thereof

A technology of natural bamboo fiber and production process, which is applied in the field of natural bamboo fiber and anti-pilling polyester blended yarn and its production process, which can solve the problems of poor air permeability and antibacterial property, easy fluffing and pilling, etc., and achieve soft hand feeling, moisture absorption and release Fast, good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

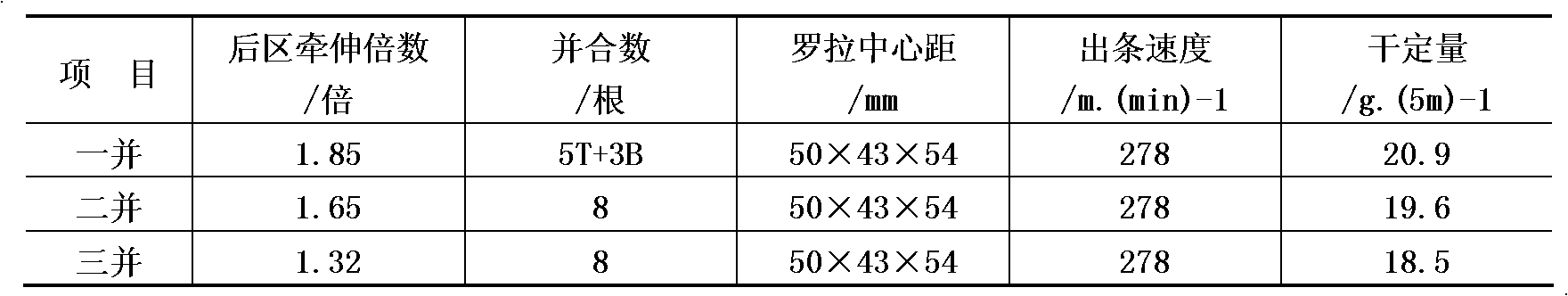

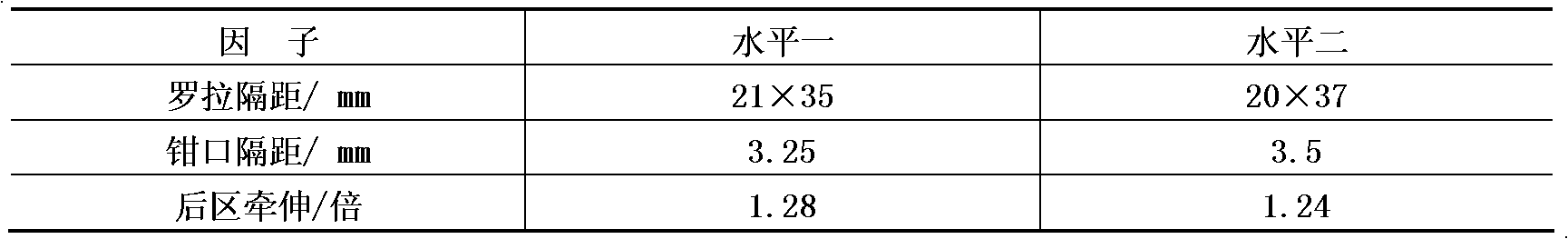

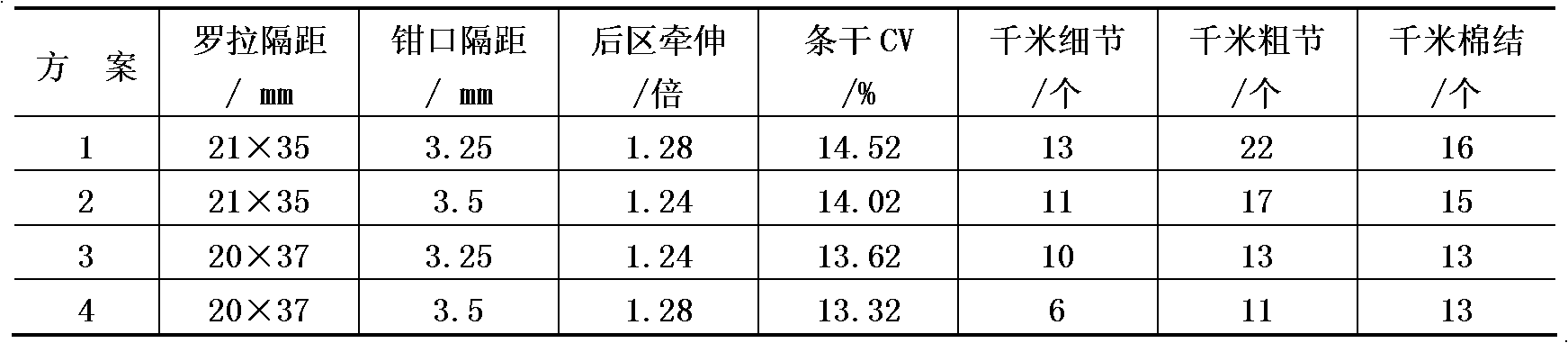

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Tianzhu fiber and anti-pilling polyester blended yarn, the blended yarn is 18.2dtex blended yarn, containing 40% of Tianzhu fiber and 60% of anti-pilling polyester. The anti-pilling polyester has a fineness of 1.67dtex, a length of 38mm, a breaking strength of 2.84CN / dtex, an elongation at break of 28.1%, and a mass specific resistance of 3.8×10 8 Ωg / cm 2 . Described Tianzhu fiber has a fineness of 1.55dtex, a length of 37.6mm, a dry breaking strength of 2.25CN / dtex, a dry breaking elongation of 20.6%, and a mass specific resistance of 4.3×10 7 Ωg / cm 2 . The "Tianzhu" fiber can be selected from the new cellulose fibers produced by Hebei Jigao Chemical Fiber Co., Ltd. using bamboo widely produced in Sichuan, China as raw materials, and bamboo pulp as raw materials through patented technology. "Tianzhu" fiber can be degraded naturally in the soil without any pollution to the environment. It maintains the original antibacterial and antibacterial effects of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com