Cu-Ni-Si copper alloy sheet with excellent deep drawability and process for producing same

A cu-ni-si, copper alloy plate technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of fatigue resistance changes, insufficient deep drawing processability, large deviation), etc., to achieve Less variation in fatigue resistance and excellent deep drawability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

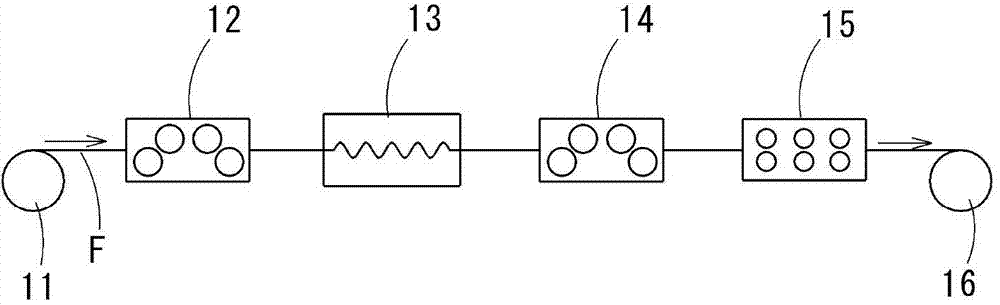

[0101] The materials were prepared to have the composition shown in Table 1, melted in a low-frequency melting furnace with a reducing atmosphere, and then cast into a copper alloy ingot with a thickness of 80 mm, a width of 200 mm, and a length of 800 mm. After heating this copper alloy ingot to 900-980 degreeC, the hot-rolled plate of thickness 11mm was formed by hot rolling, and after water-cooling this hot-rolled plate, the end faces of both surfaces were cut by 0.5 mm. Next, cold rolling is carried out at a rolling rate of 87% to produce a cold-rolled sheet with a thickness of 1.3mm, and then continuous annealing is carried out at 710-750°C for 7-15 seconds, followed by pickling and surface grinding. Furthermore, cold rolling was performed at a rolling reduction of 77% to produce a cold-rolled sheet having a thickness of 0.3 mm.

[0102] After maintaining the cold-rolled sheet at 710-780° C. for 7 to 15 seconds, it was quenched to implement solution treatment, and then ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com