Bone implant

A bone implant and porous material technology, applied in the field of prosthesis, can solve the problems of complicated operation, long operation time, and poor support ability, and achieve the effect of convenient operation, short operation time and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

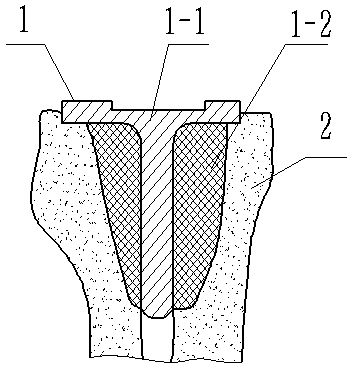

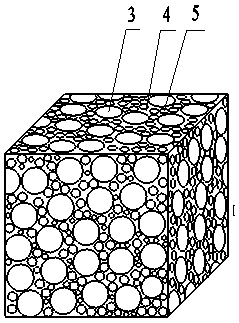

[0027] A bone implant, including a porous material, including a metal stem inside the porous material, growth factors and medicines contained in the bone implant, the porous material is a whole, the porous material is a hierarchical porous material, graded The number is two levels, the diameter of the large hole is 150µm-400µm, and the small hole is a nanoscale hole with a diameter of 5nm-400nm. The material is carbonyl apatite, and the metal stem is made of CoCrMo alloy. The preparation method of this kind bone implant is:

[0028] a. Partial preparation of hierarchically porous materials

[0029] Carbonylapatite powder with a particle size of 50nm-80nm is used as raw material, methyl cellulose with a particle size of 10nm-500nm is used as a pore-forming agent, and polystyrene with a particle size of 10nm-500nm is used as a binder According to carbonyl apatite powder: methylcellulose: polystyrene: distilled water in a volume ratio of 3:1:1:10 to prepare a slurry; using pol...

Embodiment 2

[0036] This example is similar to Example 1, except that the porous material is prepared with tricalcium phosphate, and the aperture of the small pores is 600nm-999nm. The porosity of the porous tricalcium phosphate is tested by direct observation of the cross section, which only contains small pores. The porosity of the material is 90%. The metal stem is made of medical titanium alloy TC4, and the metal stem is made of porous niobium material with nanopores. The pores are interconnected, the pore size is 20nm-60nm, and the porosity is 30%.

[0037] The preparation method of the metal stem is: select the medical titanium alloy TC4 powder with a particle size of 10µm-30µm, take austenitic stainless steel as the substrate for the titanium alloy TC4 powder to adhere to, and polish the substrate with metallographic sandpaper and polishing paste. Then pickling and organic solvent cleaning to remove surface oil, and finally ultrasonic cleaning in alcohol, take out and dry in a dryin...

Embodiment 3

[0039] This example is similar to Example 1, except that the hierarchically porous material is made of pure titanium, and the aperture of the small pores is 300 nm-600 nm. The porosity of the hierarchically porous titanium is tested by direct observation of the cross section, which only contains small pores The porosity of the material is 72%, and the pore diameter of the large pores is 200µm-500µm; the metal stem is made of medical stainless steel 316L, and the metal stem is made of porous medical stainless steel 316L with nanopores. The pores are interconnected and the pore diameter is 50nm -80nm, the porosity is 42%. The preparation method is similar to that of Example 2, except that the particle size of the stainless steel powder is 40µm-60µm, methylcellulose with a particle size of 70nm-100nm is added to the stainless steel powder, the volume is 1 / 7 of the stainless steel powder, and the nitrogen flow rate is 3L / min, the moving speed of the worktable is 15mm / s, the conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com