High-strength cold-rolled steel plate having excellent deep drawability and in-coil material uniformity, and method for manufacturing same

一种冷轧钢板、制造方法的技术,应用在制造工具、金属轧制、炉等方向,达到操作性提高、卷材内材质均匀性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

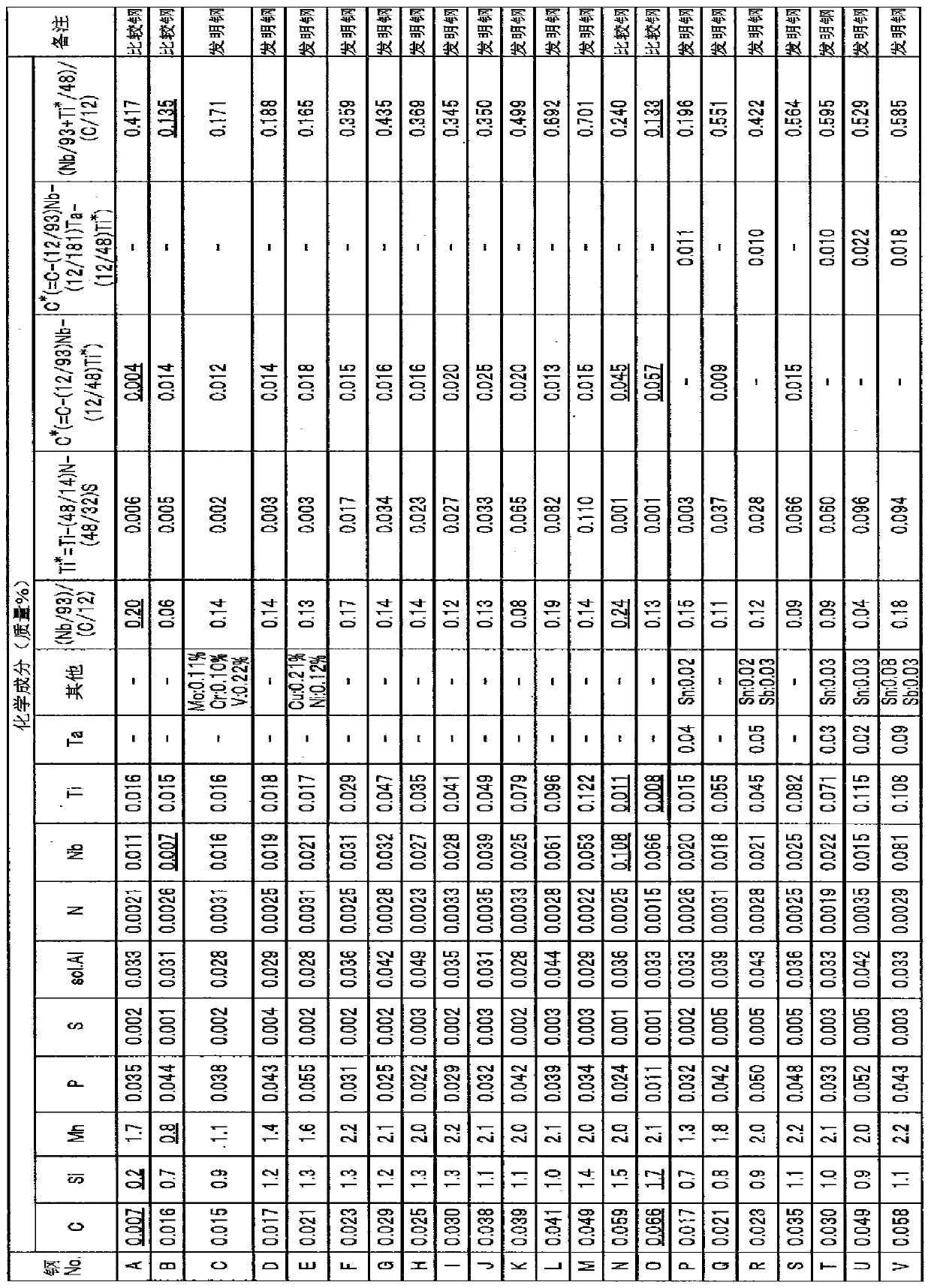

[0148] Hereinafter, the present invention will be further described by way of examples.

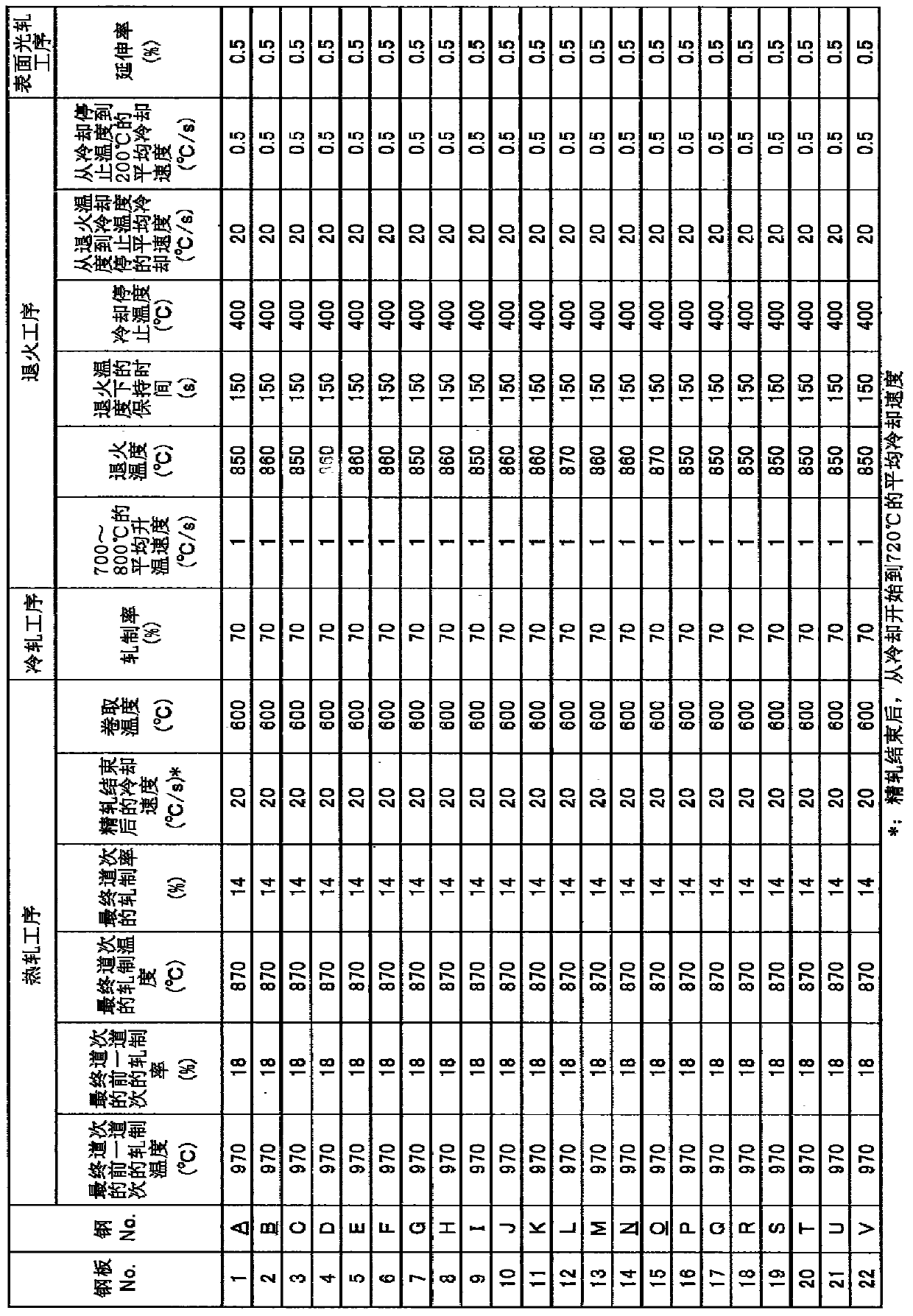

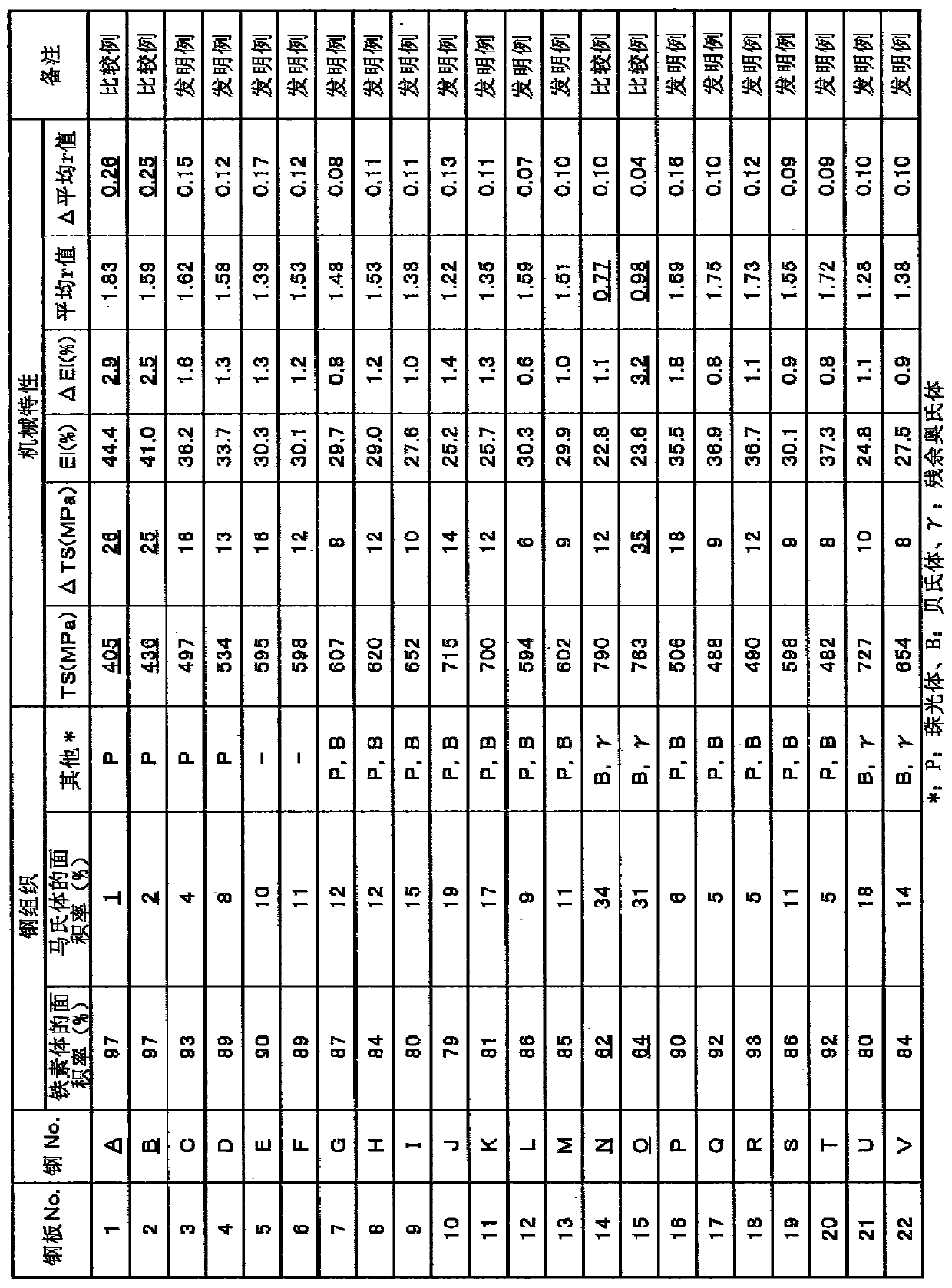

[0149] Molten steel having the composition shown in Table 1 was melted in a converter and formed into slabs by continuous casting. These steel slabs were heated to 1220° C., hot-rolled, and coiled to form a hot-rolled sheet having a thickness of 4.0 mm. In addition, the rolling temperature and rolling ratio of the final pass and the pass preceding the final pass of the above-mentioned hot rolling, the average cooling rate from the beginning of cooling to 720°C after the finish rolling, and the coiling temperature are shown in the table. 2. In addition, the time from the end of finish rolling to the start of cooling was within 3 seconds.

[0150] Next, the hot-rolled steel sheets obtained above were pickled, and then cold-rolled under the conditions shown in Table 2 to form cold-rolled steel sheets with a thickness of 1.2 mm. Next, continuous annealing was performed under the conditions...

Embodiment 2

[0167] Steels having the chemical compositions of steels D, G, and L shown in Table 1 were melted in a converter, and formed into steel slabs by continuous casting. These steel slabs were heated to 1220° C., hot-rolled, and coiled to form a hot-rolled sheet having a thickness of 4.0 mm. In addition, the rolling temperature and rolling ratio of the final pass and the pass preceding the final pass during the finishing rolling of the above-mentioned hot rolling, and the average cooling rate and coiling temperature from the beginning of cooling to 720°C after finishing rolling are shown in the table 4. In addition, the time from the end of finish rolling to the start of cooling was within 3 seconds.

[0168] Next, the obtained hot-rolled steel sheets were pickled and then cold-rolled under the conditions shown in Table 4 to form cold-rolled steel sheets with a thickness of 1.2 mm. Next, continuous annealing was performed under the conditions described in Table 4, and skin pass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com