Bumper lower stiffener with improved performance using ultra high strength steel pipe and manufacturing method thereof

A technology of reinforcing materials and manufacturing methods, applied in bumpers, vehicle parts, vehicle safety arrangements, etc., can solve problems such as damaged vehicle repair costs, refrigeration module damage, bumper damage, etc., to improve effectiveness, improve performance, minimize effect of chemical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

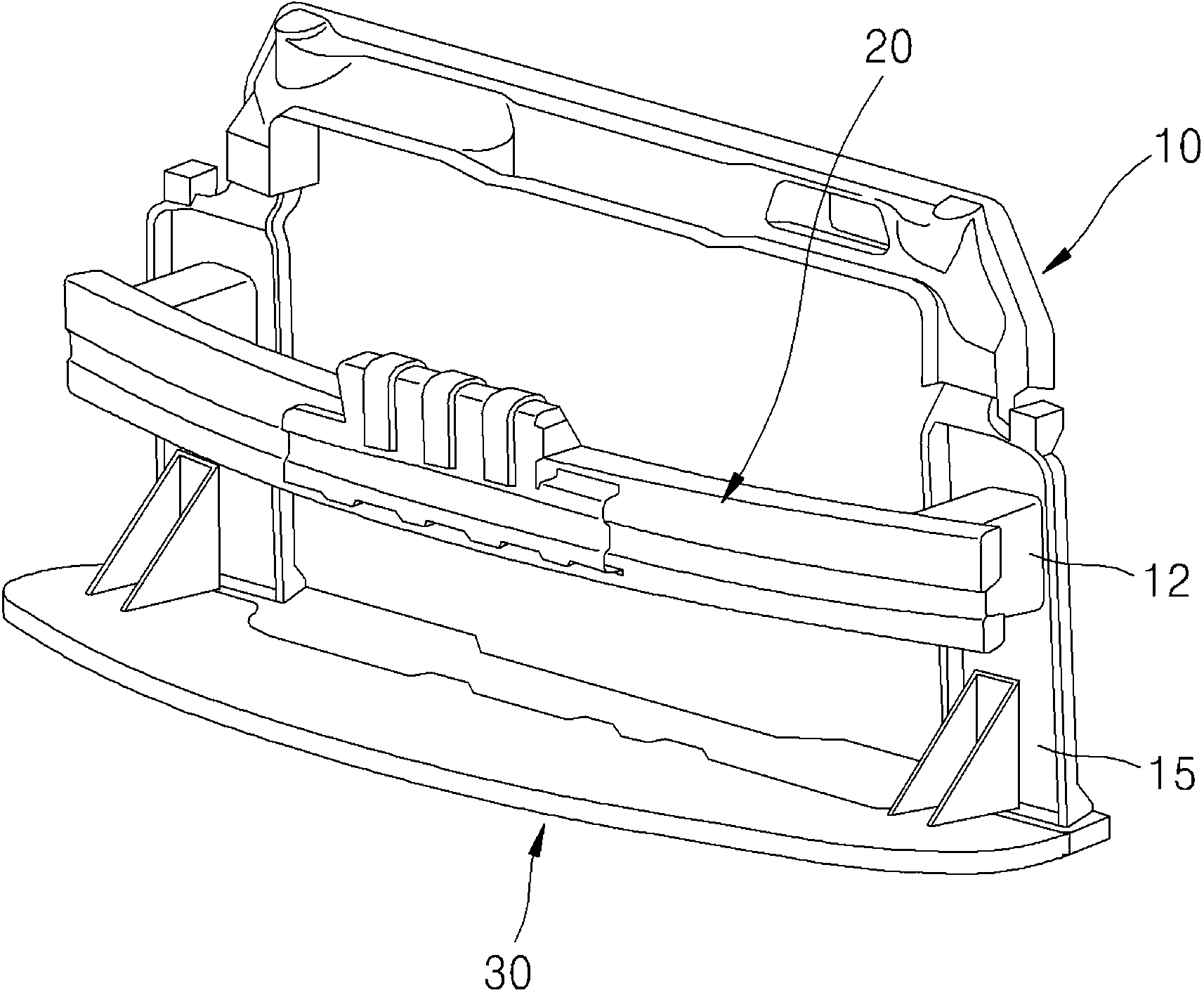

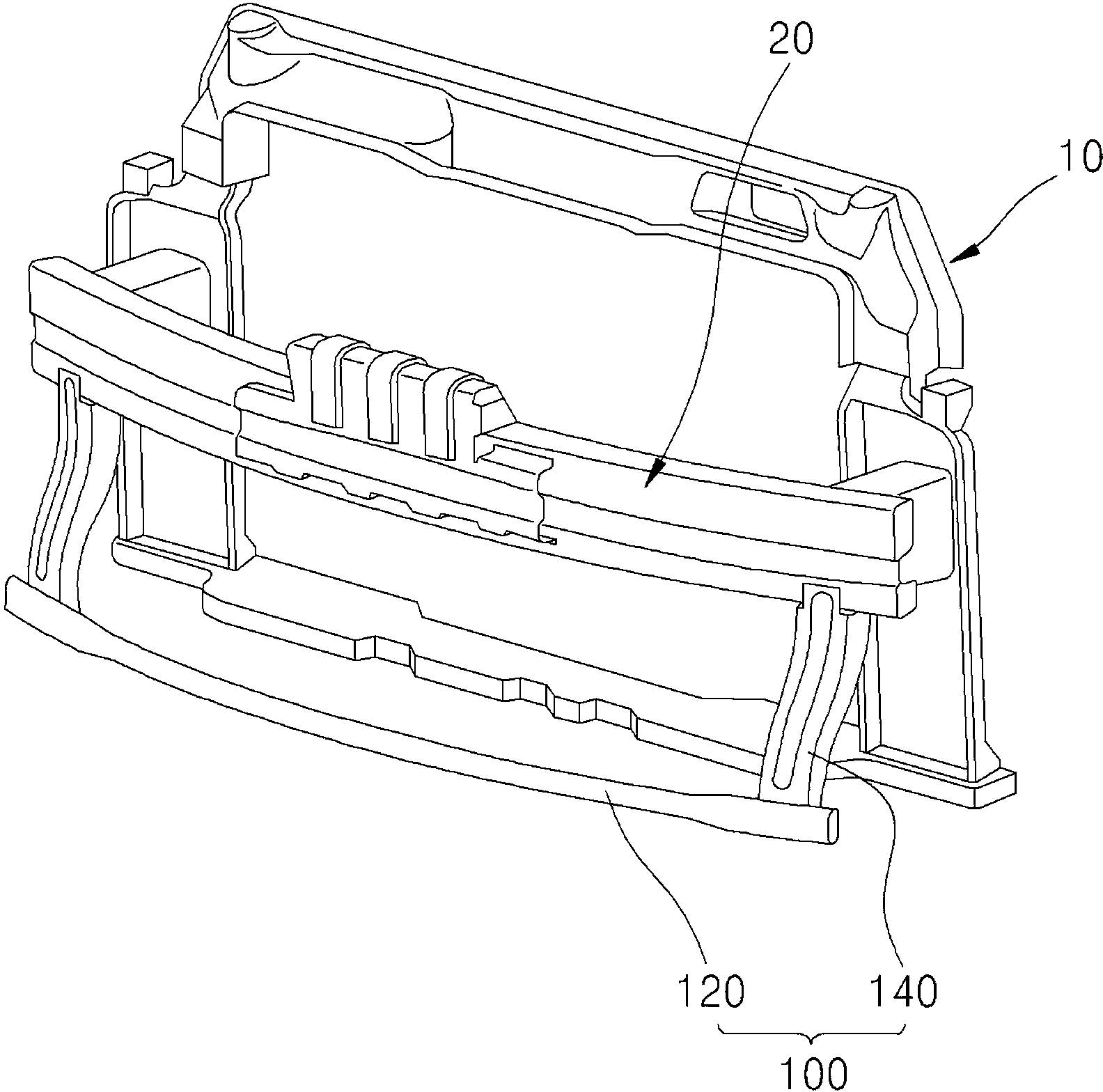

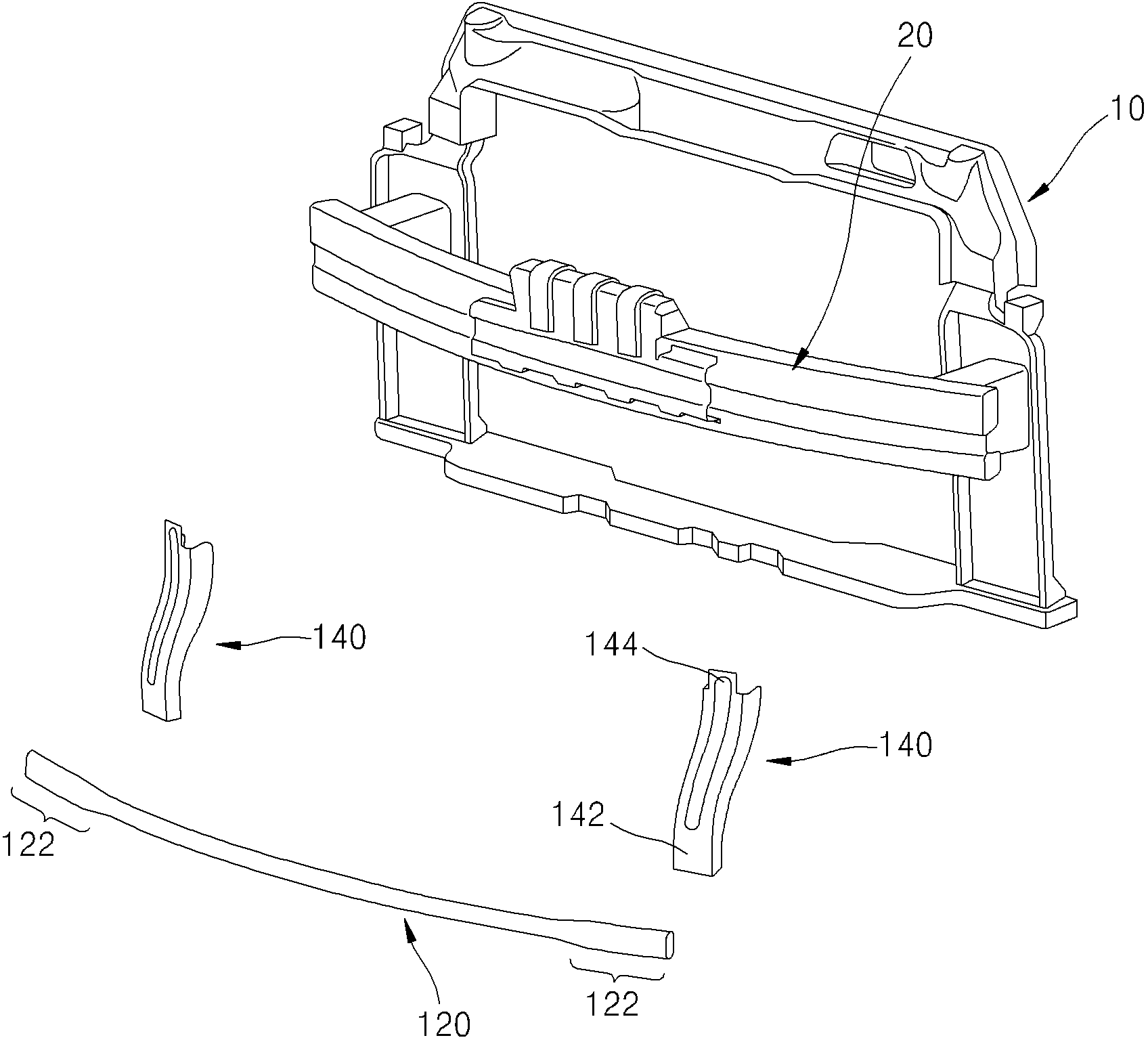

[0034] Hereinafter, a bumper lower reinforcing material whose performance is improved by utilizing the ultra-high strength steel pipe of the present invention and a method of manufacturing the same will be described in detail with reference to the accompanying drawings.

[0035] Advantages and features of the present invention, and methods for realizing them will become clear with reference to the accompanying drawings and detailed embodiments described later. However, the present invention is not limited to the embodiments disclosed below, and can be embodied in various forms that are different from each other. This embodiment only completes the disclosure of the present invention, in order to fully inform those of ordinary skill in the technical field to which the present invention belongs. The scope of the claims is provided, and the present invention is defined only by the scope of the claims. The same reference numerals refer to the same structural elements throughout the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com