Multilayer polyester film and transfer foil

A technology of polyester layer and polyester, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of high manufacturing cost and poor reusability, and achieve excellent mold release and solvent resistance , Excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

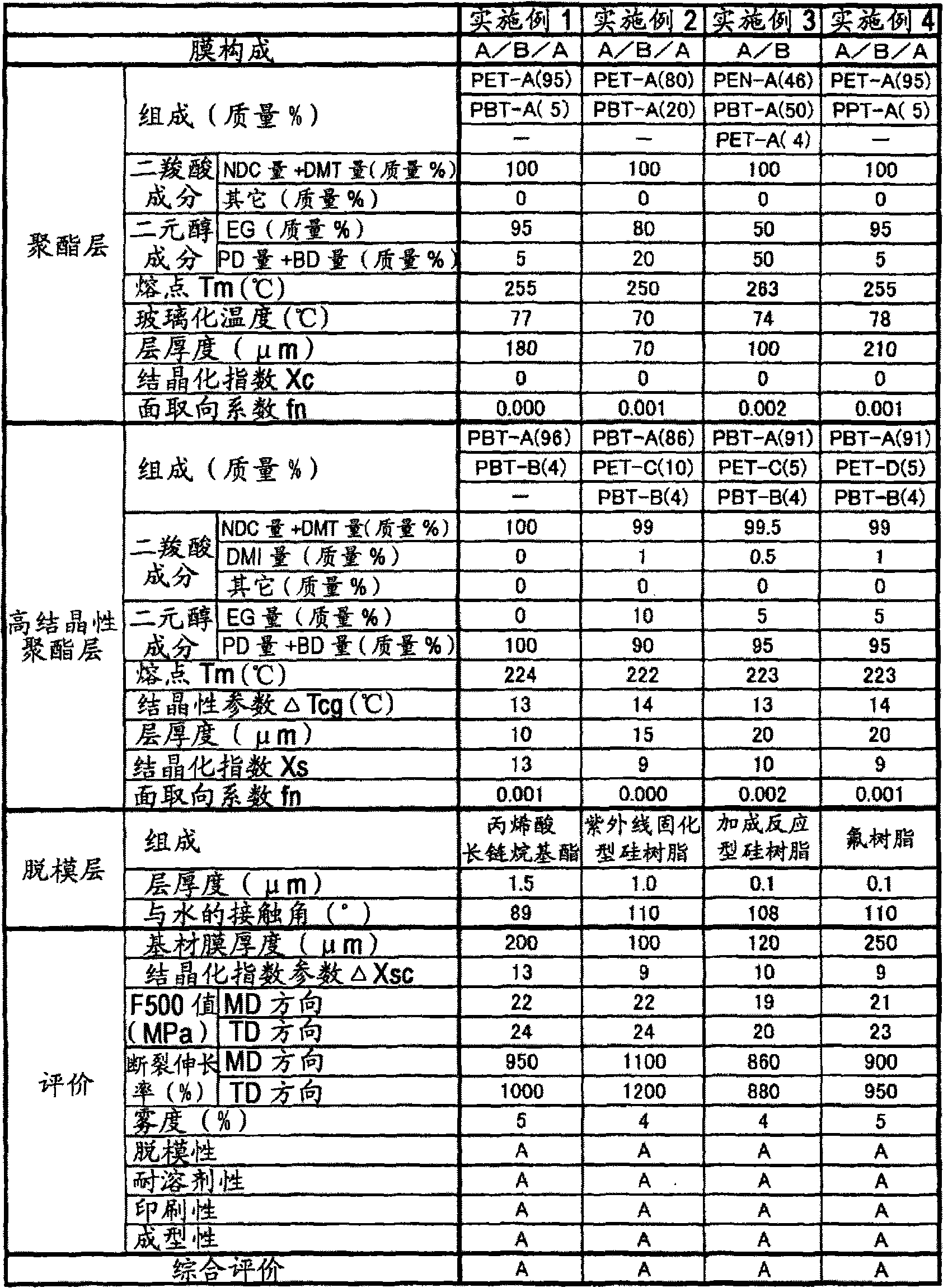

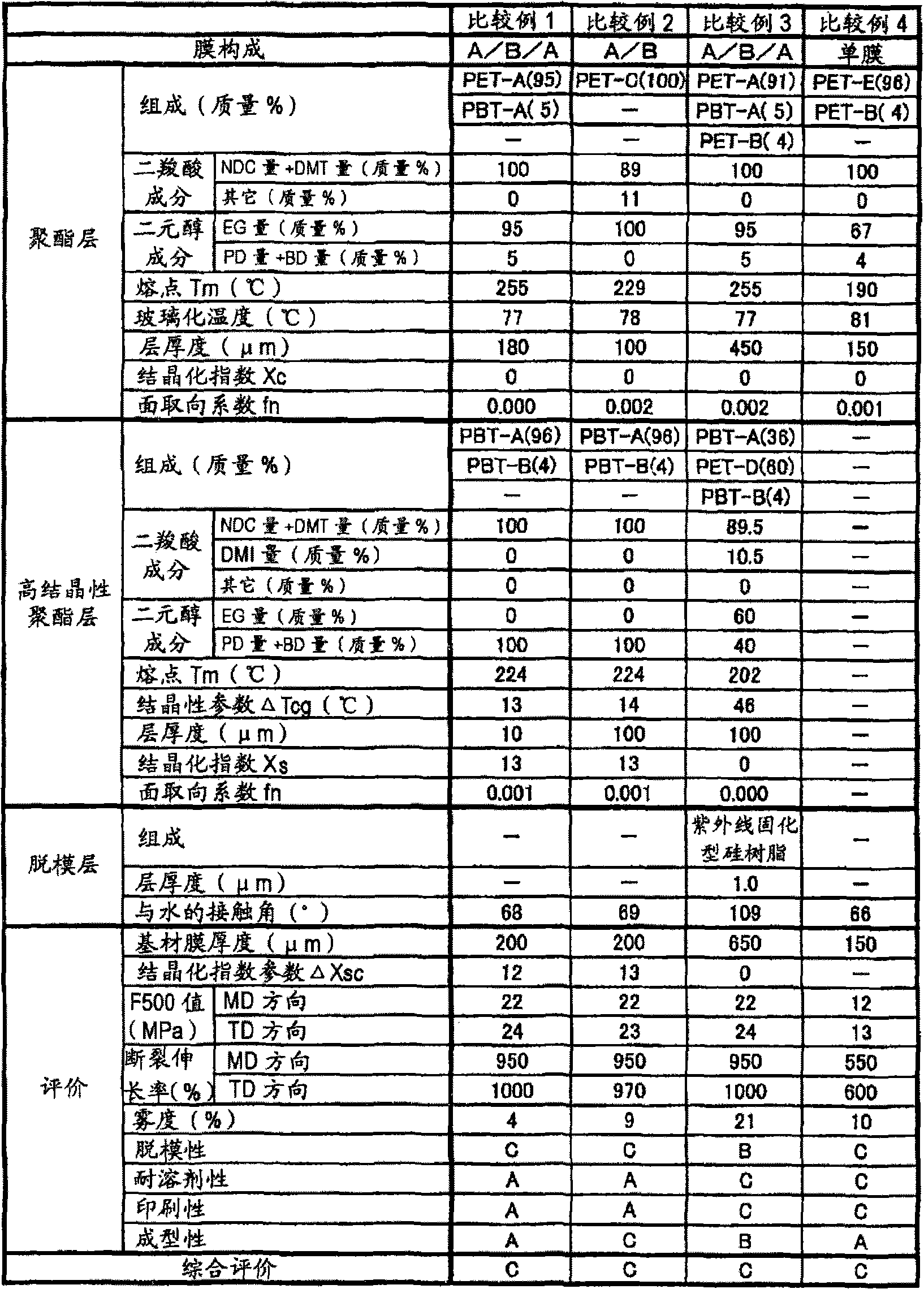

Embodiment 1

[0171] The polyester used in the polyester layer was mixed according to the ratio in Table 1. Furthermore, 0.1 mass % of stearyl phosphoric acid ("ADK STAB" (registered trademark) AX-71) manufactured by Asahi Denka Kogyo Co., Ltd.) was added separately, and it injected|thrown-in to a ventilation type twin-screw extruder (L / D=36). After melting the injected resin at 280° C., it was passed through two vacuum vents. Then, after passing the resin through a leaf-shaped disc filter with a filtration precision of 30 μm, it was put into a multi-branched pipe mold. The polyester used for the highly crystalline polyester layer was mixed according to the formulation in Table 1, put into a ventilated twin-screw extruder (L / D=36), melted at 250°C, and passed through two Vacuum vent. Then, after passing the resin through a leaf-shaped disc filter with a filtration precision of 30 μm, it was put into a multi-branched pipe mold.

[0172] After each resin in the mold passes through the bran...

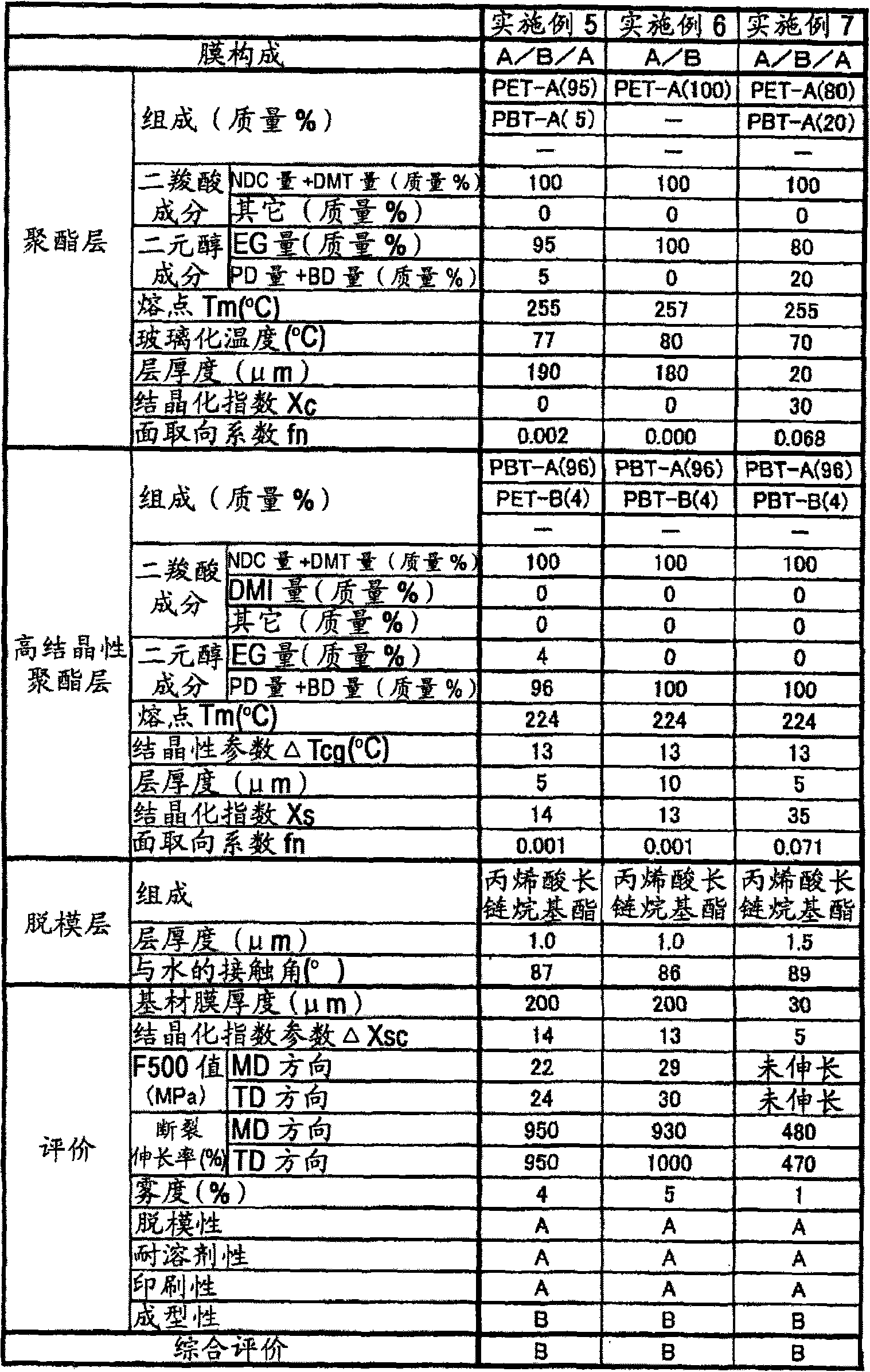

Embodiment 2

[0178] The polyester of the polyester layer and the highly crystalline polyester layer were mixed according to the composition ratio in Table 1, and the addition amount of stearyl phosphoric acid was changed to 0.15% by mass, and the single-manifold mold was used, and the same method as in Example 1 was used. A method for producing a substrate film composed of a highly crystalline polyester layer / polyester layer / highly crystalline polyester layer. The M / P value of the polyester layer of the obtained base film was 0.75. The layer thickness of one layer of the highly crystalline polyester layer was 15 μm, and the total thickness was 100 μm.

[0179] On the surface in contact with the casting drum of the obtained base film, as a release layer, a release agent is coated by wire bar coating method and cured by ultraviolet irradiation. Curable silicone resin (Silicone resin "X-62-7655" manufactured by Shin-Etsu Chemical Co., Ltd.) and a catalyst (catalyst "CAT-7603" manufactured by...

Embodiment 3

[0182] According to the polyester compounded in the polyester layer and the highly crystalline polyester layer in Table 1, the method of close contact with the casting drum was changed from the method of applying static electricity at the end using a needle-shaped edge connector to the method of applying static electricity to the entire surface using electric wires. , the dark light casting drum is changed to a mirror casting drum, so that the highly crystalline polyester layer of the molten film is in contact with the casting drum, and the melting temperature of the polyester layer and the temperature of the mold are set to 290 ° C. In addition, the adoption and implementation In the same manner as in Example 1, a base film having two types of two-layer structures of a polyester layer / a highly crystalline polyester layer was obtained. The M / P value of the polyester layer of the obtained base film was 0.99. The layer thickness of one layer of the highly crystalline polyester l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com