Thin brazing sheet fin component for high temperature brazing and method for manufacturing heat exchanger using the same

A heat exchanger and brazing plate technology, applied in heat exchange equipment, manufacturing tools, applications, etc., can solve the problems of changing the brazing arrangement direction, abnormal deformation of the end, deformation of the end, etc., to prevent the reduction of commodity value , The effect of preventing dumping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

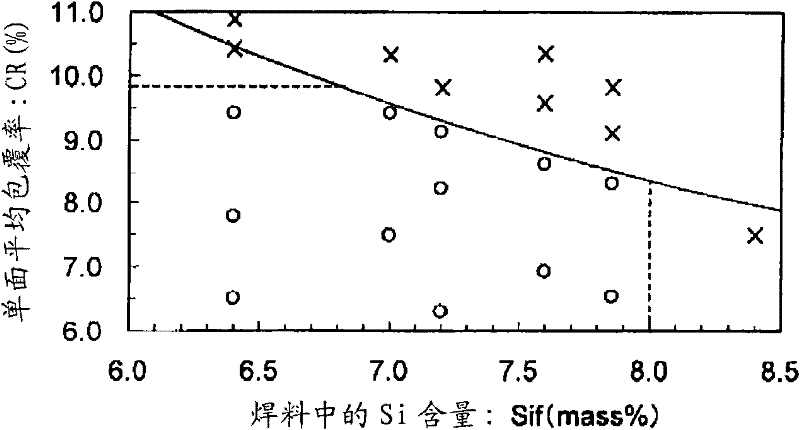

[0083] This Example 1 is equivalent to a preliminary research result, which is used to obtain conditions such as the Si content in the solder and the average coating ratio of one side of the brazing material necessary to prevent deformation of the fin end.

[0084] In Example 1, an Al-1.1mass%Mn-0.35mass%Si-0.4mass%Fe alloy was used as the core material, and a 70μm A thick brazing sheet fin member in which the Si content and coating ratio of an Al-Si alloy are variously changed. The content of Fe in the solder is in the range of 0.2 to 0.25 mass%, and in addition, in order to suppress the formation of coarse Si particles, about 0.003 mass% of Na is added during casting. Here, the core material and the solder are produced by normal DC casting, and in subsequent steps, the usual methods of cladding joining by hot rolling, cold rolling, and intermediate annealing are also used.

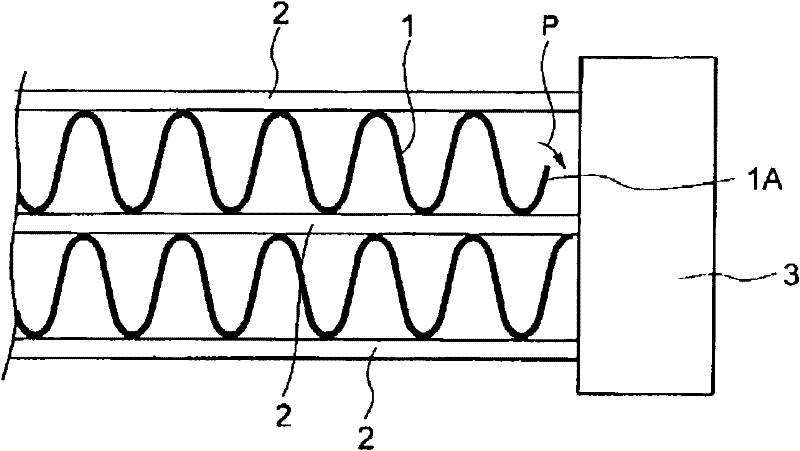

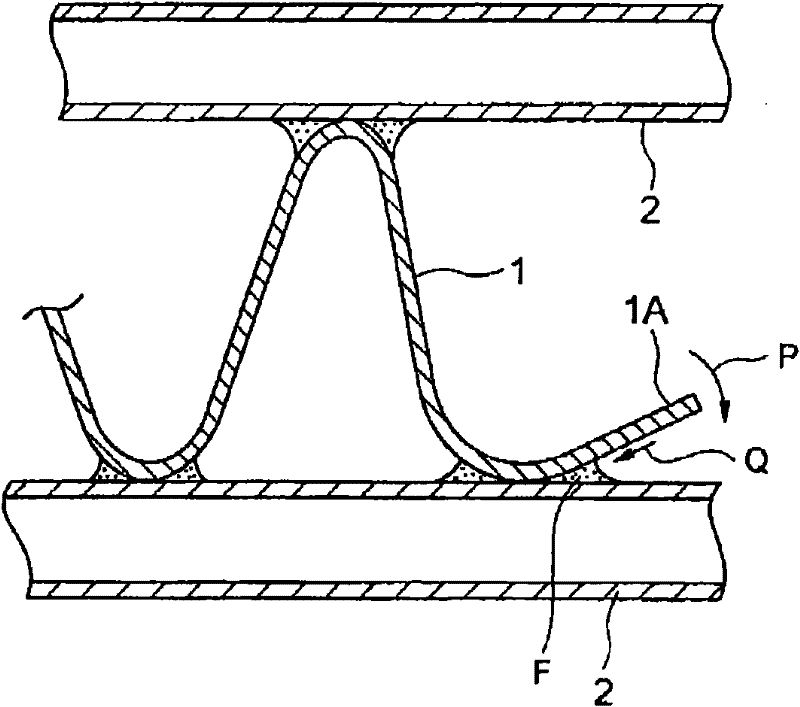

[0085] In order to investigate the deformation of the fin end, corrugated brazing plate fin parts wi...

Embodiment 2

[0090] In this Example 2, more conditions were changed variously.

[0091] First, the core material having the composition shown in Table 1 and the solder shown in Table 2 were respectively DC casted and homogenized by a conventional method. Here, in the casting of the solder, Si particle miniaturization treatment was performed by adding Na and Sr under predetermined conditions. The solder is hot-rolled to a predetermined thickness, laminated on the front and back surfaces of the surface-cut core material ingot, and further hot-rolled to perform cladding joining. Thereafter, cold rolling, intermediate annealing, and final cold rolling were performed to produce a clad member (brazing sheet fin member) having a predetermined thickness. Table 3 shows the material composition of the brazing sheet fin member as the covering member.

[0092] The cross-section in the thickness direction along the longitudinal direction of the fin member was observed with an optical microscope, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com