Patents

Literature

45results about How to "Minimizing expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

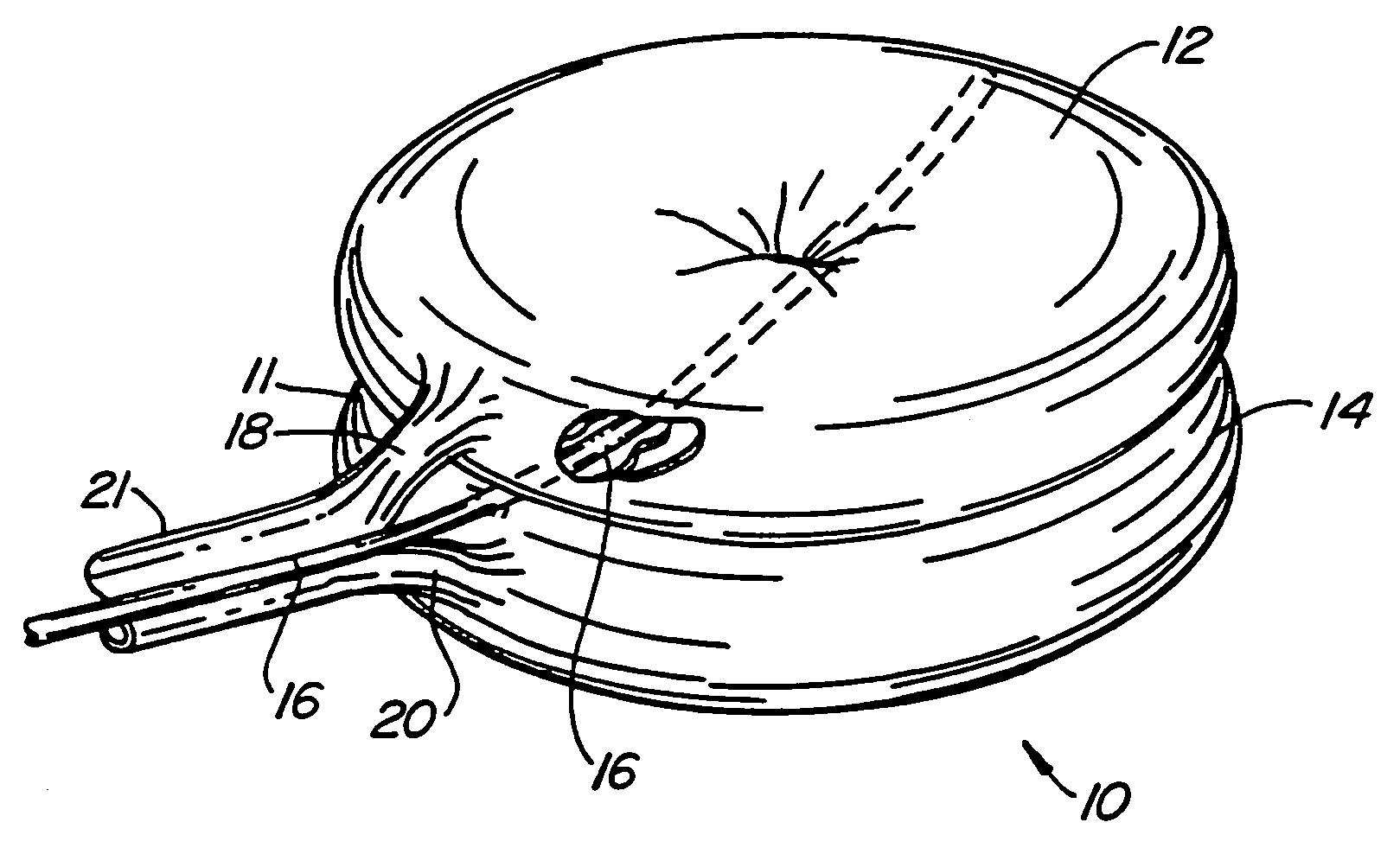

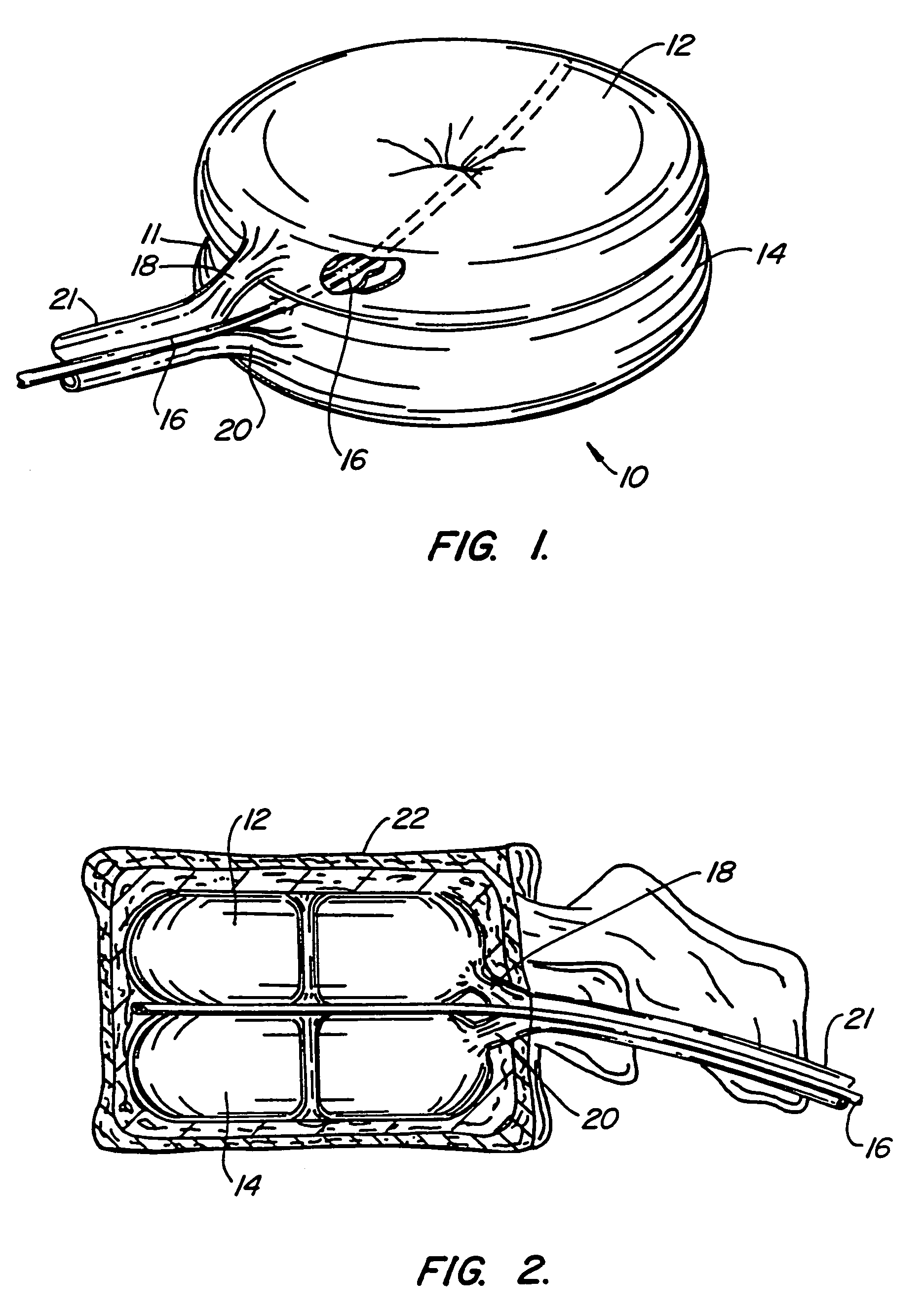

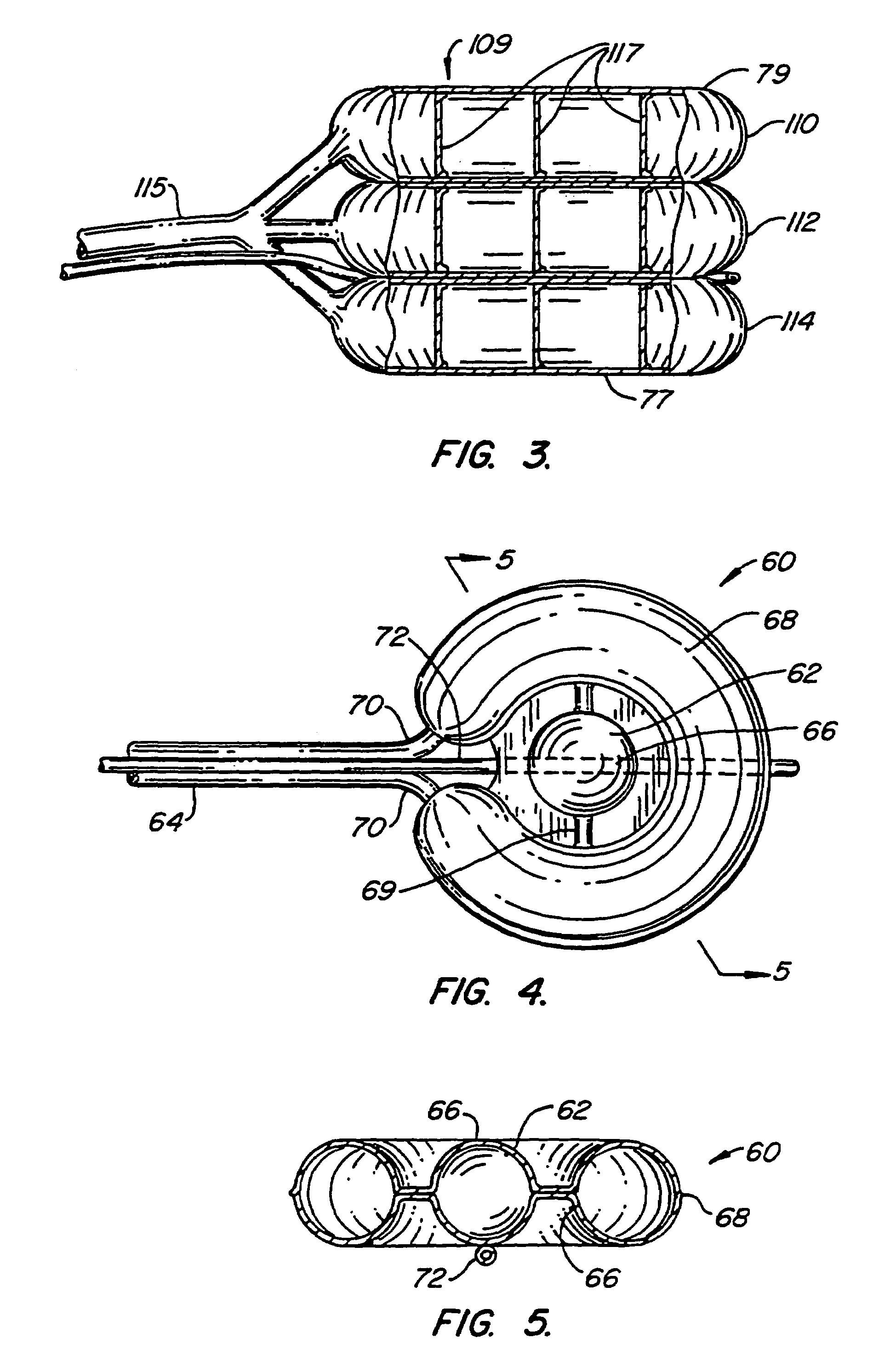

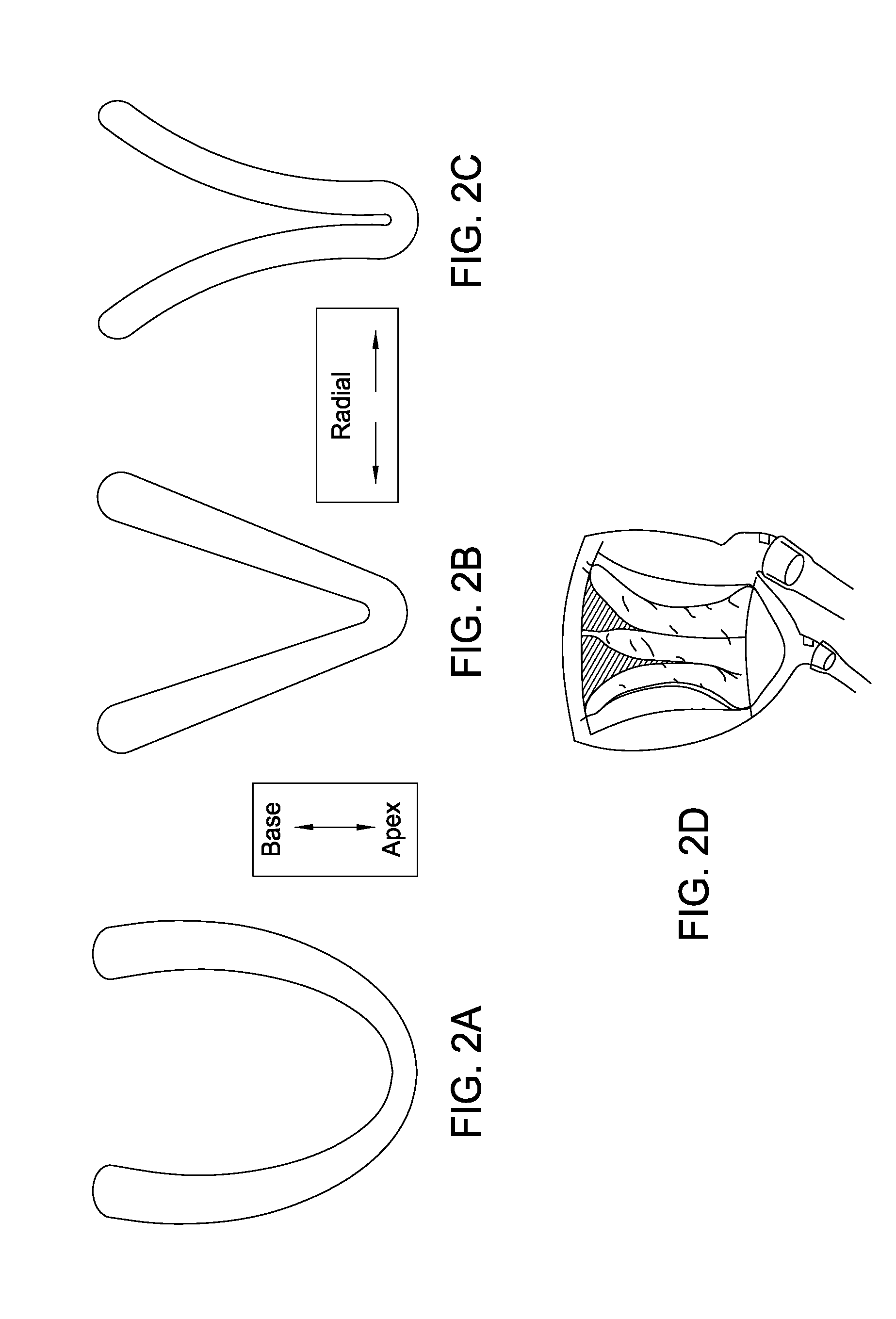

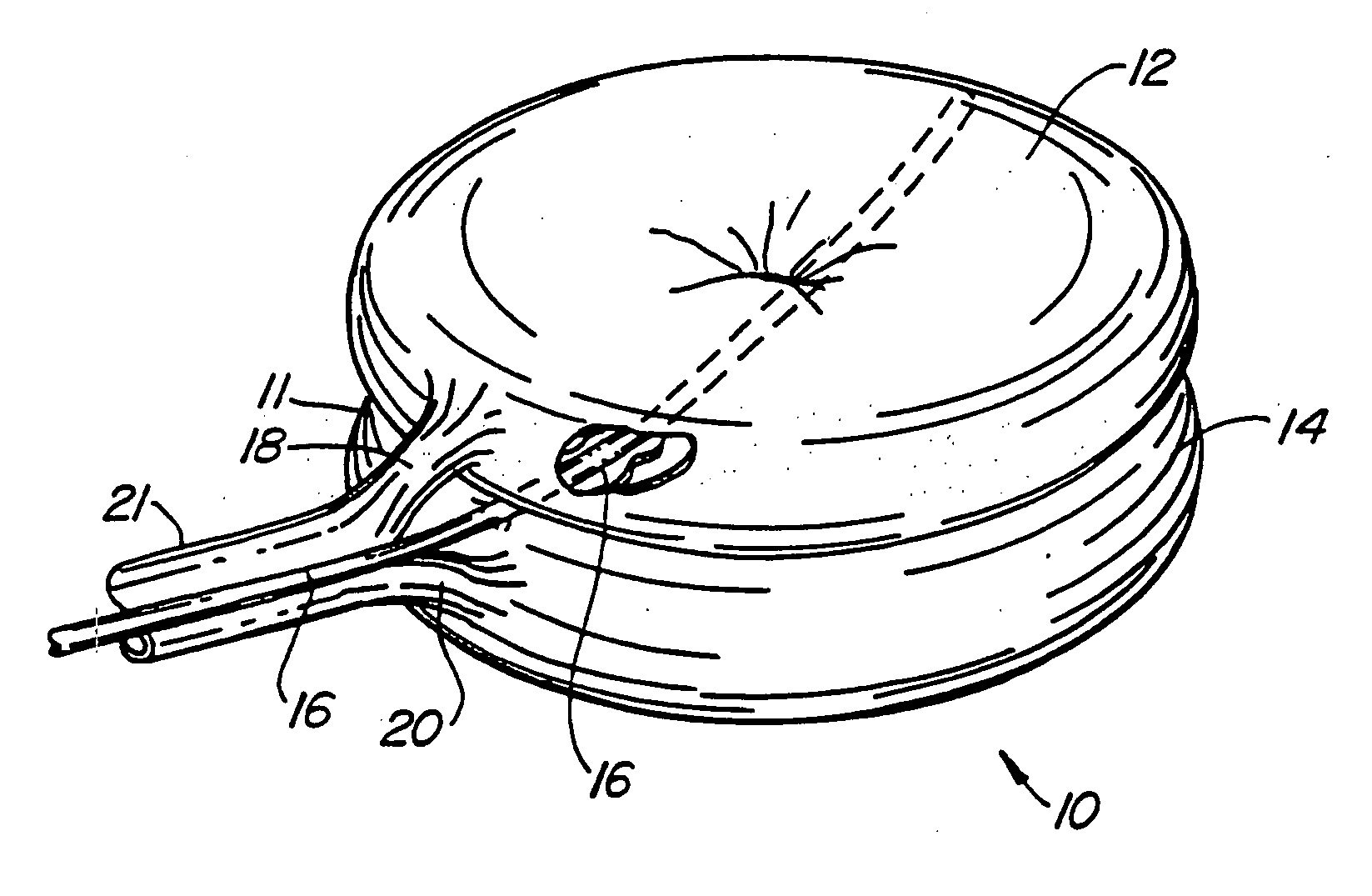

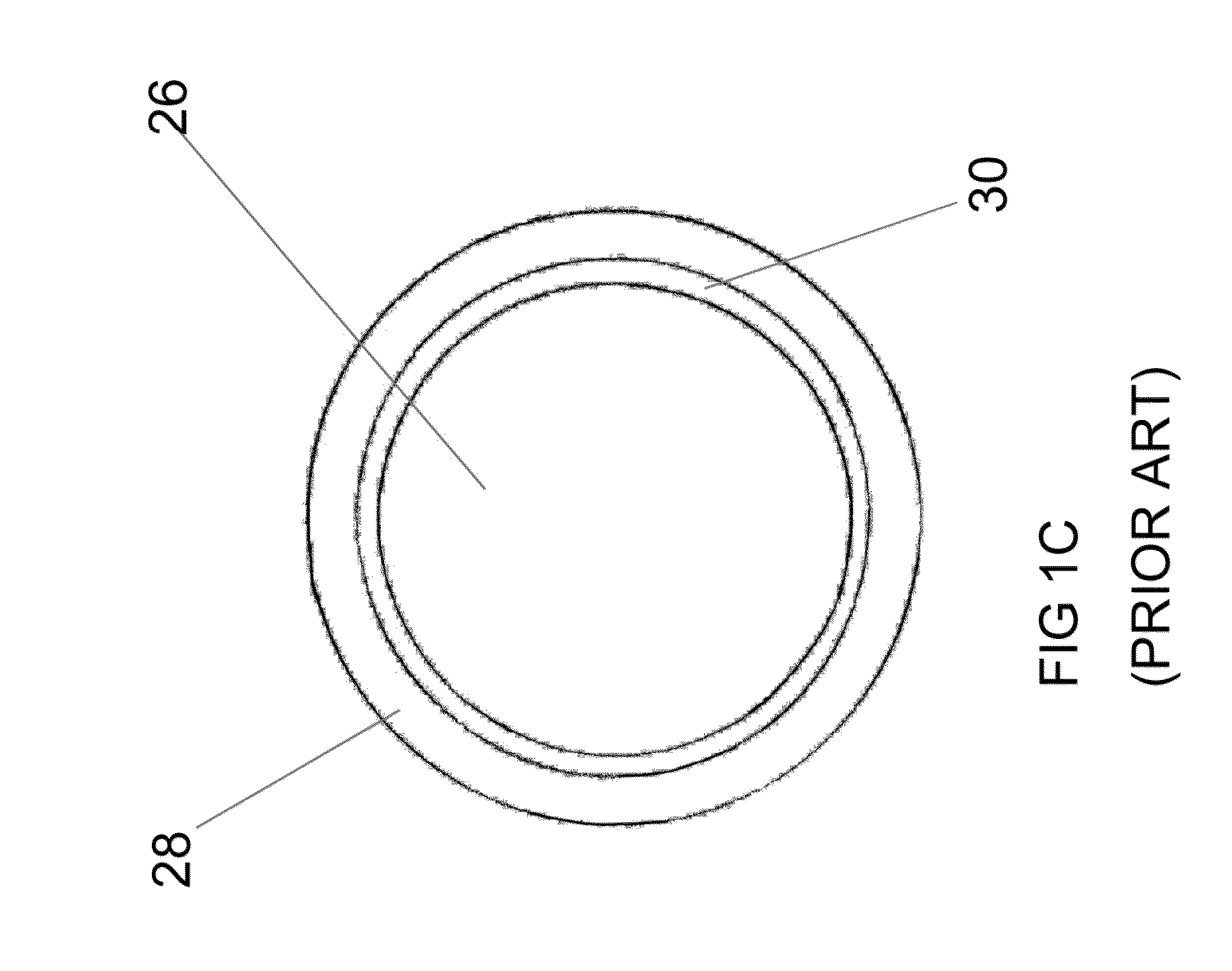

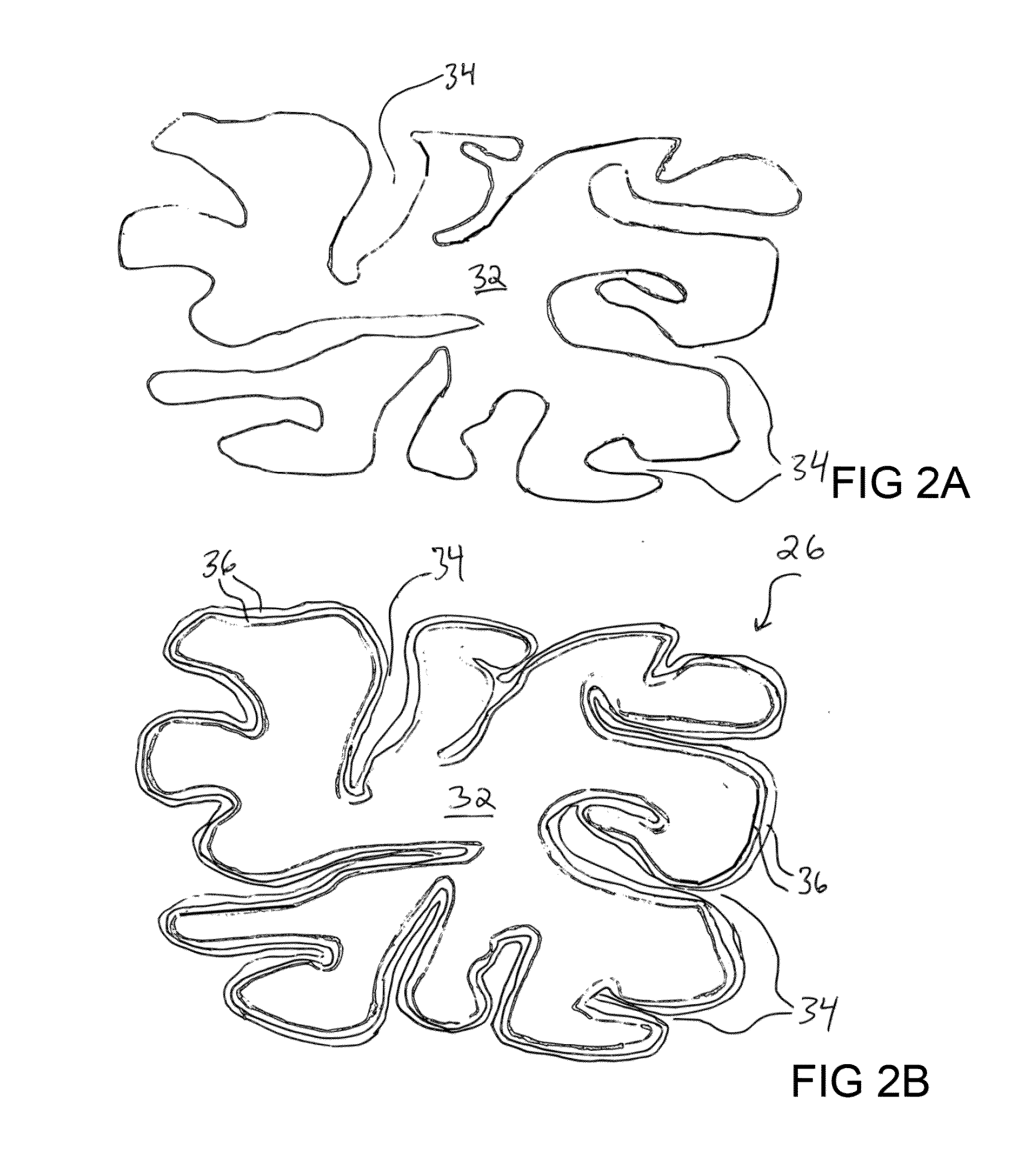

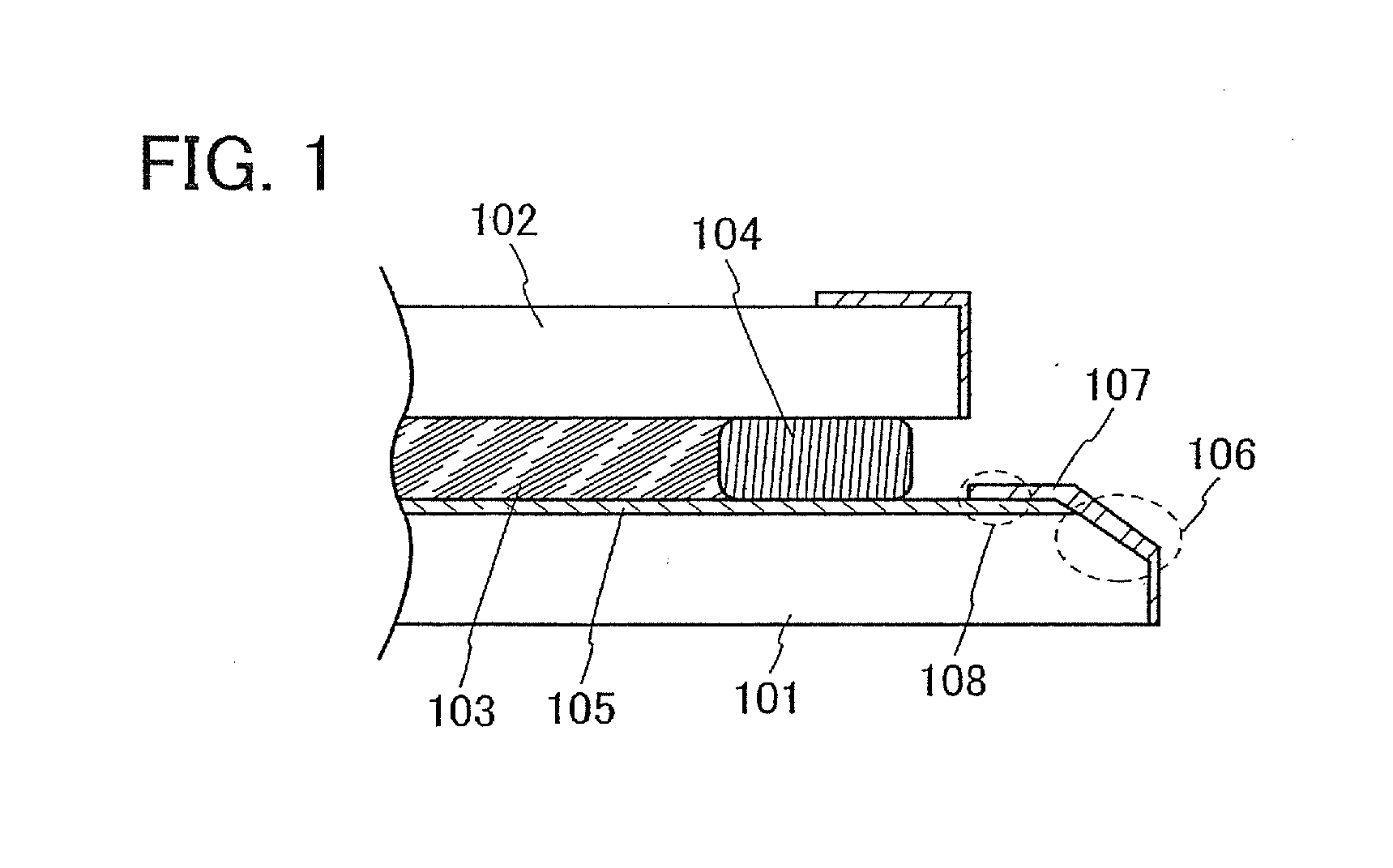

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS7261720B2Easy to compressEasy to foldSurgical furnitureInternal osteosythesisBone CortexTrabecular bone

A balloon for use in compressing cancellous bone and marrow (also known as medullary bone or trabecular bone). The balloon comprises an inflatable balloon body for insertion into said bone. The body has a shape and size to compress at least a portion of the cancellous bone to form a cavity in the cancellous bone and / or to restore the original position of the outer cortical bone, if fractured or collapsed. The balloon desirably incorporates restraints which inhibit the balloon from applying excessive pressure to various regions of the cortical bone. The wall or walls of the balloon are such that proper inflation of the balloon body is achieved to provide for optimum compression of the bone marrow. The balloon can be inserted quickly into a bone. The balloon can be made to have a suction catheter. The balloon can be used to form and / or enlarge a cavity or passage in a bone, especially in, but not limited to, vertebral bodies. Various additional embodiments facilitate directionally biasing the inflation of the balloon.

Owner:ORTHOPHOENIX

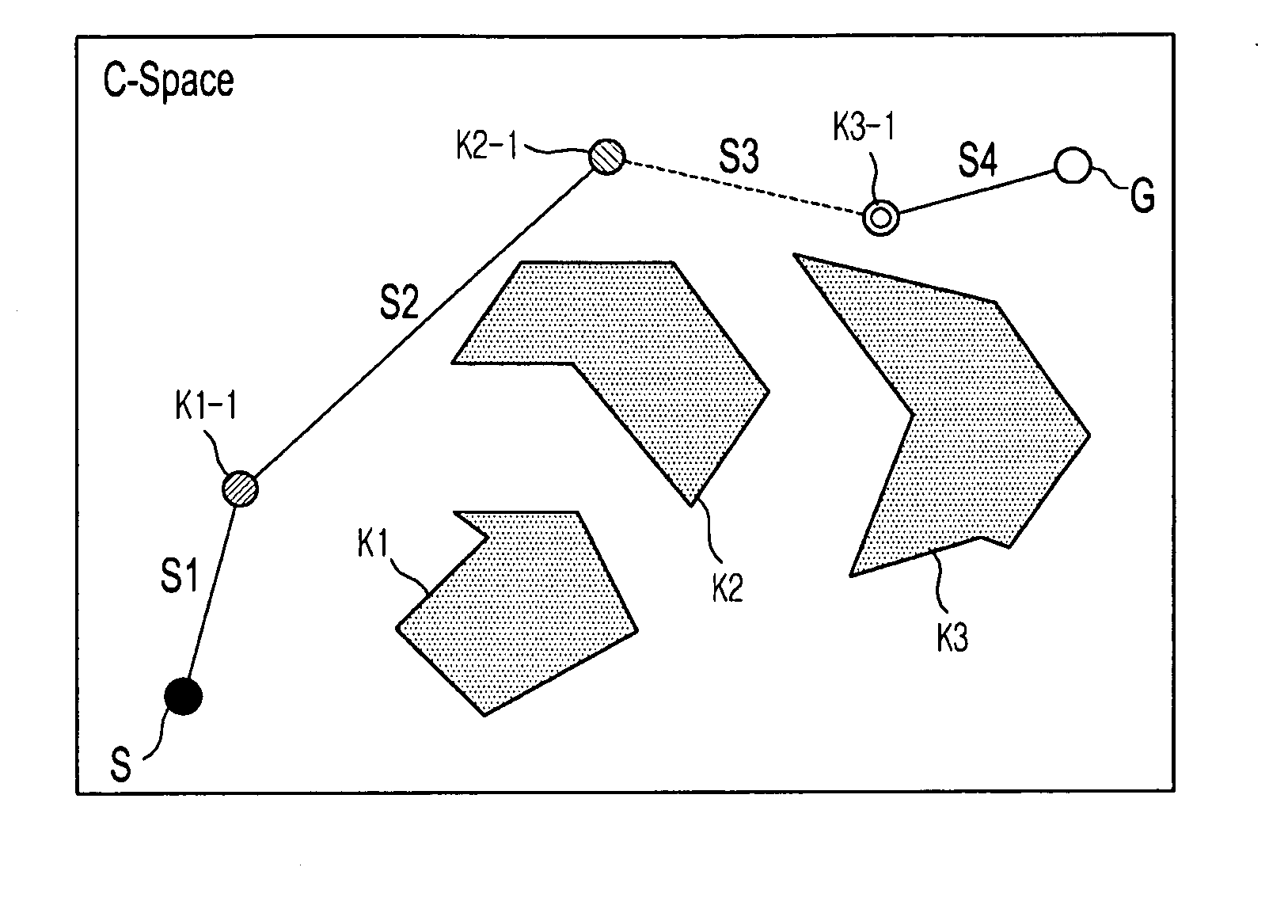

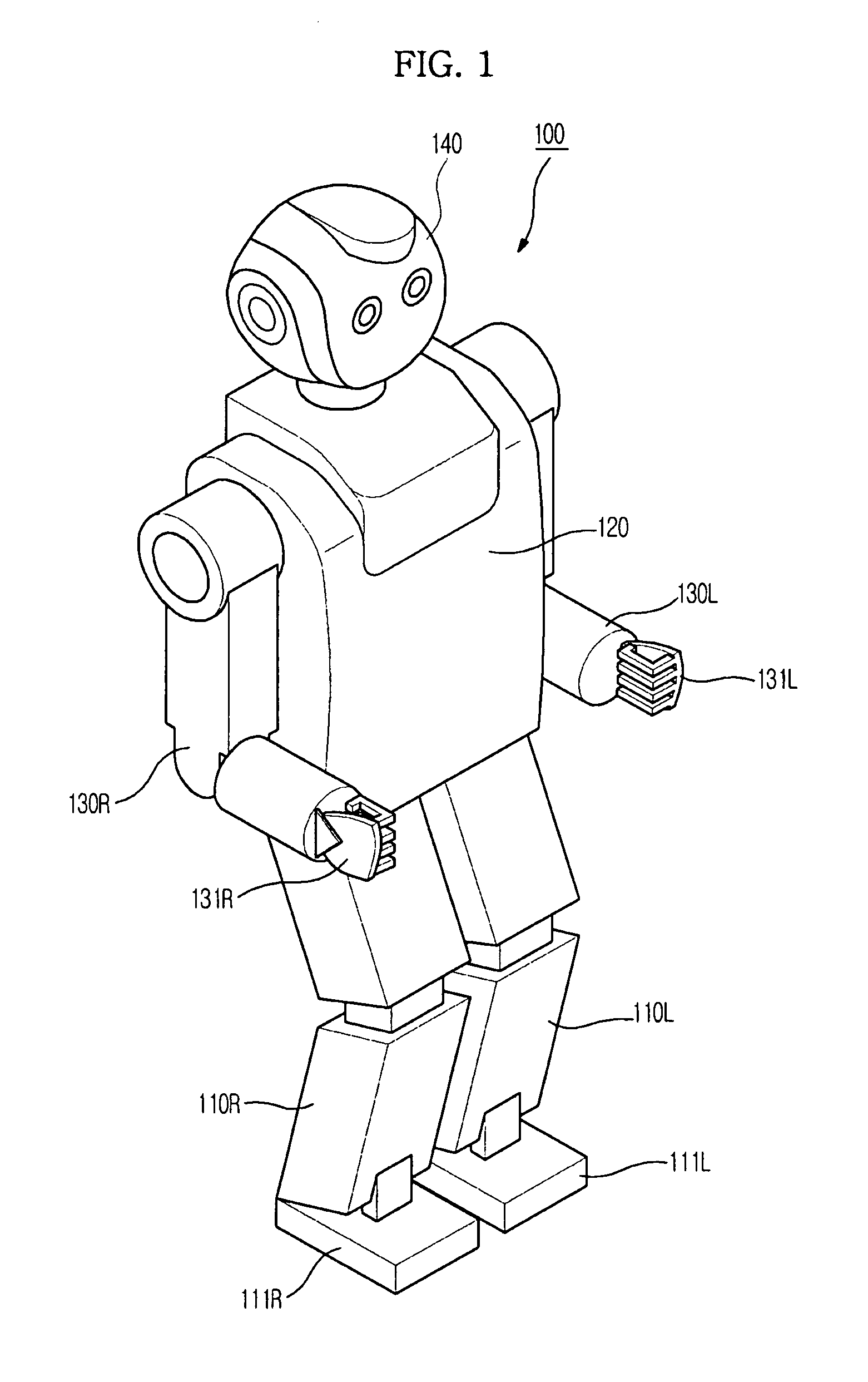

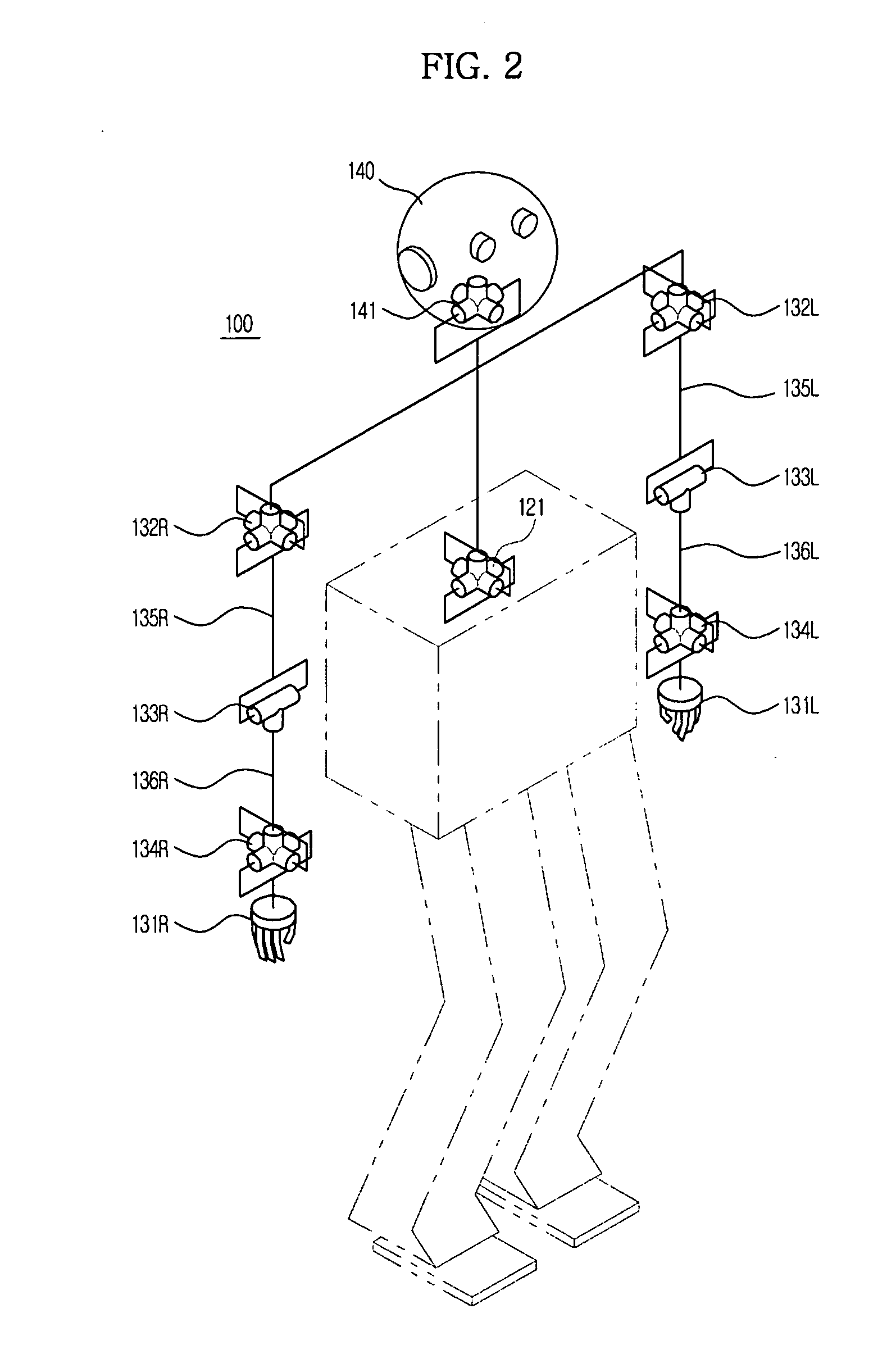

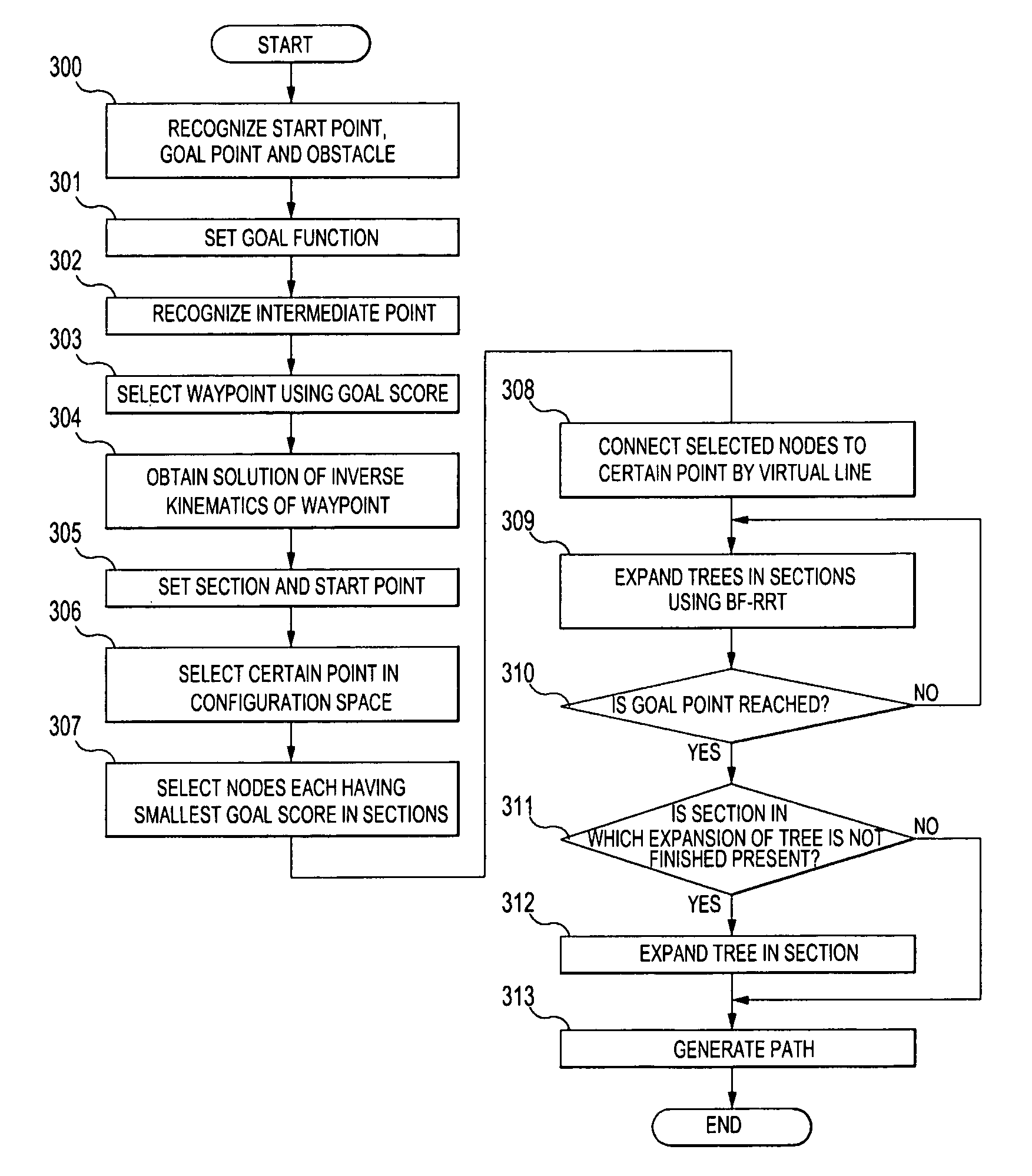

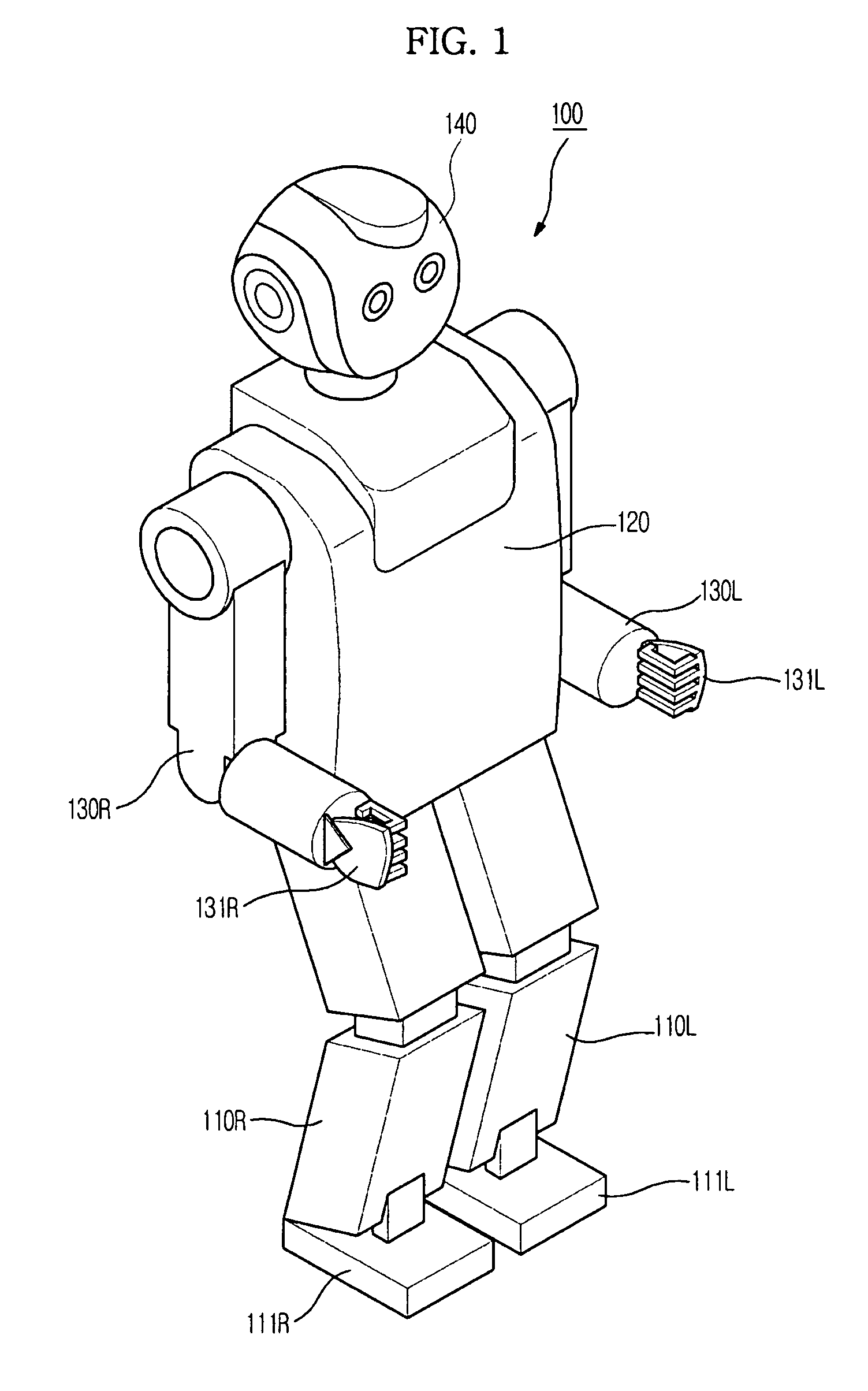

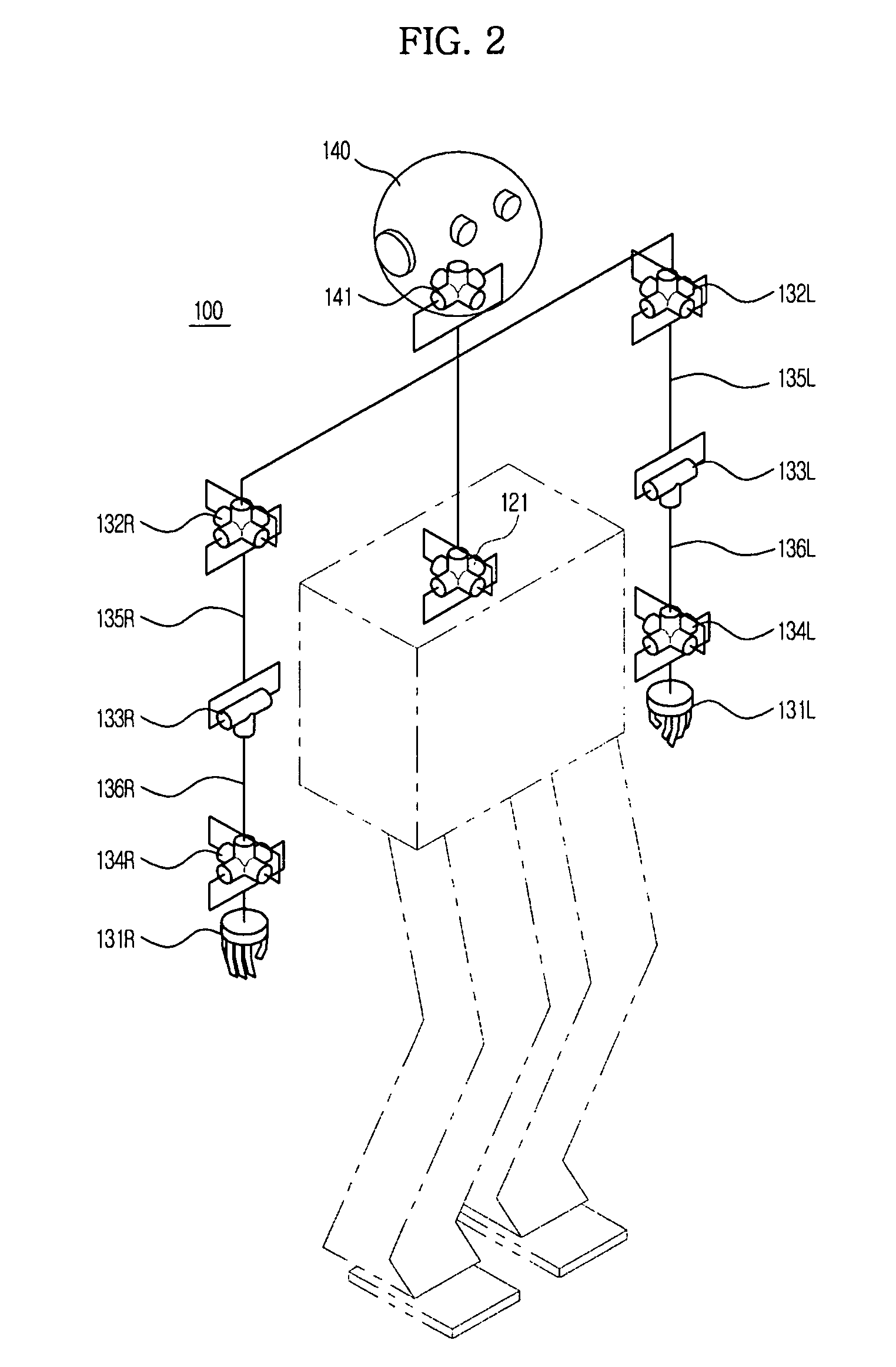

Method and apparatus to plan motion path of robot

ActiveUS20110035087A1Reduce probabilitySolution can be rapidly obtainedProgramme-controlled manipulatorInstruments for road network navigationAlgorithmRandom tree

A suitable waypoint is selected using a goal score, a section from a start point to a goal point through the waypoint is divided into a plurality of sections based on the waypoint with a solution of inverse kinematics, and trees are simultaneously expanded in the sections using a Best First Search & Rapidly Random Tree (BF-RRT) algorithm so as to generate a path. By this configuration, a probability of local minima occurring is decreased compared with the case where the waypoint is randomly selected. In addition, since the trees are simultaneously expanded in the sections each having the waypoint with a solution of inverse kinematics, the solution may be rapidly obtained. A time consumed to search for an optimal motion path may be shortened and path plan performance may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

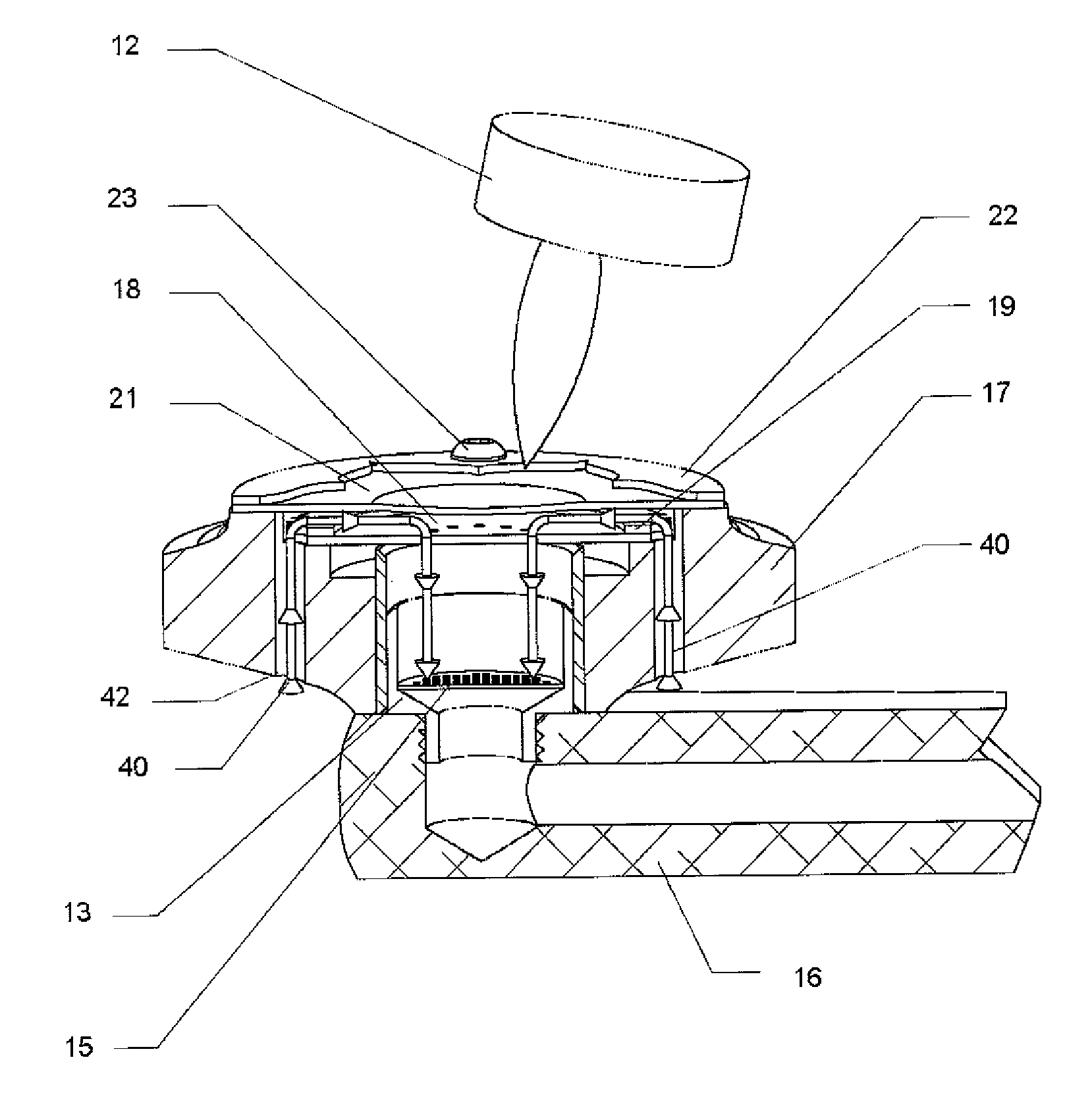

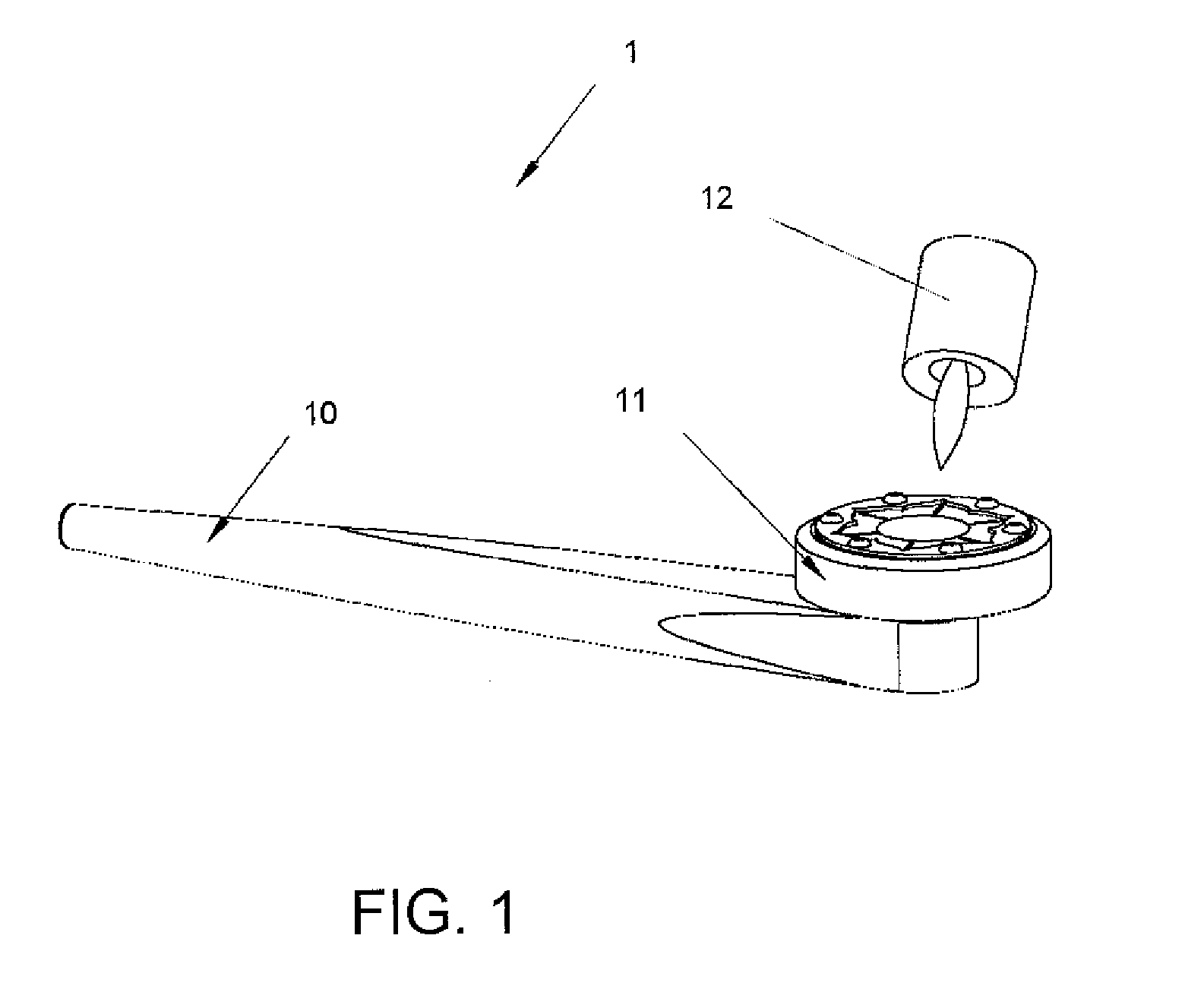

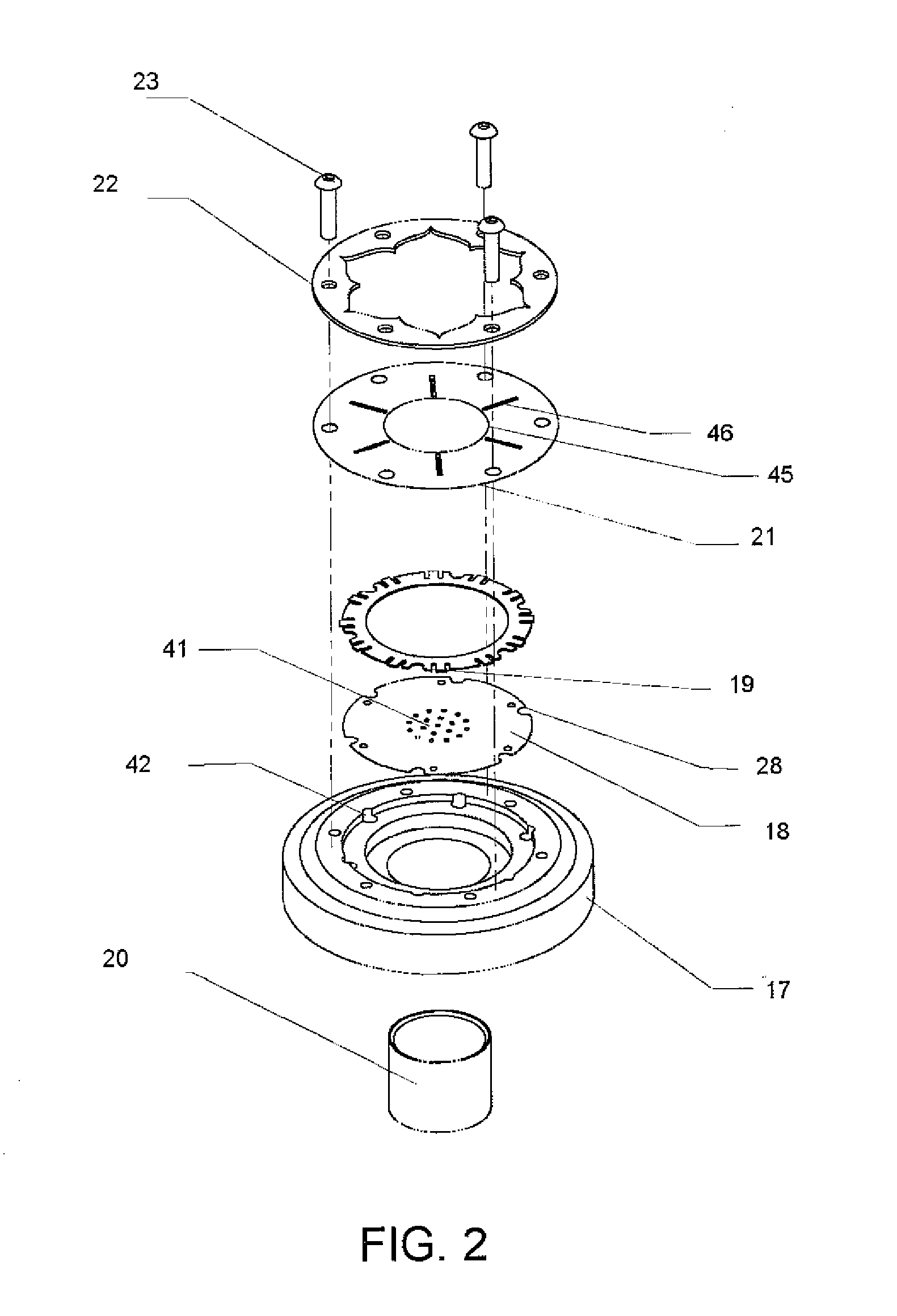

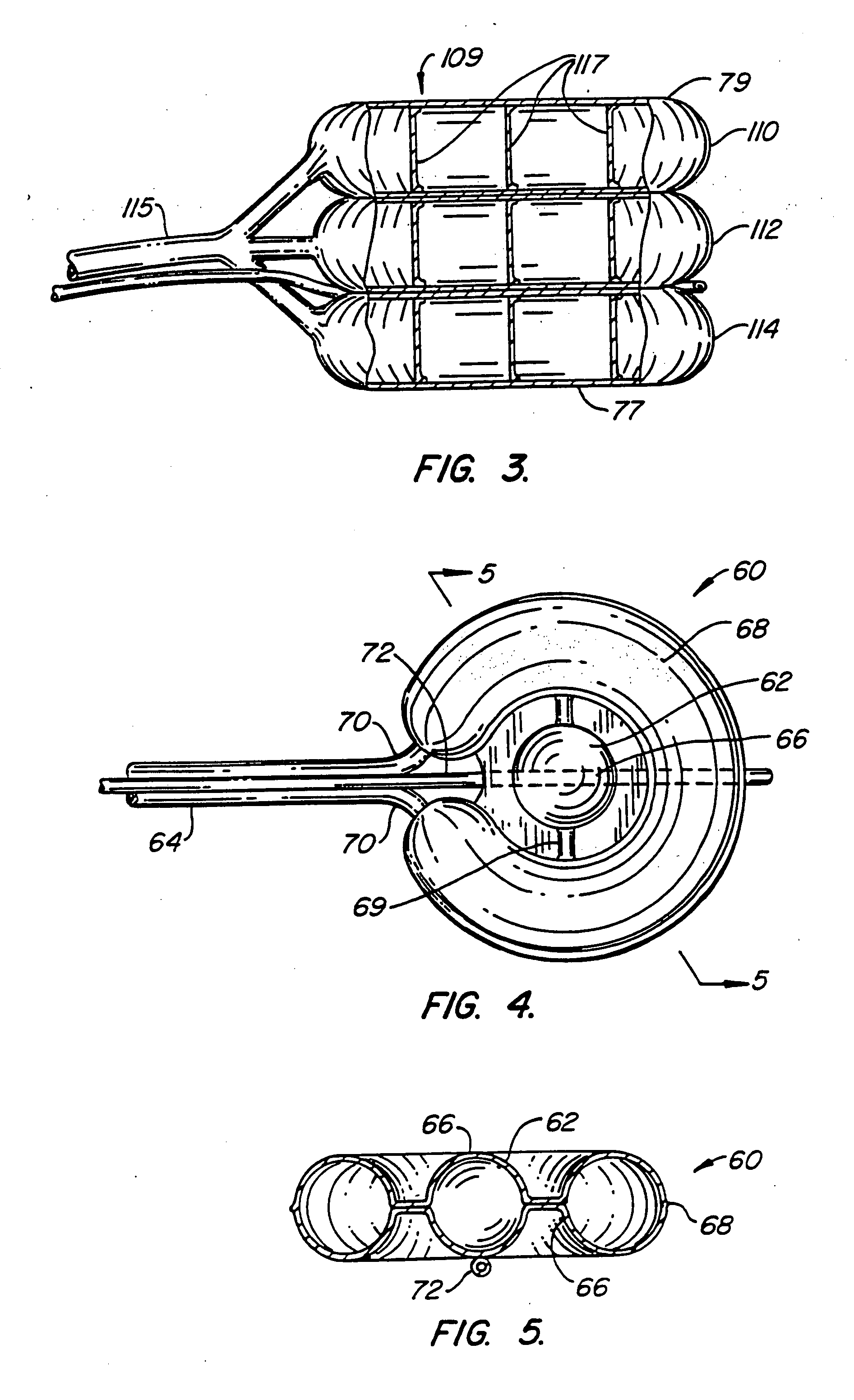

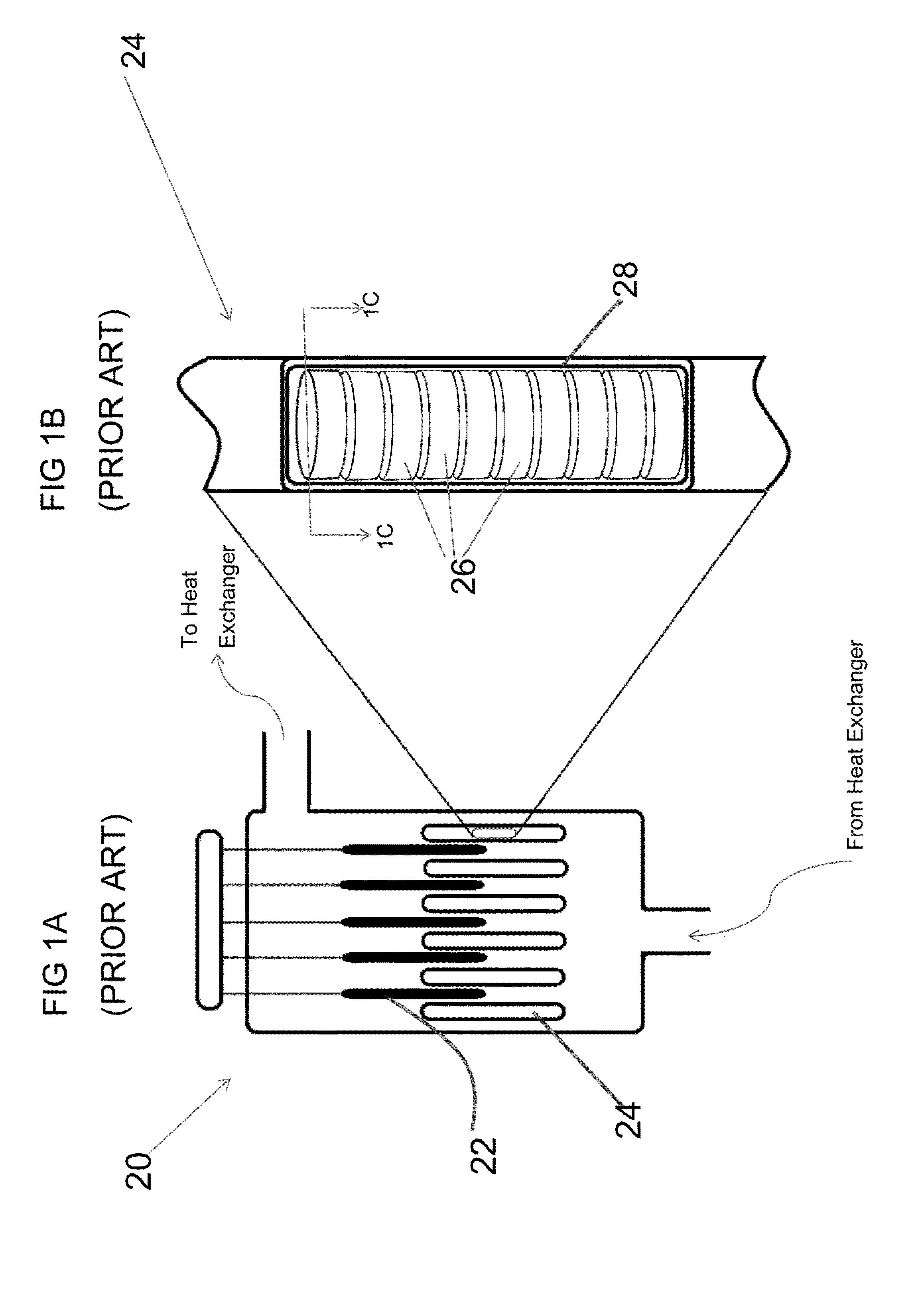

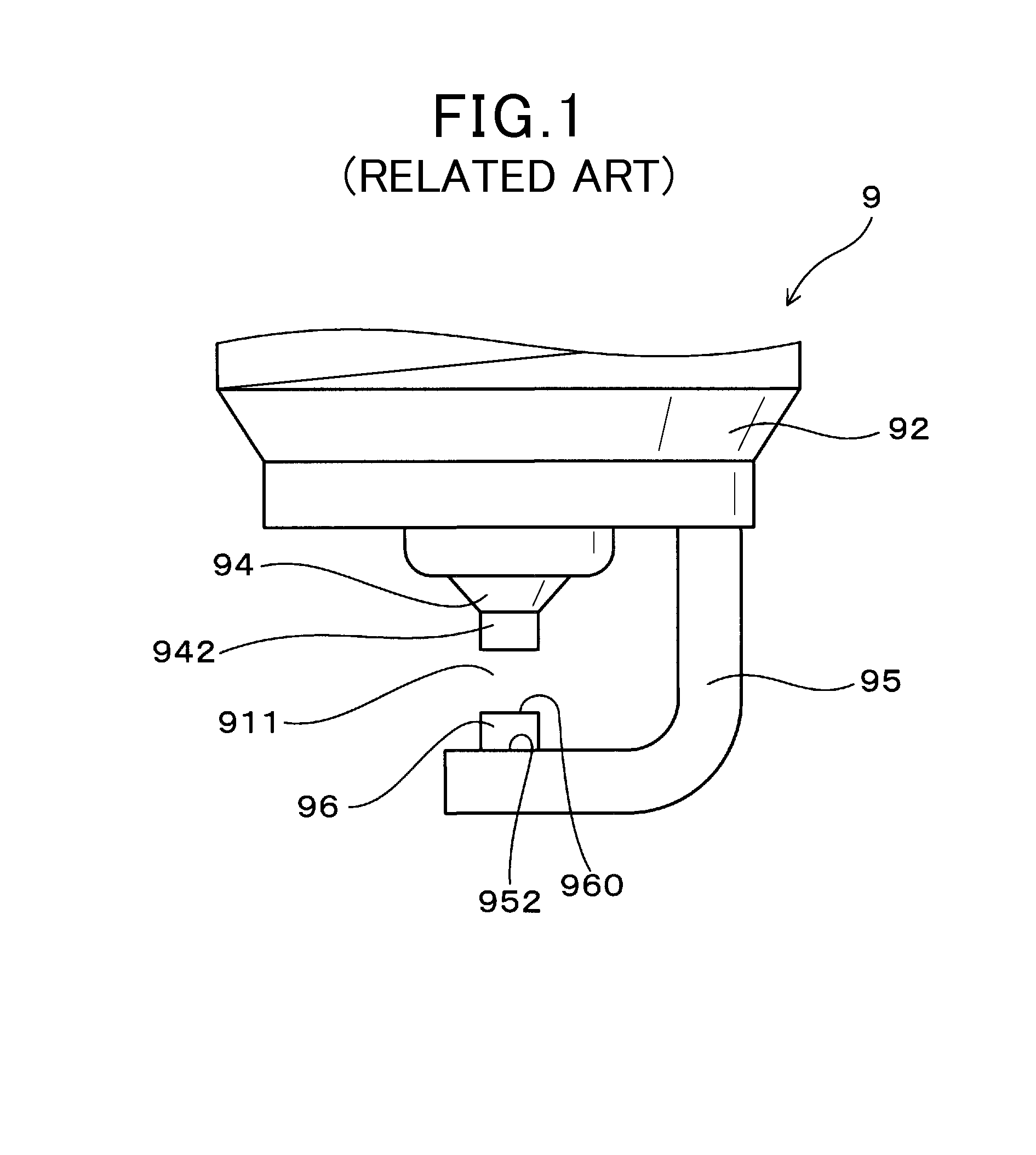

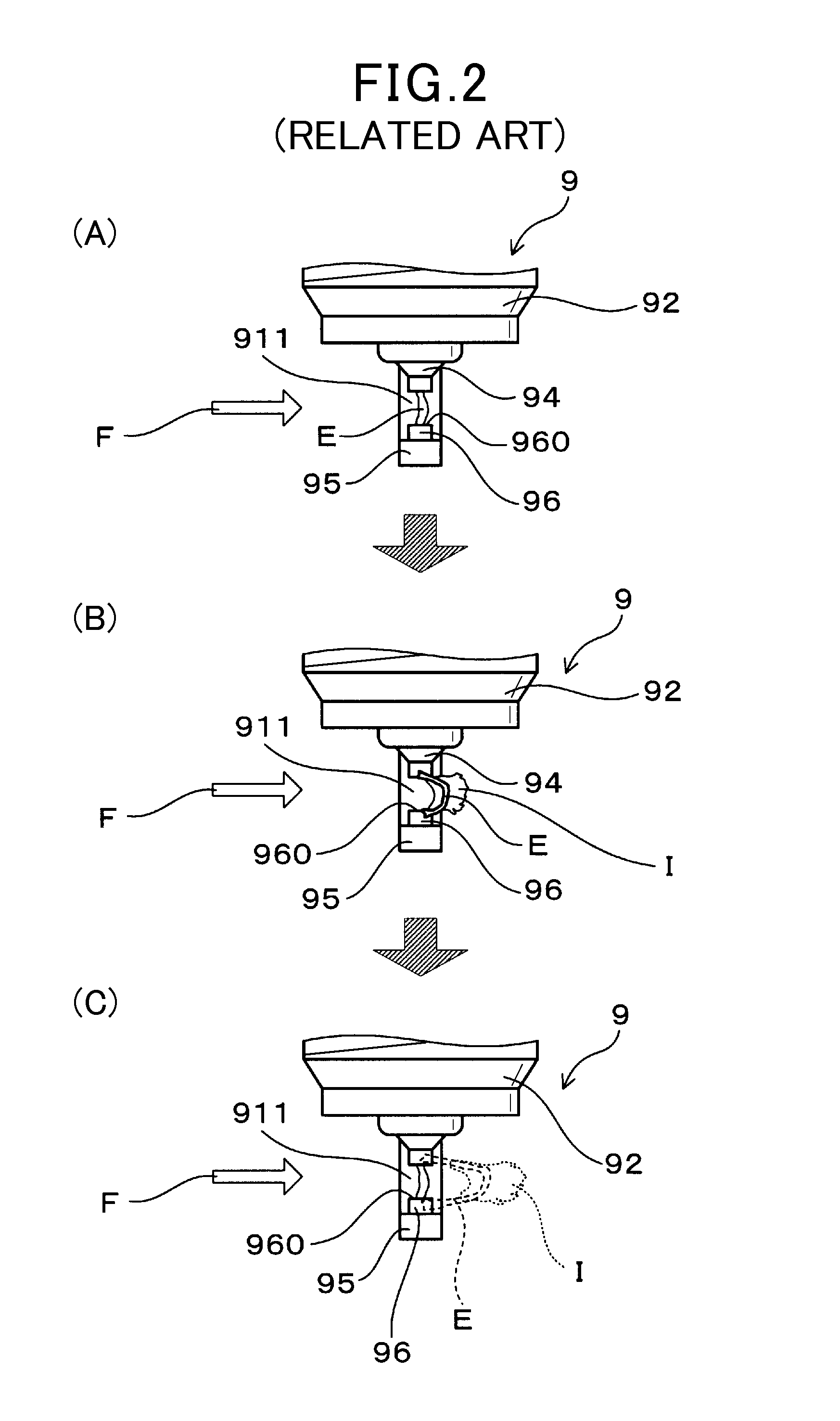

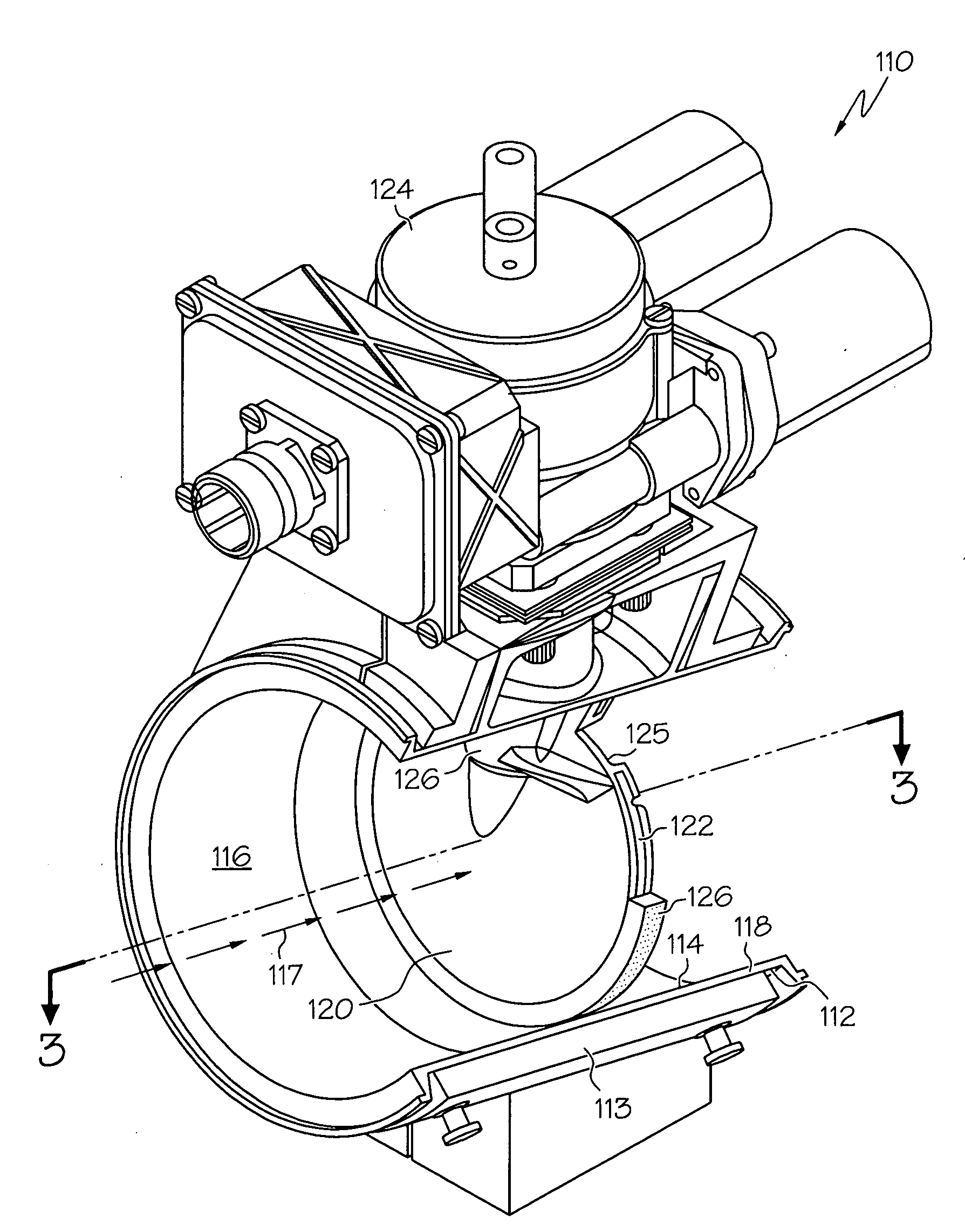

Vaporizer with foil heat exchanger

ActiveUS20110073121A1Minimize expansionMinimize flexTobacco pipesTobacco devicesPlate heat exchangerCombustion

This invention vaporizes a botanical substance for inhalation using a combustion generated heat source. A substantially planar non-porous heat exchanger transfers heat to the inhalation air and keeps combustion byproducts separated from the inhalation air. In use, air is drawn past the heat exchanger and then through a reservoir holding the botanical substance, vaporizing any volatiles in the substance. The heat exchanger assembly can be magnetically attached to the pipe assembly.

Owner:VAPMAN GMBH SRL

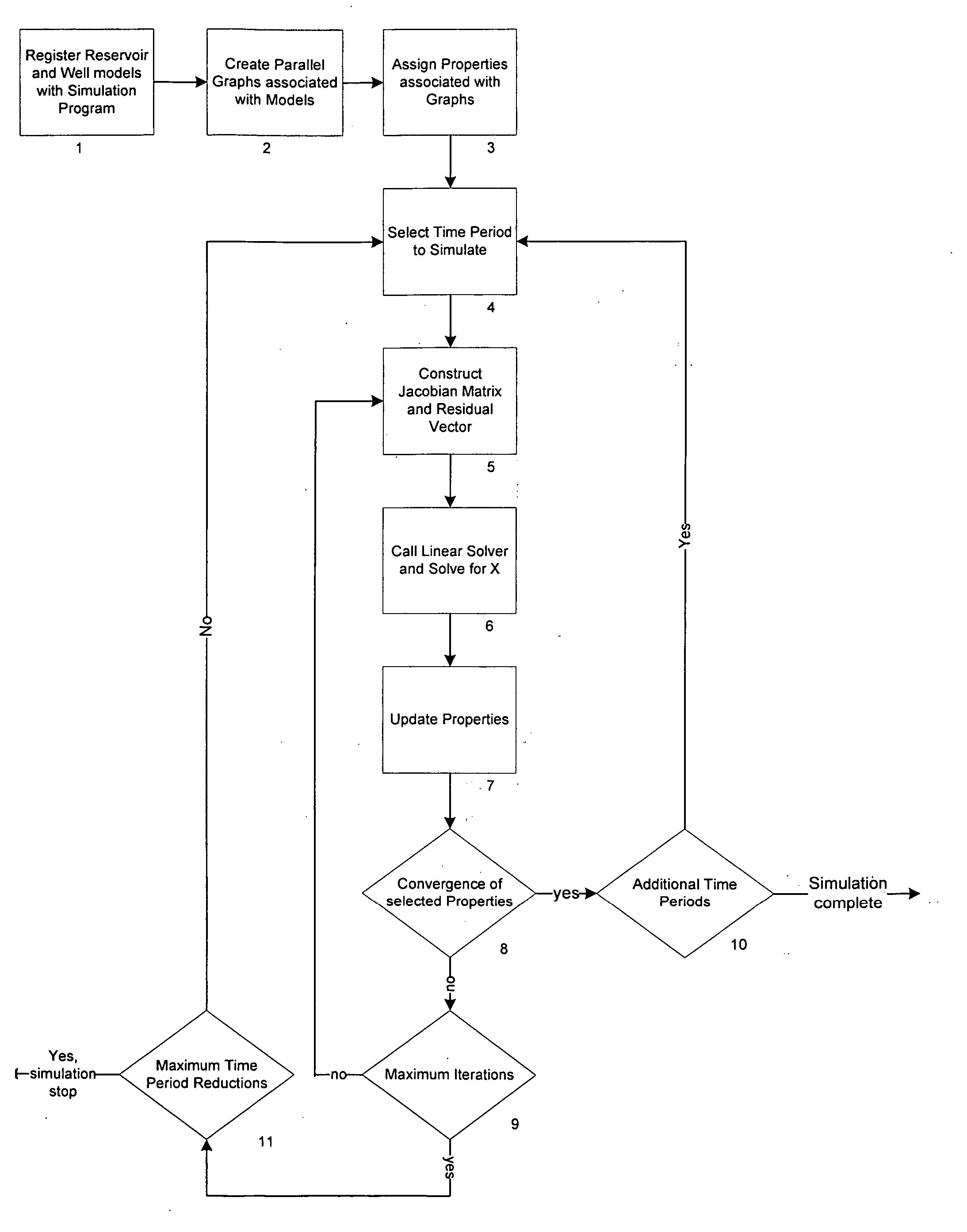

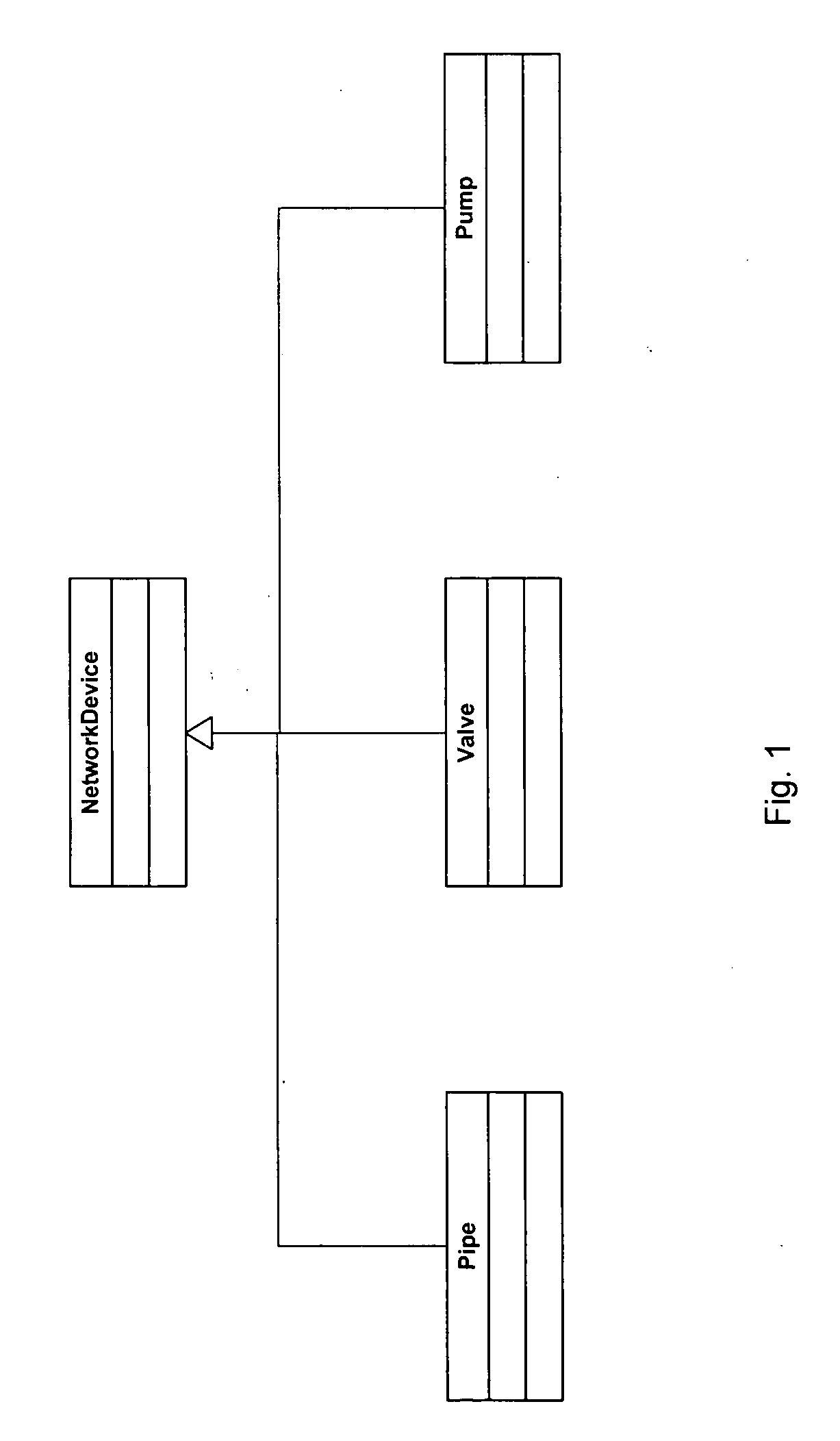

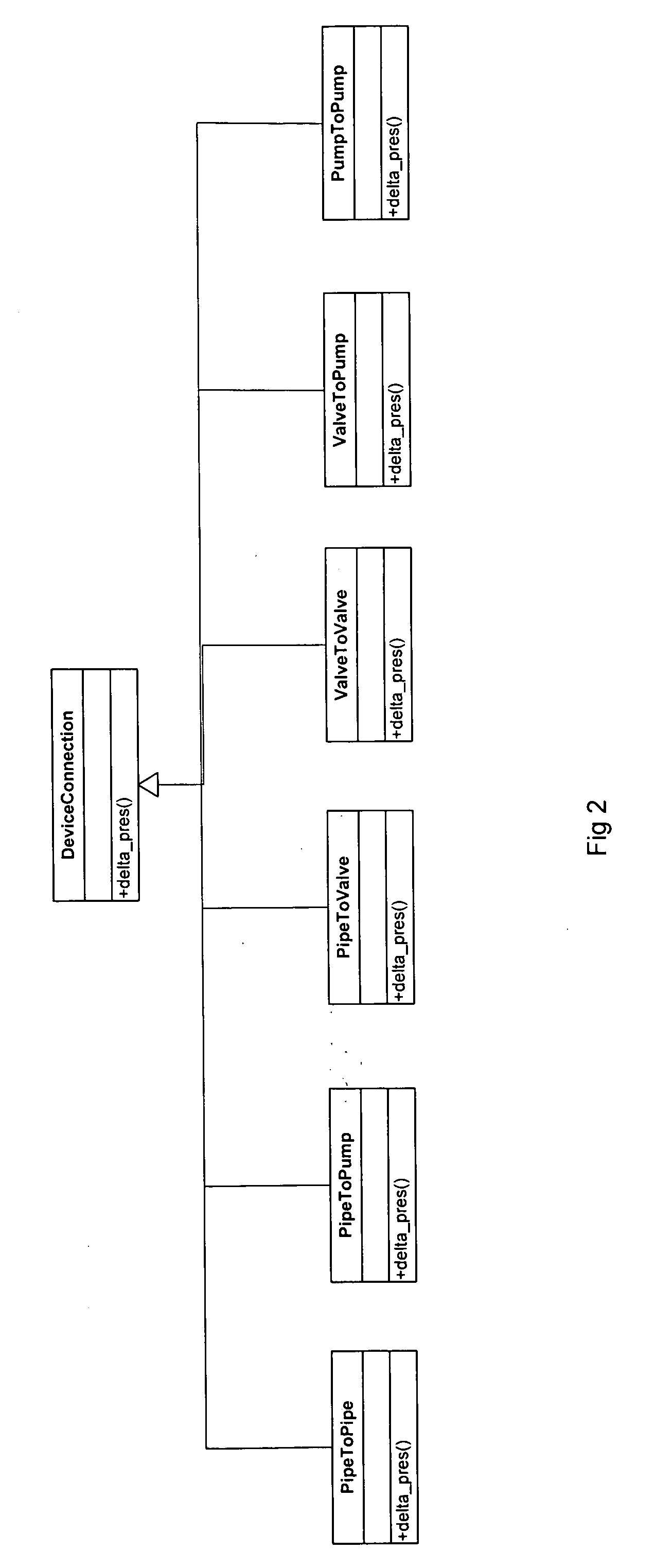

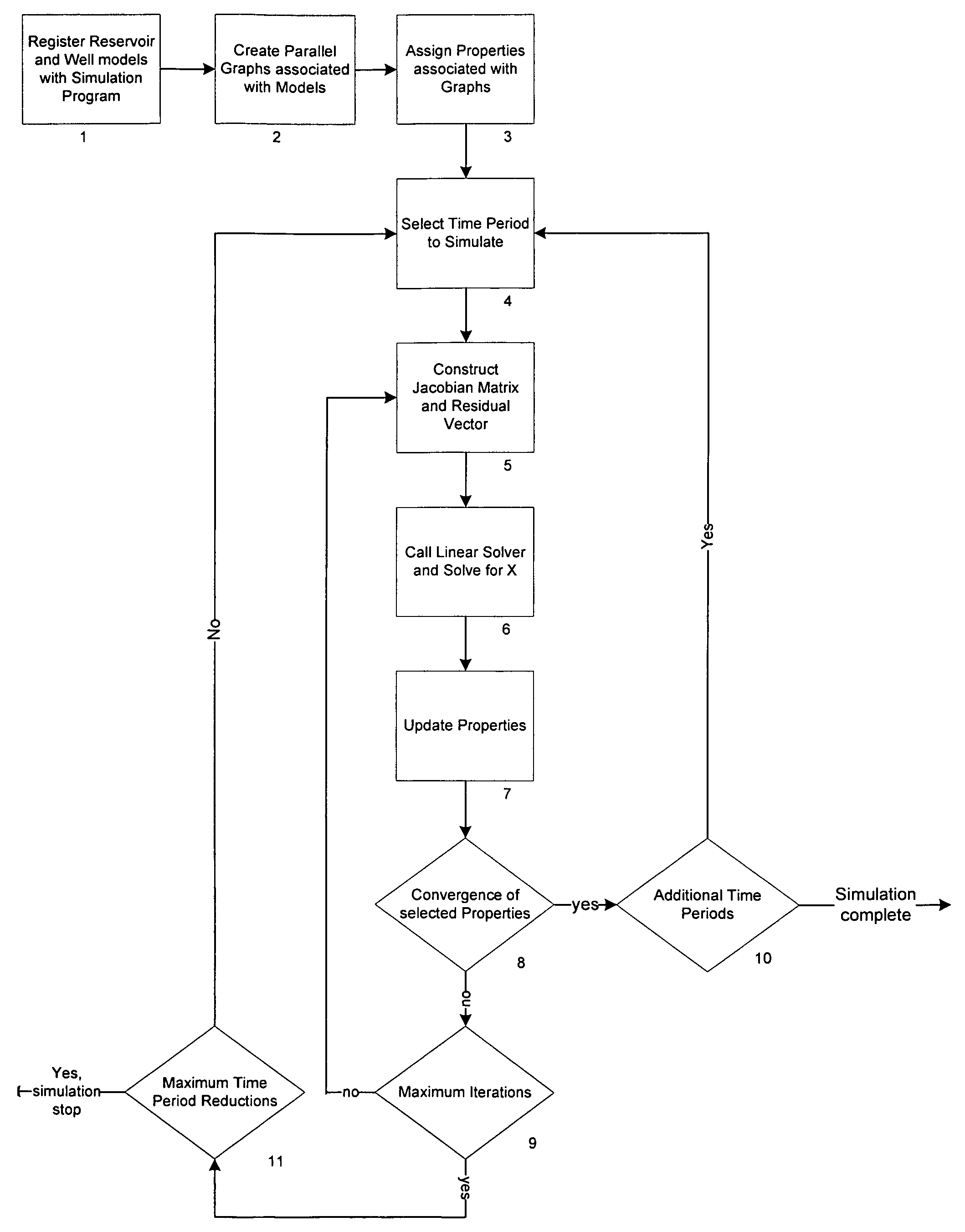

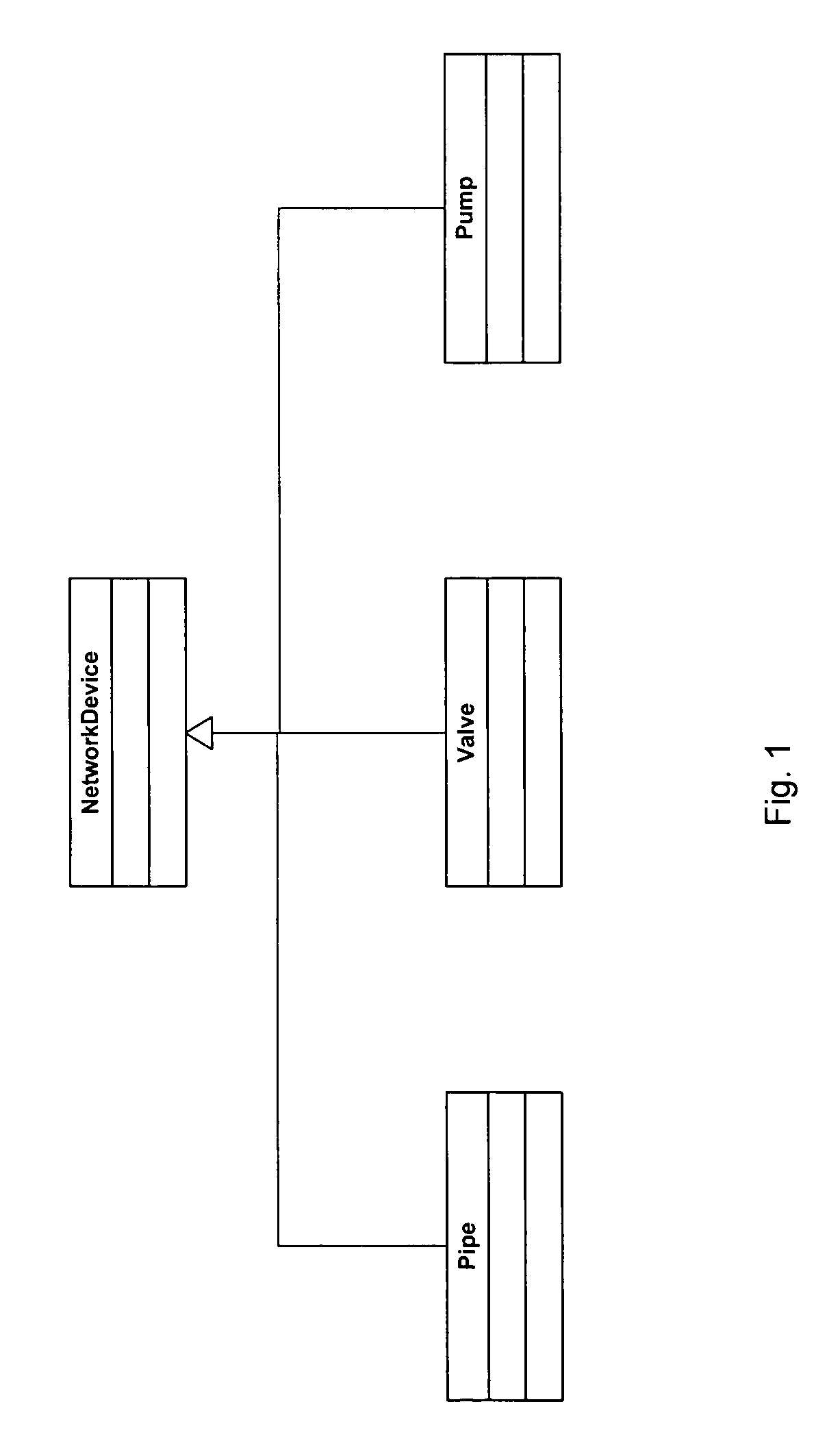

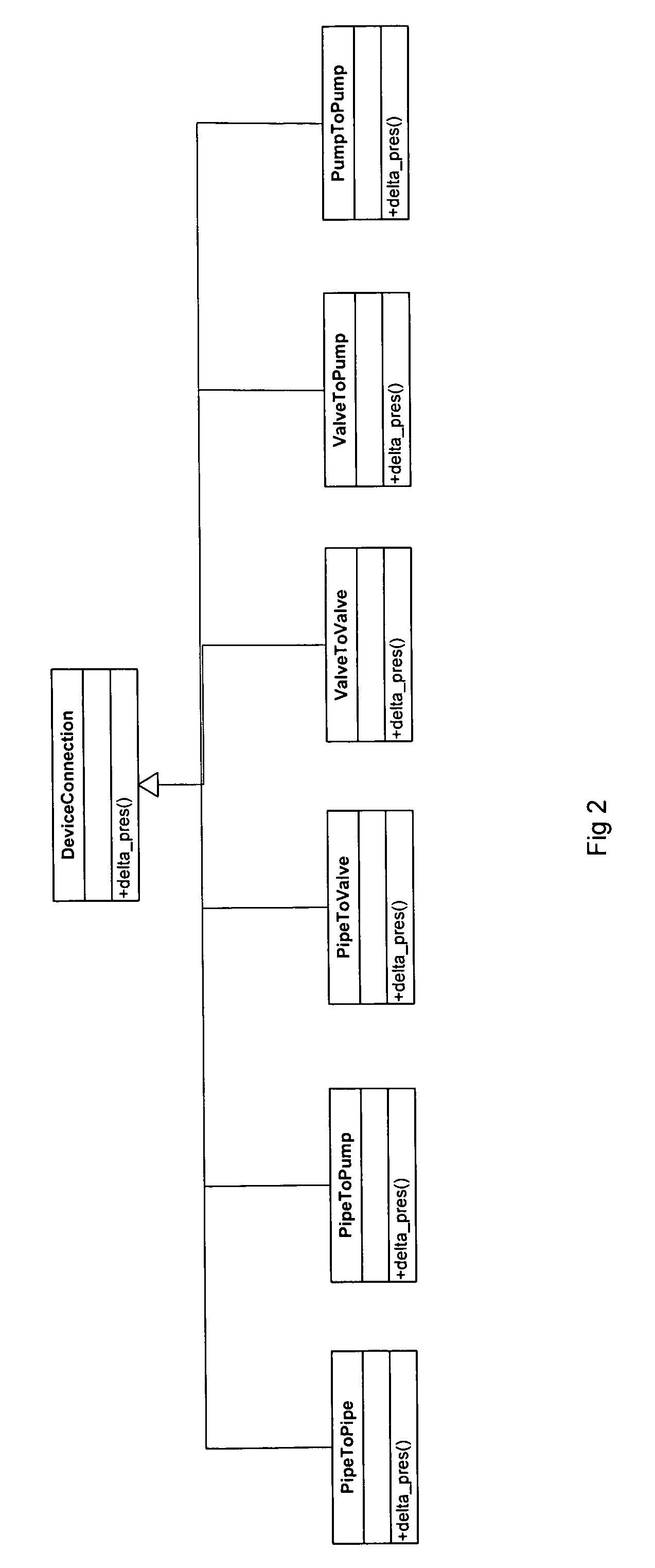

Method, system and program storage device for simulating fluid flow in a physical system using a dynamic composition based extensible object-oriented architecture

ActiveUS20060282243A1Minimizing combinatorial expansionMinimizing expansionDesign optimisation/simulationSpecial data processing applicationsComputational sciencePhysical system

The present invention provides a method, a system and a program storage device containing instructions for simulating the flow of fluid in a physical system using a composition-based extensible object-oriented program. A computer program includes: (i) a framework subsystem providing a graph package, a compute package and a property package; (ii) an engine subsystem including engine subsystem packages for performing numerical simulation, the engine subsystem packages including a linear solver package and a non-linear solver package; and (iii) a set of model components providing physical and numerical modeling behaviors utilized by the engine subsystem, the model components including at least one of a reservoir model, a well model, an aquifer model, a fluid model and a SCAL model. The framework subsystem, the engine subsystem and the model components work with one other to simulate the flow of fluid. Preferably, a partition package is used to create a partition of subsets of node and edge indices which can be used optimize computations by the program.

Owner:SCHLUMBERGER TECH CORP +1

Method, system and program storage device for simulating fluid flow in a physical system using a dynamic composition based extensible object-oriented architecture

ActiveUS7617082B2Minimizing expansionDesign optimisation/simulationSpecial data processing applicationsComputational scienceGraphics

The present invention provides a method, a system and a program storage device containing instructions for simulating the flow of fluid in a physical system using a composition-based extensible object-oriented program. A computer program includes: (i) a framework subsystem providing a graph package, a compute package and a property package; (ii) an engine subsystem including engine subsystem packages for performing numerical simulation, the engine subsystem packages including a linear solver package and a non-linear solver package; and (iii) a set of model components providing physical and numerical modeling behaviors utilized by the engine subsystem, the model components including at least one of a reservoir model, a well model, an aquifer model, a fluid model and a SCAL model. The framework subsystem, the engine subsystem and the model components work with one other to simulate the flow of fluid. Preferably, a partition package is used to create a partition of subsets of node and edge indices which can be used optimize computations by the program.

Owner:SCHLUMBERGER TECH CORP +1

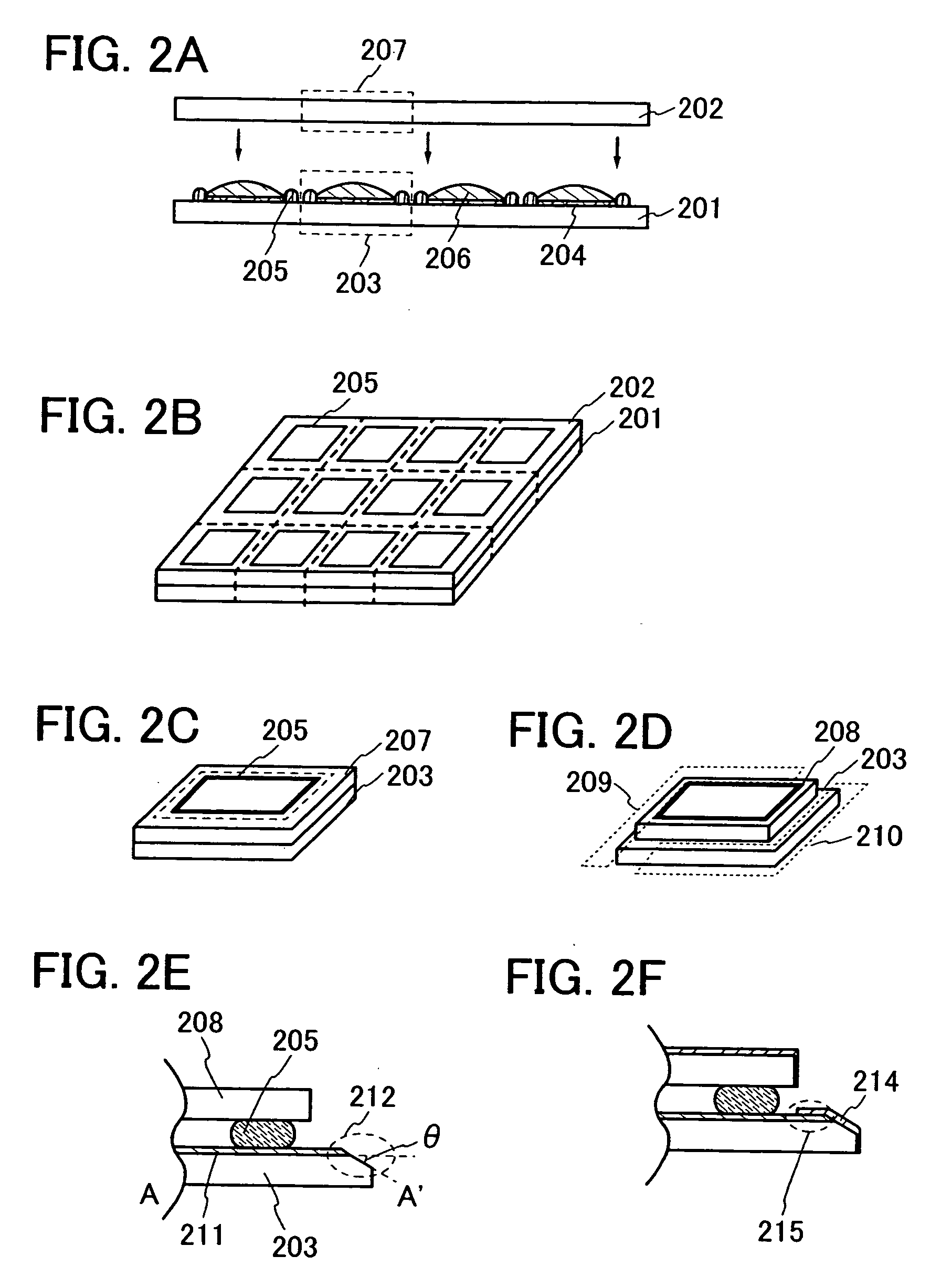

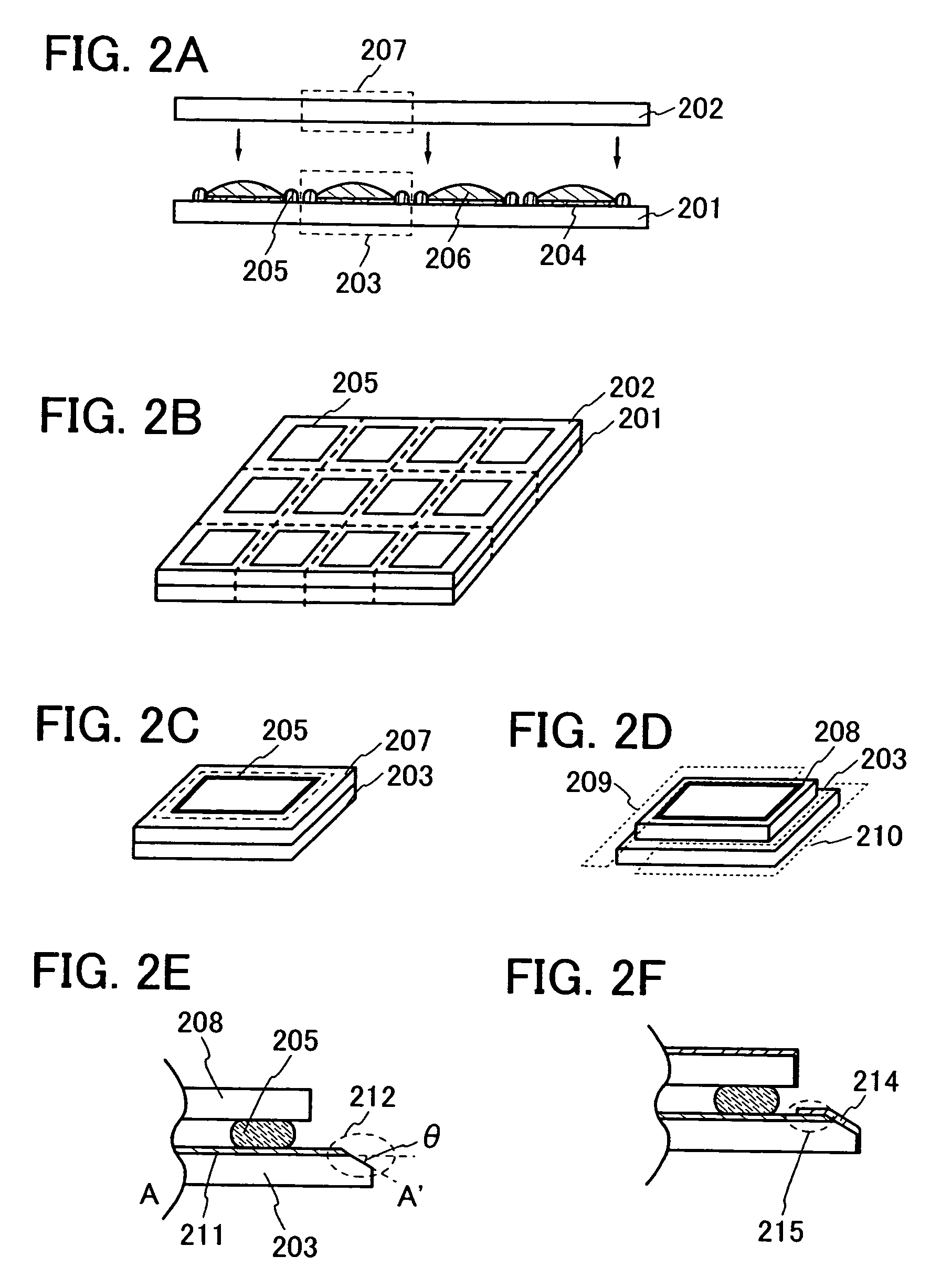

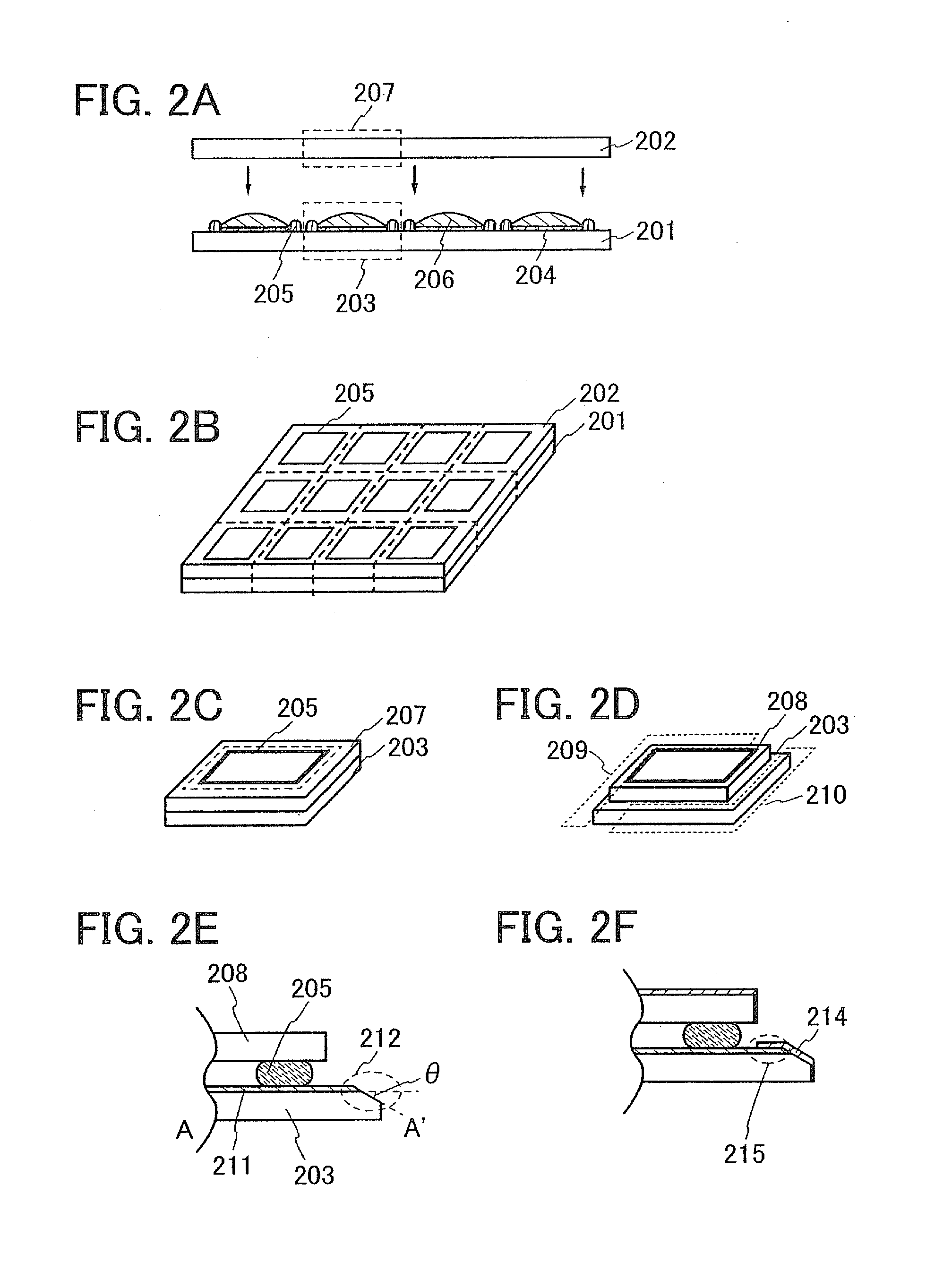

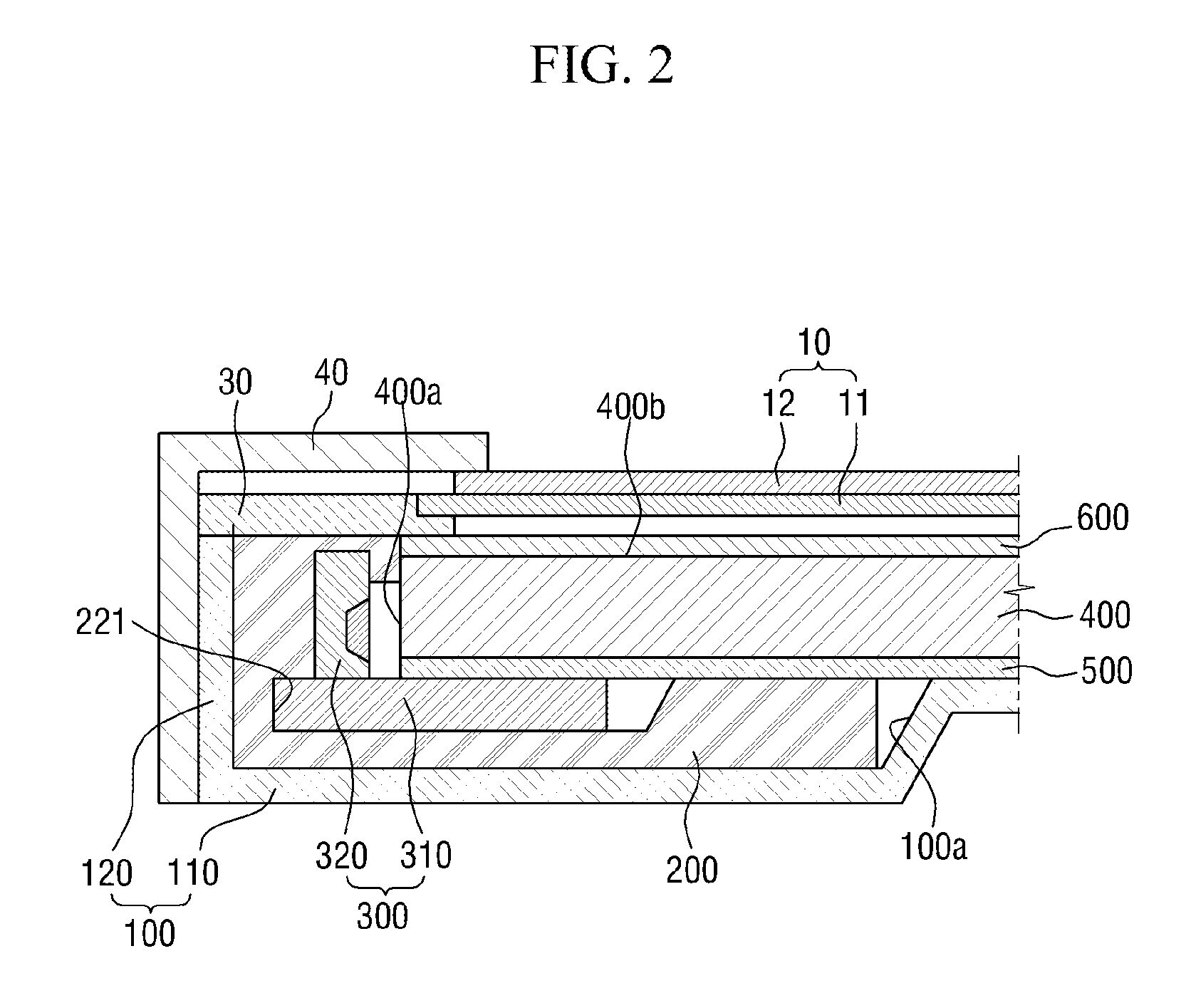

Display device

It is an object of the present invention to provide a display device where expansion of a frame portion over a substrate, which results from formation of a lead wiring over an active matrix substrate, is minimally suppressed to realize a narrow frame. According to one feature of a display device of the present invention, a chamfer portion is formed at least at an end portion of an active matrix substrate having a pixel portion of a pair of substrates disposed to be opposed to each other, and wirings (a source line, a gate line, a storage capacitor line, a leading out wiring, and the like) over the active matrix substrate are electrically connected by a common wiring formed in the chamfer portion.

Owner:SEMICON ENERGY LAB CO LTD

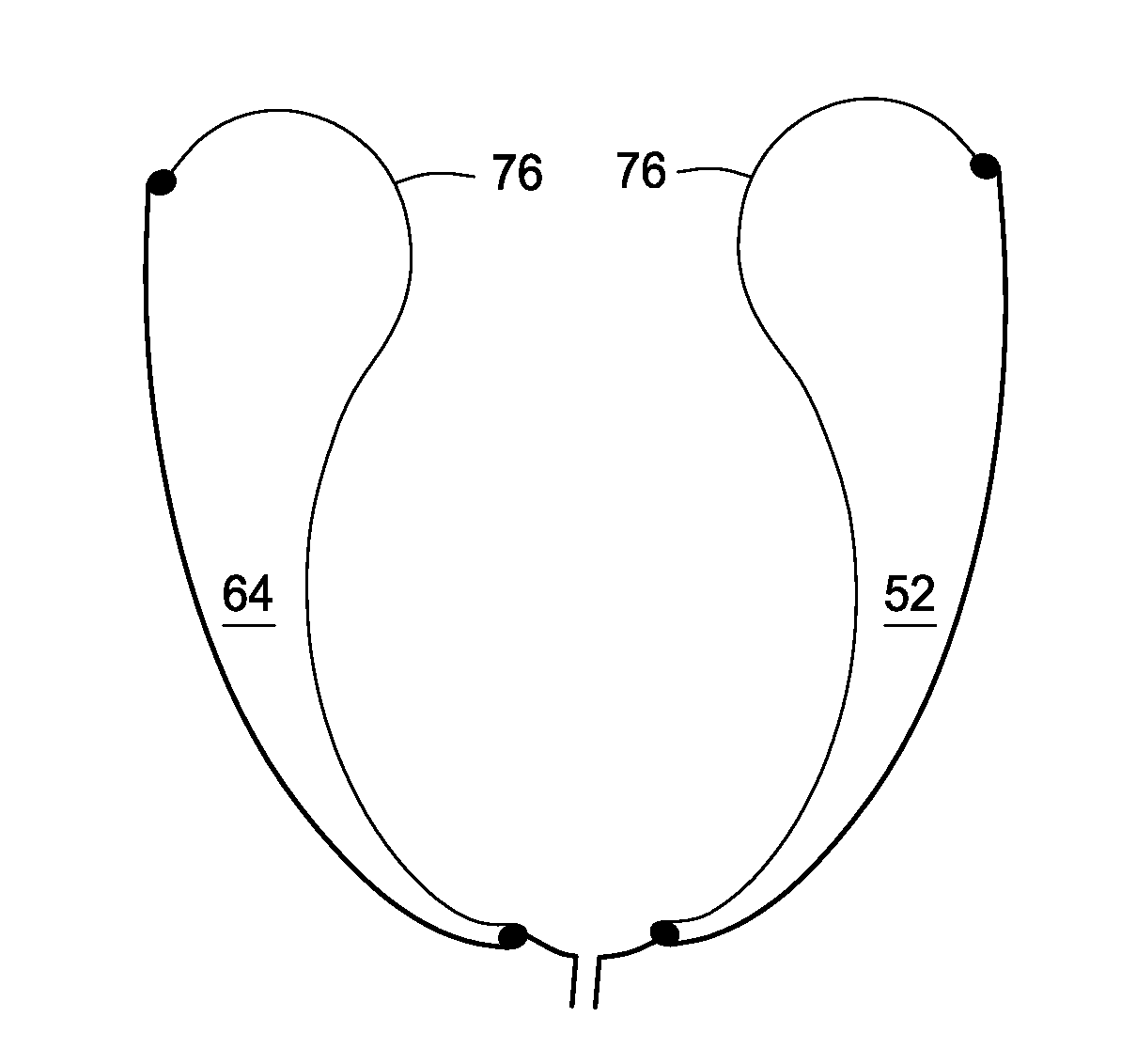

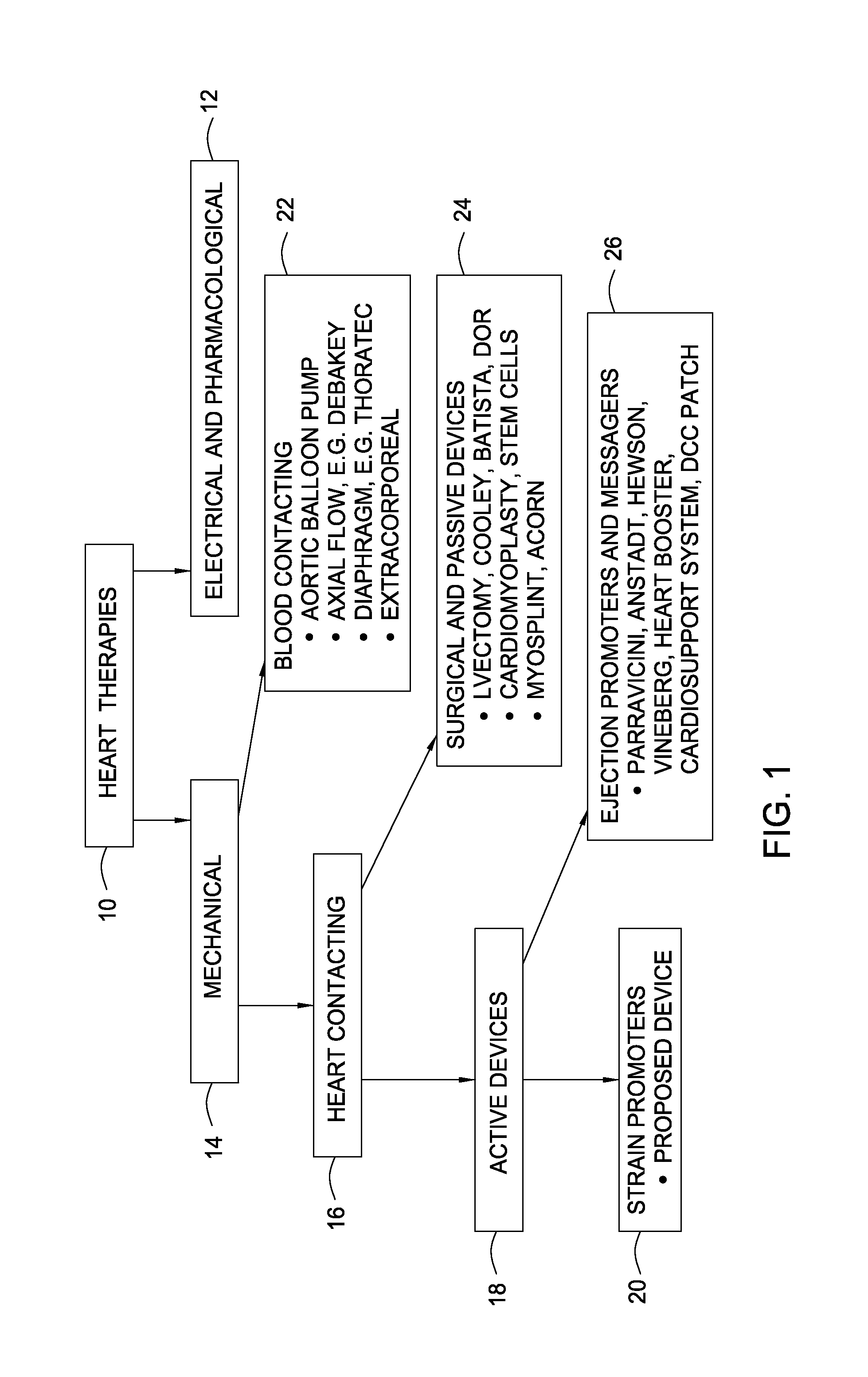

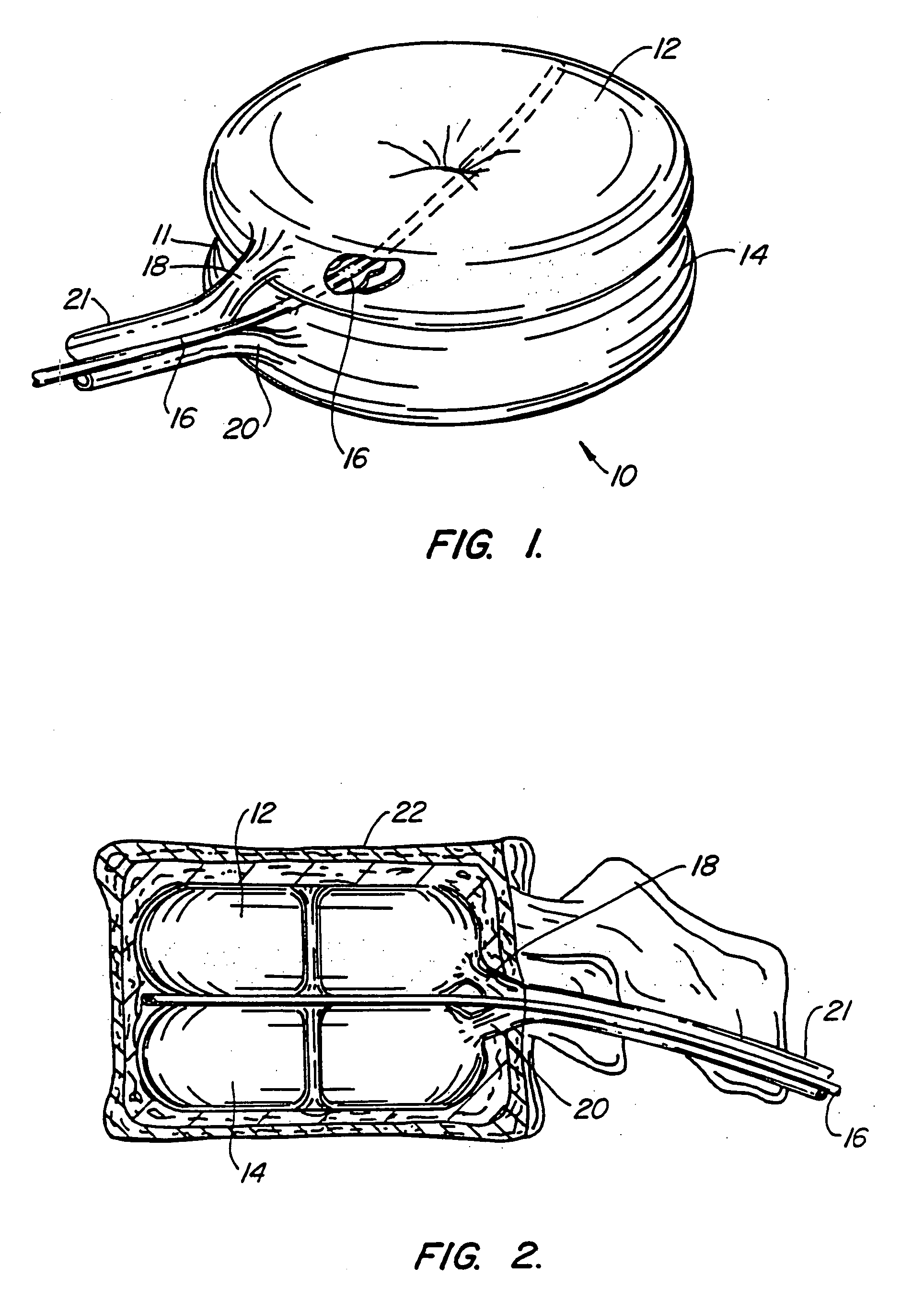

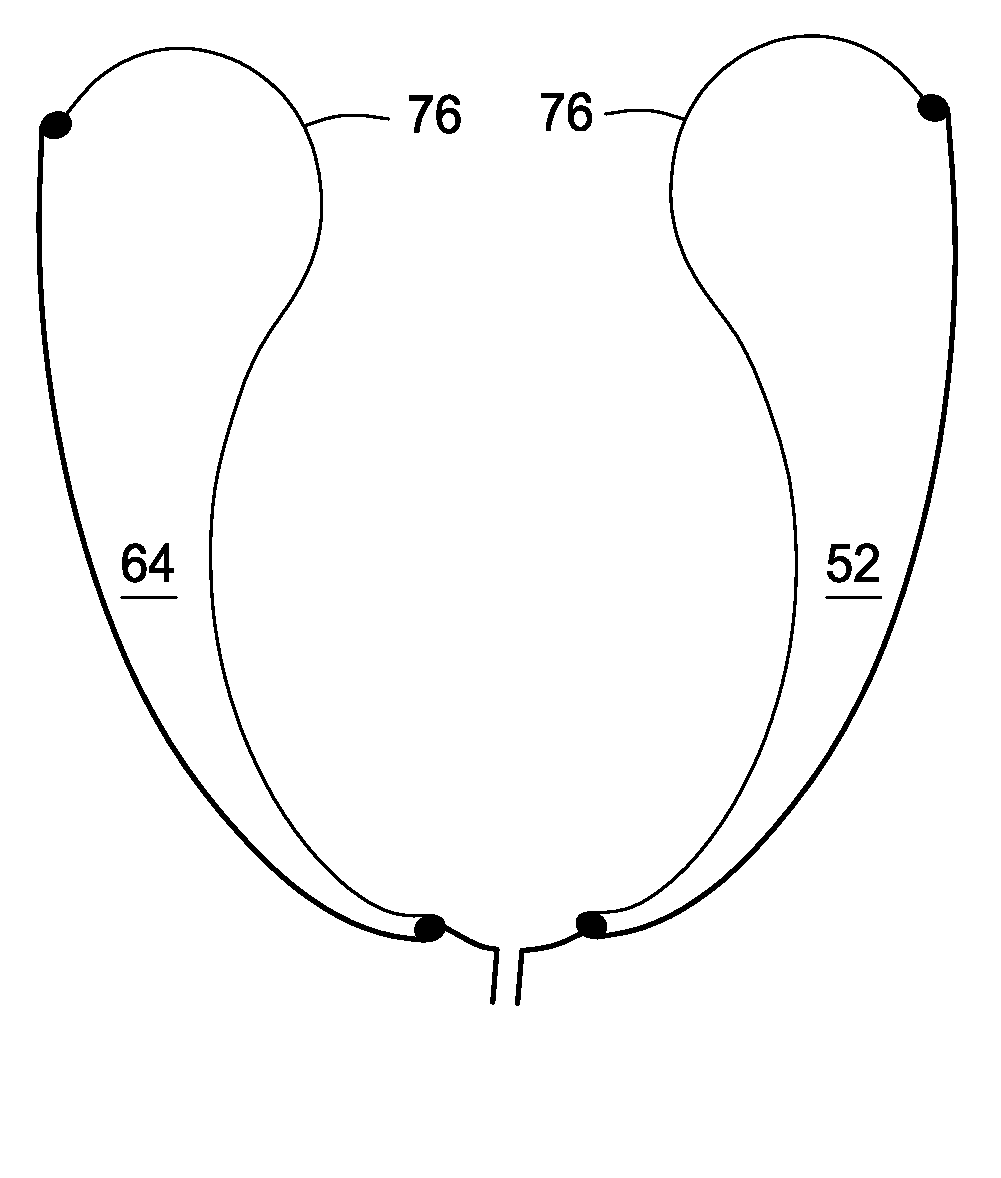

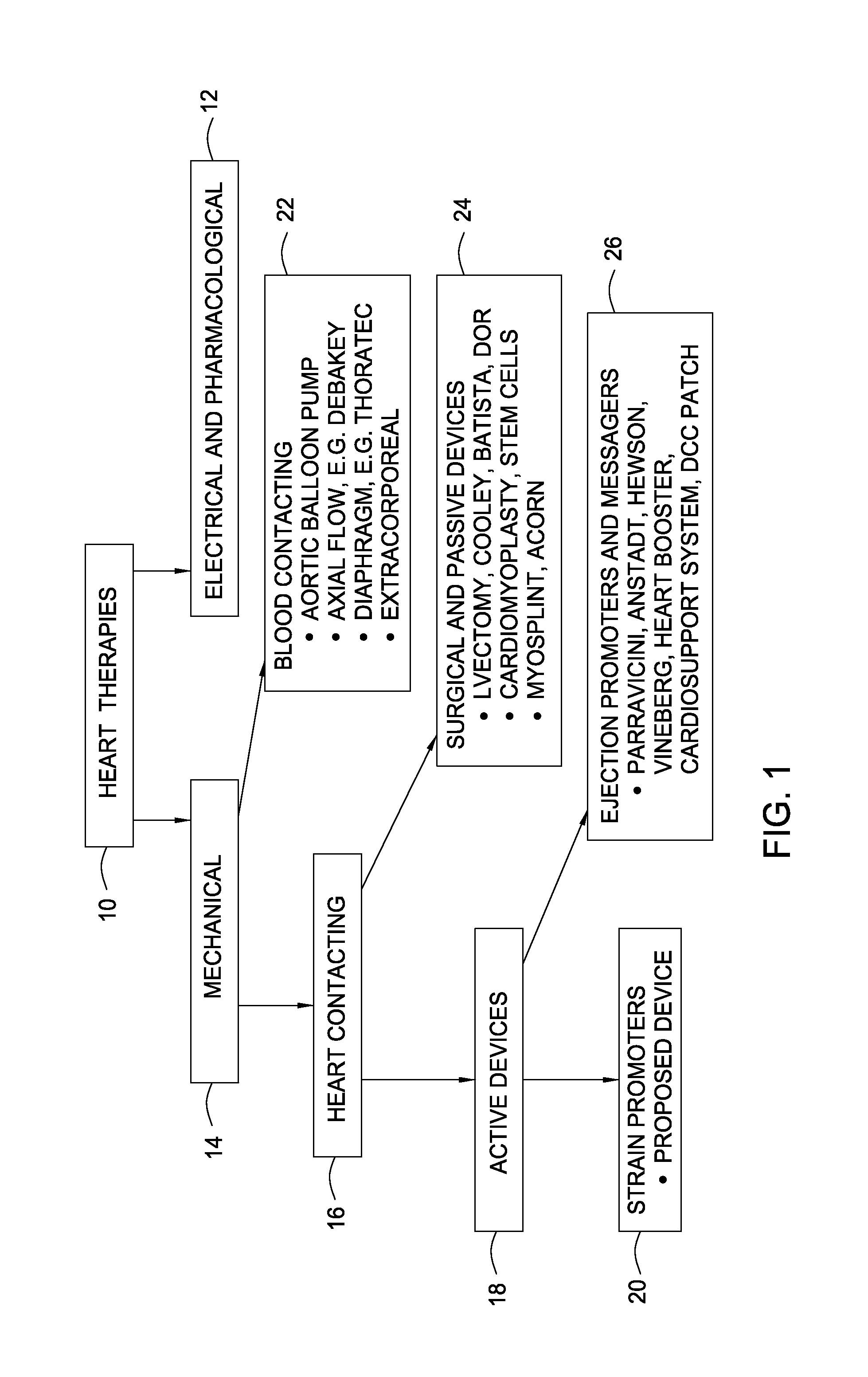

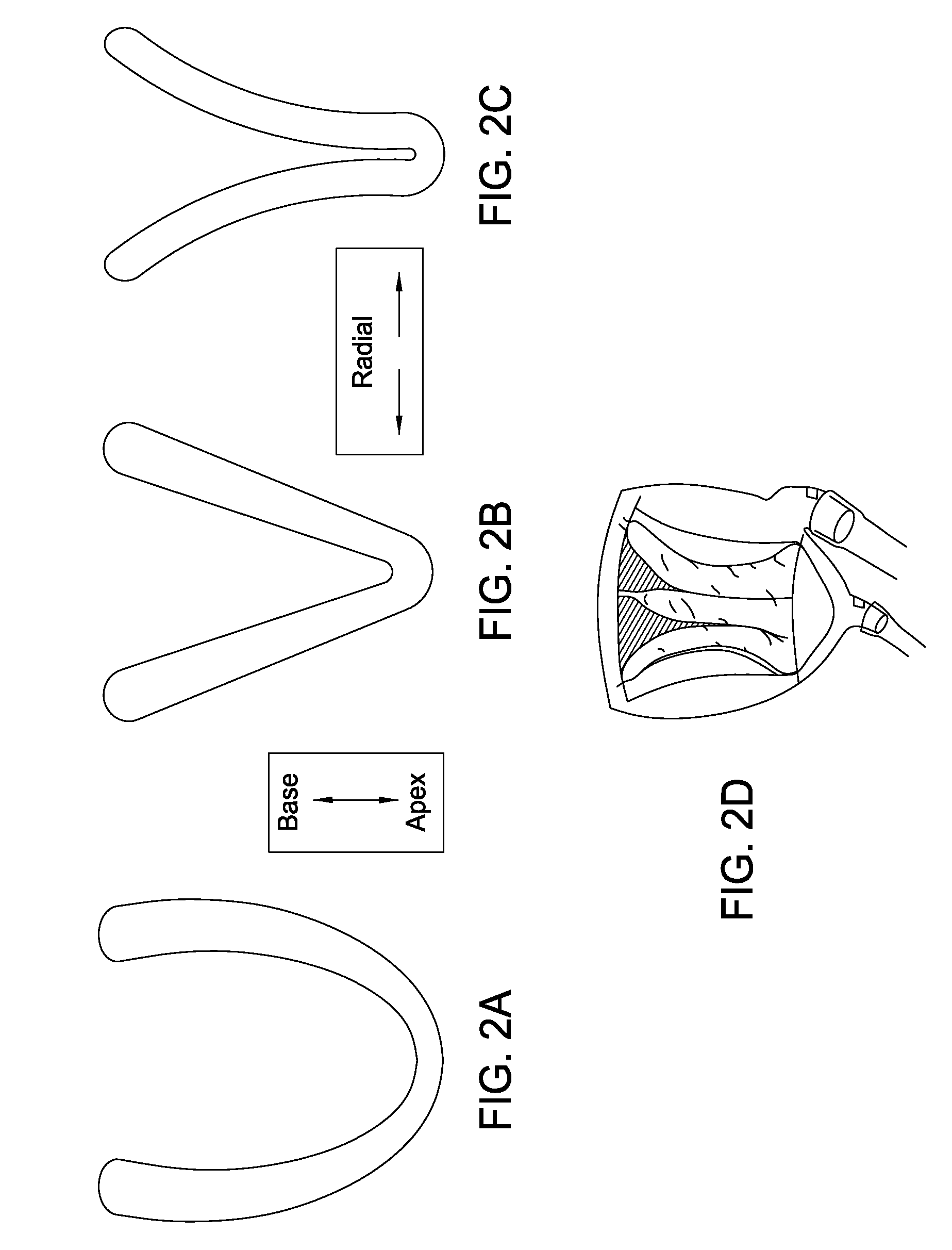

Device for the Modulation of Cardiac End Diastolic Volume

ActiveUS20080021260A1Reduce structural stiffnessSmall thoracotomyBlood pumpsIntravenous devicesCardiac deviceMotor function

The present invention provides methods, systems, kits and devices that reduce dyskinesis and hypokinesis. For example, the direct compression cardiac device may be positioned about at least a portion of a heart, and includes a resilient inner panel in contact with at least a portion of the heart periphery, one or more resilient members positioned about the resilient inner panel and at least partially surrounded by an expandable outer panel. The resistance supplied by the inner panel to the heart may be modulated to control the end-diastolic heart volume and remodel the heart, the resistance supplied by the expandable outer panel to the heart may be modulated to control the end-systolic heart volume and remodel the heart or both.

Owner:CORINNOVA +1

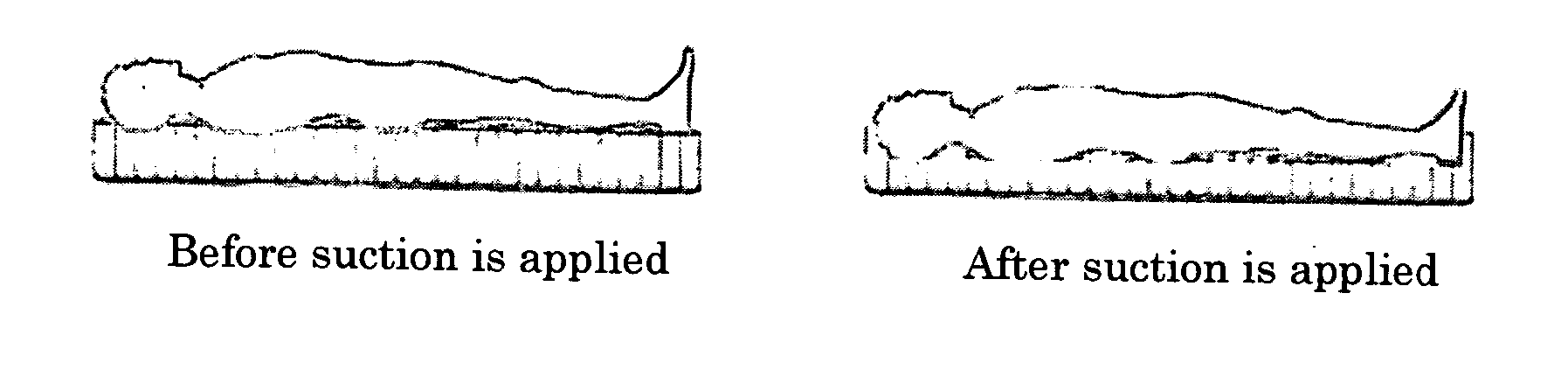

Body positioning mattress

InactiveUS20050120479A1Significant of pulmonary functionReduce riskRestraining devicesNursing bedsProne positionBody positions

A method of positioning a patient or person 0 to 90 degrees in an upright position or greater in a supine or prone position while maintaining neutral skeletal alignment (non flexed position) with a body positioning mattress capable of applying a vacuum process to remove air; molding the mattress around the body to maintain position. A means to place the support mattress onto a manual or motorized bed frame to position and maintain a patient or person 0 to 90 degrees or greater in the supine or prone position.

Owner:SLH HLDG

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS20070299455A1Easy to compressEasy to foldInternal osteosythesisSurgical furnitureBone CortexTrabecular bone

A balloon for use in compressing cancellous bone and marrow (also known as medullary bone or trabecular bone). The balloon comprises an inflatable balloon body for insertion into said bone. The body has a shape and size to compress at least a portion of the cancellous bone to form a cavity in the cancellous bone and / or to restore the original position of the outer cortical bone, if fractured or collapsed. The balloon desirably incorporates restraints which inhibit the balloon from applying excessive pressure to various regions of the cortical bone. The wall or walls of the balloon are such that proper inflation of the balloon body is achieved to provide for optimum compression of the bone marrow. The balloon can be inserted quickly into a bone. The balloon can be made to have a suction catheter. The balloon can be used to form and / or enlarge a cavity or passage in a bone, especially in, but not limited to, vertebral bodies. Various additional embodiments facilitate directionally biasing the inflation of the balloon.

Owner:ORTHOPHOENIX

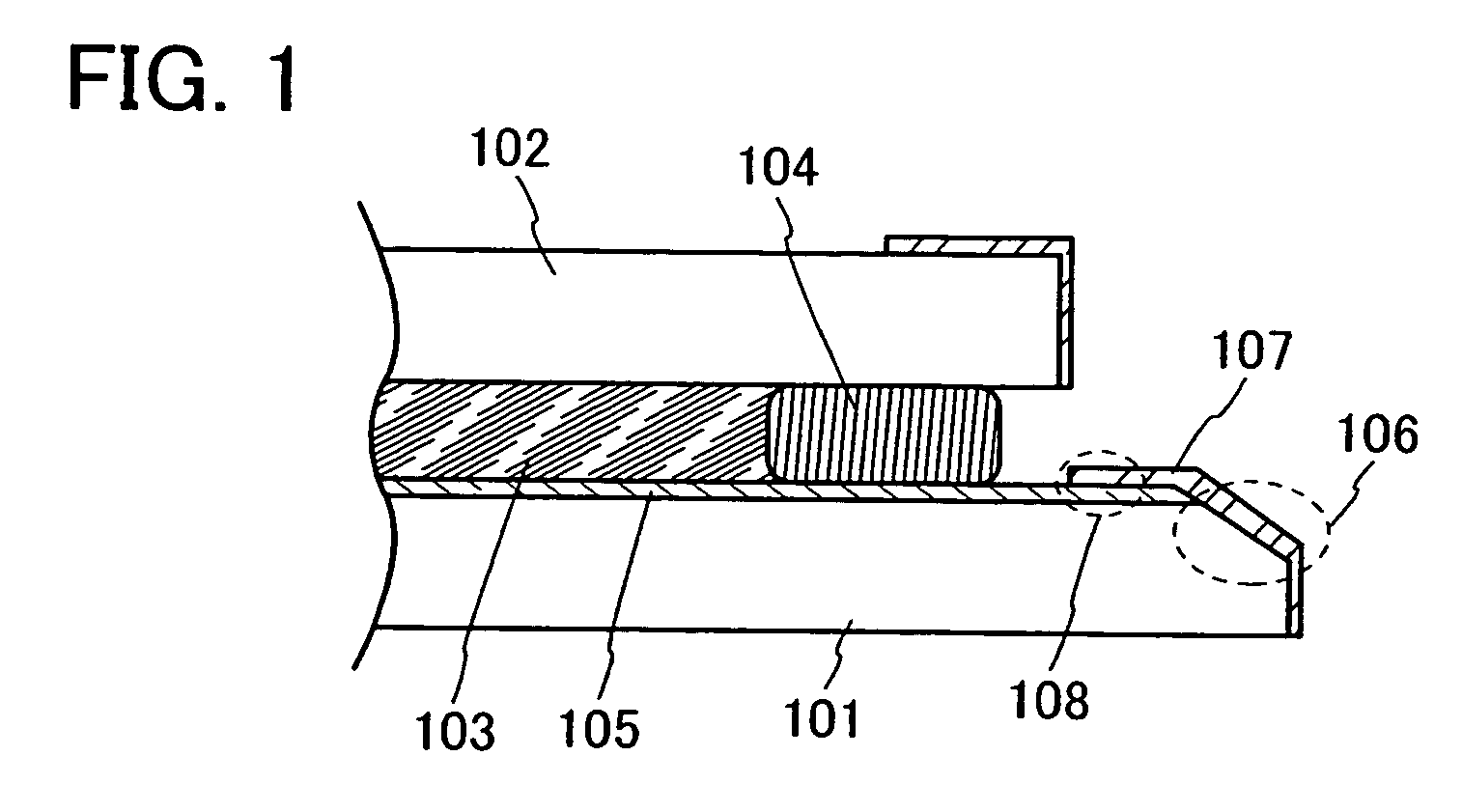

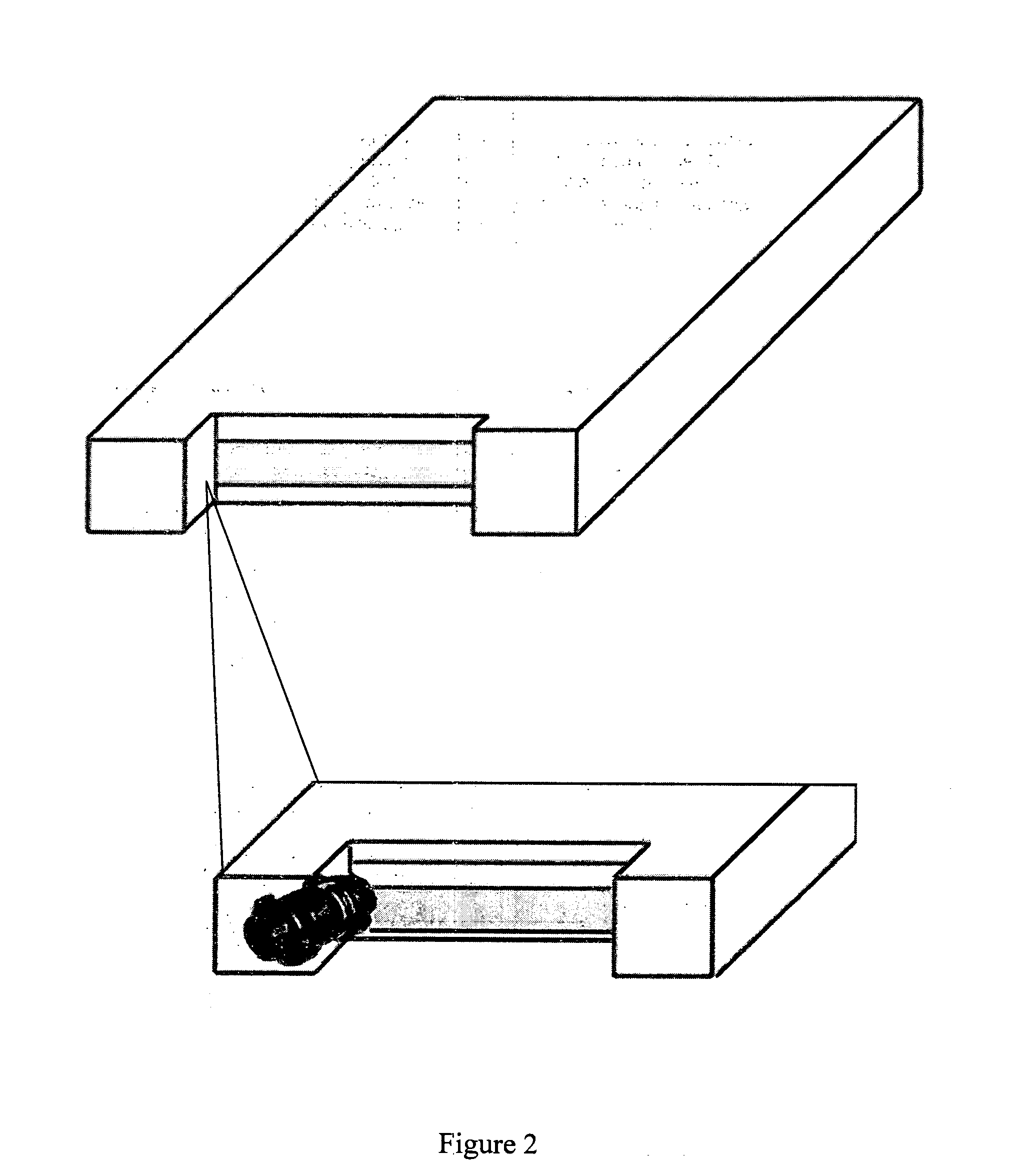

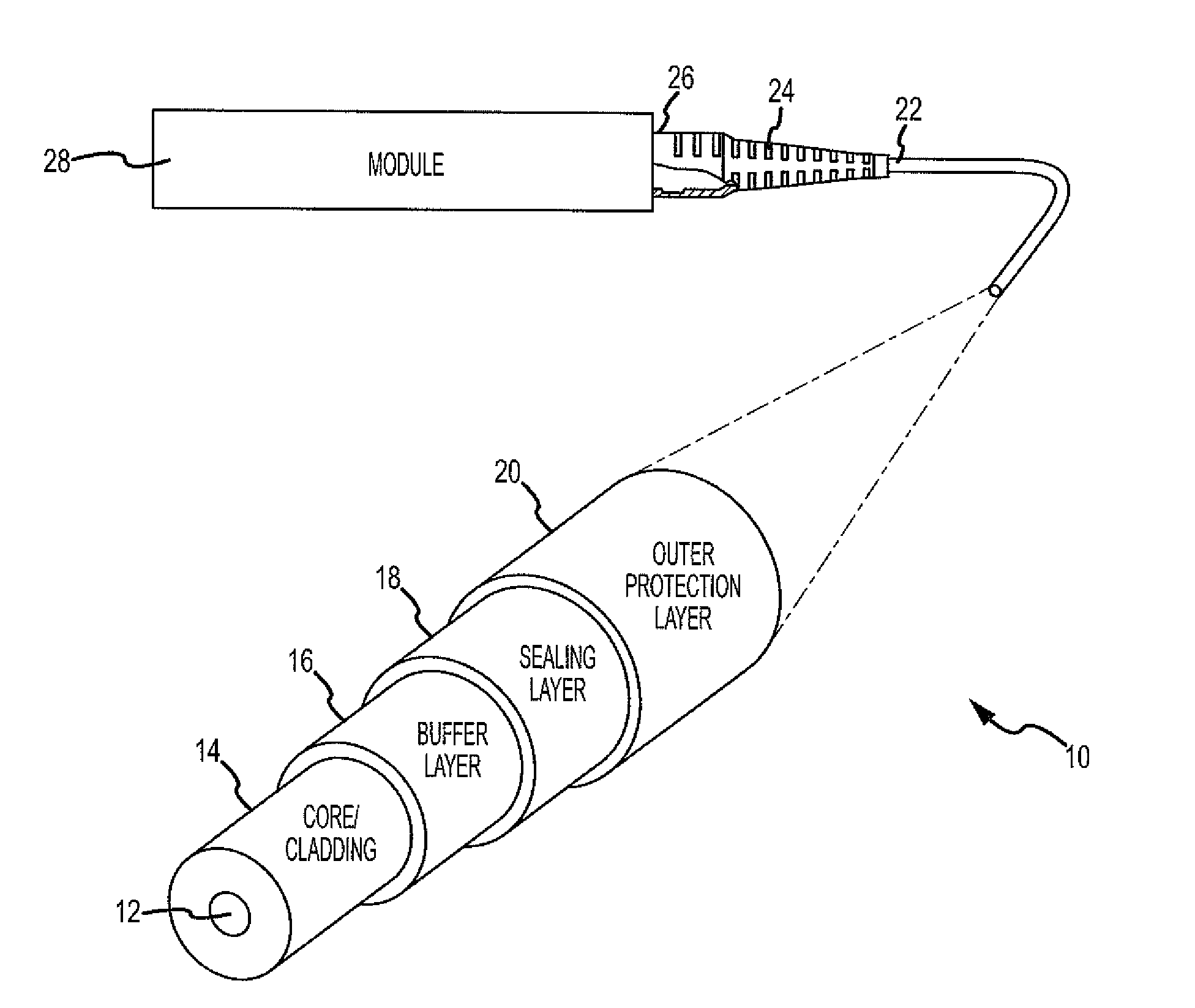

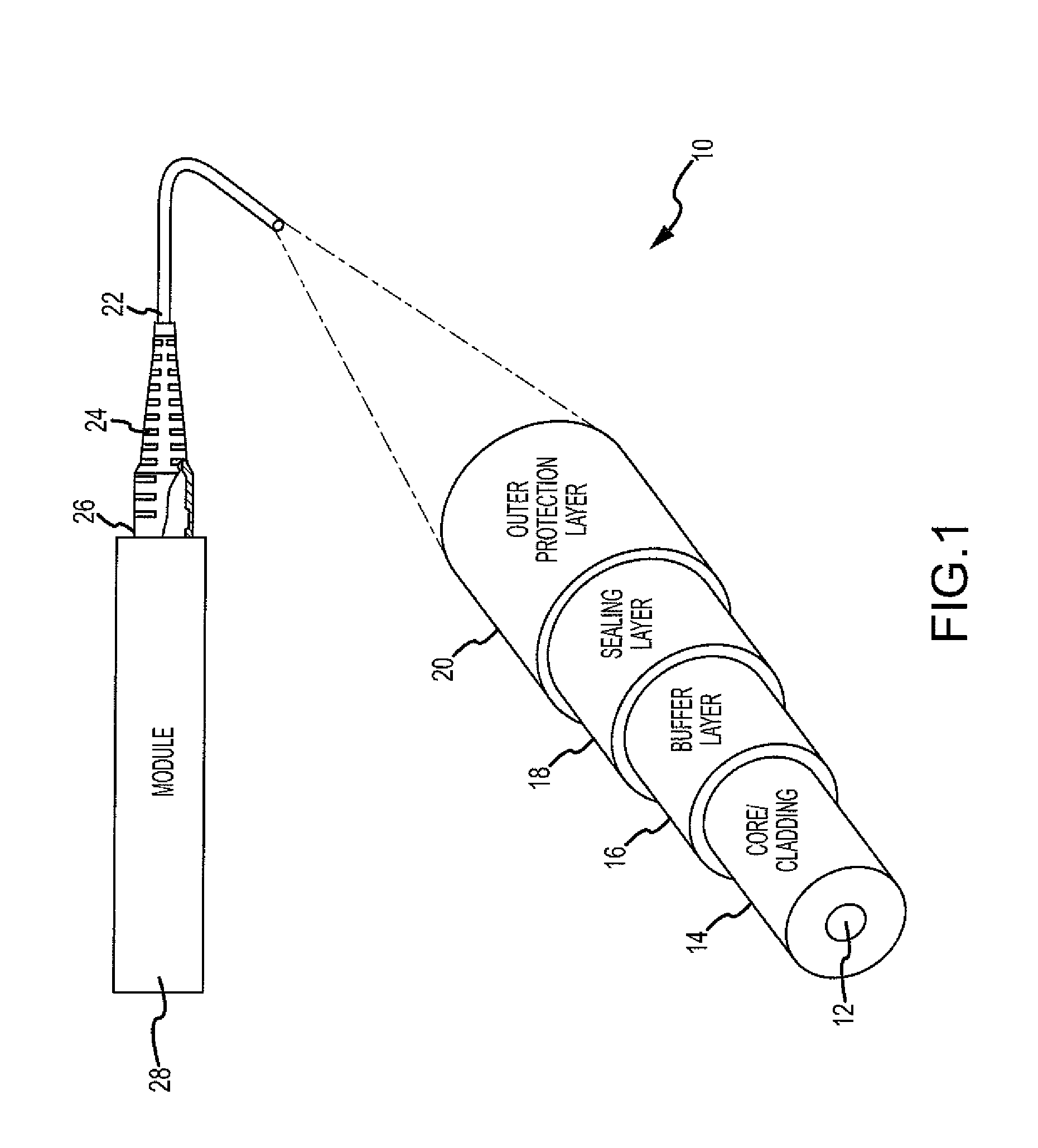

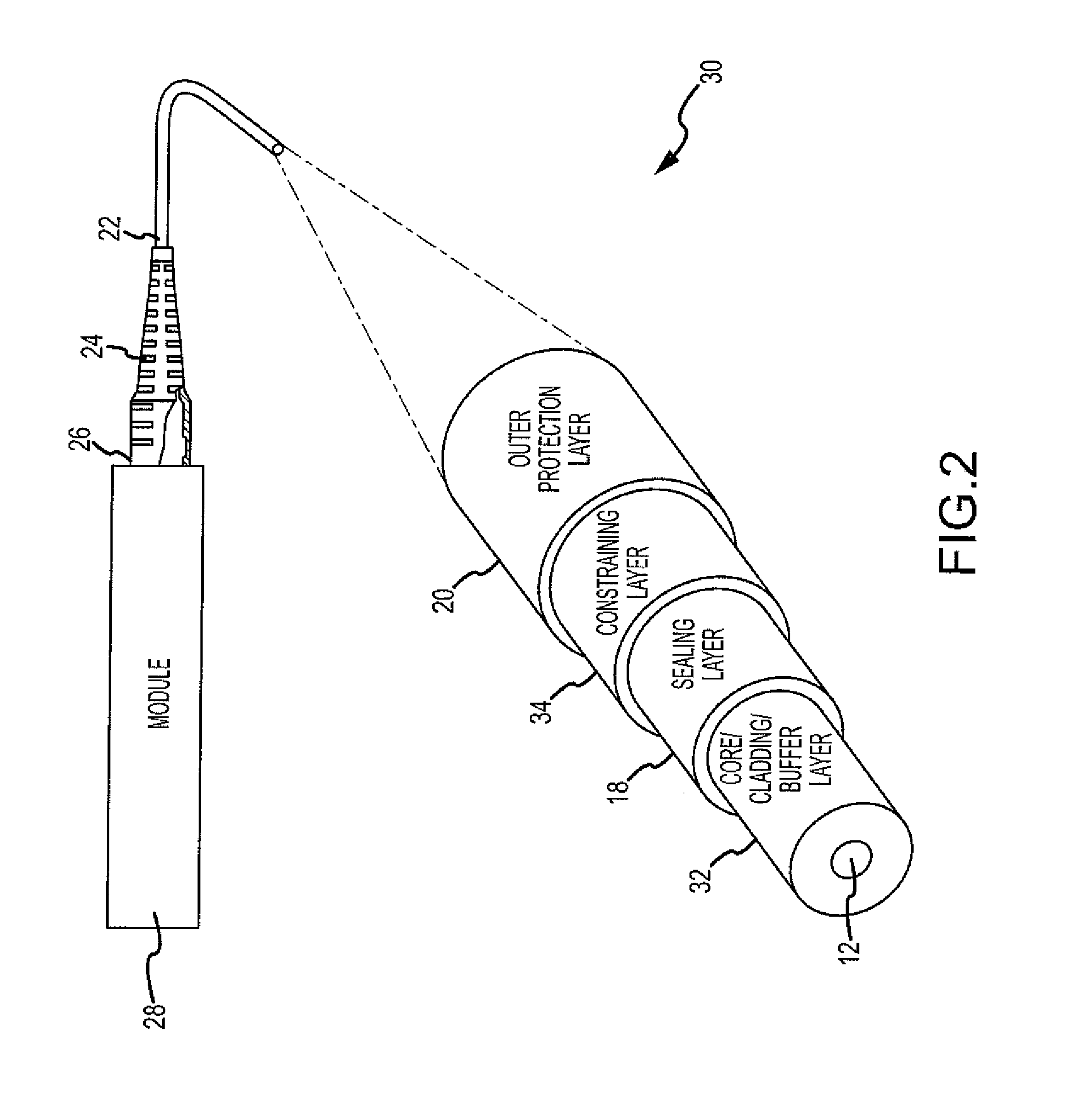

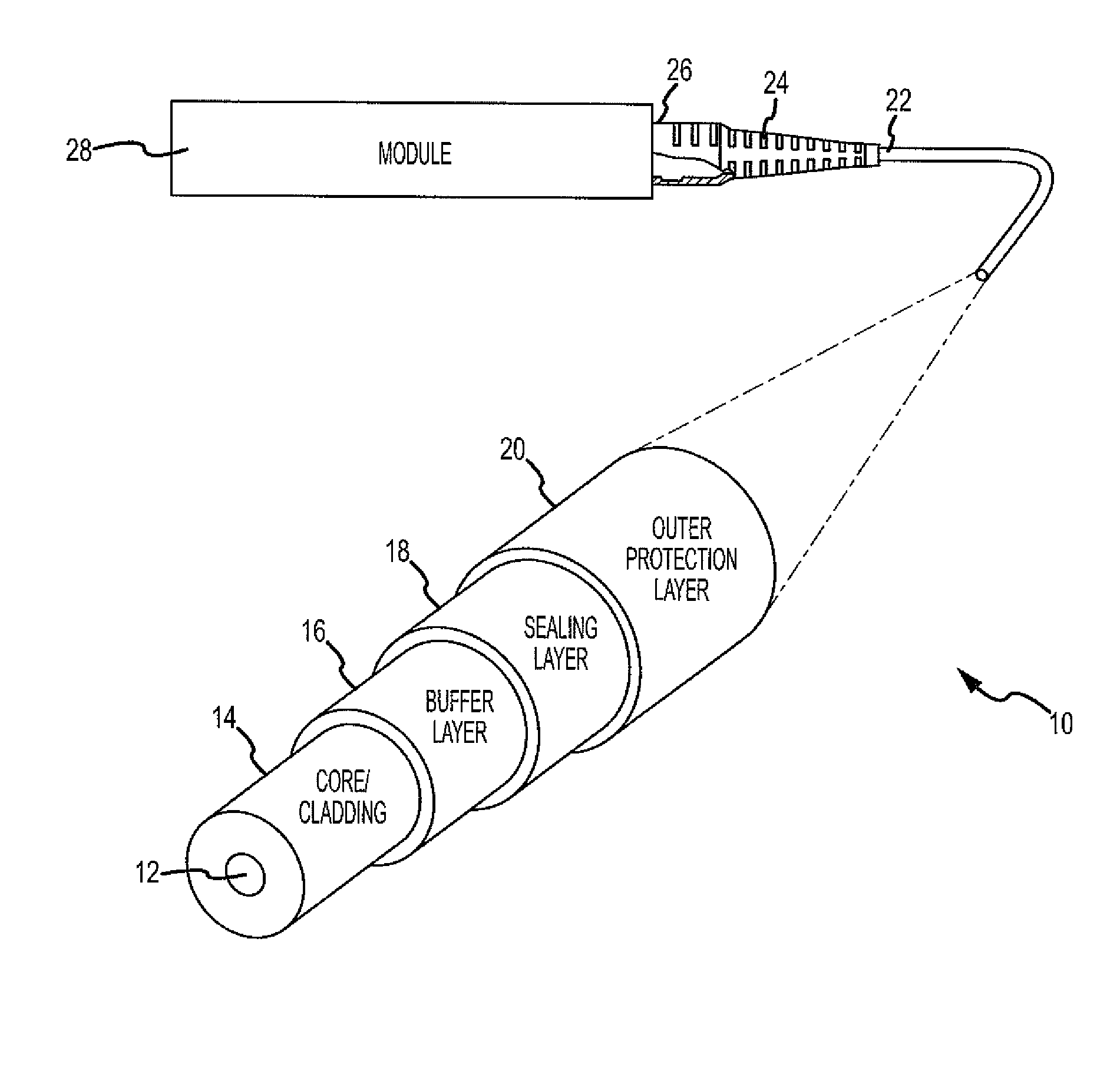

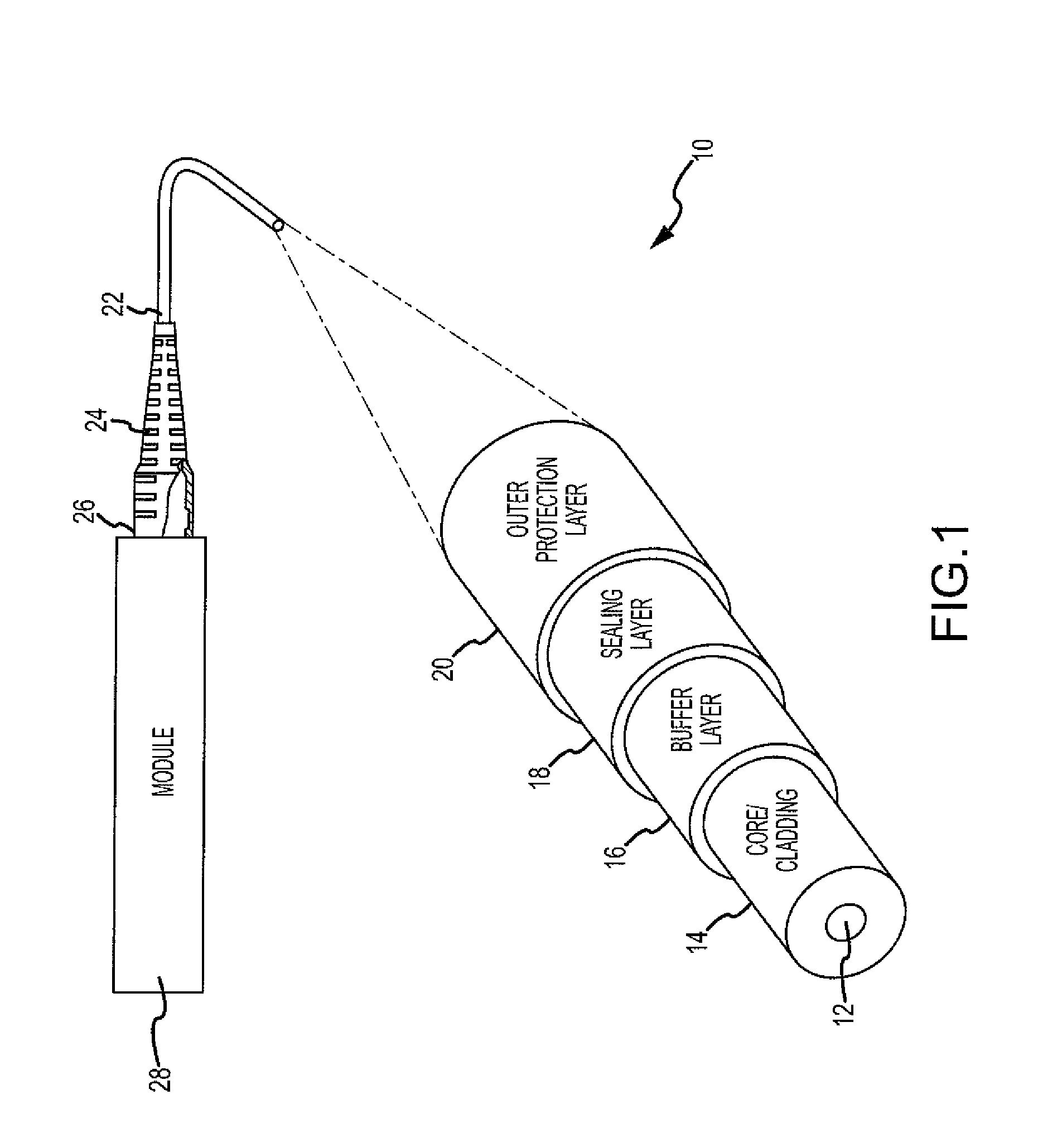

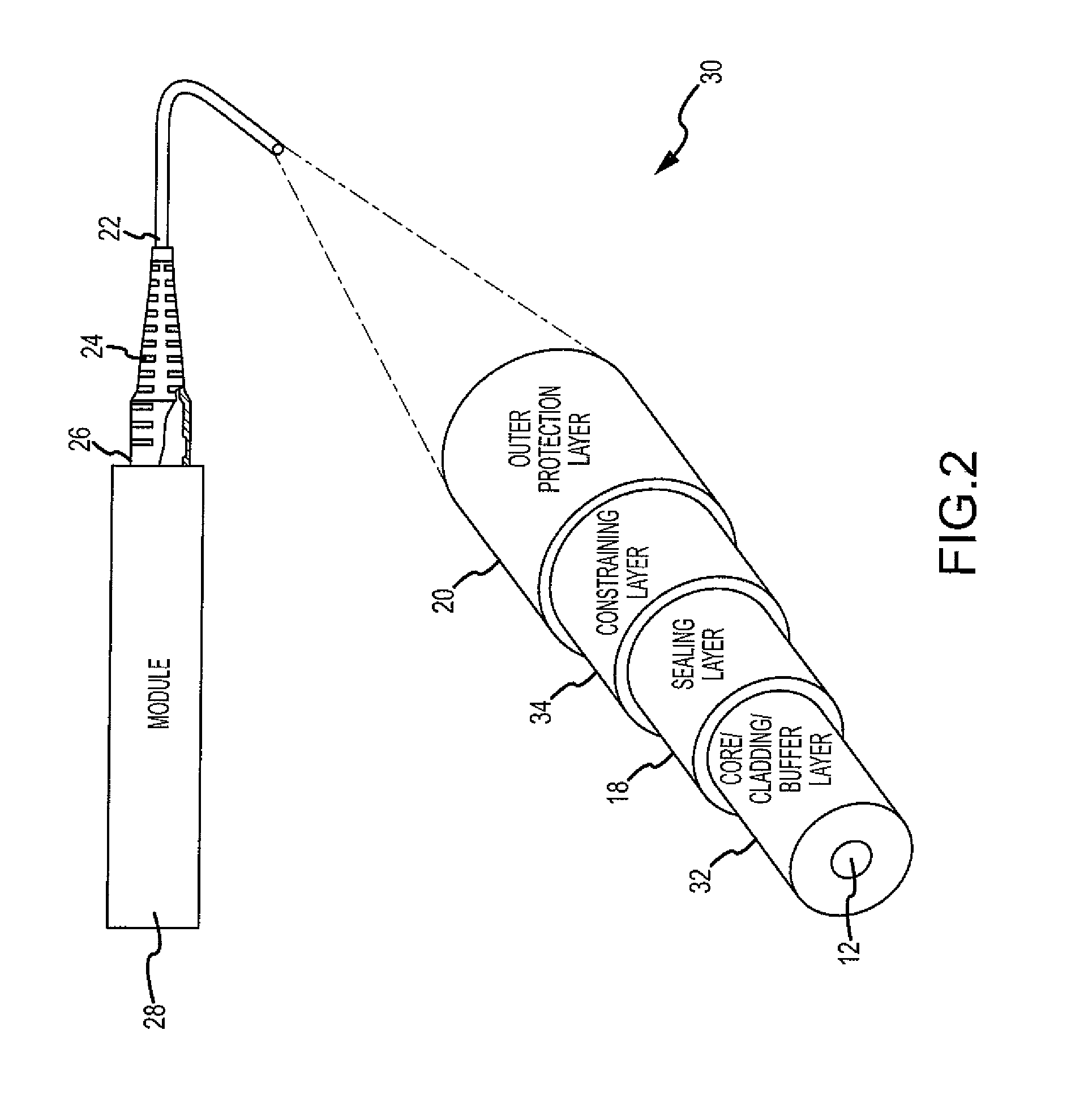

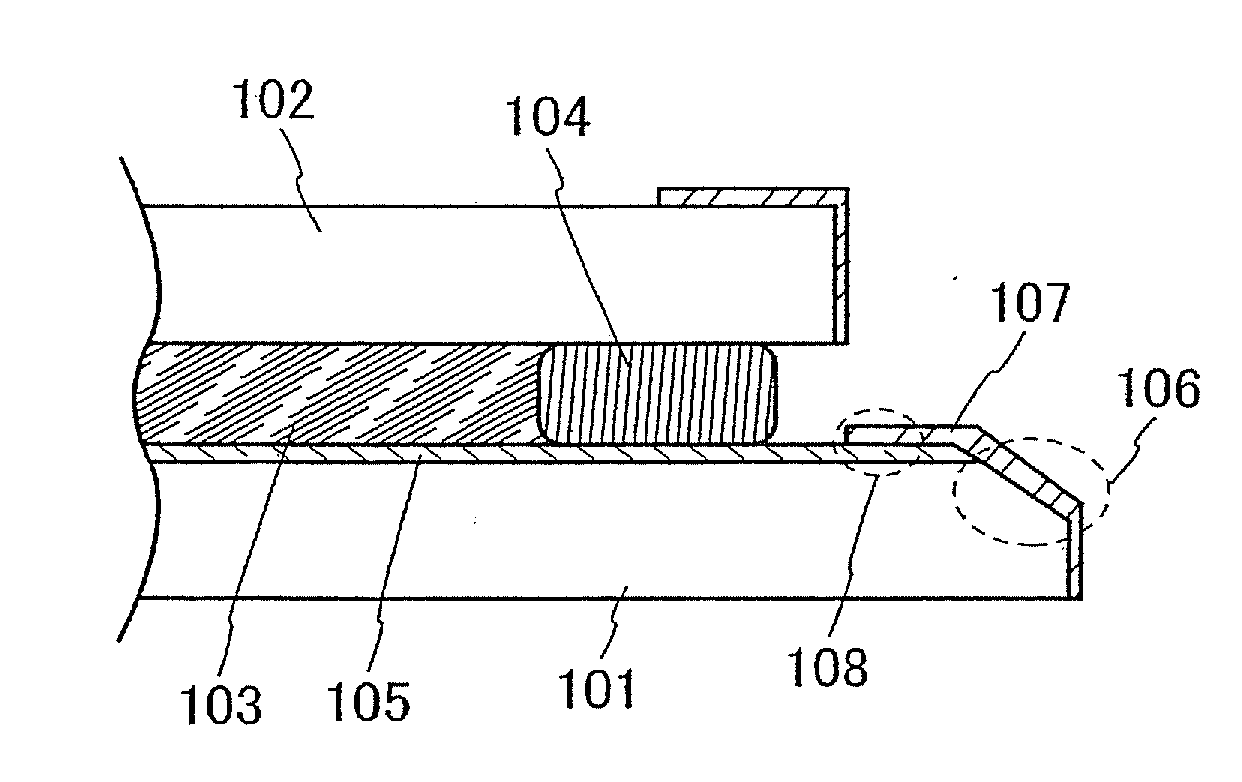

Self healing optical fiber cable assembly and method of making the same

ActiveUS20100278491A1Prolong lifeImprove reliabilityFibre mechanical structuresMetal working apparatusComputer moduleEngineering

In one of the embodiments there is disclosed a self healing optical fiber cable assembly comprising an elongated optical fiber core having a cladding layer, a buffer layer, a sealing layer that seals any microcracks or defects in the buffer layer, the cladding layer, and the optical fiber core, and, an outer protection layer, wherein an end of the outer layer is connected to a strain relief device to provide expansion protection to the cable assembly and to minimize strain on the cable assembly, and further wherein an end of the strain relief device is connected to an optical fiber module. The cable assembly may further comprise a constraining layer and / or a strengthening layer. There is also disclosed a method of making a self healing optical fiber cable assembly.

Owner:THE BOEING CO

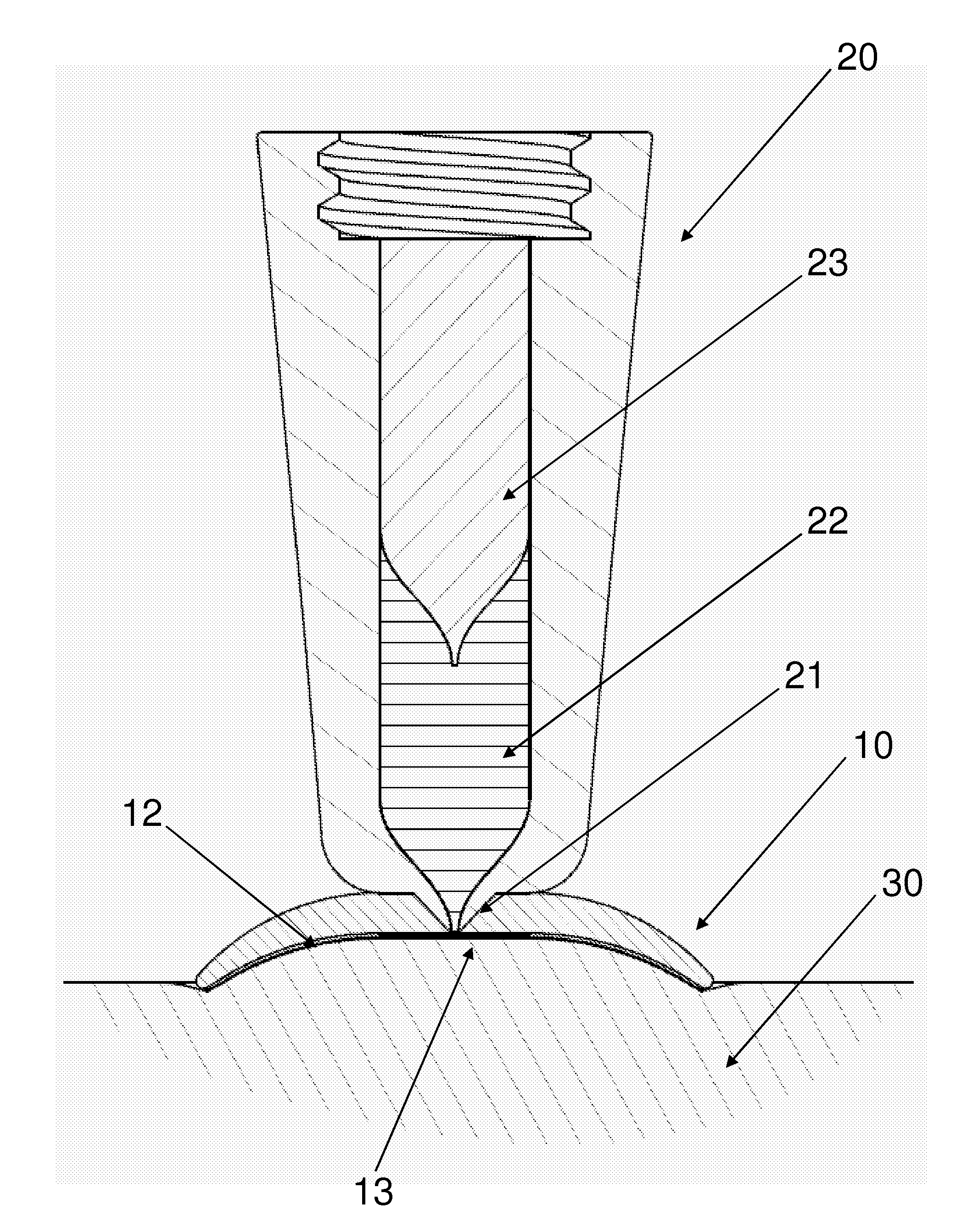

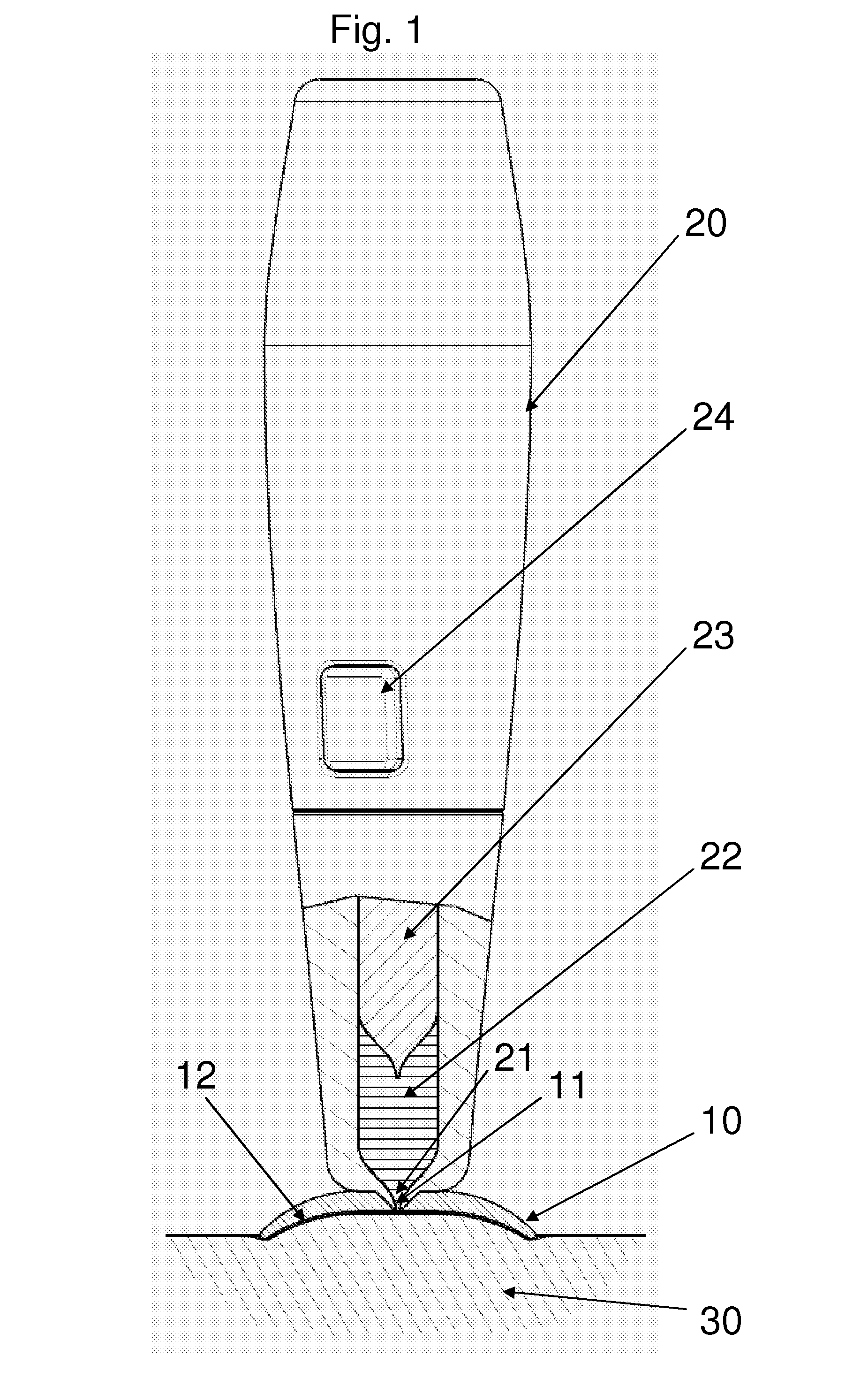

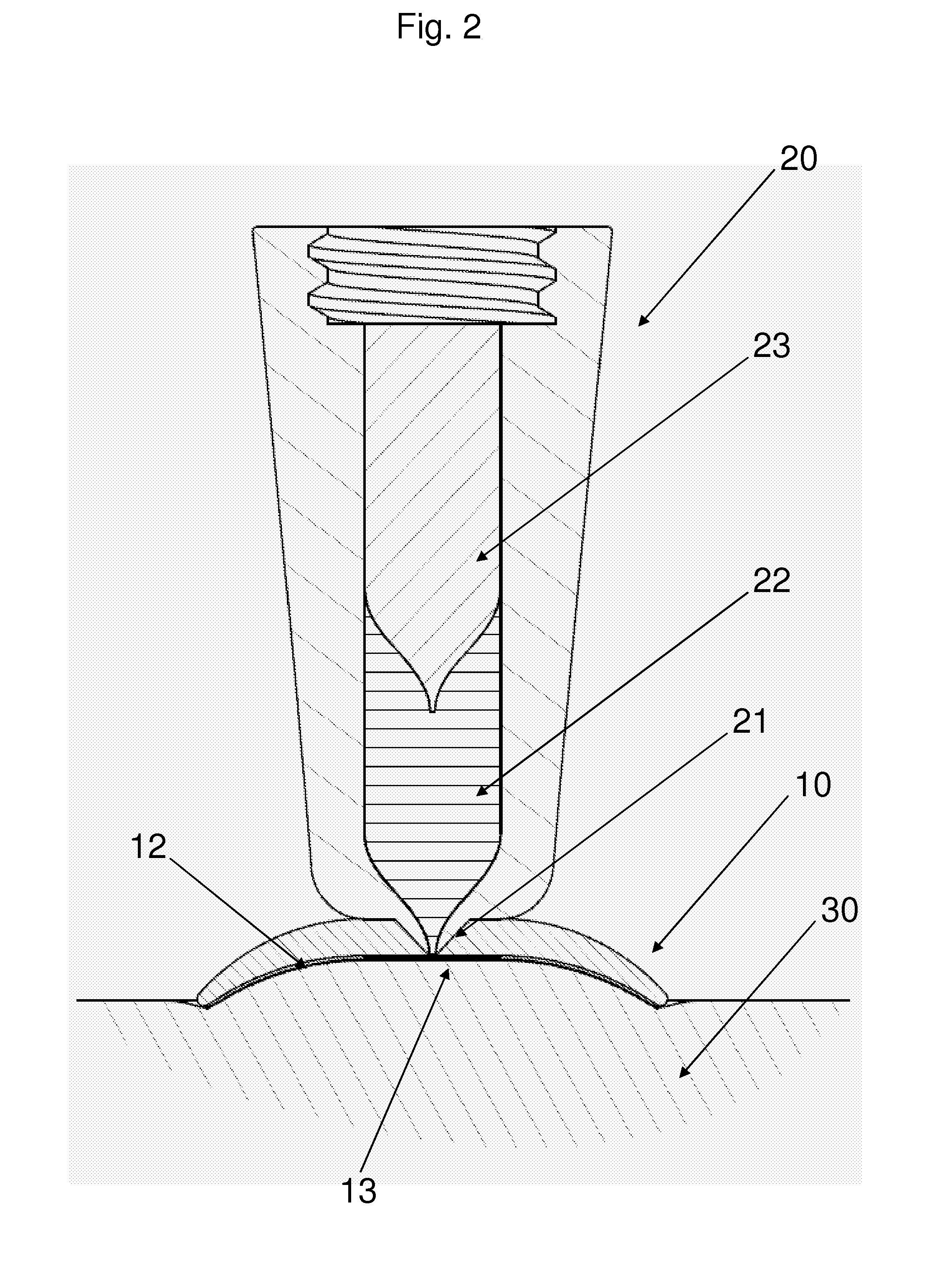

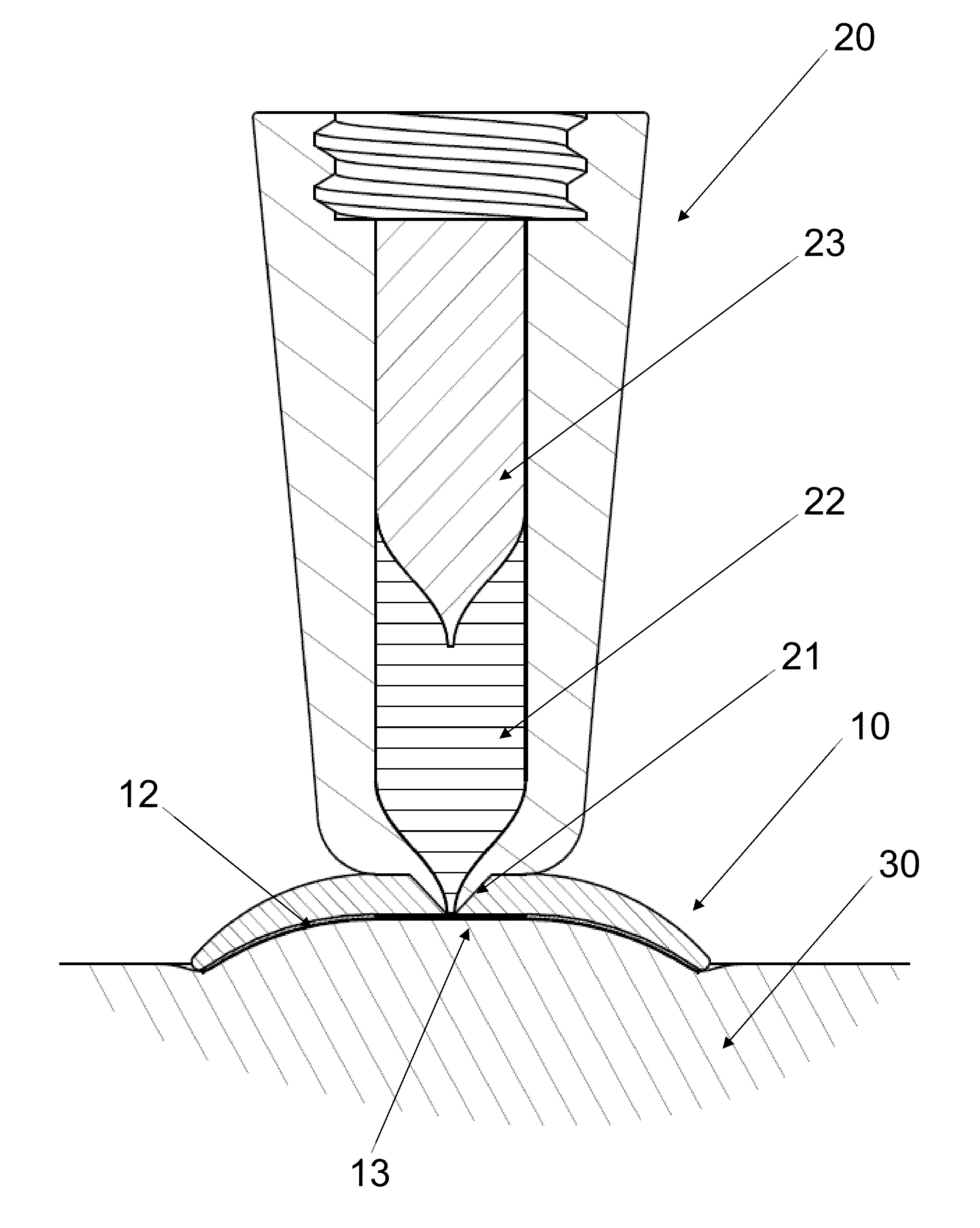

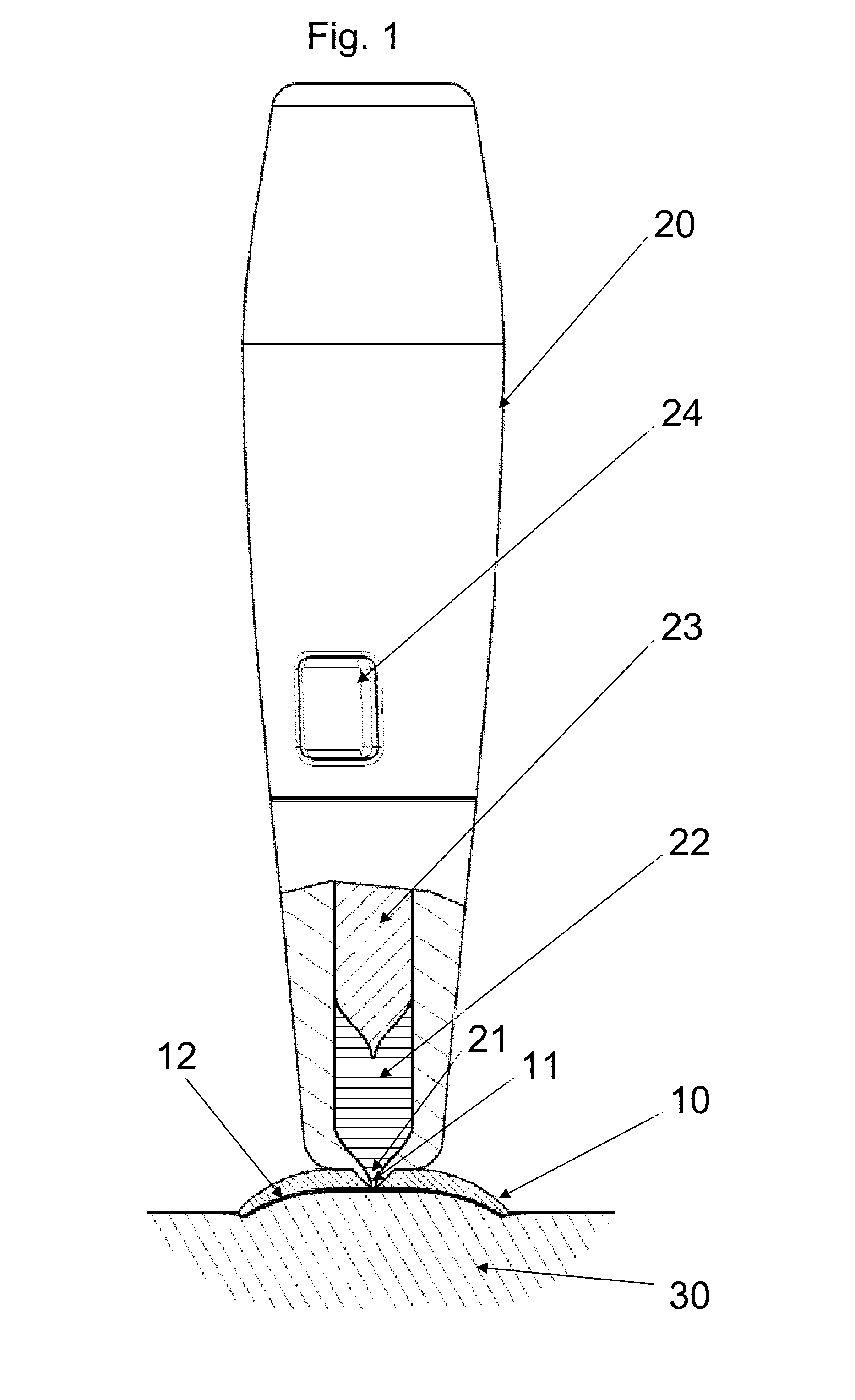

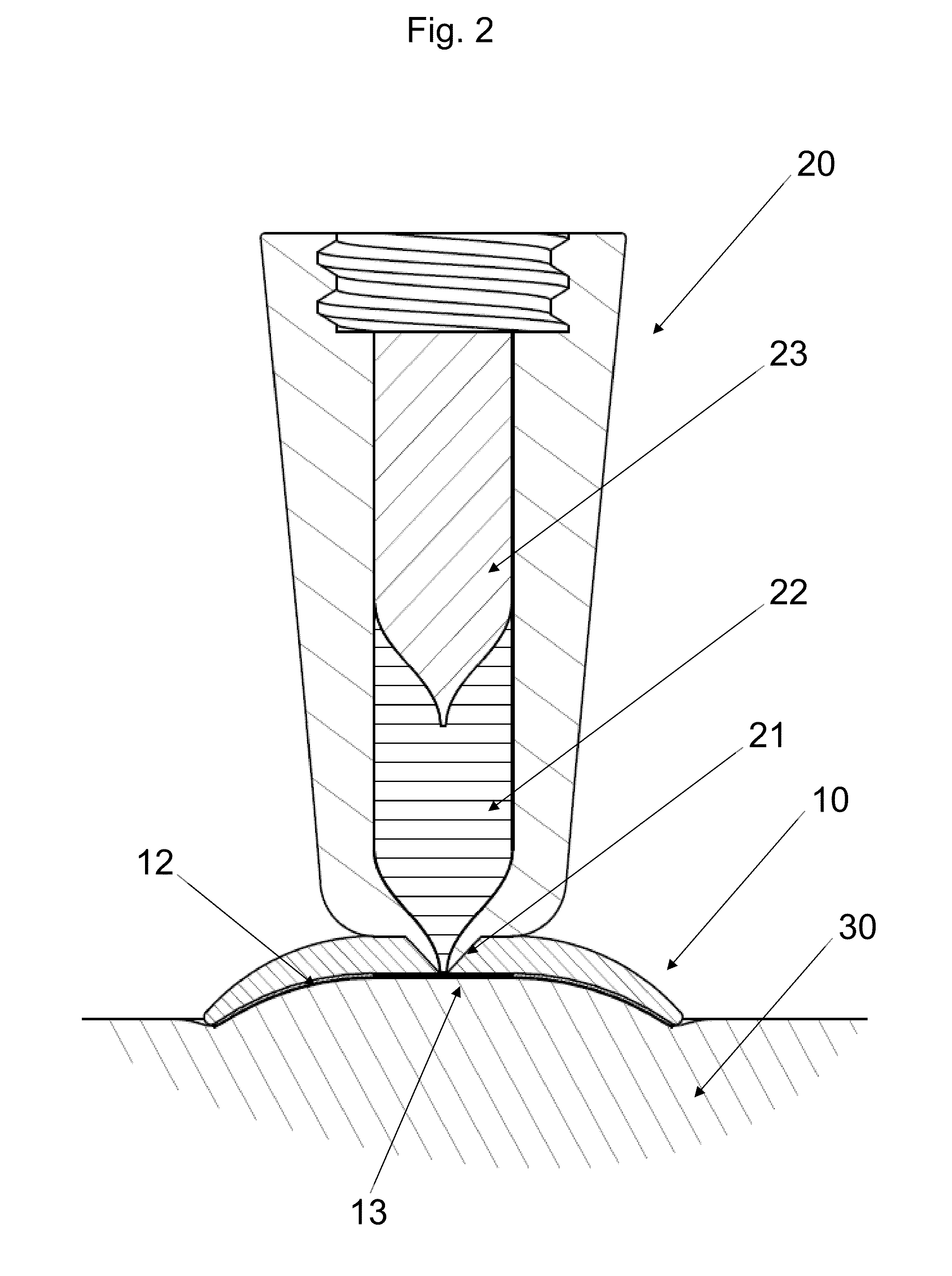

Skin Retention Device for a Medical Jet Injection Unit

InactiveUS20090227942A1Reduce the possibilityGreat degree of stretchJet injection syringesIntravenous devicesJet injectionInjection point

A skin retention device 10 for a medical jet-injection unit 20 comprises a contact face provided with adhesive 12 in the area surrounding and close to the injection opening(s) 11 of the nozzle 21 which ensures god contact between the nozzle 21 and the skin 30 of a subject in the area chosen for an injection. Consequently the injection force can be lowered dramatically. In case of two-stage jet-injections, the initial injection force can be lowered because the skin retention close to the injection point significantly reduces the energy consuming elastic expansion of the skin 30 in the injection area, and the second injection force can be lowered because of the high degree of fixed positioning of the injection opening of the nozzle 21 relative to the injection channel in the skin 30 made during the initial injection stage. Thus a high degree of injection safety is achieved, minimizing the risk of whet shots, while skin lift and lower injection force decreases the risk of damage of the underlying tissue.

Owner:NOVO NORDISK AS

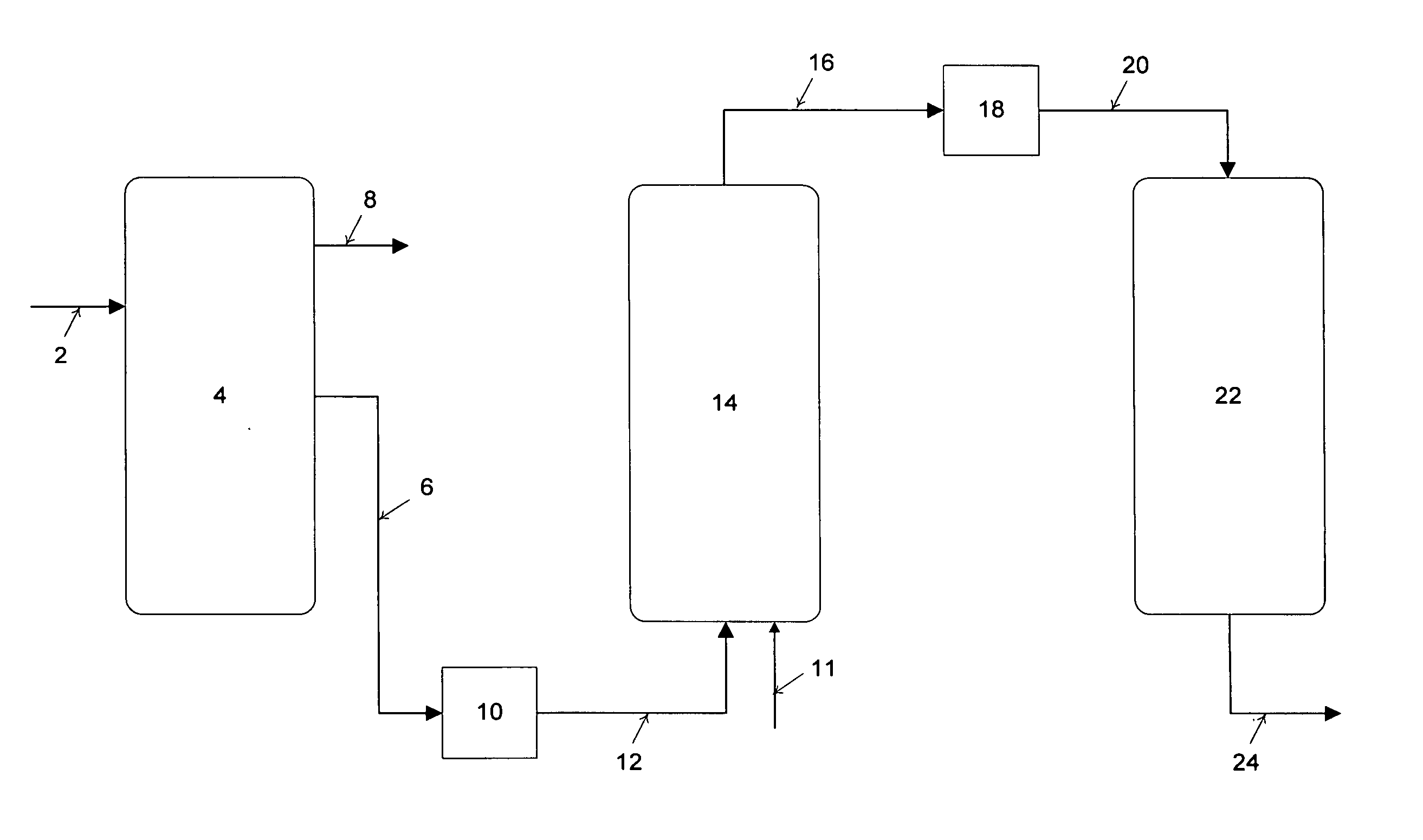

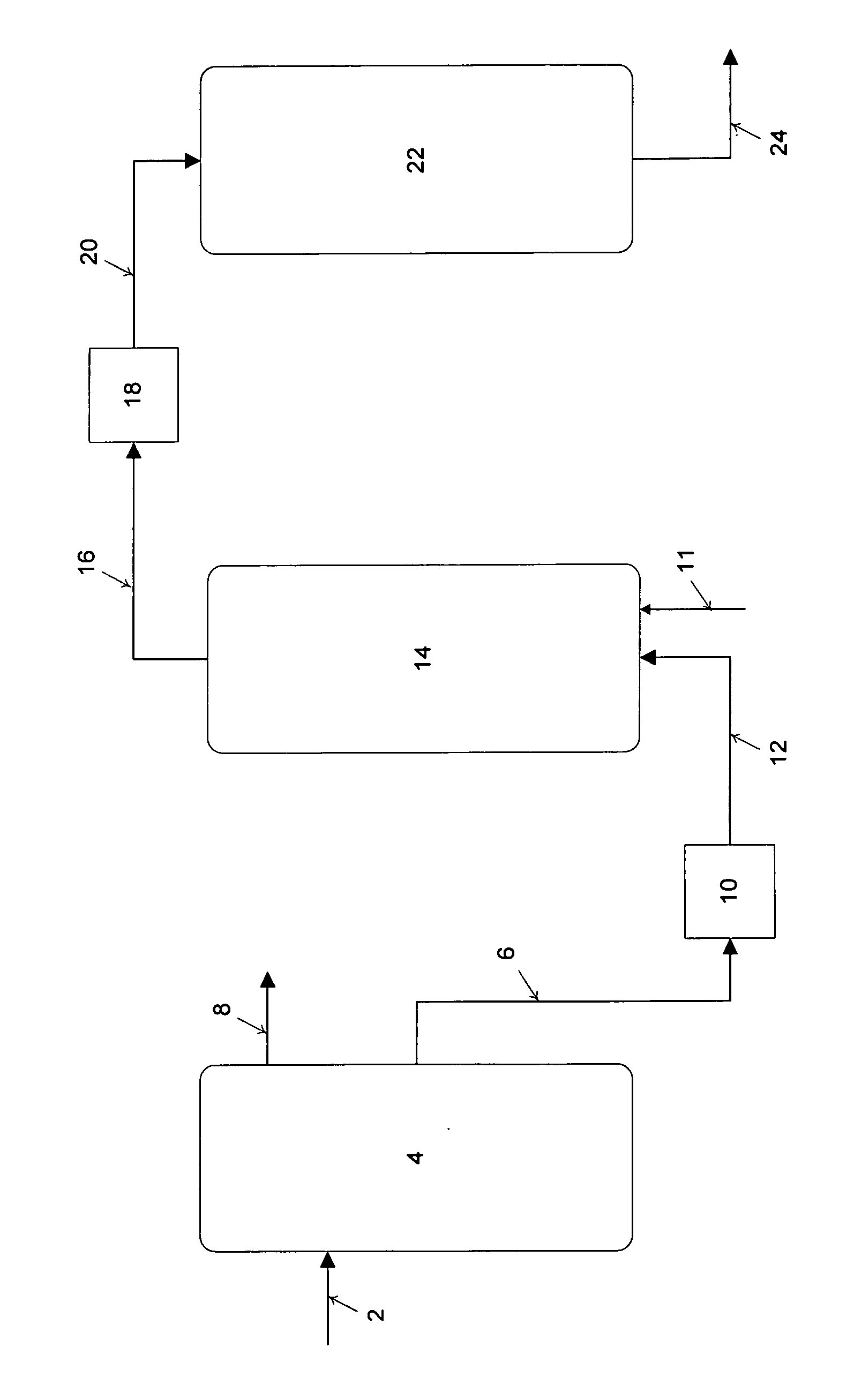

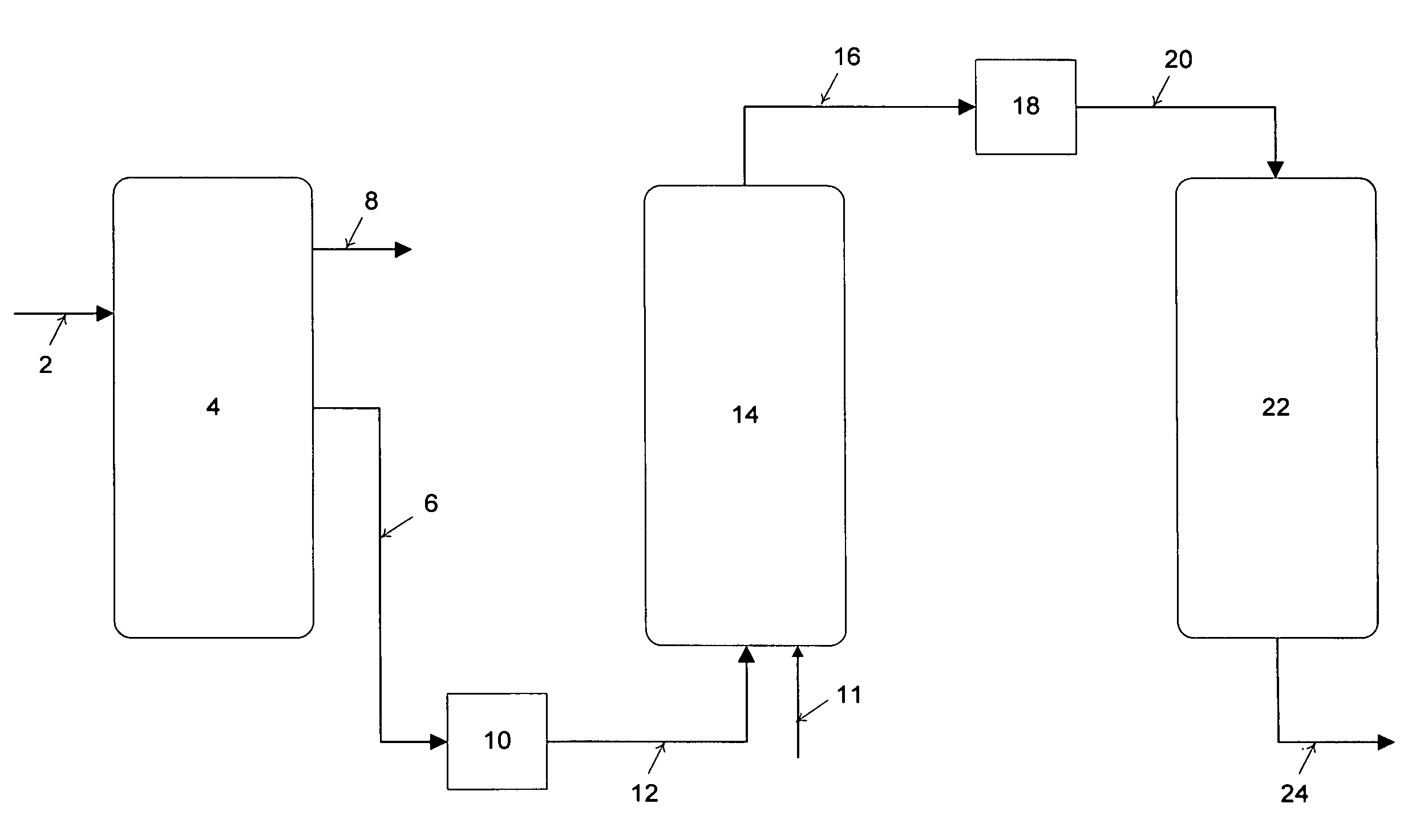

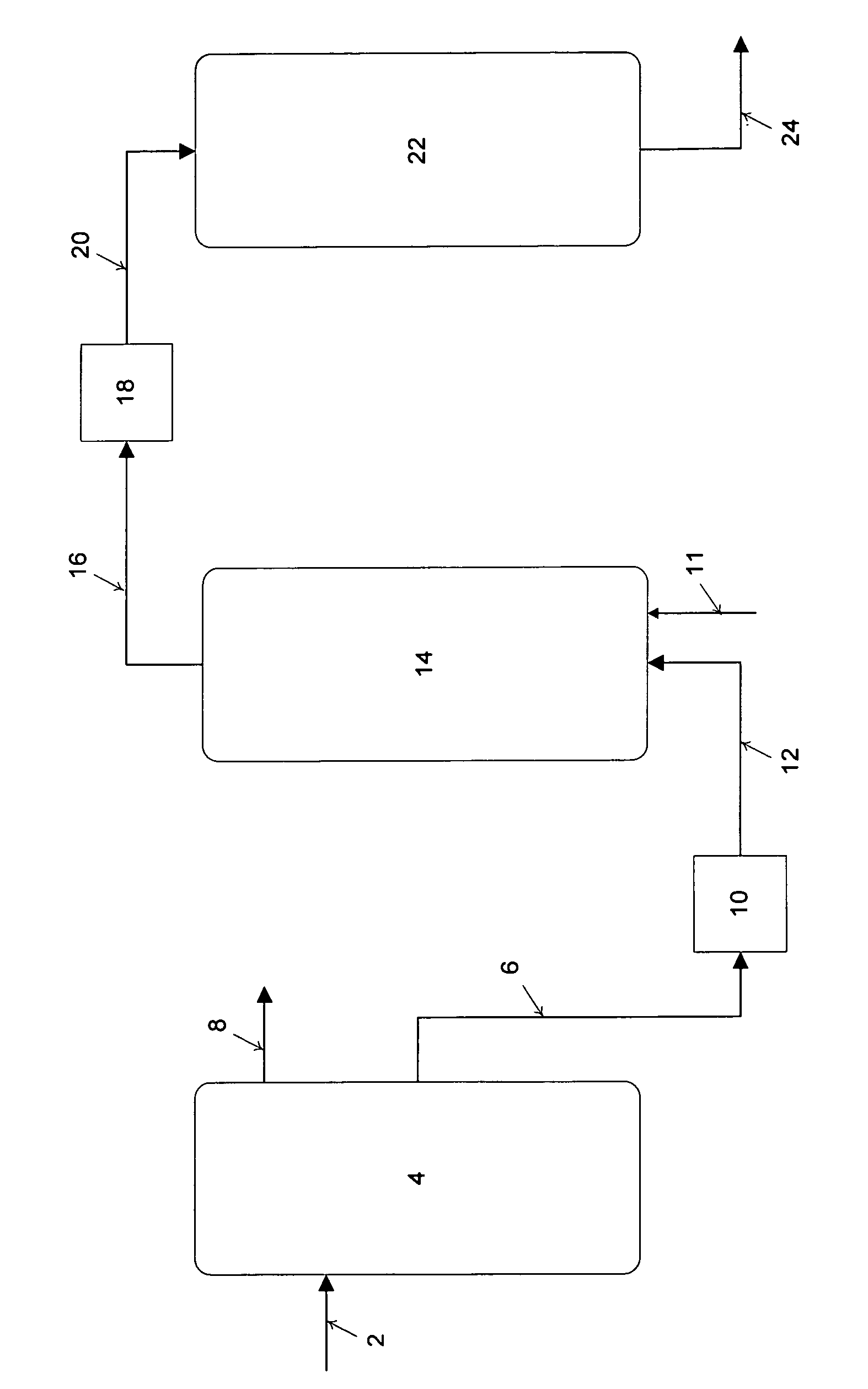

Process for removing contaminants from Fischer-Tropsch feed streams

InactiveUS20050222481A1Lower overall pressure dropImprove the immunityRefining with metalsLiquid hydrocarbon mixture productionPtru catalystEnvironmental engineering

A process for removing contaminants from the products of a Fischer-Tropsch synthesis reaction, said contaminants comprising (i) particulates having an effective diameter of greater than 1 micron and (ii) at least 5 ppm of aluminum in aluminum-containing contaminants having an effective diameter of less than 1 micron, said process comprising the steps of (a) passing the products of the Fischer-Tropsch synthesis reaction through a first particulate removal zone capable of removing particulates having an effective diameter of greater than 1 micron; (b) collecting from the first particulate removal zone a substantially particulate free Fischer-Tropsch feed stream containing 5 ppm or more of aluminum in aluminum containing-contaminants having an effective diameter of less than about 1 micron; (c) contacting the substantially particulate free Fischer-Tropsch feed stream in up-flow mode with an aluminum active catalyst in a guard-bed under aluminum activating conditions, whereby a feed stream mixture is formed which comprises aluminum-containing particles having an effective diameter of more than 1 micron in a Fischer-Tropsch hydrocarbon continuous phase; (d) passing the feed stream mixture through a second particulate removal zone capable of removing substantially all of the aluminum-containing particles formed in step (c); and (e) recovering from the second particulate removal zone a Fischer-Tropsch product containing less than about 5 ppm total aluminum.

Owner:CHEVROU USA INC

Device for the modulation of cardiac end diastolic volume

ActiveUS7871366B2Eliminate movement barriersEliminate relative motionBlood pumpsIntravenous devicesCardiac deviceHeart volume

The present invention provides methods, systems, kits and devices that reduce dyskinesis and hypokinesis. For example, the direct compression cardiac device may be positioned about at least a portion of a heart, and includes a resilient inner panel in contact with at least a portion of the heart periphery, one or more resilient members positioned about the resilient inner panel and at least partially surrounded by an expandable outer panel. The resistance supplied by the inner panel to the heart may be modulated to control the end-diastolic heart volume and remodel the heart, the resistance supplied by the expandable outer panel to the heart may be modulated to control the end-systolic heart volume and remodel the heart or both.

Owner:CORINNOVA +1

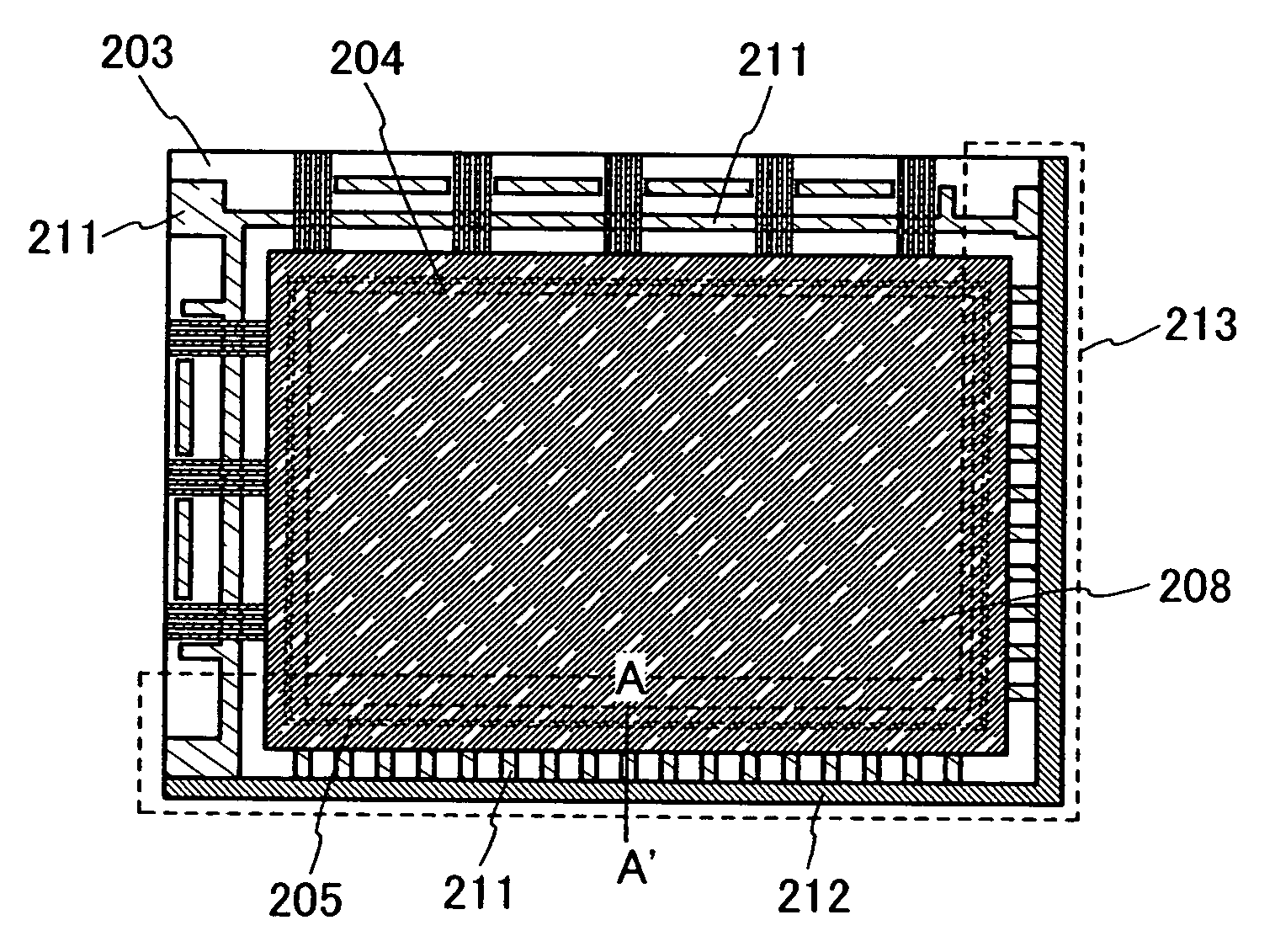

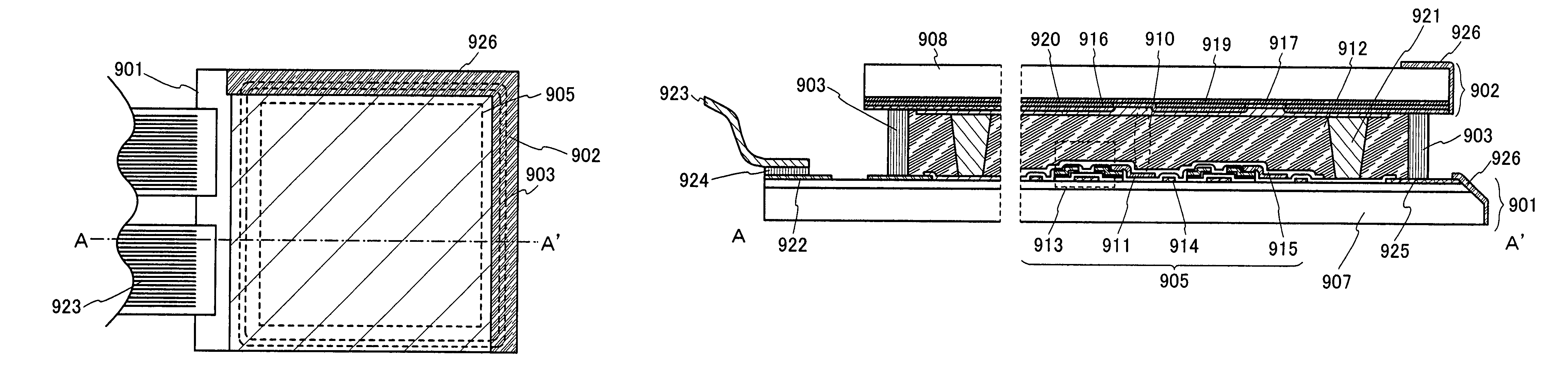

Display device

ActiveUS8395746B2Minimizing expansionExpansion of a frame portion over the substrate can minimally be suppressedNon-linear opticsElectricityActive matrix

It is an object of the present invention to provide a display device where expansion of a frame portion over a substrate, which results from formation of a lead wiring over an active matrix substrate, is minimally suppressed to realize a narrow frame. According to one feature of a display device of the present invention, a chamfer portion is formed at least at an end portion of an active matrix substrate having a pixel portion of a pair of substrates disposed to be opposed to each other, and wirings (a source line, a gate line, a storage capacitor line, a leading out wiring, and the like) over the active matrix substrate are electrically connected by a common wiring formed in the chamfer portion.

Owner:SEMICON ENERGY LAB CO LTD

Method and apparatus to plan motion path of robot

ActiveUS9411335B2Reduce time consumptionMinimizing expansionProgramme-controlled manipulatorTarget-seeking controlAlgorithmRandom tree

A suitable waypoint is selected using a goal score, a section from a start point to a goal point through the waypoint is divided into a plurality of sections based on the waypoint with a solution of inverse kinematics, and trees are simultaneously expanded in the sections using a Best First Search & Rapidly Random Tree (BF-RRT) algorithm so as to generate a path. By this configuration, a probability of local minima occurring is decreased compared with the case where the waypoint is randomly selected. In addition, since the trees are simultaneously expanded in the sections each having the waypoint with a solution of inverse kinematics, the solution may be rapidly obtained. A time consumed to search for an optimal motion path may be shortened and path plan performance may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

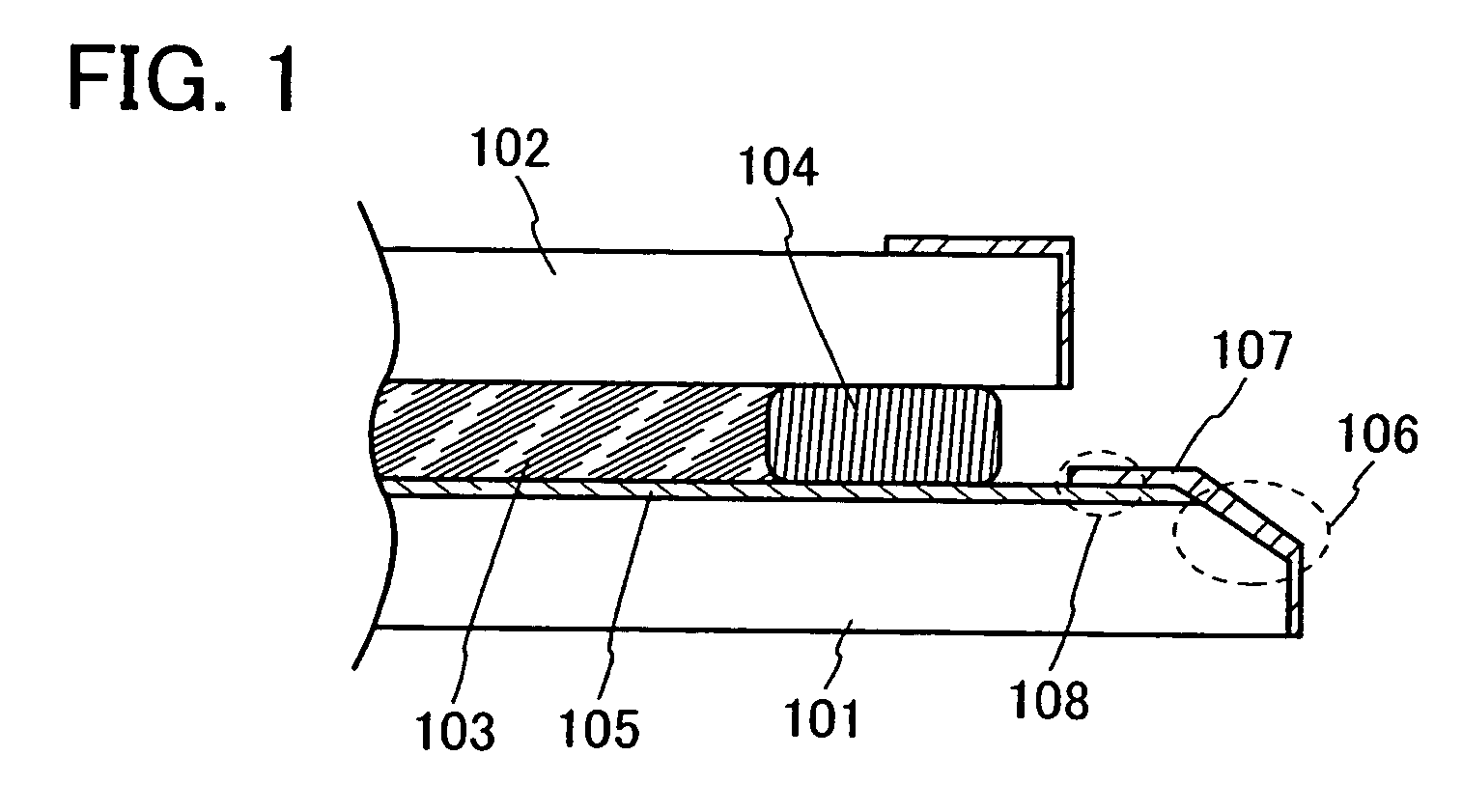

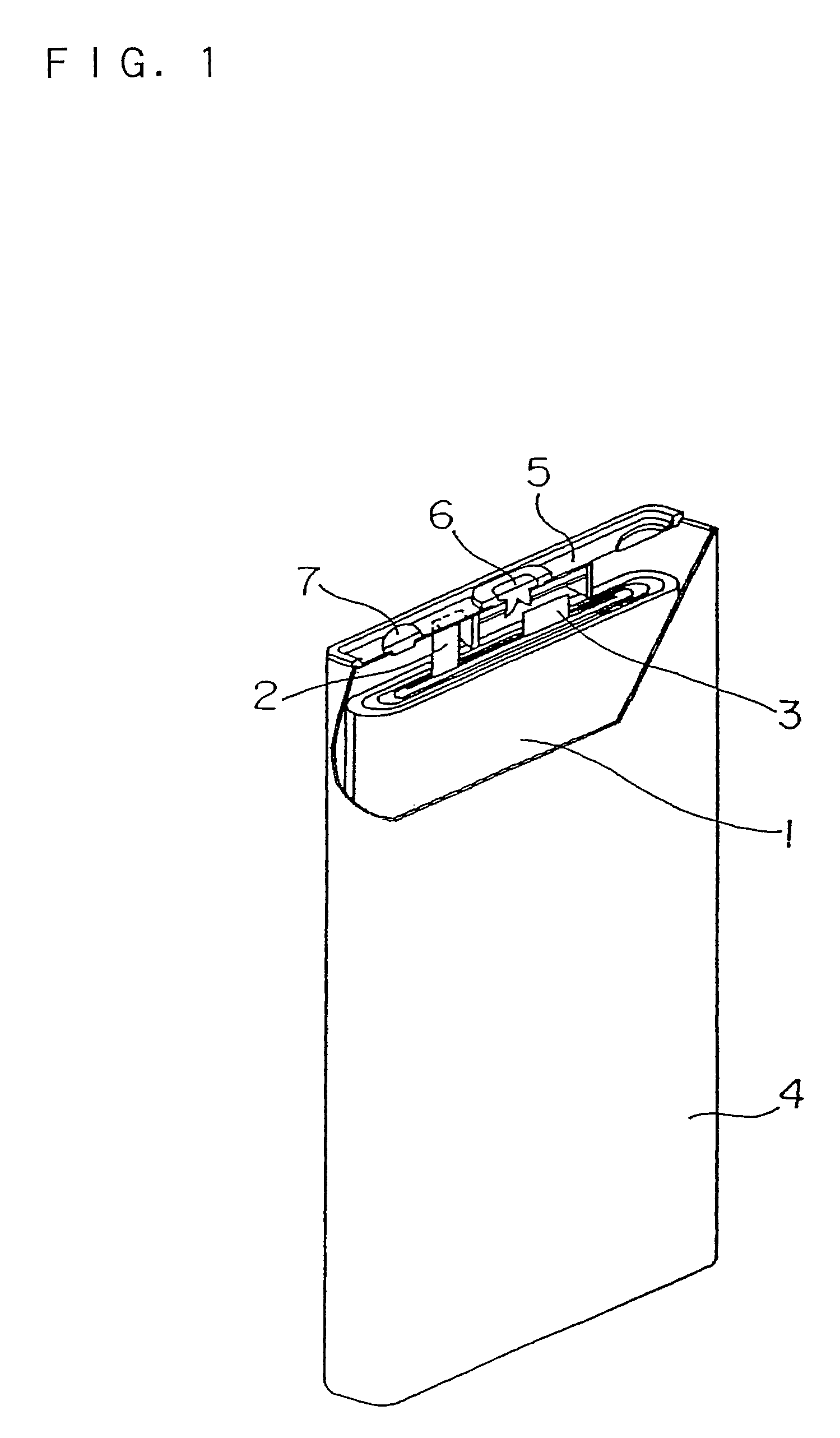

Non-aqueous electrolyte secondary battery and electrolyte for the same

InactiveUS7709157B2Minimize battery expansionMinimizing expansionElectrolytic capacitorsOrganic electrolyte cellsImideEngineering

The present invention provides a safe non-aqueous electrolyte secondary battery with characteristics analogous to those of a conventional battery by minimizing battery expansion that causes damage to a device during high temperature exposure or storage. The non-aqueous electrolyte secondary battery comprises: (a) a chargeable and dischargeable positive electrode; (b) a negative electrode capable of absorbing and desorbing lithium; (c) a separator for preventing direct electron transfer between the positive electrode and the negative electrode; and (d) an non-aqueous electrolyte; the non-aqueous electrolyte comprising a non-aqueous solvent and a solute, the non-aqueous solvent comprising a lactone, the solute comprising lithium bis(fluorosulfonyl)imide represented by the formula (1):(F—O2S—N—SO2—F)Li.

Owner:PANASONIC CORP

Process for removing contaminants from Fischer-Tropsch feed streams

InactiveUS7332073B2Lower overall pressure dropImprove the immunityRefining with metalsLiquid hydrocarbon mixture productionParticulatesHydrocarbon

Owner:CHEVROU USA INC

Designed porosity materials in nuclear reactor components

ActiveUS20150063521A1Improve efficiencyIncrease gas pressureFuel elementsNuclear energy generationPorous substrateNuclear reactor

A nuclear fuel pellet with a porous substrate, such as a carbon or tungsten aerogel, on which at least one layer of a fuel containing material is deposited via atomic layer deposition, and wherein the layer deposition is controlled to prevent agglomeration of defects. Further, a method of fabricating a nuclear fuel pellet, wherein the method features the steps of selecting a porous substrate, depositing at least one layer of a fuel containing material, and terminating the deposition when the desired porosity is achieved. Also provided is a nuclear reactor fuel cladding made of a porous substrate, such as silicon carbide aerogel or silicon carbide cloth, upon which layers of silicon carbide are deposited.

Owner:UCHICAGO ARGONNE LLC

Self healing optical fiber cable assembly and method of making the same

ActiveUS8050527B2Prolong lifeImprove reliabilityFibre mechanical structuresMetal working apparatusComputer moduleEngineering

In one of the embodiments there is disclosed a self healing optical fiber cable assembly comprising an elongated optical fiber core having a cladding layer, a buffer layer, a sealing layer that seals any microcracks or defects in the buffer layer, the cladding layer, and the optical fiber core, and, an outer protection layer, wherein an end of the outer layer is connected to a strain relief device to provide expansion protection to the cable assembly and to minimize strain on the cable assembly, and further wherein an end of the strain relief device is connected to an optical fiber module. The cable assembly may further comprise a constraining layer and / or a strengthening layer. There is also disclosed a method of making a self healing optical fiber cable assembly.

Owner:THE BOEING CO

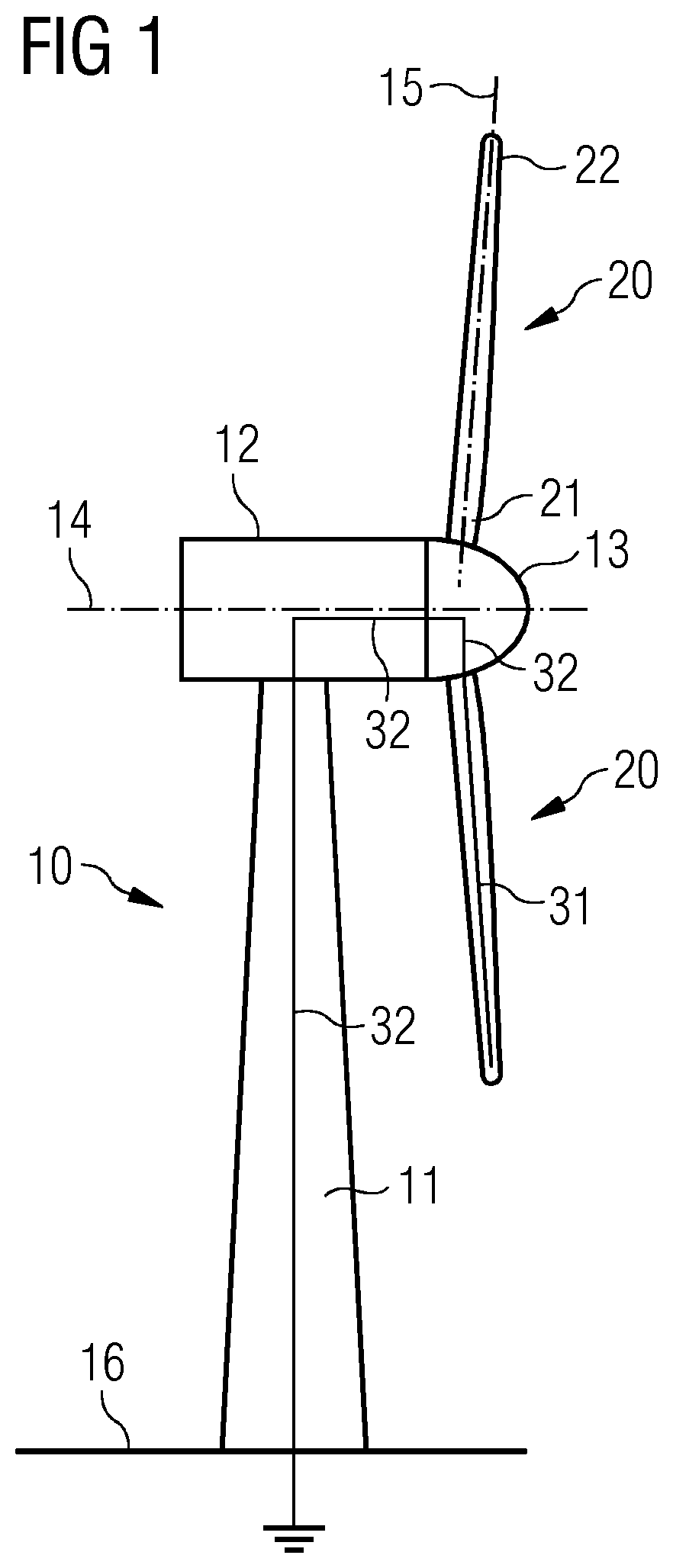

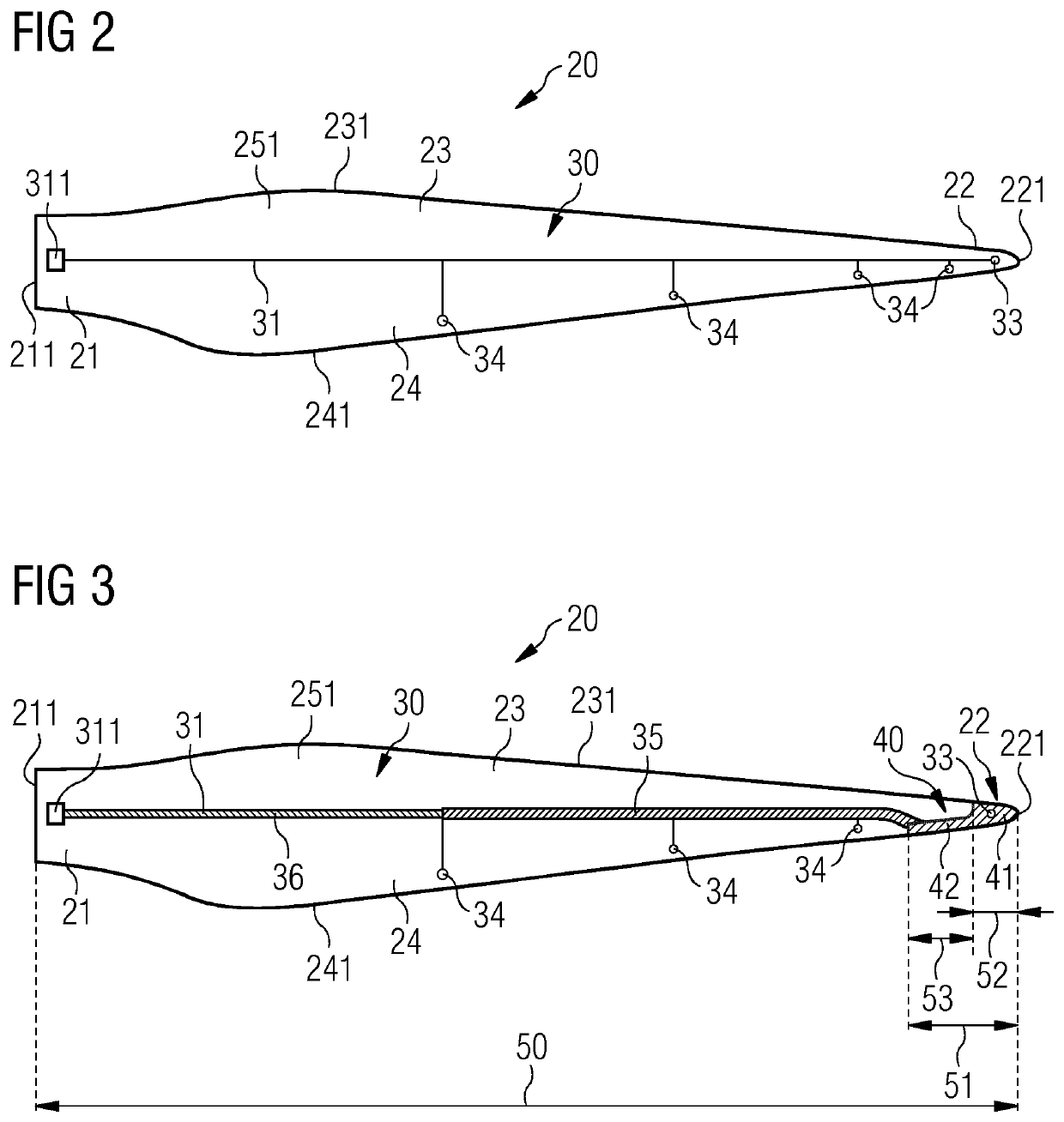

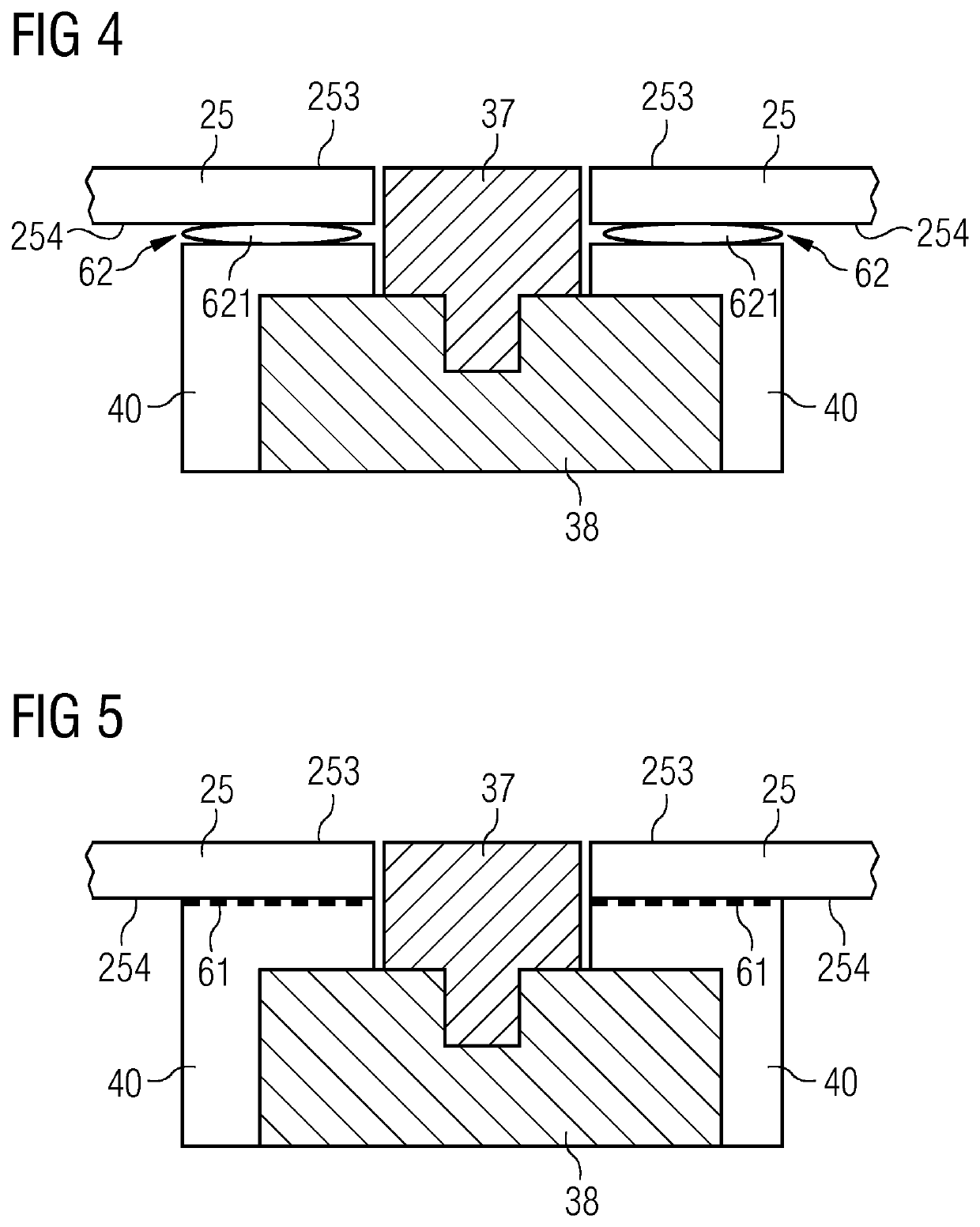

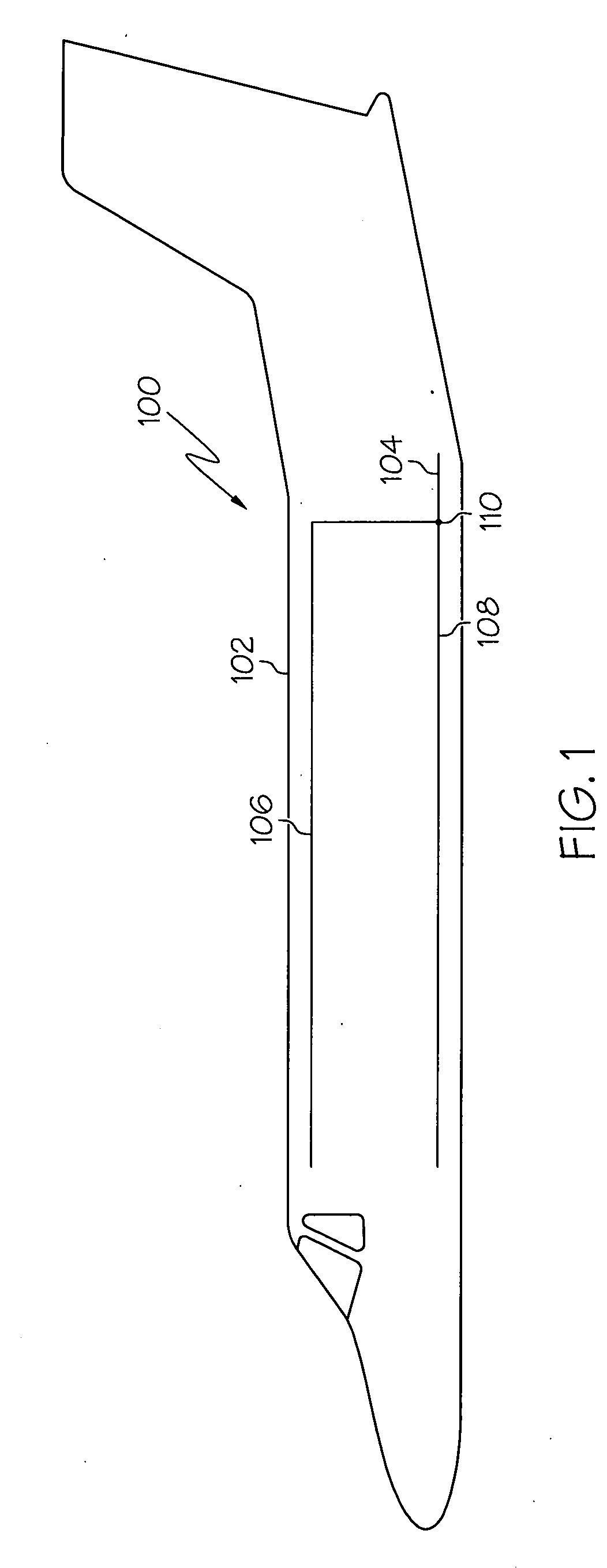

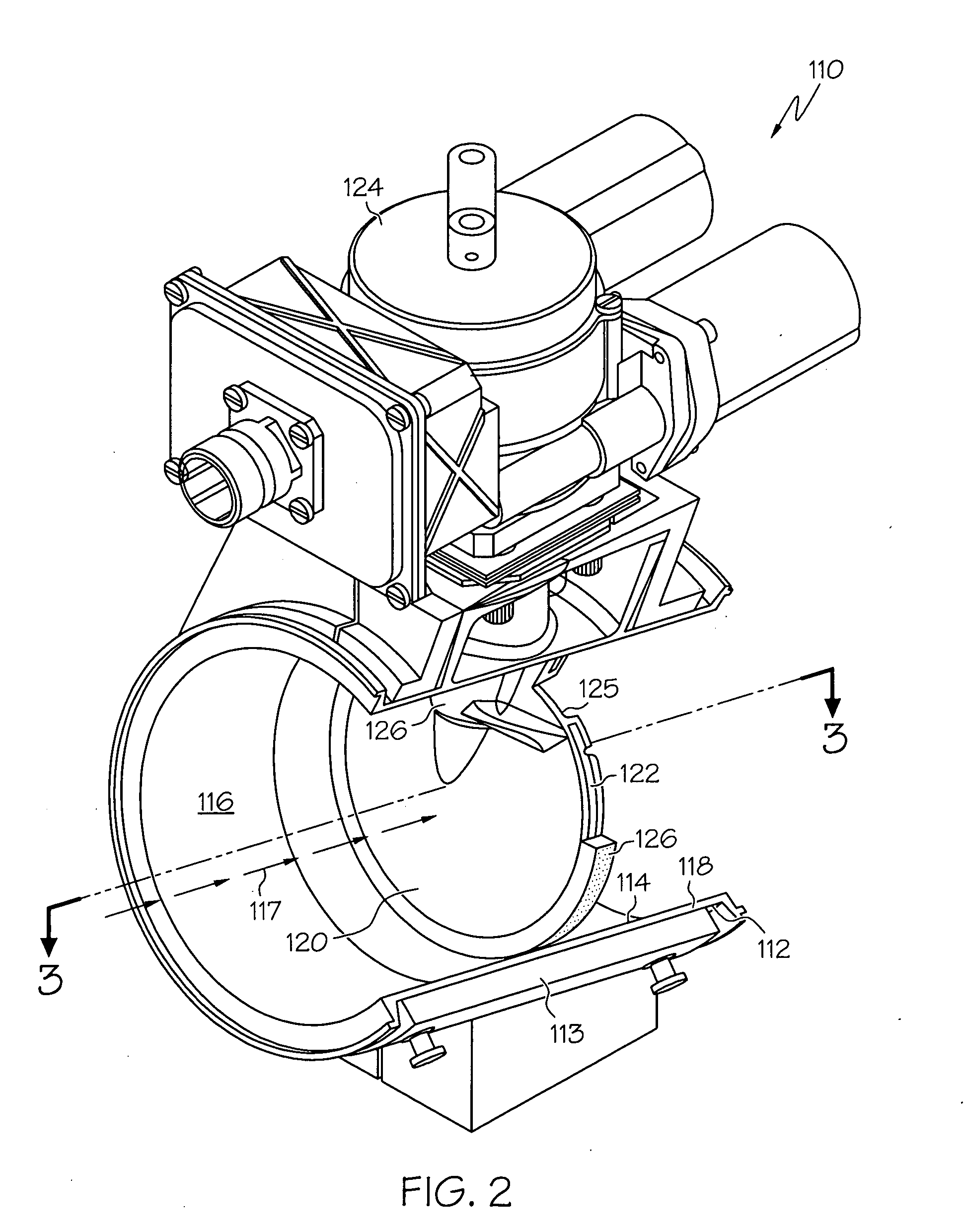

Lightning protection system for a wind turbine blade

ActiveUS20200056596A1Easy to fixImprove sealingEngine manufactureFinal product manufactureElectrical conductorTurbine blade

Provided is a rotor blade of a wind turbine, wherein the rotor blade includes a trailing edge section with a trailing edge and a leading-edge section with a leading-edge, a root section with a root and a tip section with a tip, a shell which defines the outer shape of the rotor blade and a cavity which is confined by the shell, and a lightning protection system with an internal down conductor extending from the root section of the rotor blade to the tip section of the rotor blade, wherein the internal down conductor is connectable at the root section to a grounding system of the remainder of the wind turbine and at the tip section to at least one tip lightning receptor which is positioned at the surface of the rotor blade. In addition, the rotor blade comprises an electrically insulating tip part.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

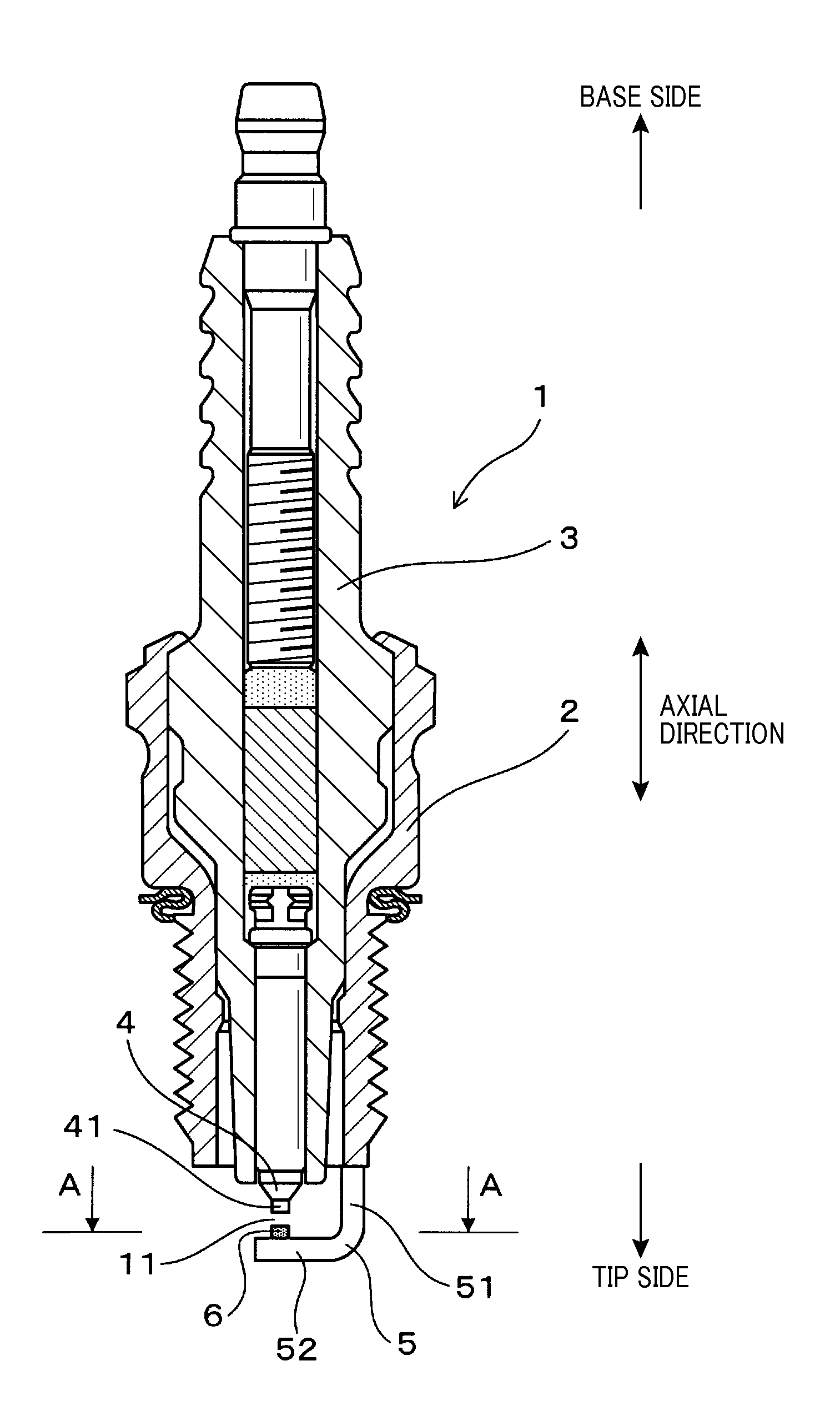

Spark plug for internal combustion engines and mounting structure for the spark plug

ActiveUS20140265816A1Prolong lifeWear minimizationSparking plugsMachines/enginesCombustionEngineering

A spark plug for an internal combustion engine is provided, which includes a housing, an insulation porcelain, a center electrode and a ground electrode. At least one of a tip portion of the center electrode and an opposing portion of the ground electrode is provided with a projection portion. At least one of the projection portions has a cross section perpendicular to the axial direction of the plug, the cross section having a minimum curvature radius portion and being in a specific shape that satisfies a predetermined requirement. The requirement is that, when a first straight line, a first line segment and a second straight line are provided, and when the cross section is divided into a first region and a second region by the second straight line, the second region has an area larger than the area of the first region.

Owner:DENSO CORP

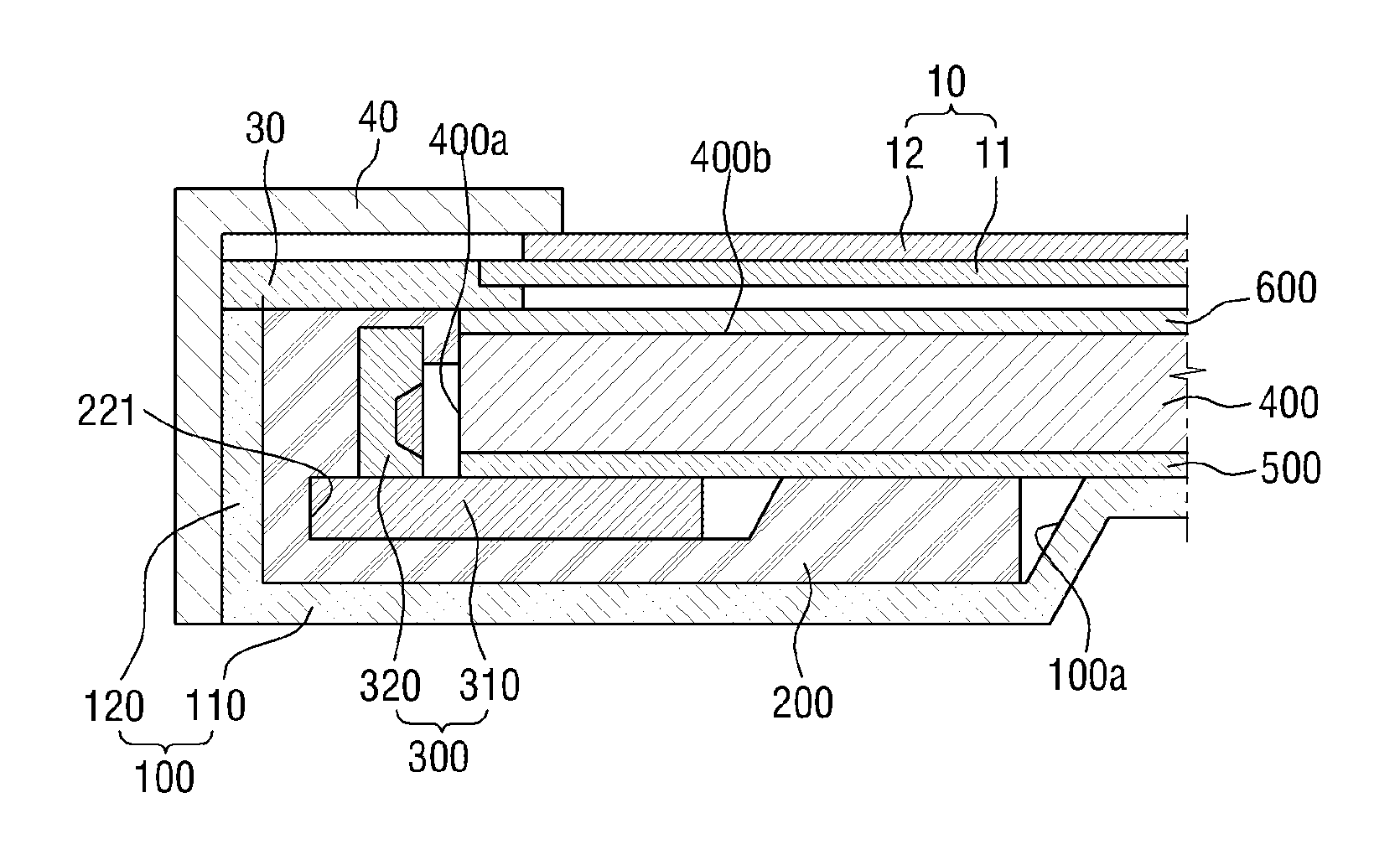

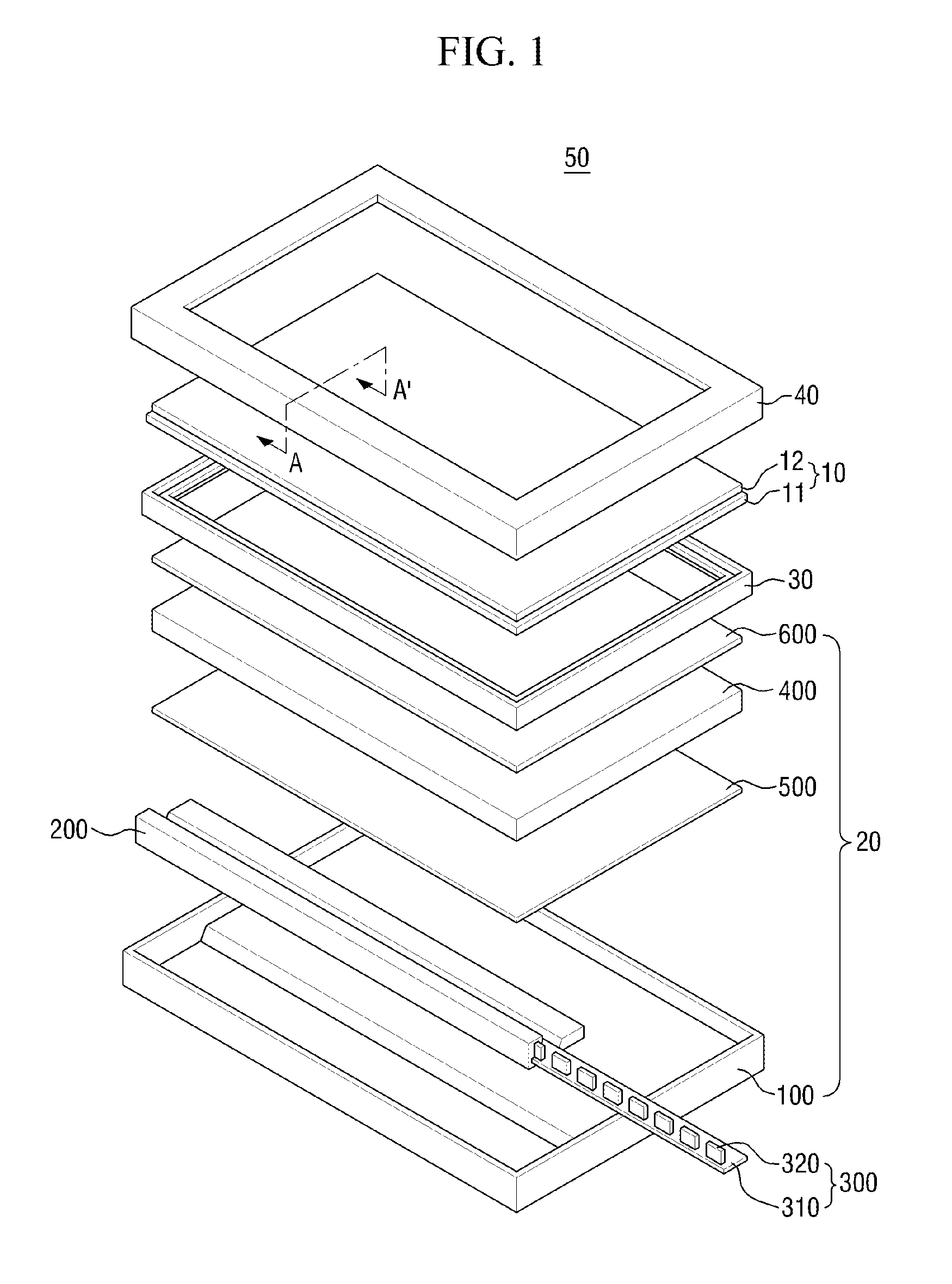

Display device

ActiveUS20130182199A1Minimizing expansionExpansion of a frame portion over the substrate can minimally be suppressedNon-linear opticsCapacitanceElectricity

It is an object of the present invention to provide a display device where expansion of a frame portion over a substrate, which results from formation of a lead wiring over an active matrix substrate, is minimally suppressed to realize a narrow frame. According to one feature of a display device of the present invention, a chamfer portion is formed at least at an end portion of an active matrix substrate having a pixel portion of a pair of substrates disposed to be opposed to each other, and wirings (a source line, a gate line, a storage capacitor line, a leading out wiring, and the like) over the active matrix substrate are electrically connected by a common wiring formed in the chamfer portion.

Owner:SEMICON ENERGY LAB CO LTD

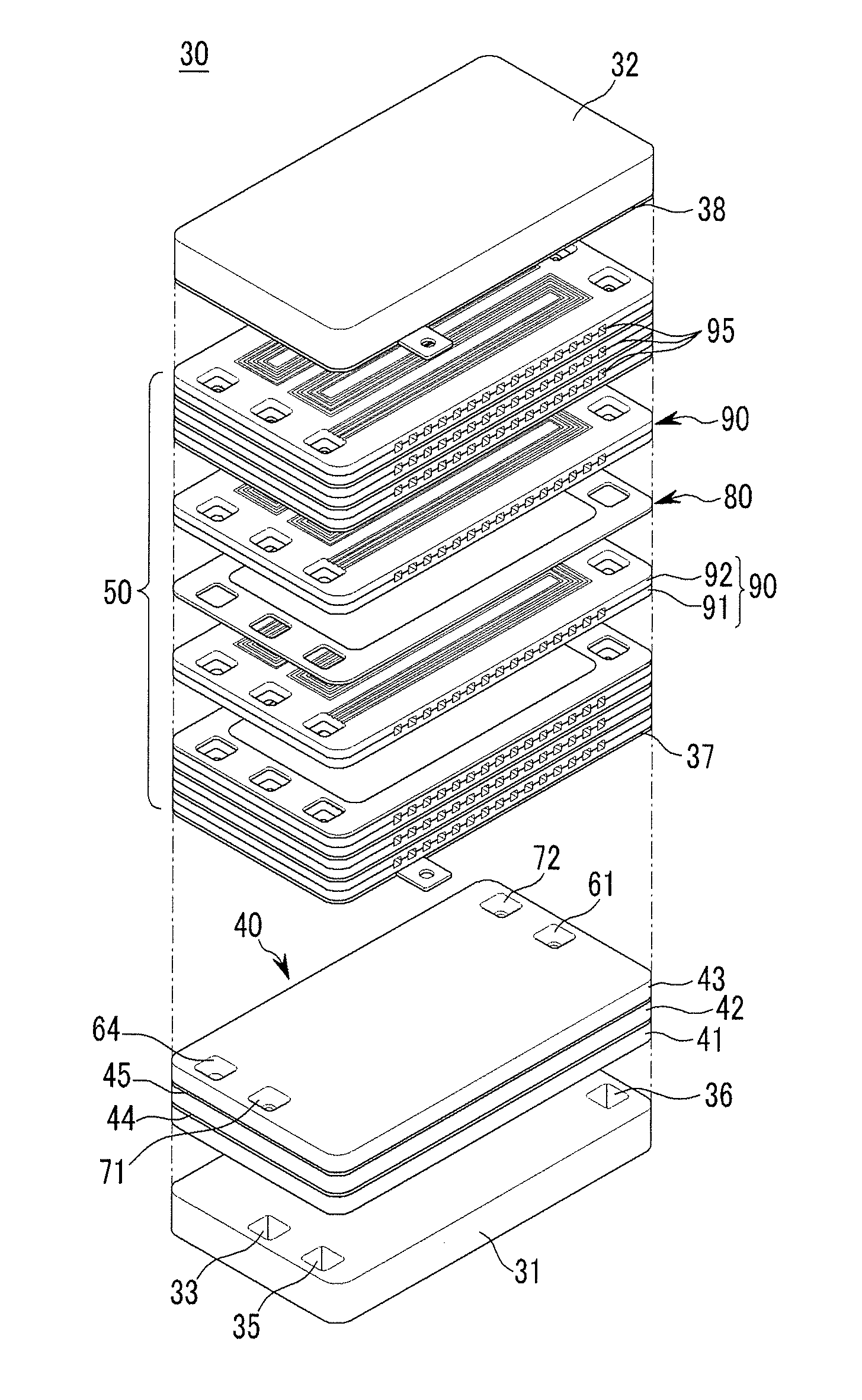

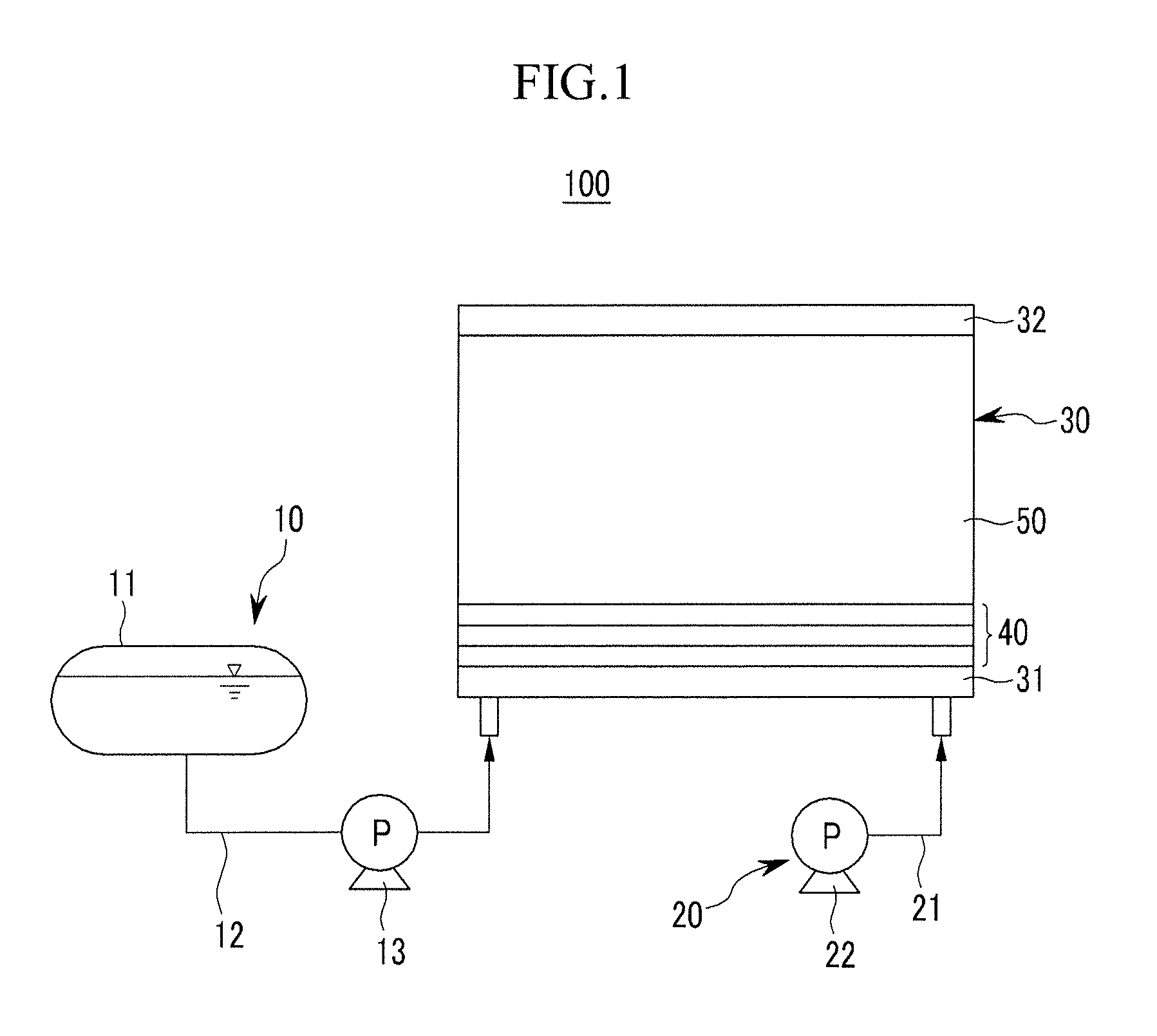

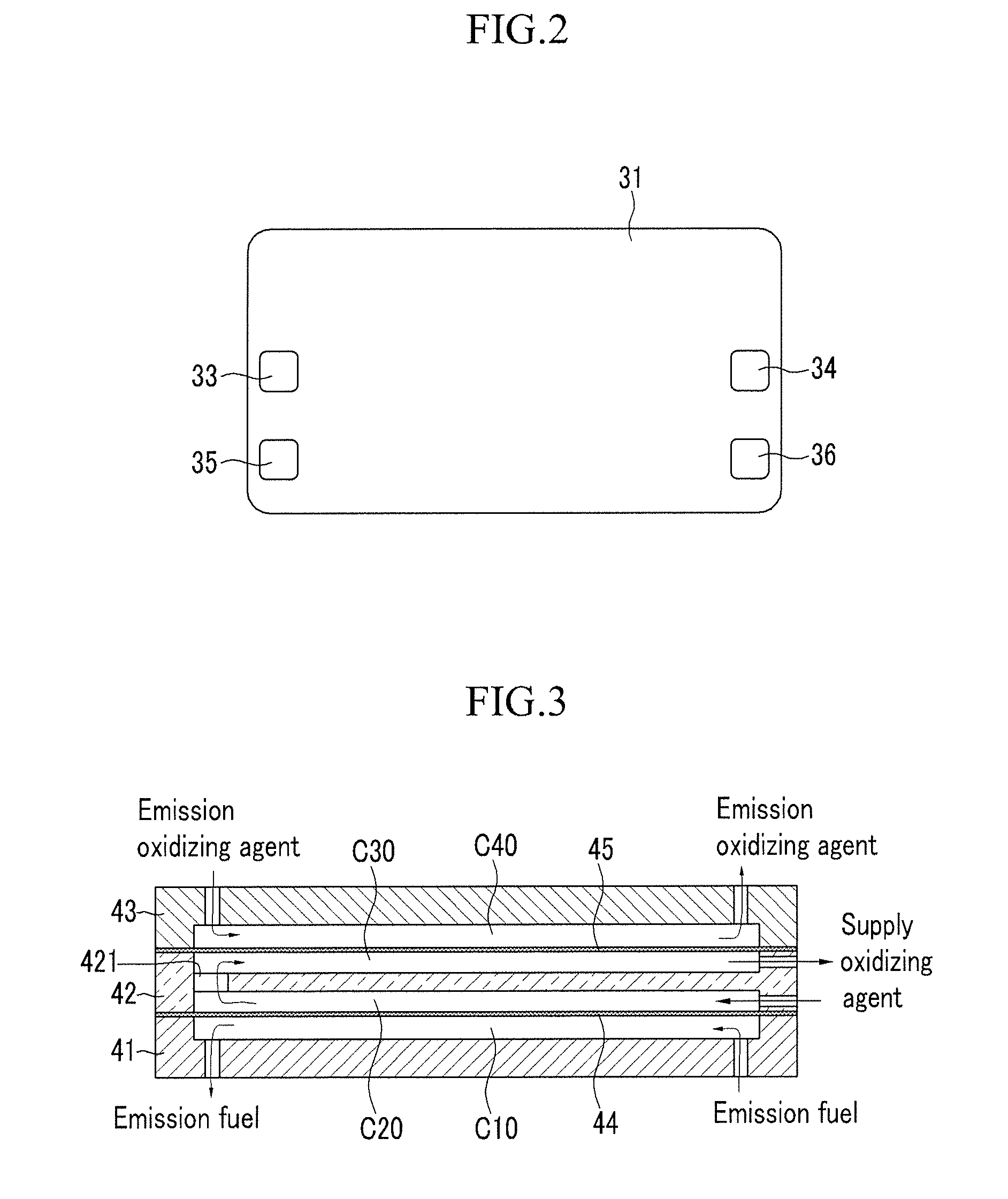

Fuel cell system

InactiveUS20110244342A1Simple configurationMinimizing volume expansion and number of partFuel cell auxillariesSolid electrolyte fuel cellsFuel supplyEngineering

The fuel cell system includes a fuel cell stack, a fuel supply supplying a fuel to the fuel cell stack, and an oxidizing agent supply supplying an oxidizing agent to the fuel cell stack. The fuel cell stack includes a first end plate, a moisture exchanger, an electrical generator, and a second end plate. The moisture exchanger includes a first area where a dried supply oxidizing agent flows, a second area where a humid emission fuel flows, and a third area where a humid emission oxidizing agent flows, and the first area exchanges moisture with the second and third areas using a moisture exchange layer.

Owner:SAMSUNG SDI CO LTD

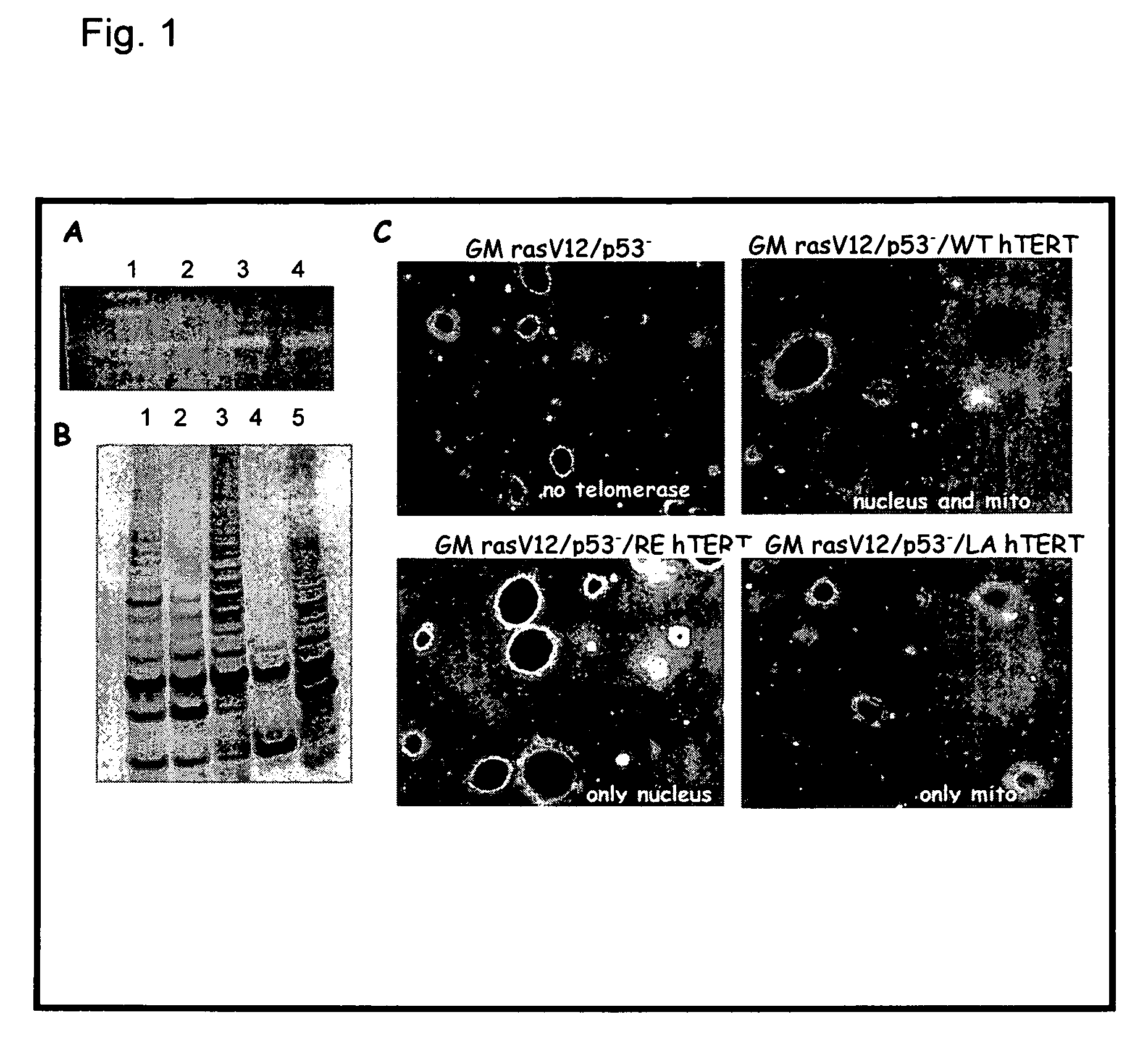

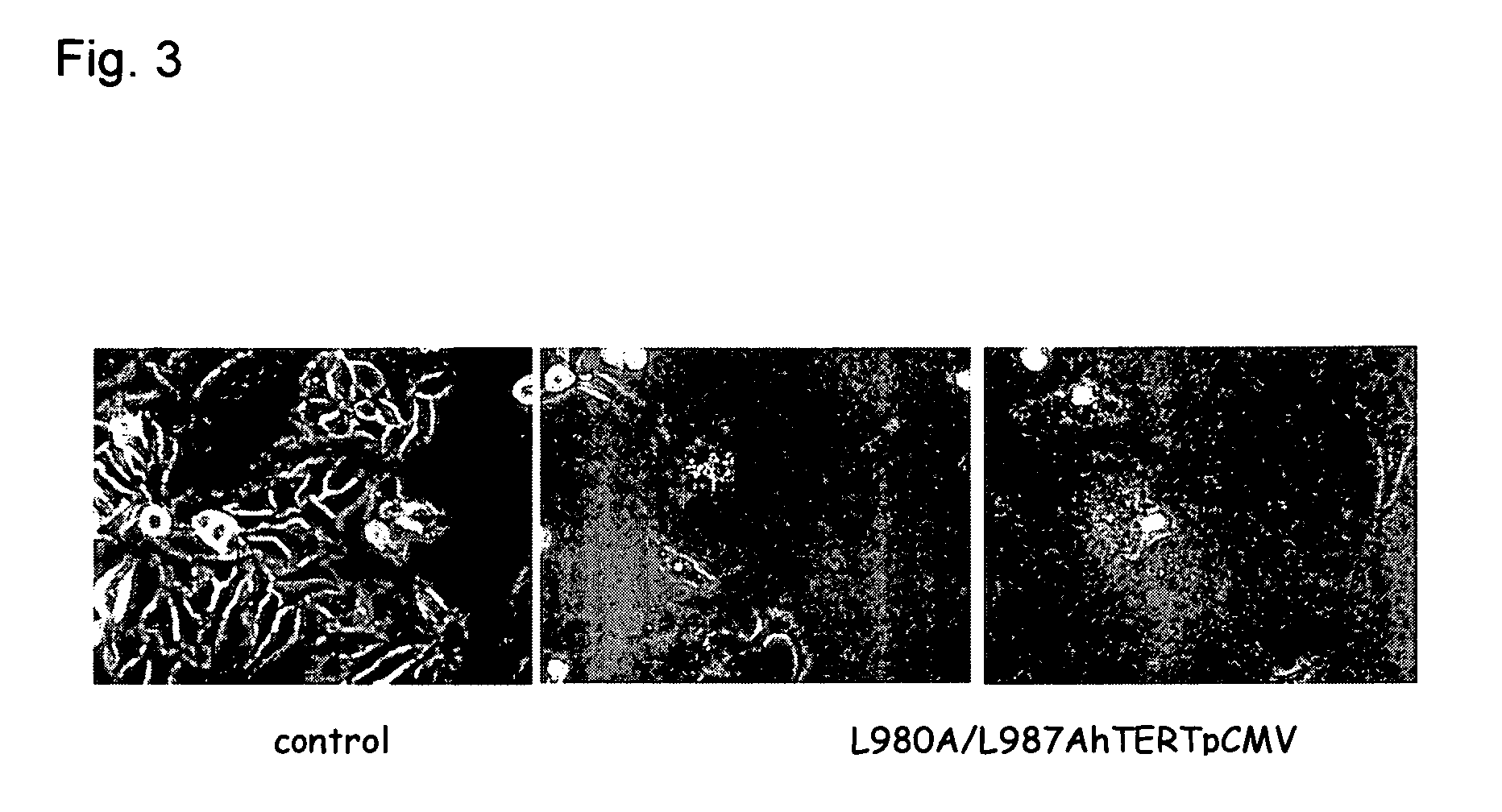

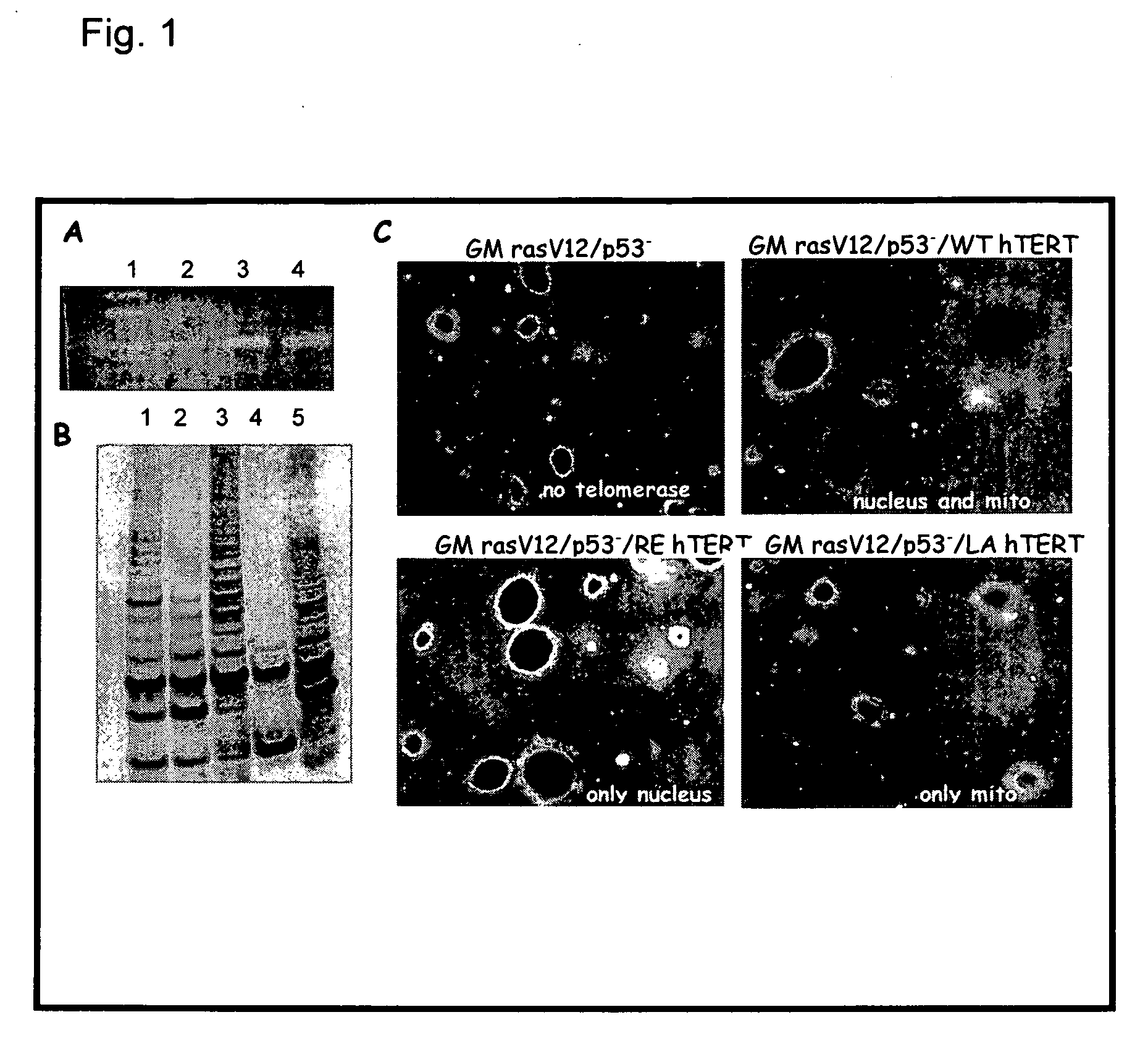

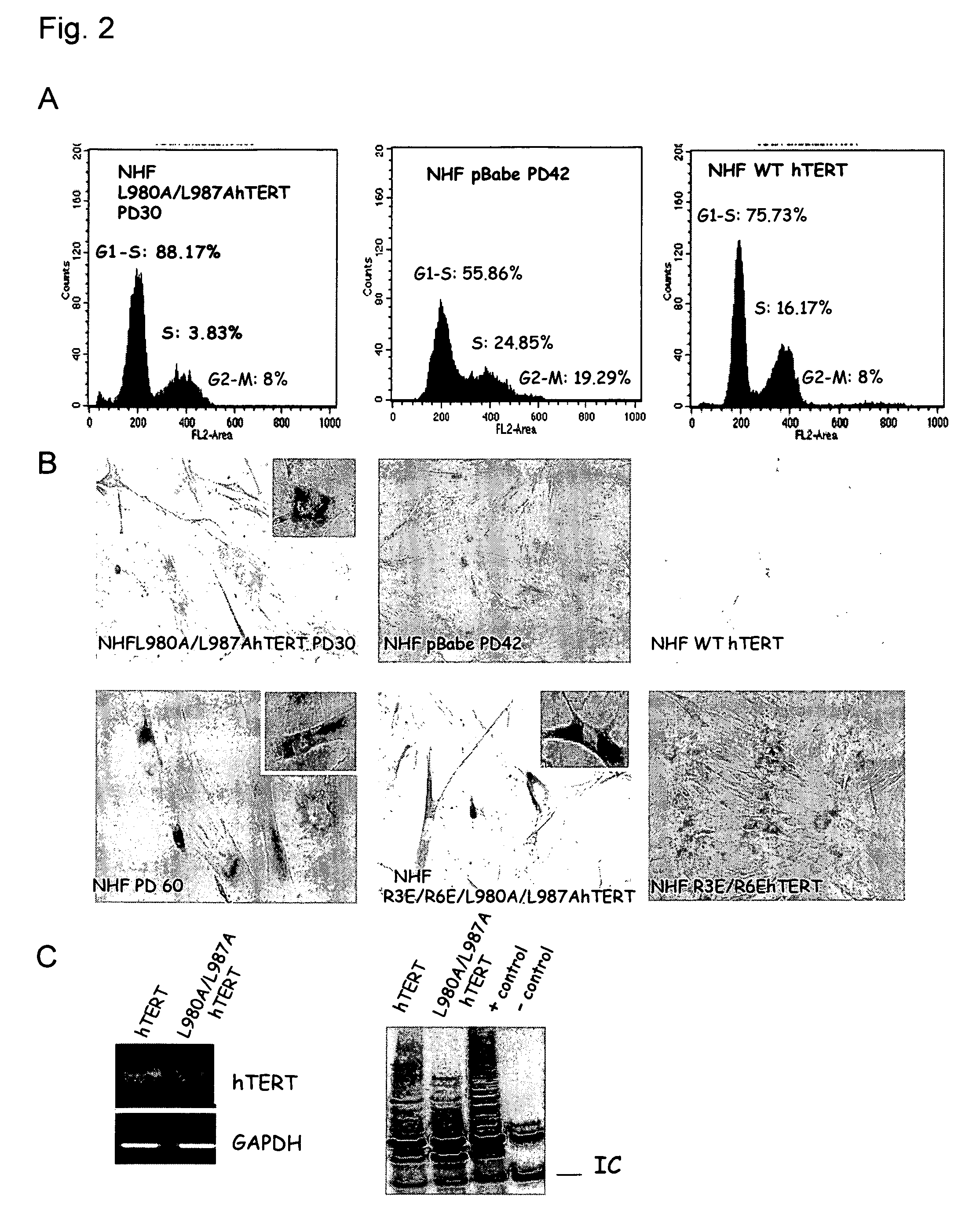

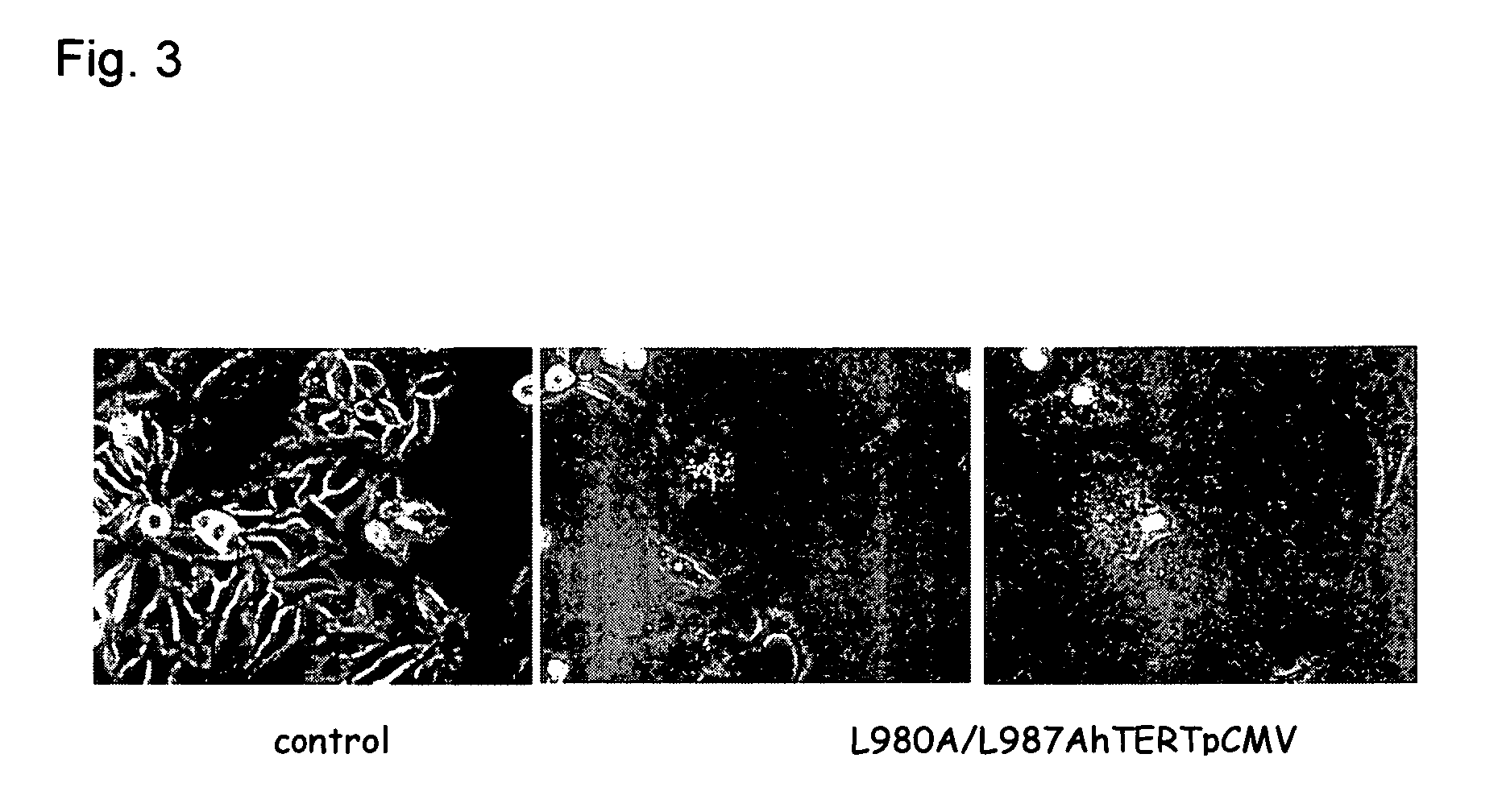

Telomerase reverse transcriptase variant

InactiveUS8362209B2Increasing tumor sensitivityMore sensitive to mitochondrial DNAPowder deliveryPeptide/protein ingredientsReverse transcriptaseWild type

The present invention relates to nucleic and amino acid sequences of a novel variant of the telomerase reverse transcriptase. More particularly, the present invention is directed to a novel variant of human telomerase reverse transcriptase, which displays properties distinct from those of wildtype telomerase reverse transcriptase, and methods of use thereof.

Owner:RUTGERS THE STATE UNIV

Skin Retention Device for a Medical Jet Injection Kit

InactiveUS20110270217A1Risk minimizationLow pressureJet injection syringesMedical devicesJet injectionInjection point

A skin retention device 10 for a medical jet-injection unit 20 comprises a contact face provided with adhesive 12 in the area surrounding and close to the injection opening(s) 11 of the nozzle 21 which ensures god contact between the nozzle 21 and the skin 30 of a subject in the area chosen for an injection. Consequently the injection force can be lowered dramatically. In case of two-stage jet-injections, the initial injection force can be lowered because the skin retention close to the injection point significantly reduces the energy consuming elastic expansion of the skin 30 in the injection area, and the second injection force can be lowered because of the high degree of fixed positioning of the injection opening of the nozzle 21 relative to the injection channel in the skin 30 made during the initial injection stage. Thus a high degree of injection safety is achieved, minimizing the risk of whet shots, while skin lift and lower injection force decreases the risk of damage of the underlying tissue.

Owner:NOVO NORDISK AS

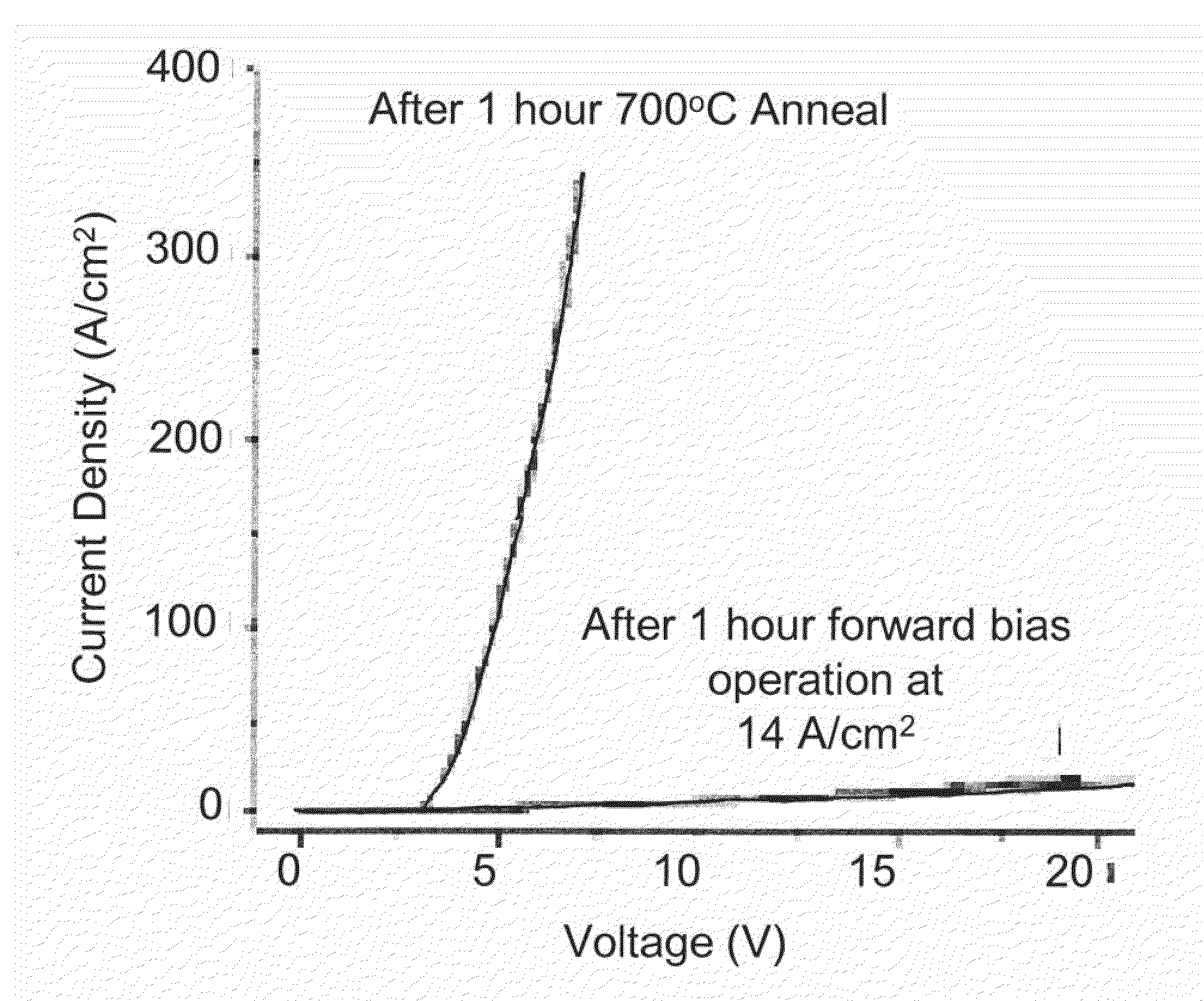

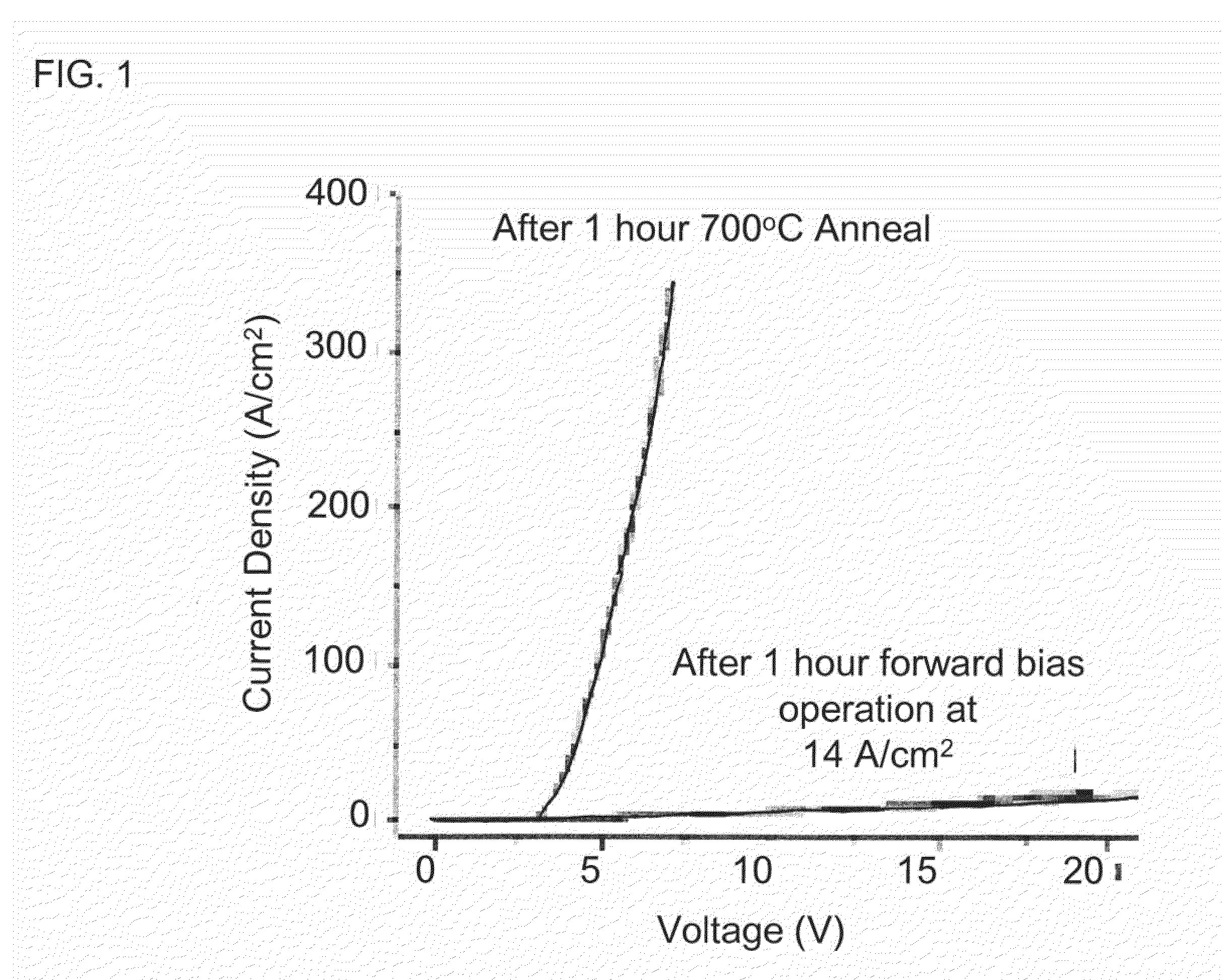

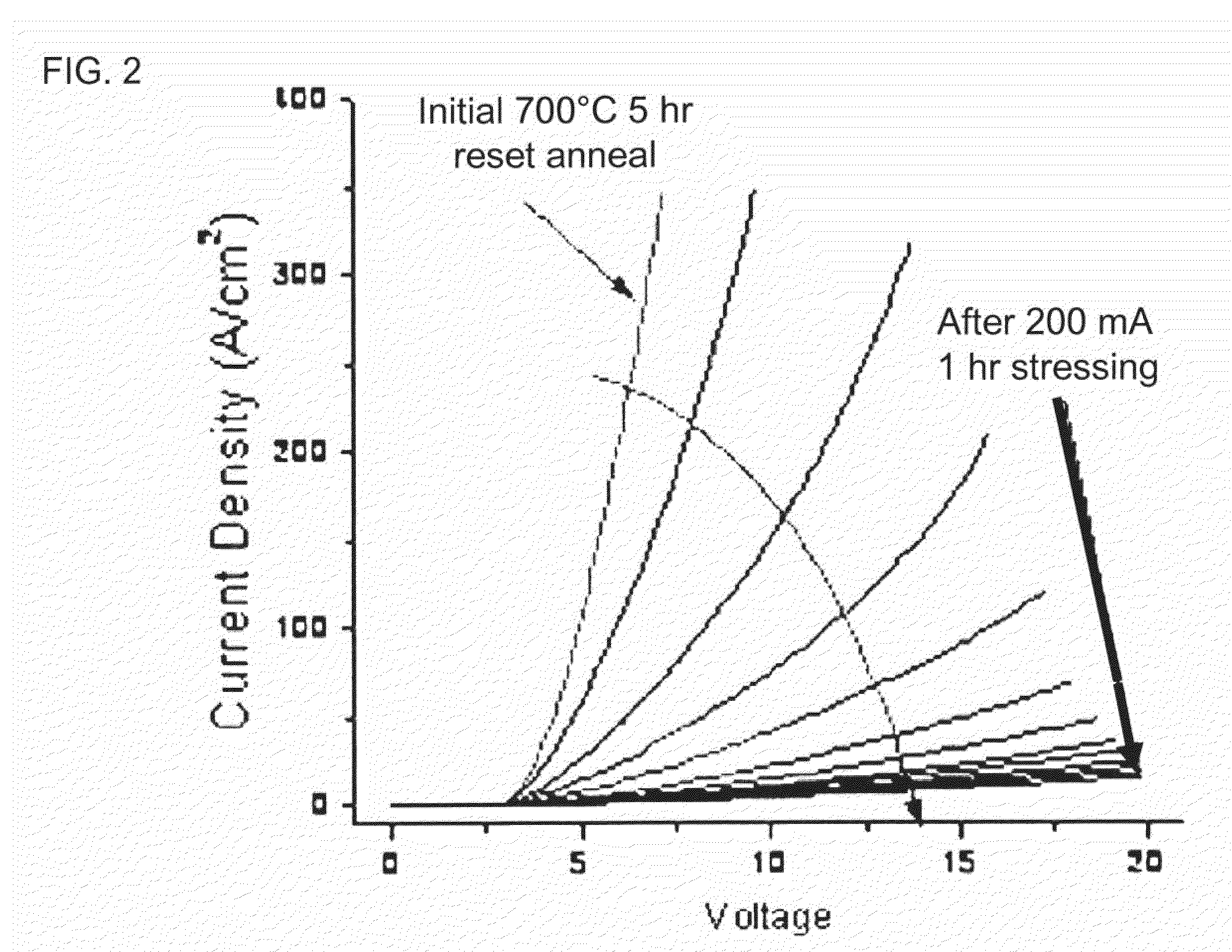

Method of mediating forward voltage drift in a sic device

InactiveUS20090273390A1Reduce the impactCommercially viableSemiconductor/solid-state device manufacturingElectric pulse generator detailsStacking faultEngineering

A method of reversing Shockley stacking fault expansion includes providing a bipolar or a unipolar SiC device exhibiting forward voltage drift caused by Shockley stacking fault nucleation and expansion. The SiC device is heated to a temperature above 150° C. A current is passed via forward bias operation through the SiC device sufficient to induce at least a partial recovery of the forward bias drift.

Owner:THE U S AS REPRESENTED BY THE SEC OF THE NAVY

Backlight assembly having support frame

ActiveUS9529143B2Improve performanceAvoid damageMechanical apparatusPlanar/plate-like light guidesEngineeringPrinted circuit board

A backlight assembly comprises: a receptacle; a support frame; and a light source module. The support frame is arranged on one side of the receptacle. The light source module is accommodated in the support frame and includes a printed circuit board and light sources. The support frame includes: a bottom portion; a side wall portion; a cover portion; a gap holding portion; and an insertion groove. The side wall portion extends from the bottom portion. The cover portion extends from the side wall portion to an inside. The gap holding portion extends from an end portion of the cover portion in a direction of the bottom portion. The printed circuit board is partially inserted into the insertion groove to be arranged on the upper surface of the bottom portion. The light sources are surrounded by the side wall portion, the cover portion, and the gap holding portion.

Owner:SAMSUNG DISPLAY CO LTD

Butterfly valve plate sealing assembly

Butterfly valve plate sealing assemblies are provided that include a sealing ring and a retention spacer disposed at least partially within a sealing ring groove formed about a periphery of a butterfly valve plate. The sealing ring includes a first portion, a second portion configured substantially perpendicular to the first portion, and a substantially L-shaped cross-section. The sealing ring is positioned at least partially within a groove opening and a groove body defining the sealing ring groove. The retention spacer is positioned at least partially within the groove opening and adjacent the first portion of the sealing ring. The retention spacer is configured to limit expansion of the sealing ring when under the influence of a pressurized fluid flow. The second portion of the sealing ring may be configured to optimize stiffness for a desired sealing ring tension.

Owner:HONEYWELL INT INC

Telomerase reverse transcriptase variant

InactiveUS20100247657A1Increasing tumor sensitivityMore sensitive to mitochondrial DNAPowder deliveryOrganic active ingredientsReverse transcriptaseWild type

The present invention relates to nucleic and amino acid sequences of a novel variant of the telomerase reverse transcriptase. More particularly, the present invention is directed to a novel variant of human telomerase reverse transcriptase, which displays properties distinct from those of wildtype telomerase reverse transcriptase, and methods of use thereof.

Owner:RUTGERS THE STATE UNIV

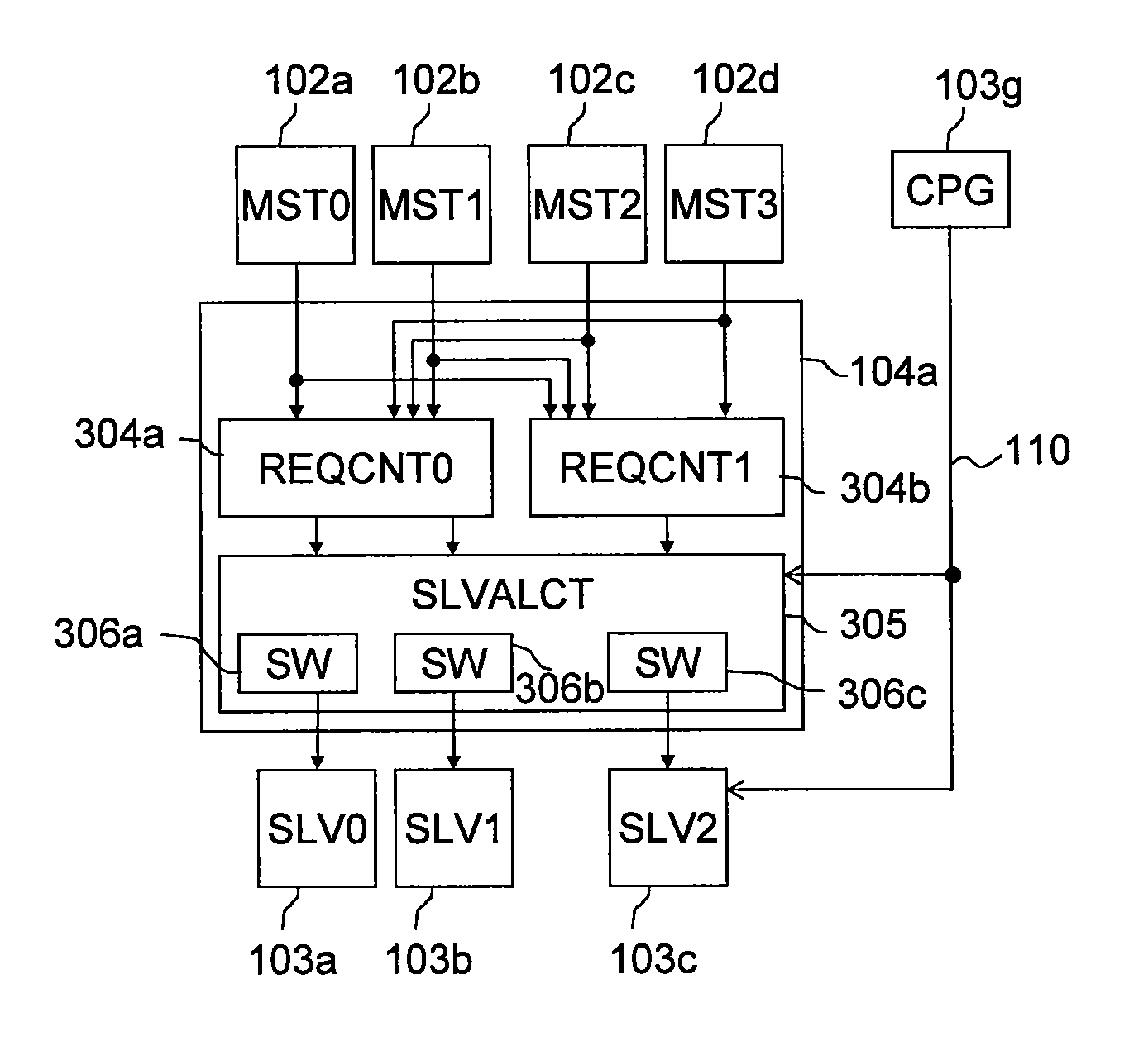

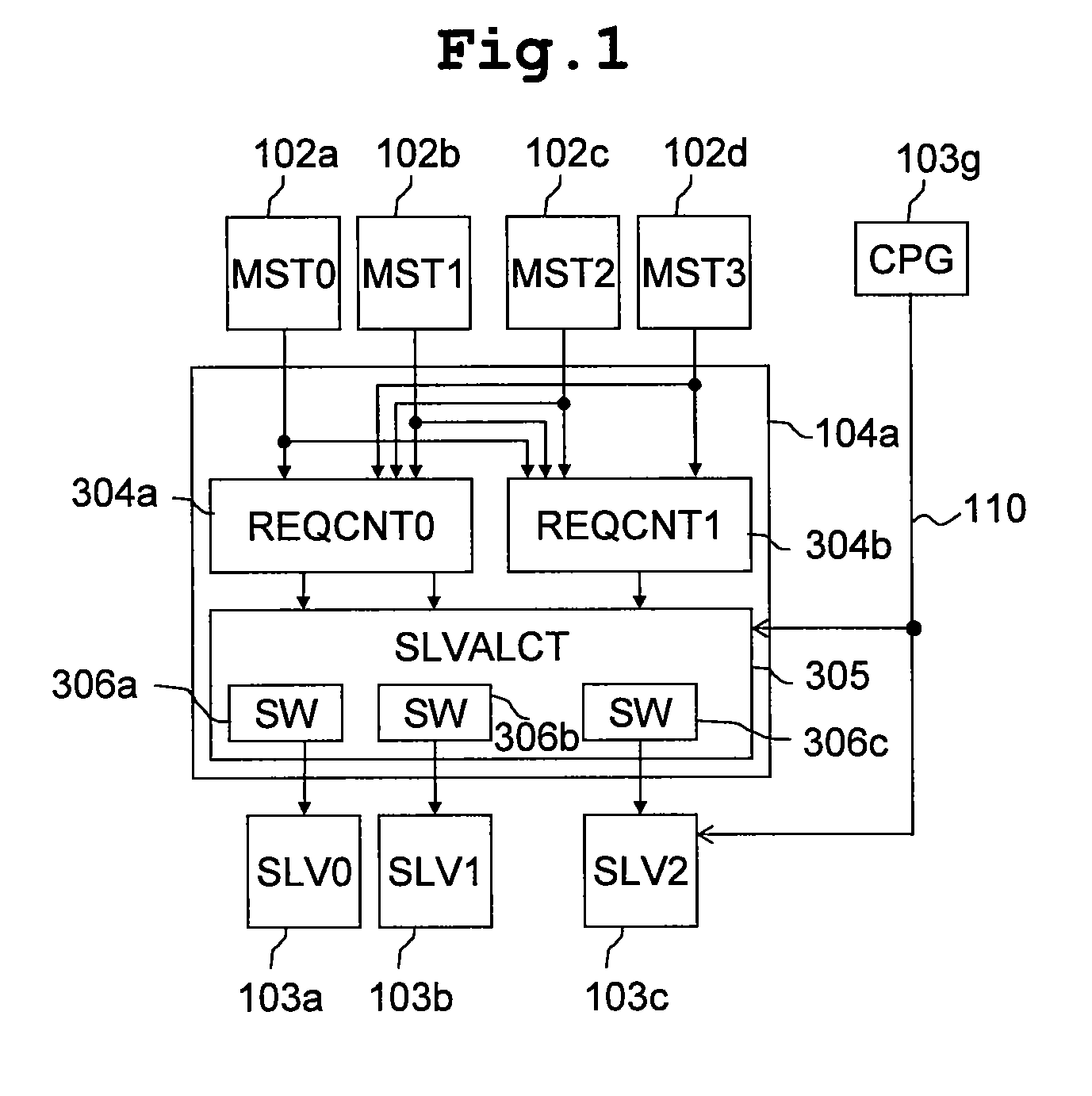

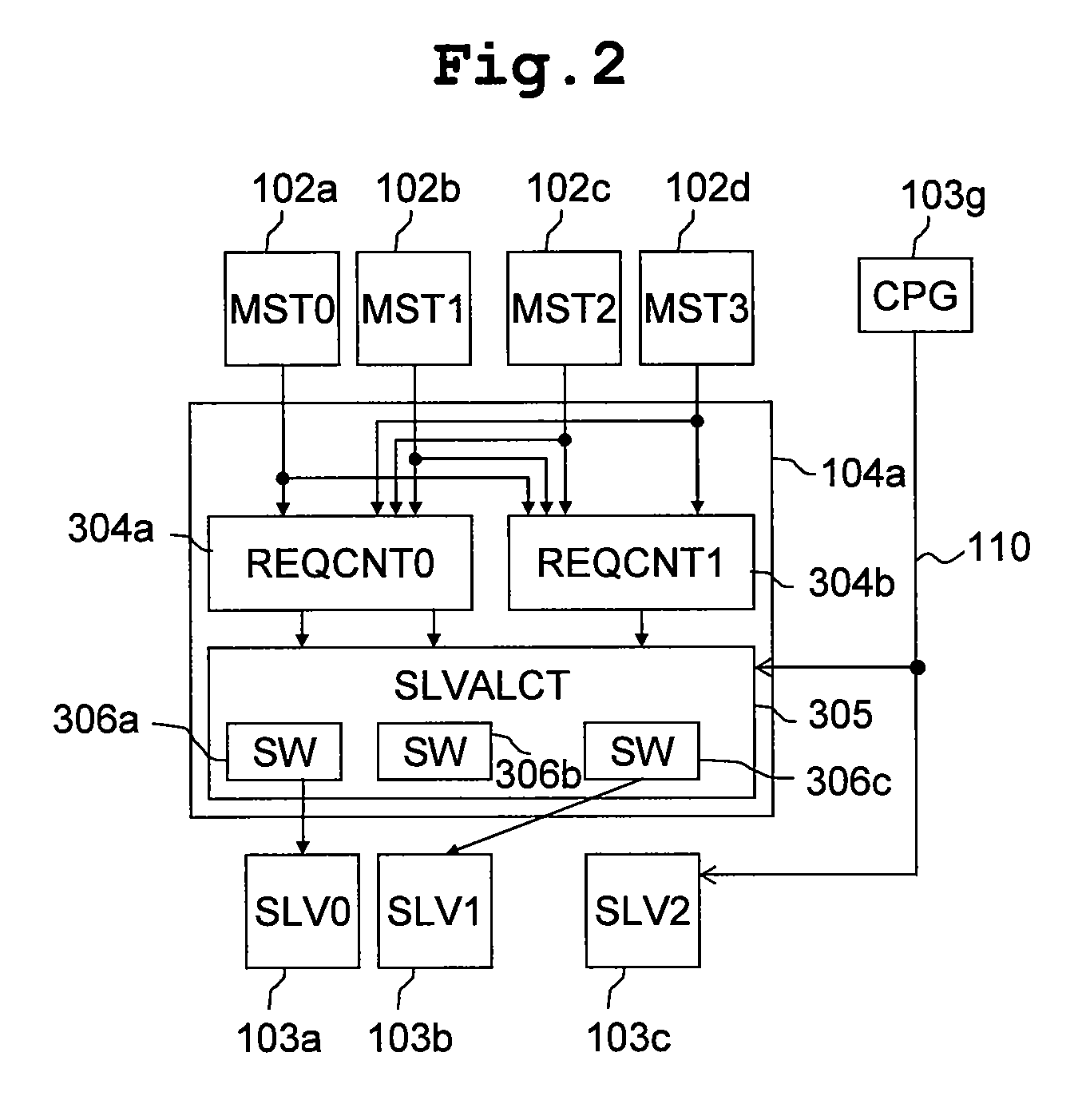

Semiconductor device

InactiveUS7984215B2Suppress decrease in bus throughput and data-processing throughputReduce in quantityMultiplex system selection arrangementsCircuit switching systemsPower semiconductor deviceControl circuit

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com