Thin brazing sheet fin component for high temperature brazing and method for manufacturing heat exchanger using the same

A technology of heat exchangers and brazing plates, applied in heat exchange equipment, manufacturing tools, welding/welding/cutting items, etc., can solve problems such as changing the direction of brazing configuration, end deformation, abnormal end deformation, etc., to achieve Prevents reduction in product value, prevents deformation from being dumped, and improves production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

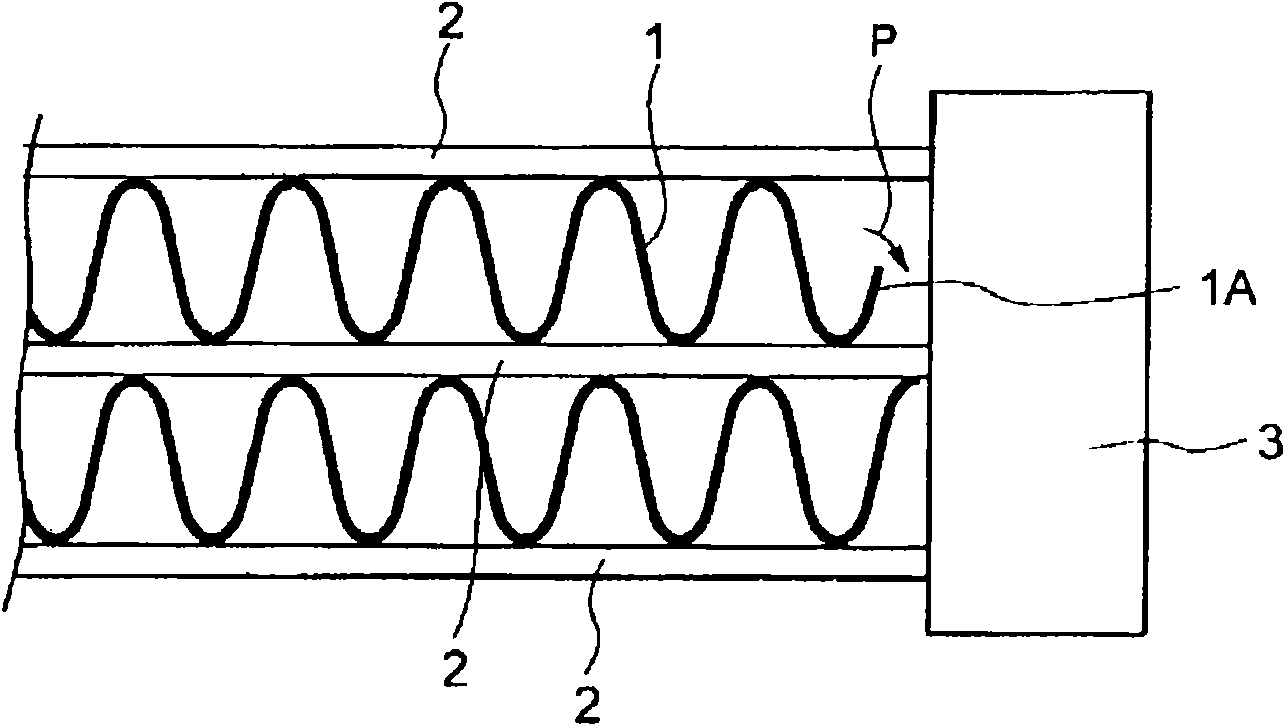

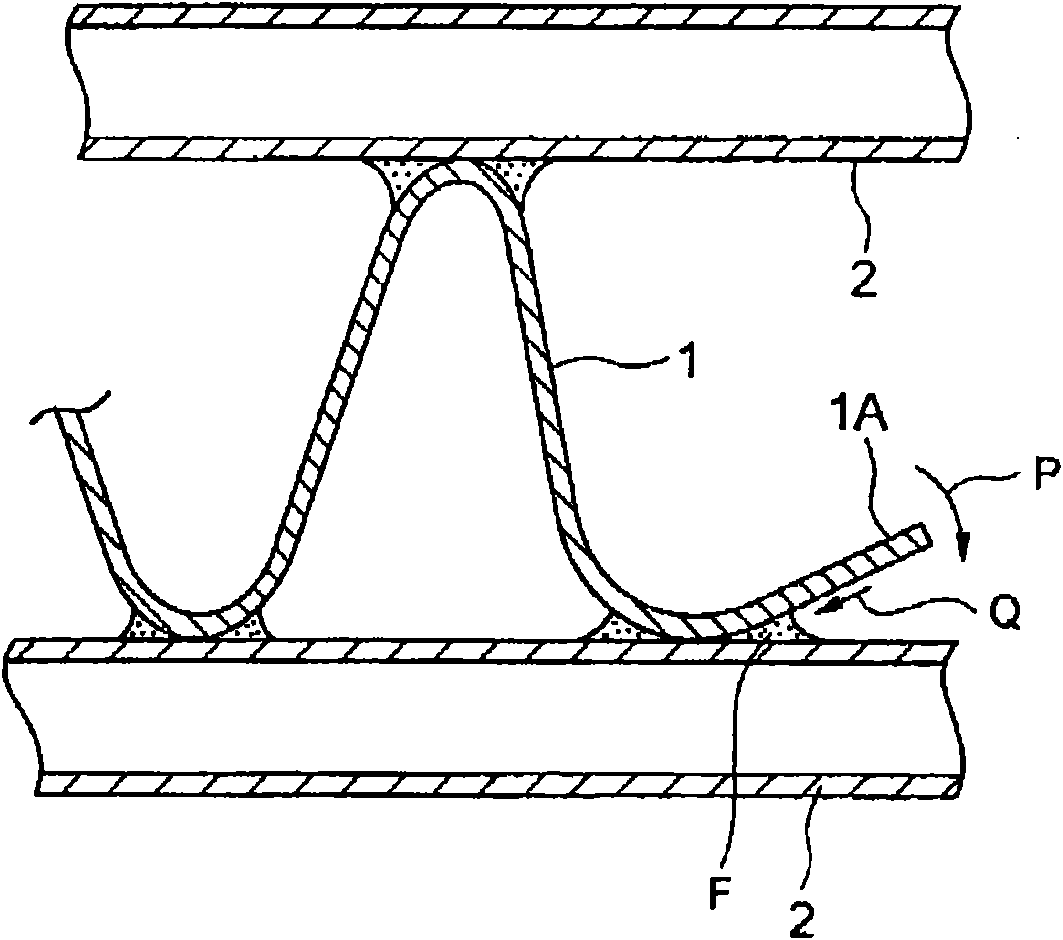

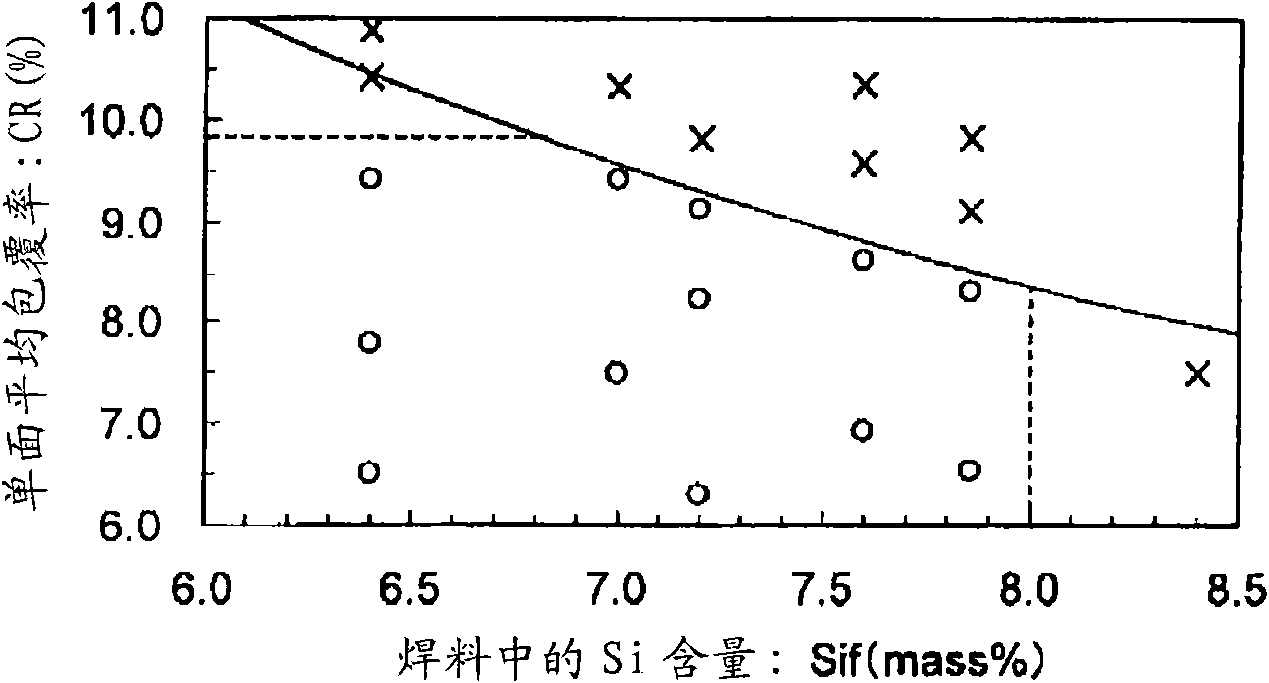

[0083] This Example 1 is equivalent to a preliminary research result, and is used to determine the conditions such as the Si content in the solder necessary to prevent the deformation of the fin end and the average coverage rate of the single side of the brazing material.

[0084] In the first embodiment, the core material used Al-1.1mass%Mn-0.35mass%Si-0.4mass%Fe alloy, and the core material is made of solder made of Al-Si-based alloy, 70μm For thick brazing plate fin parts, various changes are made to the Si content and cladding ratio of Al-Si alloys. The content of Fe in the solder is within the range of 0.2 to 0.25 mass%. In addition, in order to suppress the formation of coarse Si particles, Na is added at about 0.003 mass% during casting. Here, the core material and the solder are produced by ordinary DC casting, and in the subsequent steps, the usual methods, namely, clad bonding by hot rolling, cold rolling, and intermediate annealing are also used.

[0085] In order to in...

Embodiment 2

[0090] In this Example 2, more conditions were changed in various ways.

[0091] First, the core material having the composition shown in Table 1 and the solder shown in Table 2 were respectively subjected to DC casting by a conventional method, and homogenized. Here, in the casting of the solder, the refining treatment of Si particles in which Na and Sr are added under predetermined conditions is performed. The hot-rolled solder is made to have a predetermined thickness, is laminated on the surface and the back of the core material ingot that has been cut on the surface, and is further hot-rolled to perform clad bonding. After that, cold rolling, intermediate annealing, and final cold rolling were performed to produce a clad member (brazed plate fin member) with a predetermined thickness. Table 3 shows the material composition of the brazing plate fin member as the clad member.

[0092] The cross section in the thickness direction along the length direction of the fin member was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com