Cold-rolled steel sheet, electrolytic zinc-coated cold-rolled steel sheet, hot-dip zinc-coated cold-rolled steel sheet, alloyed hot-dip zinc-coated cold-rolled steel sheet, and methods for producing said steel sheets

A technology of cold-rolled steel sheet and hot-dip galvanizing, applied in the field of cold-rolled steel sheet, can solve the problems of deterioration of deep drawability, improper crystal orientation, lack of rigidity, etc., and achieves improved workability, improved Young's modulus, The effect of improving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0175] The present invention will be described more specifically by giving examples of the cold-rolled steel sheet, zinc-based electroplated cold-rolled steel sheet, hot-dip galvanized cold-rolled steel sheet, alloyed hot-dip galvanized cold-rolled steel sheet and their production methods. The present invention is not limited to the following embodiments, and can be implemented with appropriate changes within the scope of meeting the above gist and the following gist, and these changes are all included in the technical scope of the present invention.

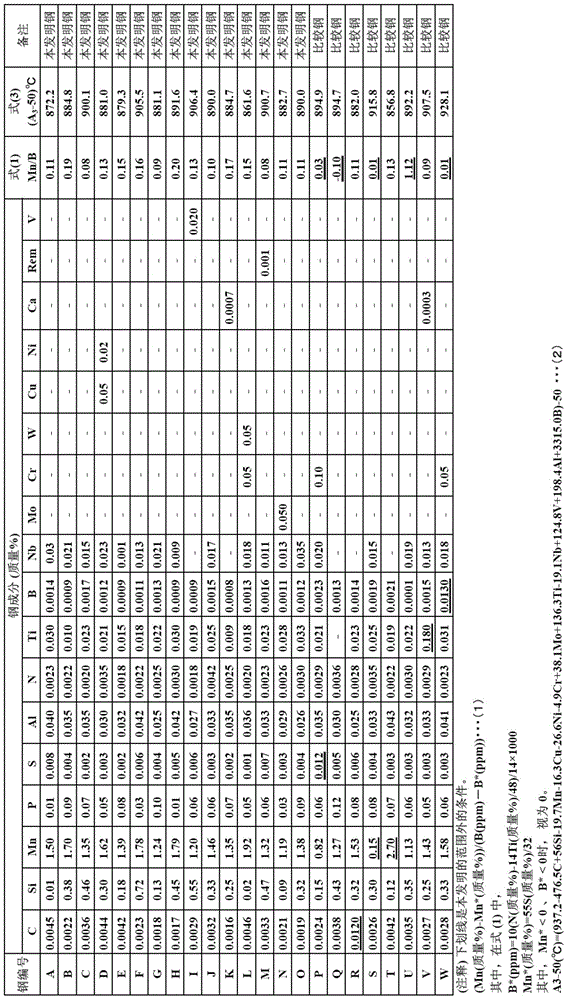

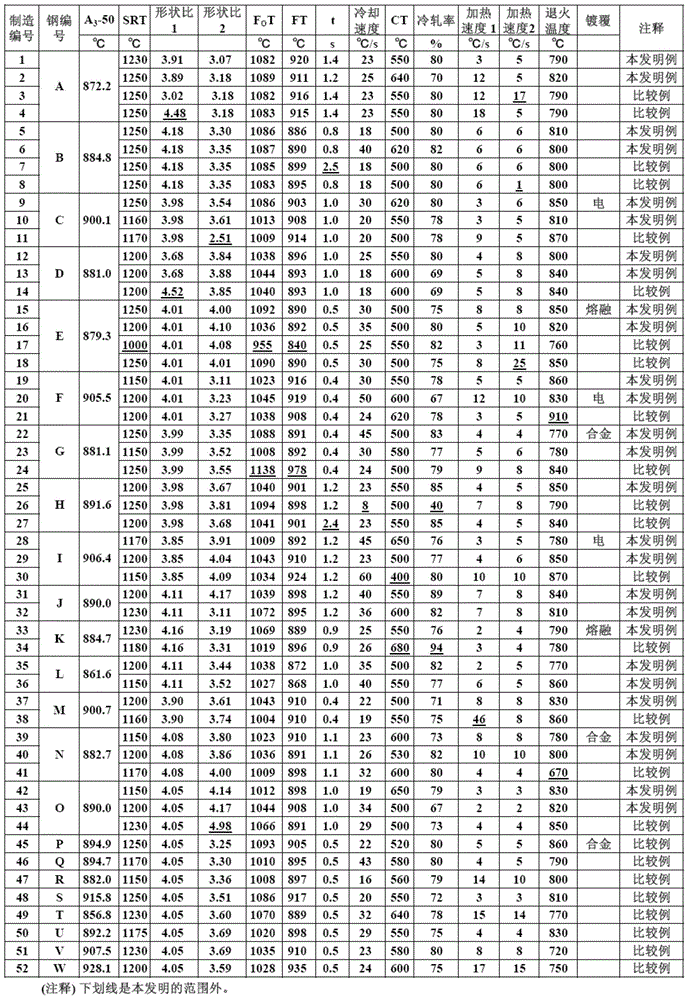

[0176] In this example, first, steel having the composition shown in Table 1 was melted to produce a billet. Each steel slab in Table 1 was heated and hot-rough rolled, and then finish rolled under the conditions shown in Table 2. The finishing rolling mill consists of 7 sections in total, and the roll diameter is 650-830mm. In addition, the final plate thickness after the final pass is 2.3 mm to 4.5 mm.

[0177] In Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com