Piston top curved surface processing device for verticle lathe

A curved surface processing and vertical lathe technology, which is applied in the field of machining tooling, can solve the problems that the precision and surface roughness of the concave curved surface of large-diameter pistons cannot meet the requirements, low efficiency, and high labor intensity, etc., to achieve small labor and high efficiency High and prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

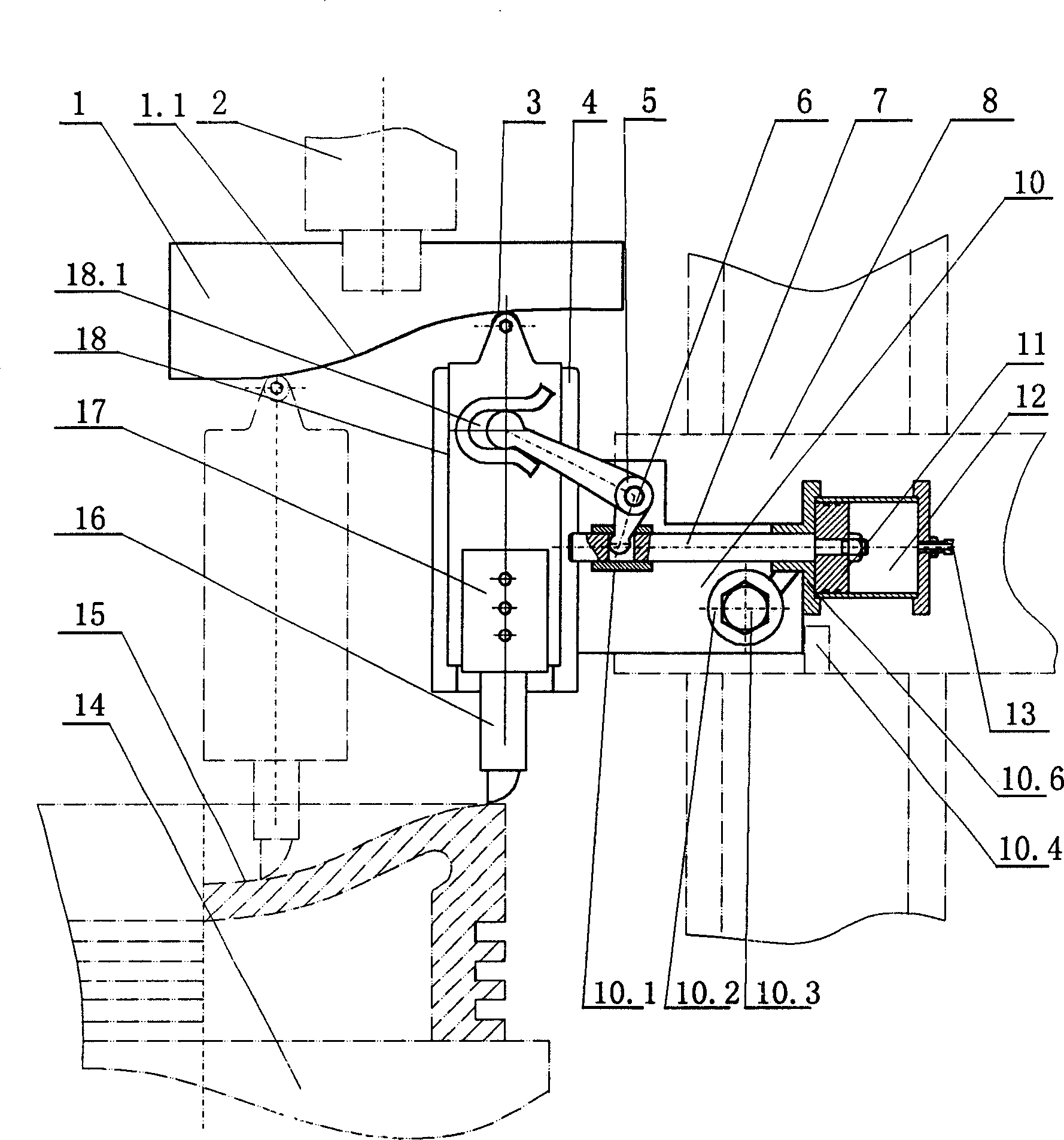

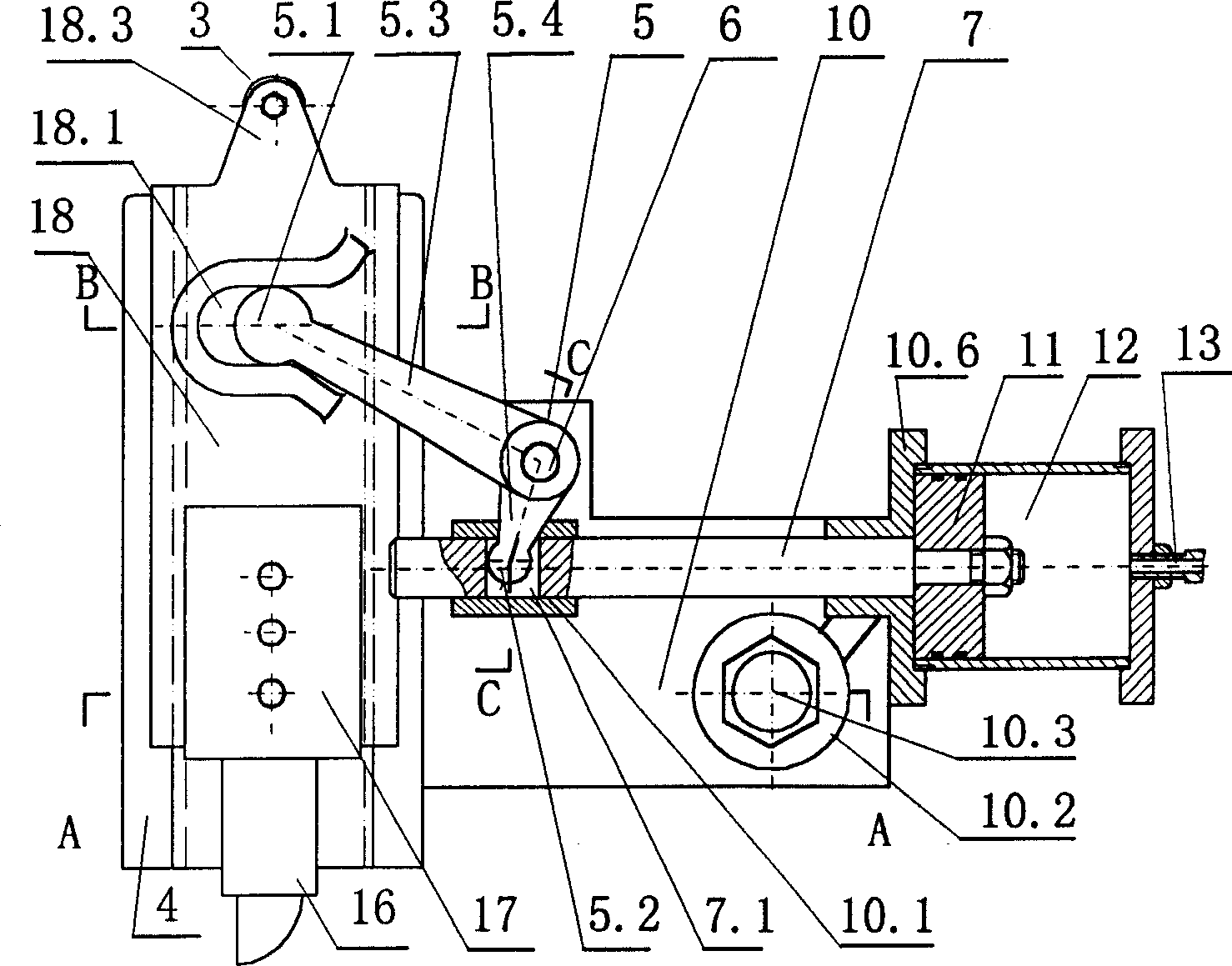

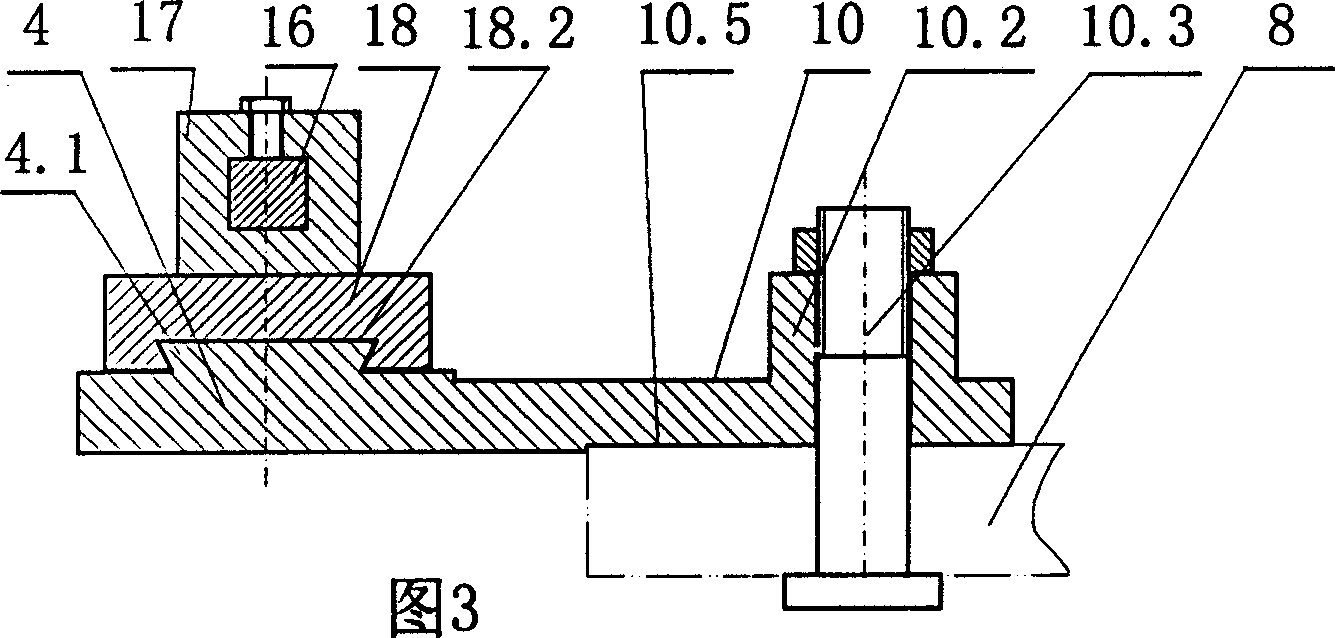

[0015] figure 1 Among them, at the lower end of the vertical tool rest 2 of the vertical lathe, be fixed with its bottom edge 1.1 and piston top shaft cross-section 15 half of the shape of the same template 1; The horizontal connecting plate 10 parallel to the template 1 is fixed in such a way that the plane 10.5 on the back of the connecting plate 10 leans against the side elevation of the side tool holder 8, and the fixing bolt 10.3 passes through the upper boss of the connecting plate 10 from the quilt surface Tighten the hole on 10.2 with a nut, and at the same time, the right end surface of the connecting plate 10 leans against the positioning platform 10.4 of the side tool rest 8 (see Figure 3);

[0016] On the connecting plate 10, a power cylinder 12 whose piston push rod 7 is directed to the vertical tool rest 2 is fixedly installed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com