Highly anti-static thermoplastic polyurethane (PU) conveyer belt for textile industry and preparation method thereof

A thermoplastic polyurethane and elastomer technology, used in conveyors, textiles and papermaking, belts, etc., can solve problems such as inability to directly achieve, and achieve the effects of excellent performance, widening the scope of use, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

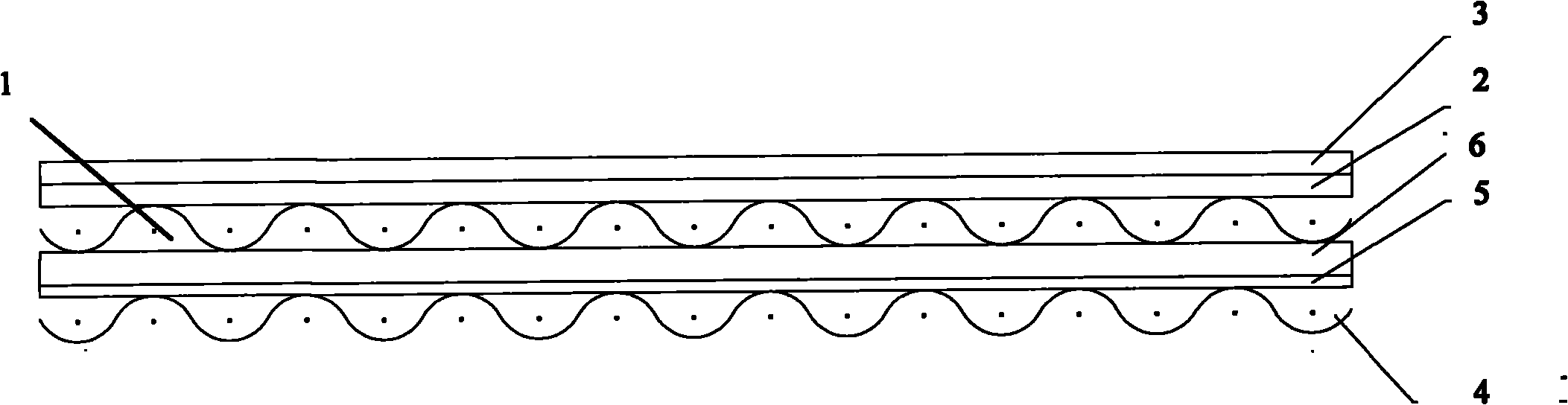

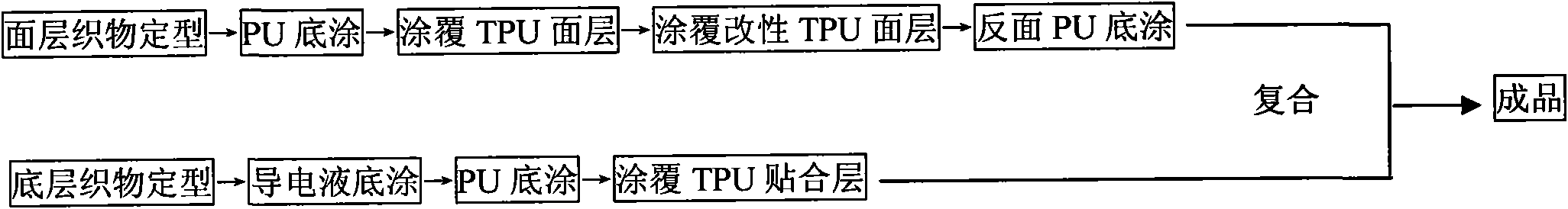

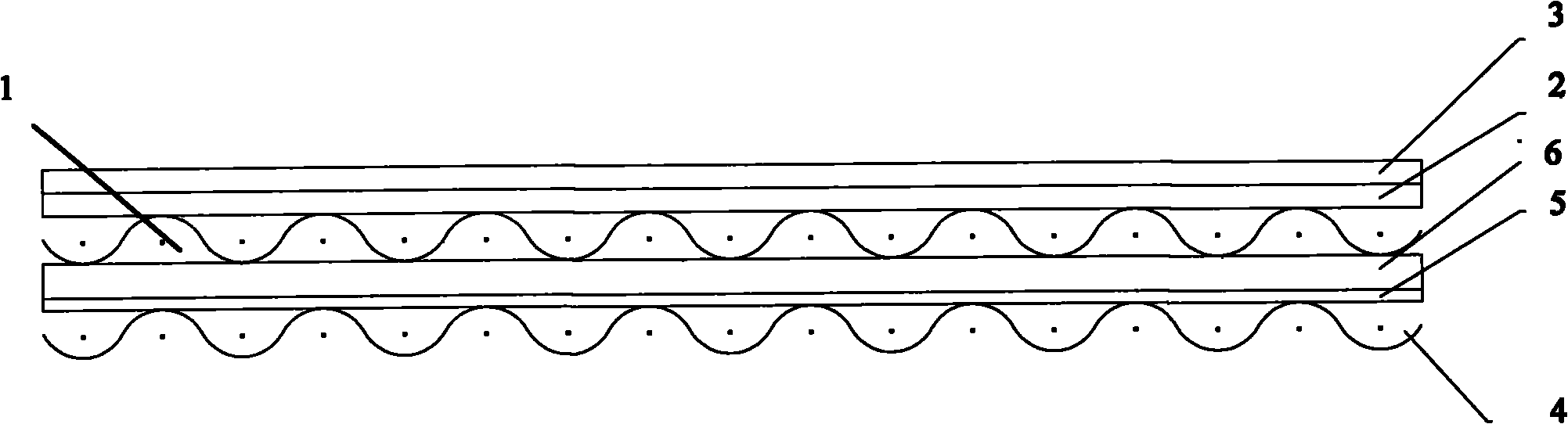

[0049] A method for manufacturing a high antistatic thermoplastic polyurethane elastomer conveyor belt for the textile industry, comprising the steps of:

[0050] Coating of facing fabric 1:

[0051] The first step: the surface fabric 1 is finalized;

[0052] The second step: coating the polyurethane primer (not shown in the figure) on the upper surface of the surface layer fabric 1, and the processing temperature is 170° C. to 190° C.;

[0053] Step 3: Coating thermoplastic polyurethane elastomer surface layer 2 on the base coat, the processing temperature is 190°C-220°C;

[0054] Step 4: Coating carbon nanotube modified thermoplastic polyurethane elastomer surface layer 3 on the surface layer, the processing temperature is 190°C-220°C;

[0055] Step 5: Coating a polyurethane primer (not shown in the figure) on the lower surface of the surface layer fabric 1, the processing temperature is 170°C-190°C;

[0056] Coating of the underlying fabric:

[0057] Step 1: adding 20-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com