Antistatic warp-knitted face fabric

An anti-static, warp knitting technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of unnatural comfort, chemical fiber hygroscopicity, poor water absorption, and undeveloped fabrics, etc., and achieve small coil curvature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] ① The conductive yarn used in the present invention is the conductive yarn MEGANA(R) manufactured by UNITIKA TEXTILES, Japan.

[0054] ②Because the conductive yarn is too thin, the operability of direct weaving with it is very poor, and it needs to be combined with other yarns before use, and the method of yarn combination can be covered and twisted.

[0055] ③ After the conductive yarn is properly prepared, it is warped on the warping machine, and then knitted on the warp knitting machine:

[0056] Warping machine: DS 21 / 30 (manufactured by Karl Mayer)

[0057] Warp knitting machine: HKS 4 EL EBC E 28 (manufactured by Karl Mayer)

[0058] ④ Warp knitting process:

[0059] Density: 21.6C / cm;

[0060] Working width: 560 x 6 weaving beams (3360 120 inches);

[0061] The width of gray cloth is: 270CM;

[0062] Gram weight: 185g / m 2 (55c / in, 31w / in).

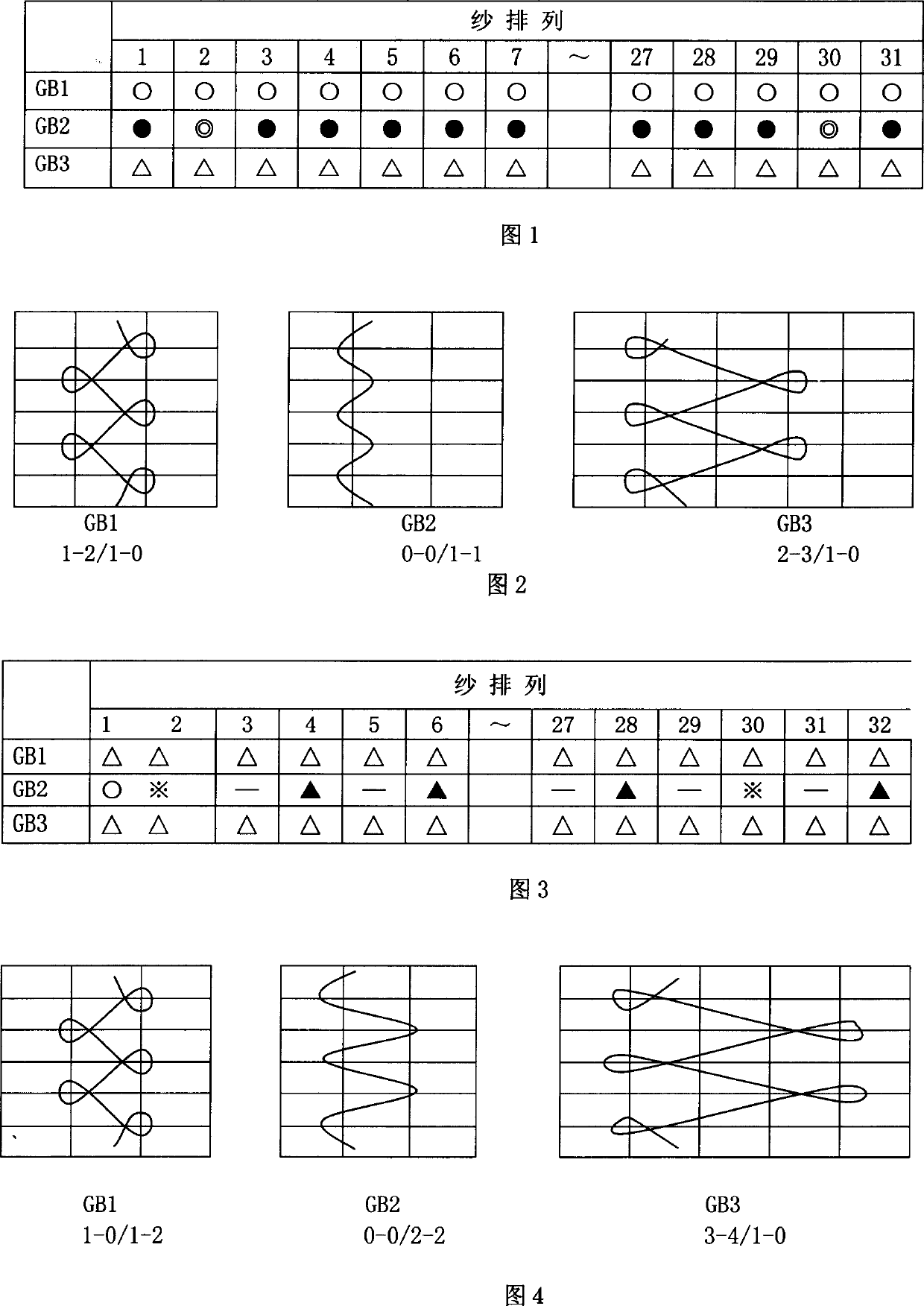

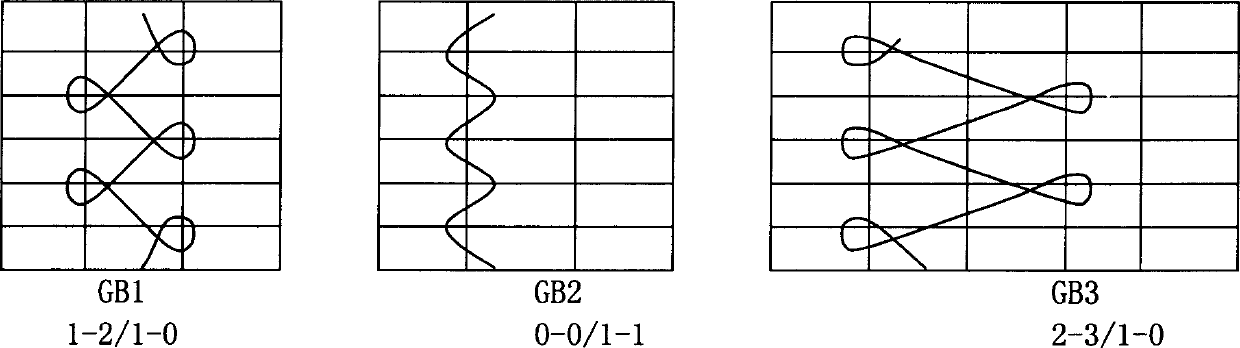

[0063] See Table 2 for process details

[0064] comb

use yarn

yarn arrangement

organize

Let...

Embodiment 2

[0081] ① The conductive yarn used is MEGANA(R) conductive yarn manufactured by UNITIKA TEXTILES, Japan.

[0082] ②Because the conductive yarn is too thin, the operability of direct weaving with it is very poor, and it needs to be combined with pure cotton combed yarn (70S / 2) before use, and the yarn combination method adopts parallel twisting.

[0083] ③ After the conductive yarn is ready, it is warped on the warping machine, and then knitted on the warp knitting machine:

[0084] Warping machine: DS 21 / 30 (manufactured by Karl Mayer)

[0085] Warp knitting machine: HKS 4 EL EBC E 28 (manufactured by Karl Mayer)

[0086] ④ Warp knitting process:

[0087] Density: 18.9C / cm;

[0088] Working width: 588 x 4 weaving beams (2352 84 inches);

[0089] The width of gray cloth is: 150CM;

[0090] Gram weight: 200g / m 2 (50c / in, 29w / in).

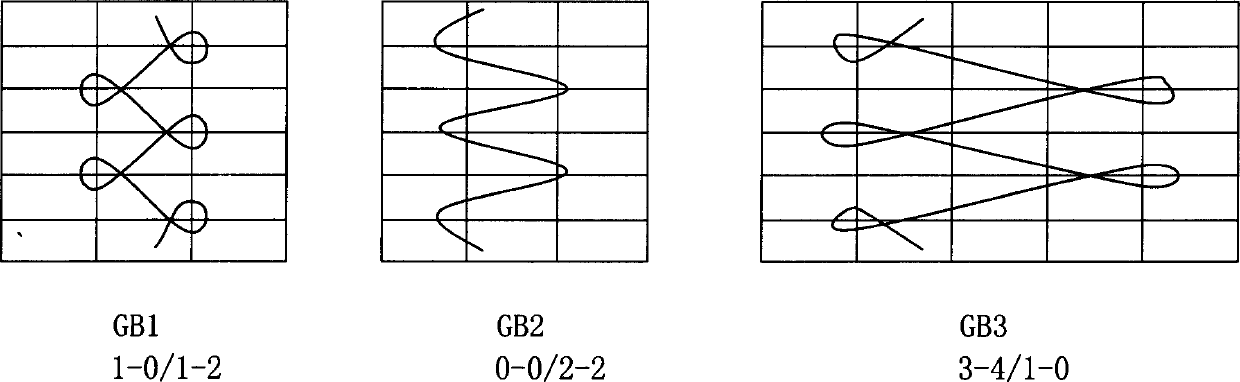

[0091] See Table 5 for process details

[0092] comb

use yarn

yarn arrangement

organize

Let-off amount

G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com