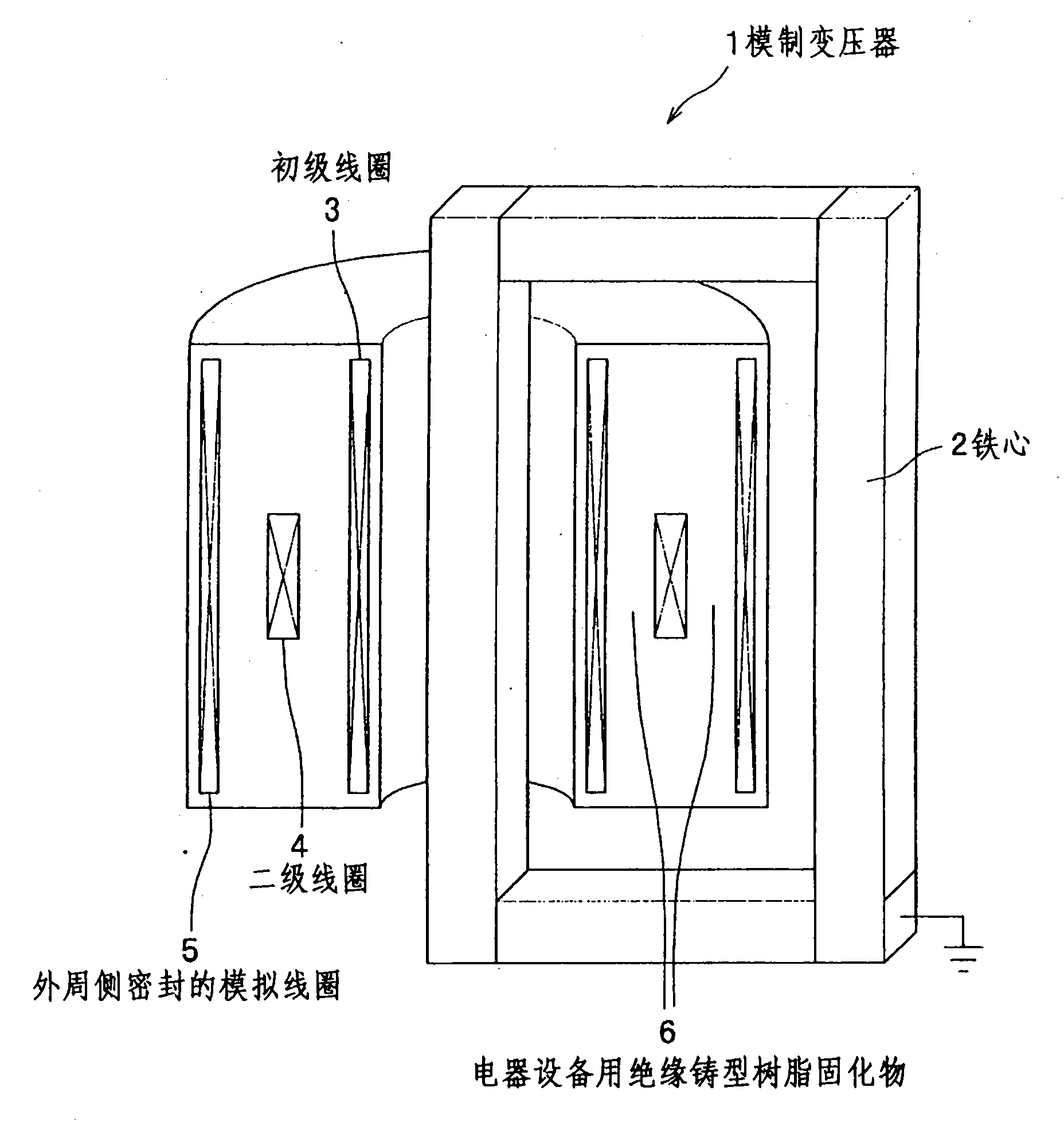

Cast insulation resin for electric apparatus and high voltage electric apparatus using the same

A technology for electrical equipment and casting resin, which is used in the fields of insulating casting resin and high-voltage electrical equipment, can solve the problems of failing to improve the failure toughness of resin, failure toughness, and failure to improve the resin itself. The effect of suppressing the occurrence of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In Example 1, in order to confirm the effect of the fine elastomer particles, an insulating casting resin (resin main ingredient) for electrical equipment was produced with the materials and addition amounts shown in Table 1.

[0083] Table 1 shows the types and amounts of materials constituting the main resin ingredients. The epoxy resins shown in Table 1 have a typical bisphenol A structure and have two epoxy groups in one molecule of the monomer. As the inorganic compound, pulverized silica (average particle diameter: 50 μm) was used in a large amount (450 parts by weight). In addition, aluminum hydroxide as an anti-sedimentation agent was added in an amount of about 5 parts by weight. In addition, in Table 1, the curing agent is also described together. As a curing agent, phthalic anhydride which is an acid anhydride is used.

[0084] Table 1

[0085]

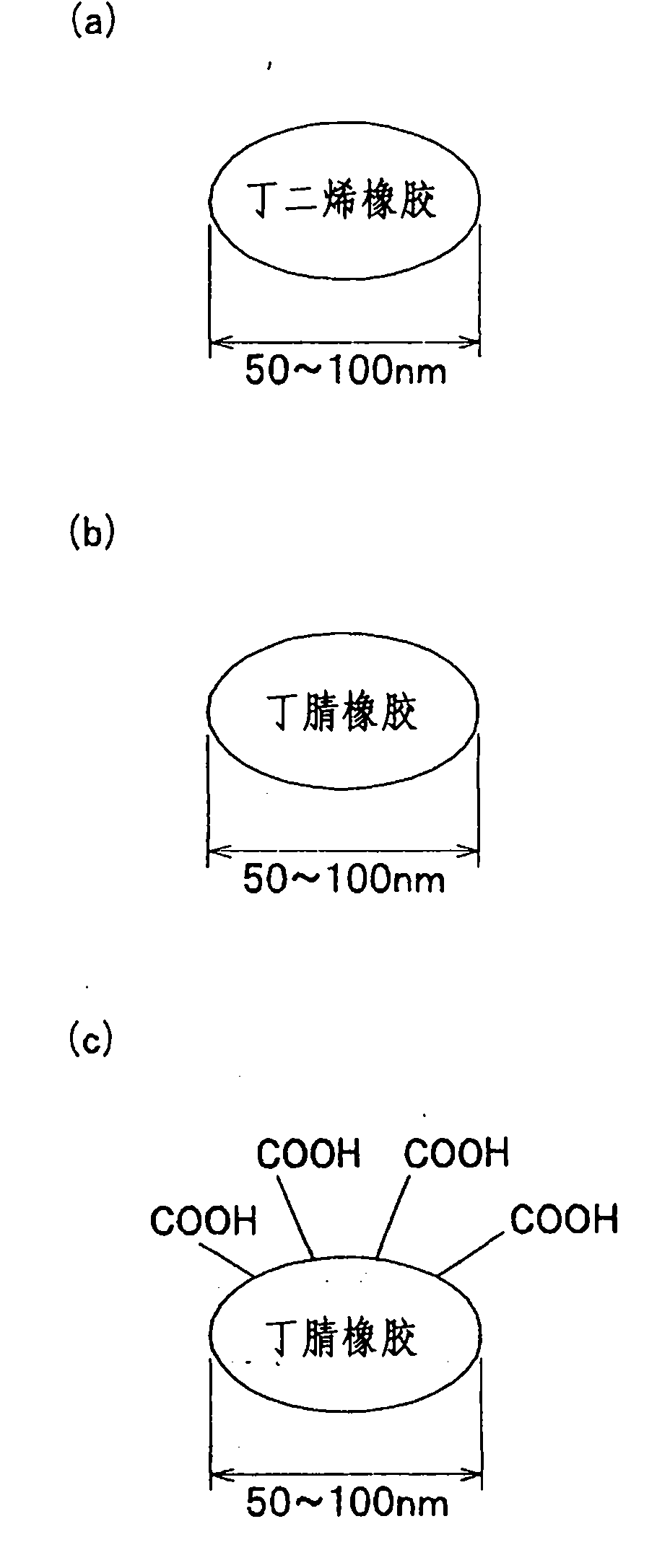

[0086] Furthermore, three types of fine elastomer particles shown in Table 2 were prepared and added to the...

Embodiment 2

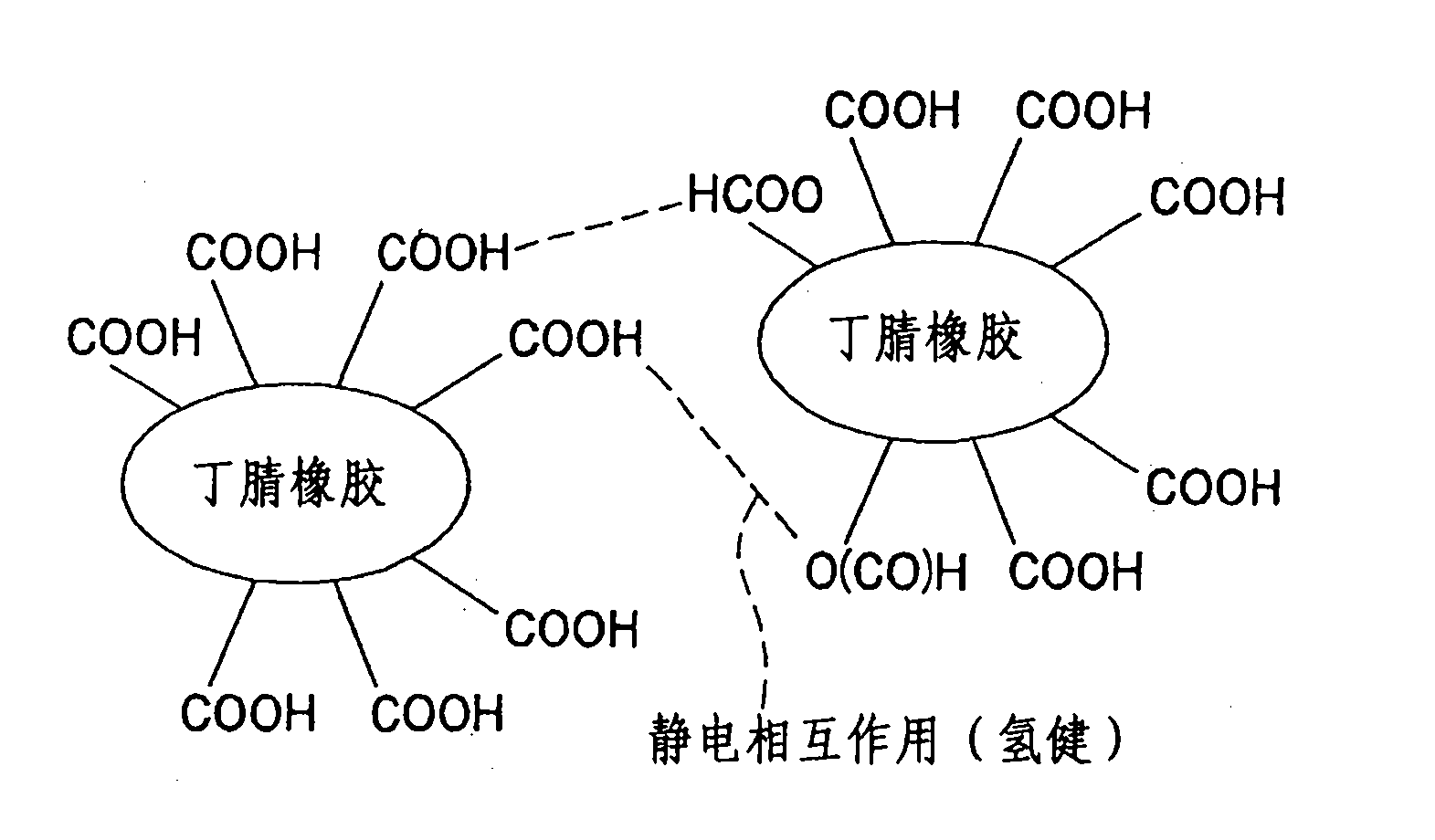

[0108] In Example 2, fine elastomer particles of nitrile rubber and nitrile rubber surface-modified with carboxyl groups were used. For Example 2, utilize the same method as Example 1 to measure the fracture toughness. As a result, the fracture toughness value (Klc) in Example 2 is less than 2 in relative value with respect to the test piece that the above-mentioned resin main agent (A) is cured into. times. The Pauling electronegativity of N contained in nitrile rubber is 3.04, and that of O is 3.44. Both are values higher than 2.55 of C, and this is one of the reasons for attaching high polarity to the cyano group and carboxyl group in the molecule. Similarly, it was remarkably shown that the same effects as in Example 1 could be obtained by introducing acrylic acid groups, acid anhydrides, and methacrylic acid groups. The Pauling electronegativity is shown in Table 4. As shown in Table 4, it is considered that by introducing any element having a Pauling electronegativi...

Embodiment 3

[0113] As used in Example 1 above, the linear expansion coefficient can be lowered by kneading the pulverized silica into the main resin. The linear expansion coefficient of the bisphenol A type epoxy resin (being resin main agent (A)) that does not add silica is 60 * 10 -6 / K or so, but can be reduced to 20~30×10 by adding silica -6 / K (Example 3). That is, the coefficient of linear expansion of metals (aluminum oxide, copper, etc.) can be approximated. Therefore, it can interact with the effect of improving fracture toughness by adding fine elastomer particles, and suppress the occurrence of cracks in insulating resins used for electrical equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com