Ferritic stainless steel sheet, method for producing same, and ferritic stainless steel member

A stainless steel and system technology, applied in the field of ferritic stainless steel plate and its manufacturing, and ferritic stainless steel components, can solve the problems of poor formability of stainless steel plate, limited use parts, limited use and part shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

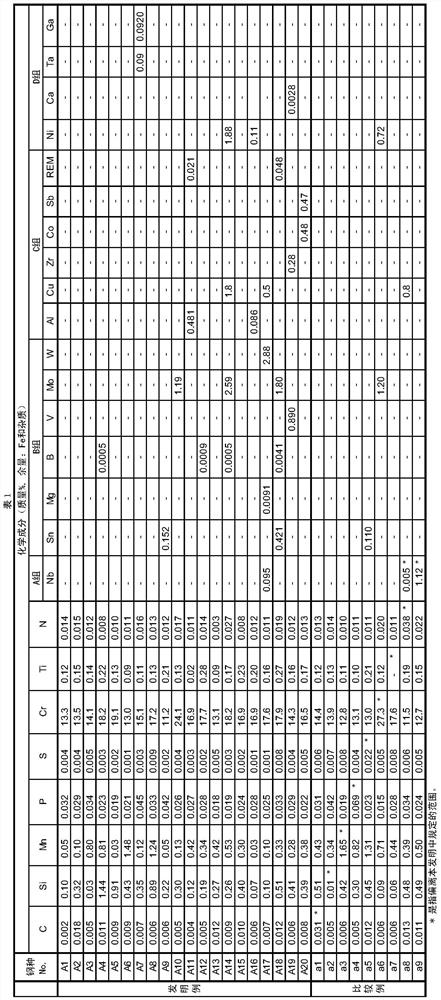

[0272] The steel with the composition shown in Table 1 was melted, cast into a slab, and hot-rolled under the conditions of a slab heating temperature of 1150°C and a coiling temperature of 500°C to produce a hot-rolled steel sheet.

[0273] [Table 1]

[0274]

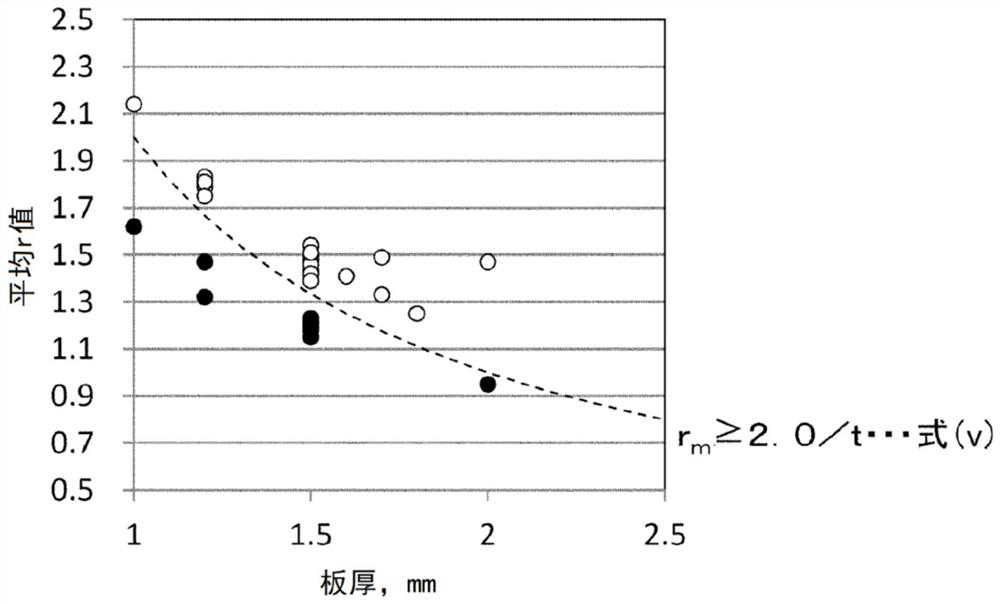

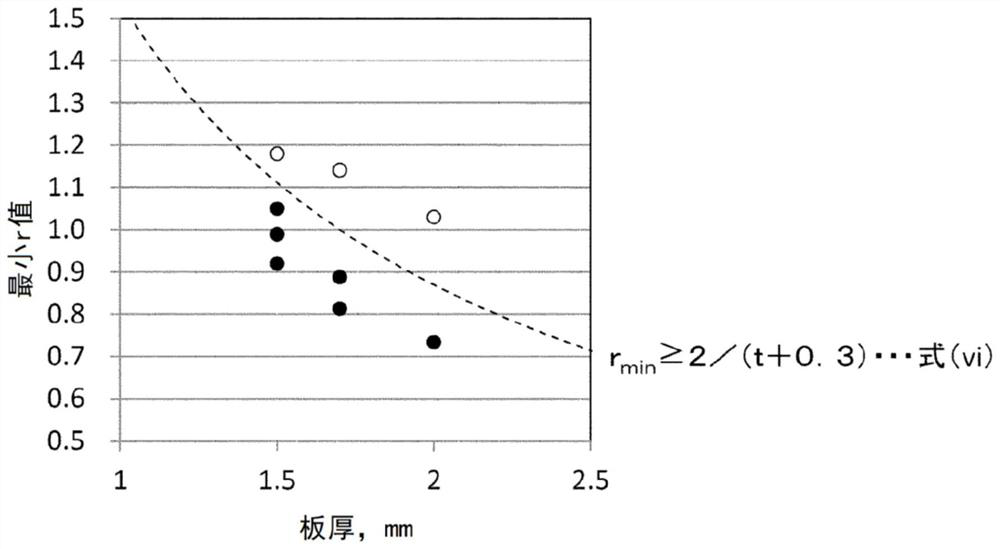

[0275] Thereafter, the pickled hot-rolled steel sheet was cold-rolled to the thickness shown in Table 2 using rolls with a diameter of 400 to 500 mm, and continuous annealing and pickling were performed. In this way, the r-value measurement and the crystal orientation strength measurement were performed on the obtained cold-rolled annealed sheet.

[0276] The r value was carried out by the method described above in accordance with JIS Z 2254. Test pieces were taken from directions parallel to the rolling direction, 45°, and 90° to obtain the r value, and then calculate the average r value. Specifically, the JIS13 No. B tensile test piece is taken, and the above-mentioned value is calculated by a predetermined metho...

Embodiment 2

[0284] Table 3 shows properties when the steel types described in Table 1 were produced under the production conditions shown in Table 3. Evaluation of formability was performed under the same conditions as in Example 1 by a cylindrical deep drawing test.

[0285] In Table 3, as in Table 2, the case where formability was possible was marked as ○, the case where necking occurred near the punch shoulder was marked as △, and the case where forming cracks occurred during the process was marked as ×.

[0286] [table 3]

[0287]

[0288] Examples C1 to C3 of the present invention shown in Table 3 have good r values and processability because their compositions are within the range specified by the present invention and the production conditions satisfy the preferred conditions in the present invention. On the other hand, the production conditions of Comparative Examples c1 to c6 deviated from the preferred production conditions in the present invention. Therefore, the crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com