Ultra-white float glass

An ultra-white float glass and glass technology, applied in the field of float glass, can solve the problems of reduced glass transmittance and large amount of addition, and achieve the effect of improving chemical stability and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below by specific examples.

[0031] Table 1 shows representative examples of base glass compositions

[0032] Table 1 Main components of glass

[0033] SiO 2 Na 2 o CaO MgO Al 2 o 3 Component 1 (wt%) 65 10 15 5 5 Component 2 (wt%) 75 20 5 0 0 Component 3 (wt%) 73.5 14.5 10.5 0.5 1.0

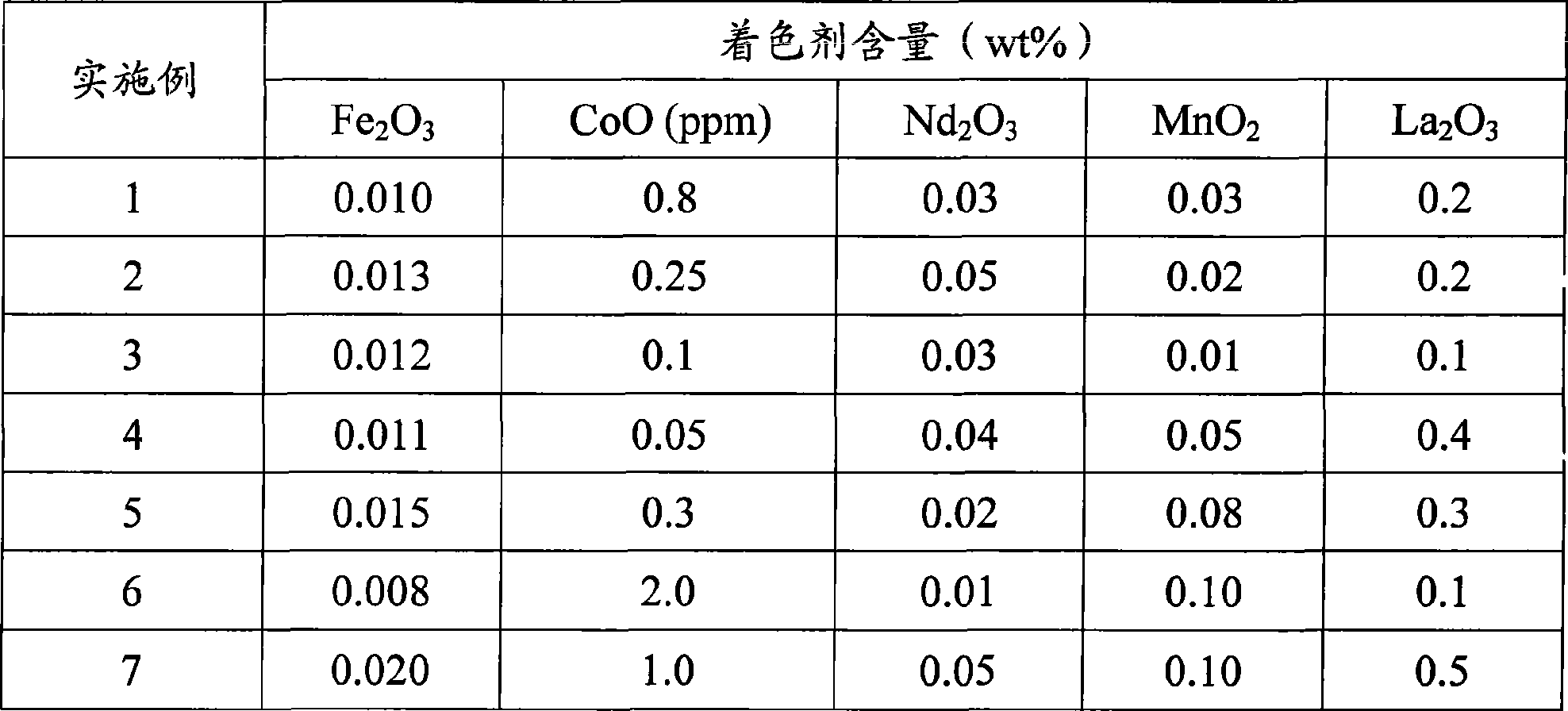

[0034] In the above-mentioned base glass component 3, the embodiment of adding the coloring agent (accounting for the percentage content of base glass weight) given by the present invention is shown in Table 2:

[0035] Table 2

[0036]

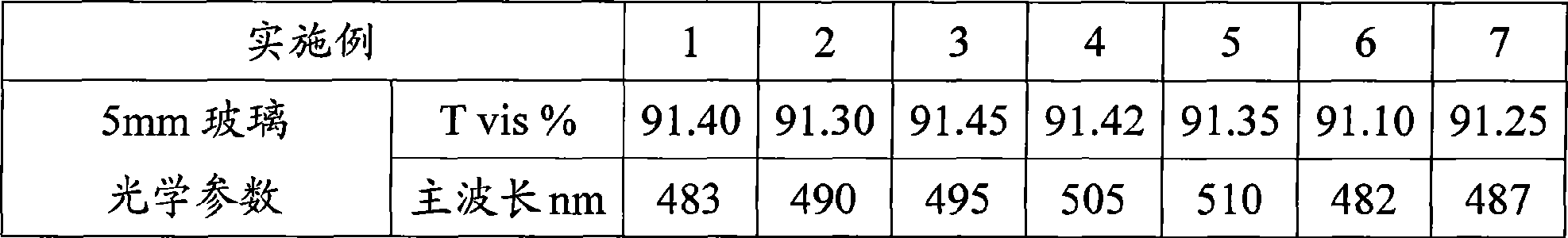

[0037] In the specific implementation process, in order to increase the accuracy and uniformity of the ingredients, cobalt oxide and dry silica sand or soda ash can be expanded to a concentration of 1 / 100, and put into use with other colorants at the same time, after uniform stirring and high temperature melting , Float forming can produce ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com