Steel sheet for can, and method for manufacturing same

A manufacturing method and steel plate technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as cracks and low drawing formability, and achieve the effects of excellent drawing formability, low cost, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

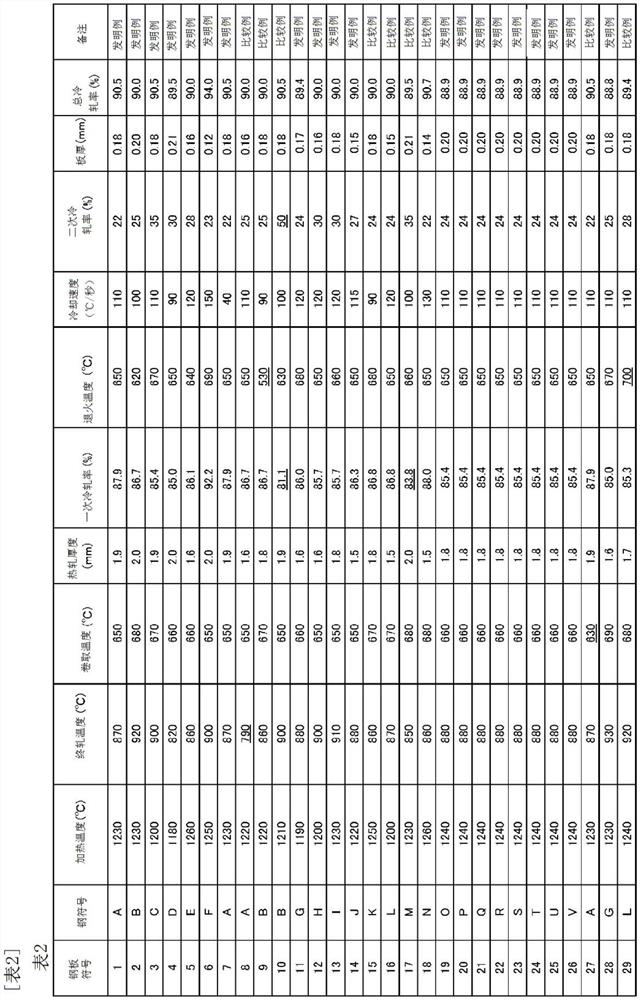

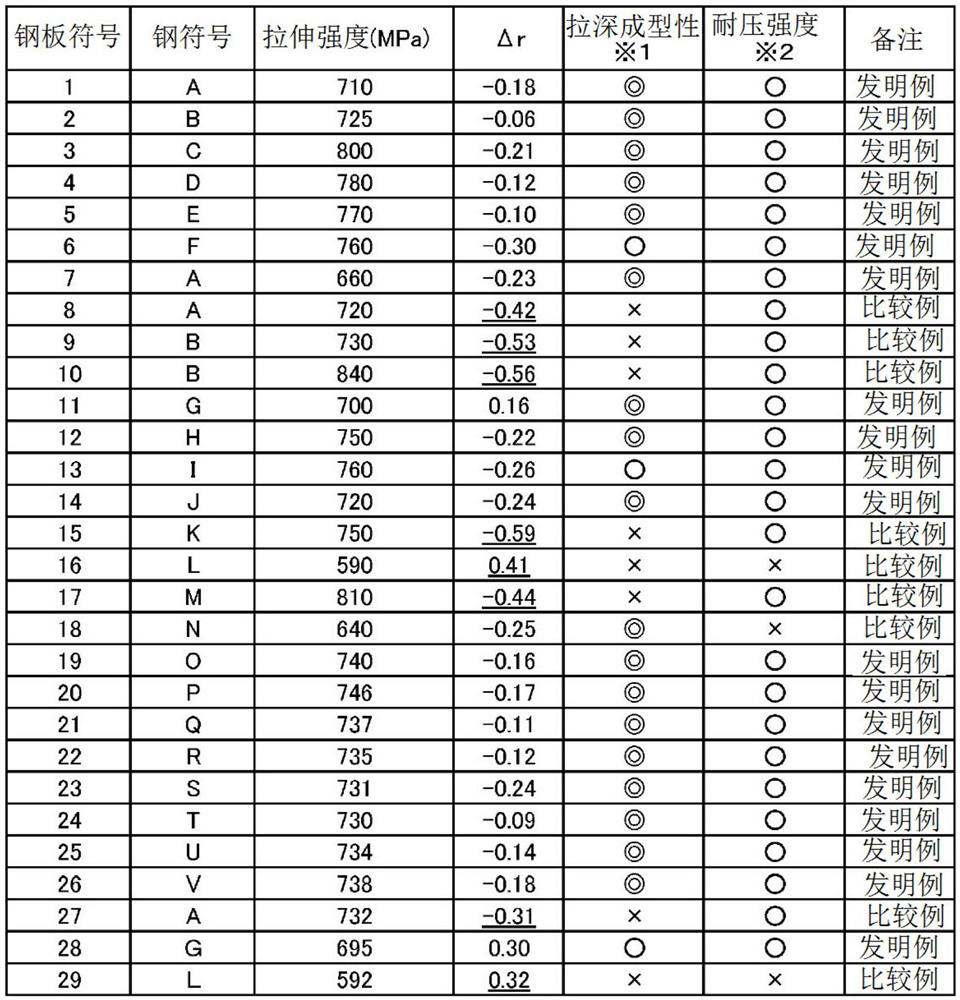

[0081] Steels containing the components of steel codes A to V shown in Table 1 and the remainder consisting of unavoidable impurities and Fe were melted to obtain billets. The obtained slabs were heated under the conditions shown in Table 2, followed by hot rolling and coiling, followed by pickling to remove scale, cold rolling once, and annealing at various annealing temperatures in a continuous annealing furnace. The obtained annealed sheet was subjected to secondary cold rolling at each secondary cold rolling ratio to obtain a steel sheet having a thickness of 0.12 to 0.22 mm (steel sheet codes 1 to 29).

[0082] [Table 1]

[0083] Table 1

[0084] steel symbol C Si mn P S Al N other Remark A 0.032 0.01 0.25 0.011 0.011 0.016 0.0151 - Invention example B 0.020 0.02 0.30 0.014 0.012 0.016 0.0139 - Invention example C 0.039 0.01 0.14 0.009 0.013 0.010 0.0163 - Invention example D 0.040 0.01 0.50 0.013 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com