Pouring furnace base and constructing method for heating furnace

A construction method and heating furnace technology, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of poor support strength and pressure resistance, short life, reduced production efficiency, etc., and achieve support strength and pressure resistance. Strong, long service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

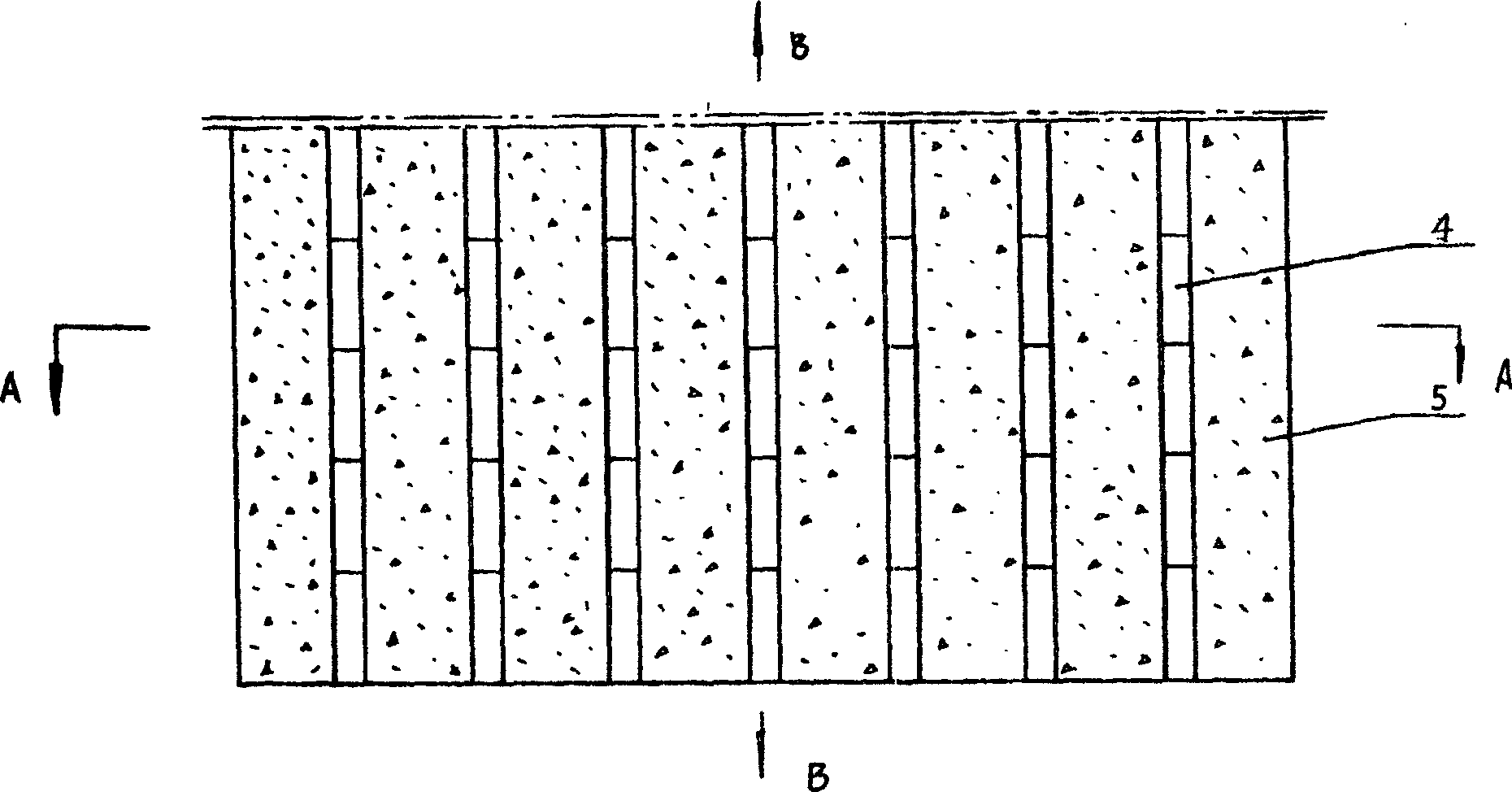

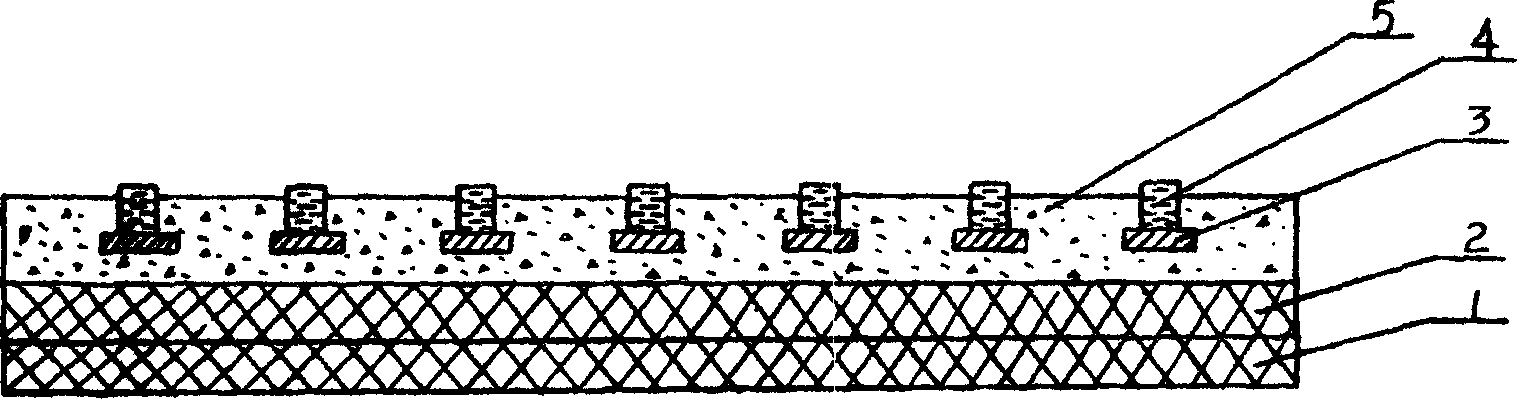

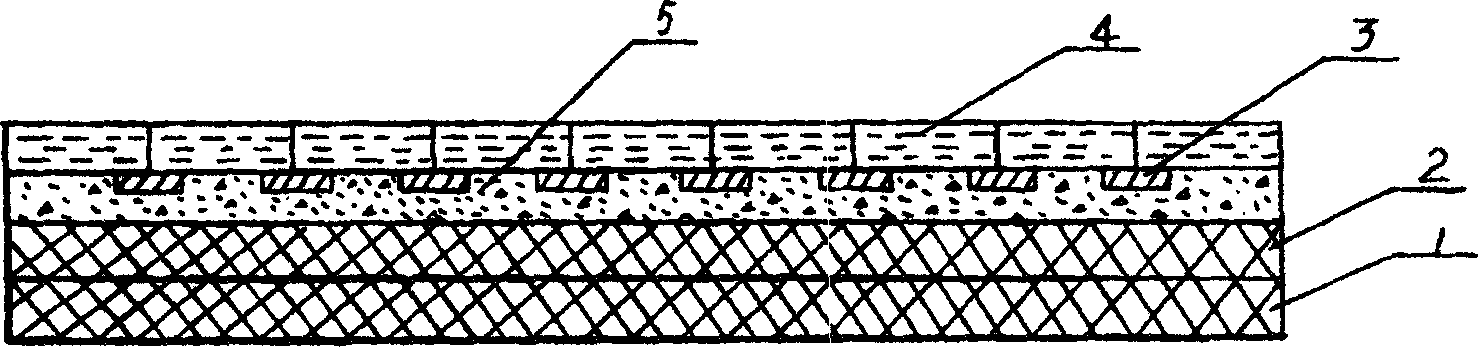

Image

Examples

Embodiment 1

[0032] In the rolling mill of Shandong Taishan Iron and Steel Co., Ltd., a high-efficiency regenerative blast furnace gas heating furnace, in July 2003, a "bulging" phenomenon occurred on the side wall of the heating furnace, which affected the pushing steel and had to be shut down for maintenance. When the construction period is tight and the task is heavy, this method is used to repair the furnace bottom in the soaking section. Only the furnace bottom repair is required, and the construction period is only 1 day, which is 10 days shorter than the conventional furnace repair process and saves material costs by nearly 30. The direct economic benefit is nearly 4 million yuan. After the furnace was started for production, the oxidation burning rate decreased by one percentage point, the accumulation of oxide scale on the bottom of the furnace was significantly reduced, the cleaning cycle was increased from 15 days to half a year, and the labor intensity of workers was significantl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com