Method for preparing super-hydrophobic nano modified cellulose material

A technology for modifying cellulose and superhydrophobic, which is applied in dry-cleaning fiber products, fiber treatment, plant fibers, etc. It can solve the problems of temperature control and other problems, and achieve the effects of toughness and mechanical strength, wide sources, and simple and easy operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

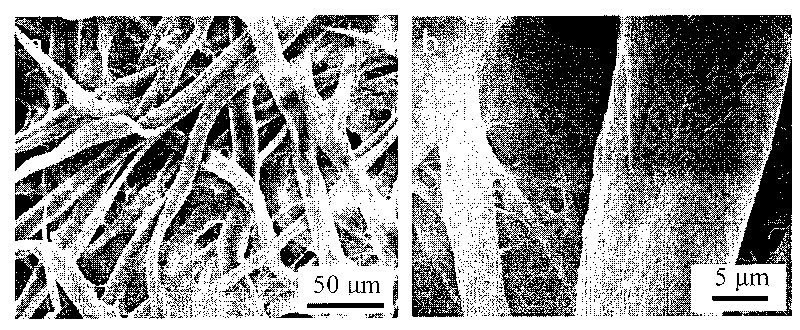

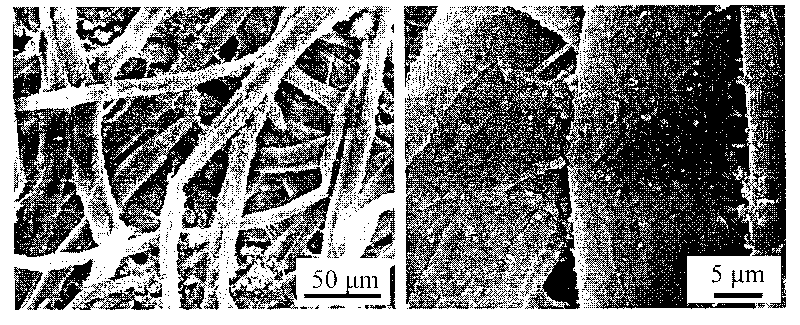

Image

Examples

Embodiment 1

[0032] 1) Toluene and ethanol with a volume ratio of 1:1 were used as solvents to prepare a tetrabutyl titanate solution with a concentration of 100 mM, and stirred at room temperature for 1 hour.

[0033] 2) Place the commonly used quantitative filter paper in the suction filter device, rinse the filter paper with ethanol for 2 to 3 times, and vacuum dry it.

[0034] 3) Add 10 mL of tetrabutyl titanate solution in step 1) to the suction filtration device in step 2), and let it stand for 2 to 3 minutes, which is the deposition process.

[0035] 4) Low vacuum until the liquid level of tetrabutyl titanate is slightly higher than the surface of the filter paper, quickly add ethanol to rinse for 2 to 3 times, let it stand for 2 to 3 minutes, filter with low vacuum, and then add pure water to rinse for 2 to 3 times 3 times, let it stand for about 3 minutes, this is the hydrolysis process, and vacuum dry after hydrolysis.

[0036] 5) The liquid level in steps 3) and 4) should alway...

Embodiment 2

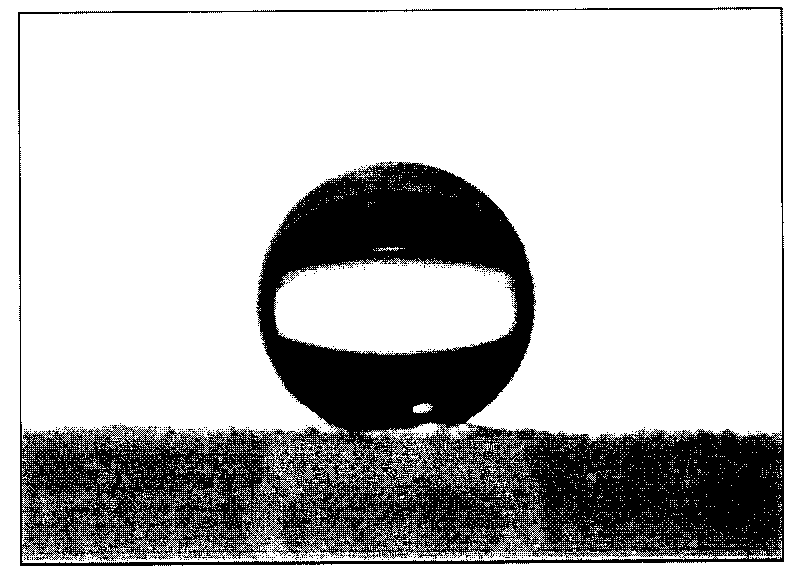

[0043] After the water drop is placed on the surface of the superhydrophobic nano-modified cellulose material prepared in Example 1 for different times, its contact angle is measured, as shown in the attached Figure 5 The relationship curve between the contact angle value and time is shown, and it is found that the contact angle value on the surface of the superhydrophobic nano-modified cellulose material remains basically unchanged with time. After being placed at room temperature for more than ten months, there is no change in the contact angle value, and the superhydrophobicity is well maintained.

Embodiment 3

[0045] The change of the contact angle value of the liquid droplets of different pH values on the surface of the superhydrophobic nano-modified cellulose material prepared in Example 1 is shown in the attached Figure 6 As shown, within the scope of error tolerance, the contact angle values of droplets on the surface of the superhydrophobic nano-modified cellulose material with different pH values (pH=1.0, 3.0, 5.0, 7.0, 9.0, 11.0, 13.0) are basically the same (about is 155°), its contact angle value basically does not change, and it has long-lasting chemical stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com