Automatic locating and unlocking device of gearshift

A technology of automatic shifting and unlocking device, which is applied in the direction of control device, transportation and packaging, vehicle parts, etc., can solve the problem of the complex structure of the limit unlocking device of the automatic gear shifter, the many parts of the shifter, and the complicated welding tooling, etc. problem, to achieve the effect of not easy to skip gears, light weight and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

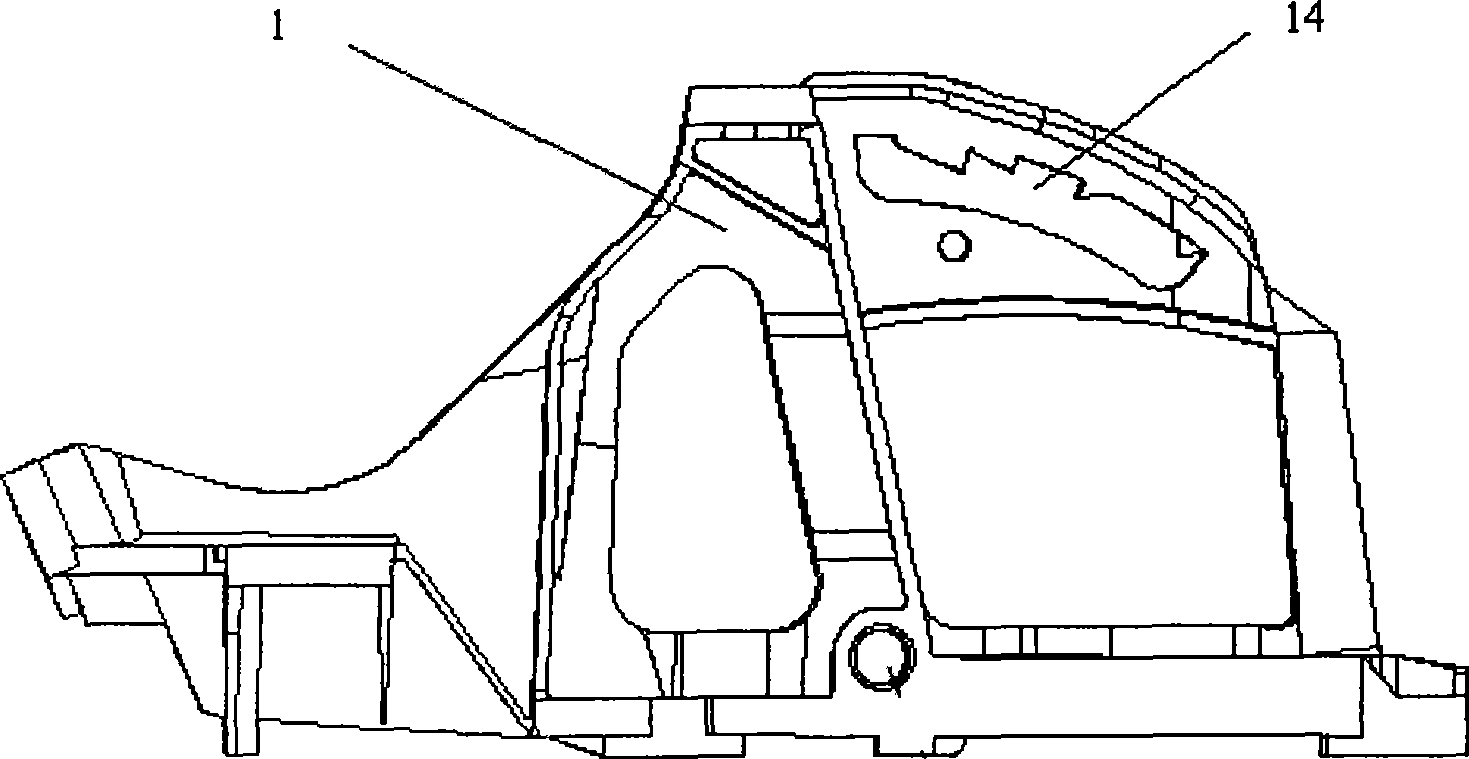

[0023] The limit unlocking device of the automatic gear shifter can be divided into two parts: a base 1 and a shift assembly installed on the base through a rotating shaft 3 . see figure 2 , the base 1 has a limited step hole 14, and one end of the flat spring 2 is also connected to the base 1. The shaft hole 15 is used for installing the rotating shaft 3 .

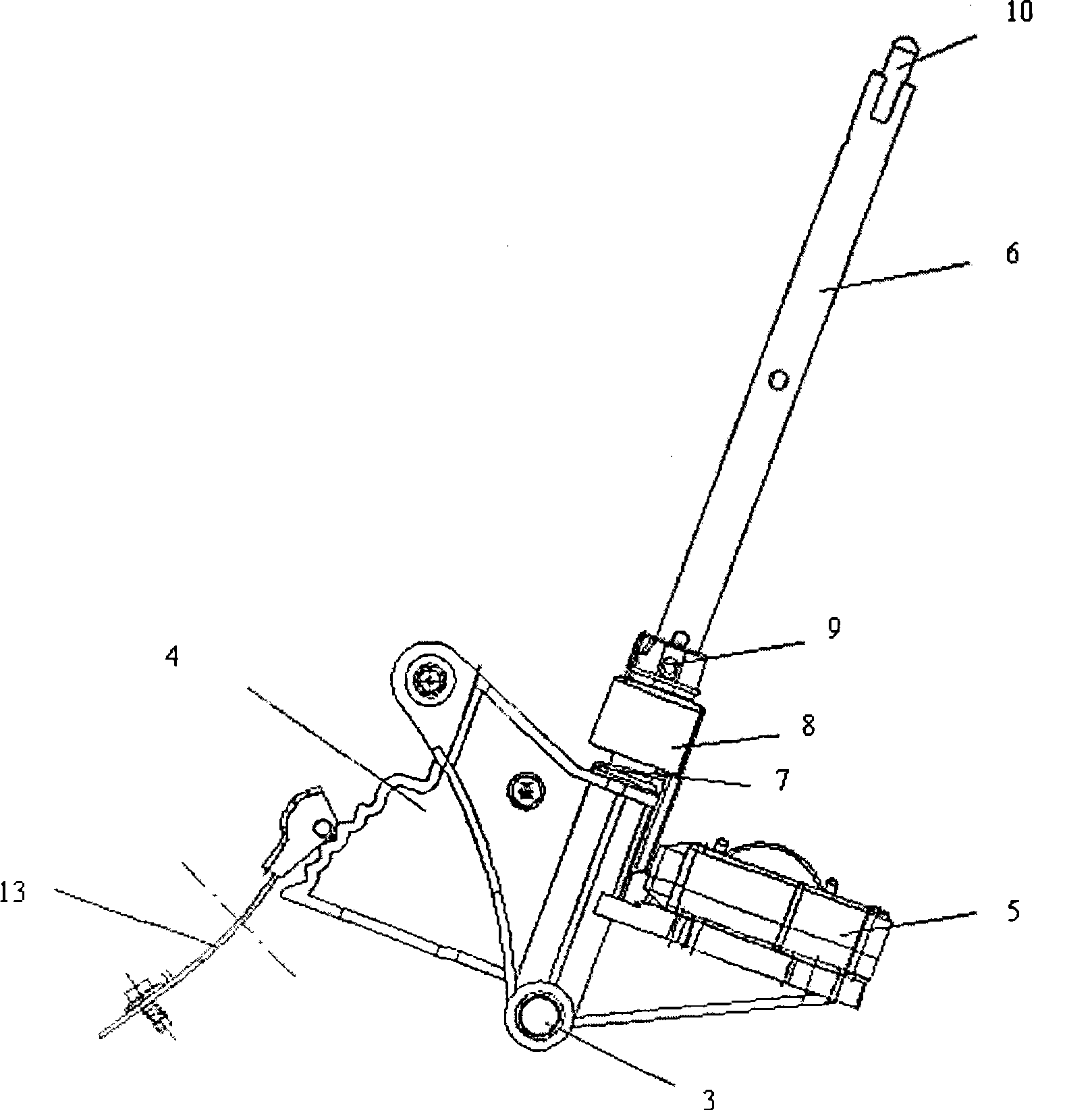

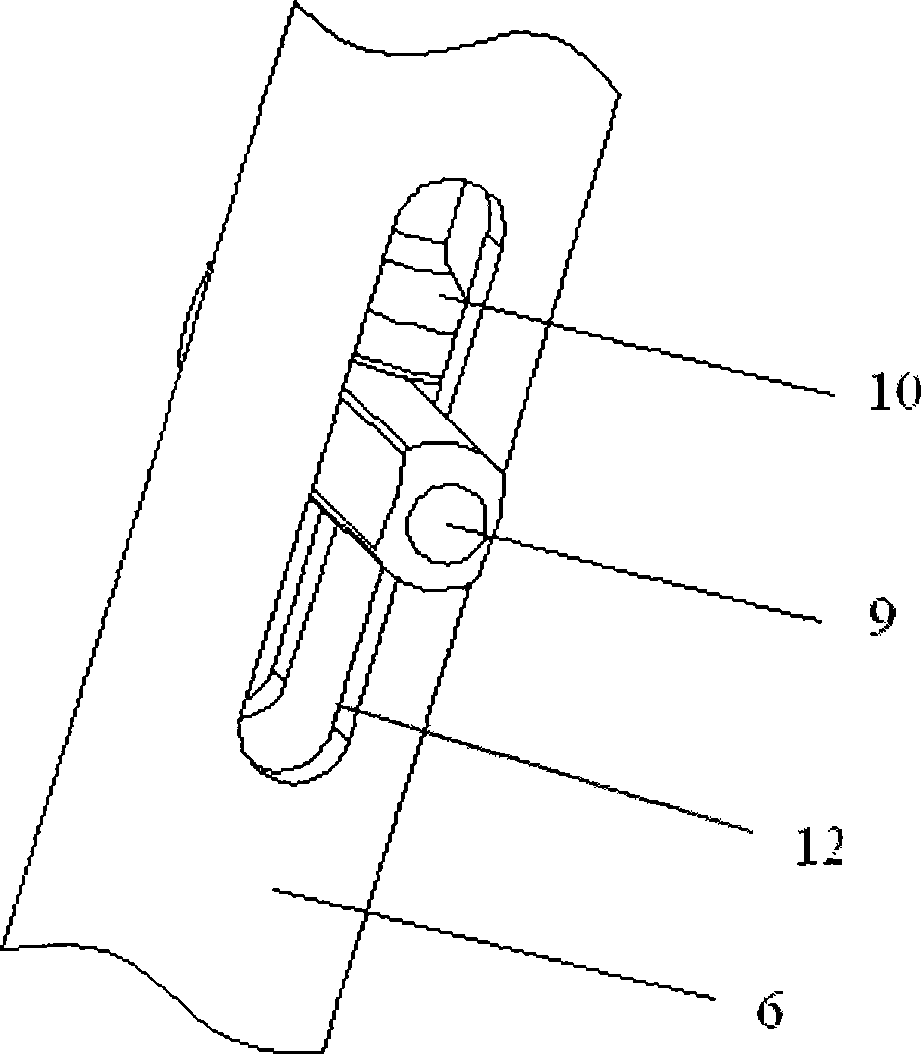

[0024] see figure 1 , The shift assembly includes a limit device 4, a shift lever 6, a return spring 7, a flat pin 8, a limit pin 9, a force transmission mandrel 10, and the like. The power transmission mandrel 10 is placed in the shift rod 6 and can slide freely. There is a strip-shaped hole 12 at the lower end of the shift rod 6. The limit pin 9 is connected to the lower end of the dowel rod and crosses the strip-shaped hole 12. The strip-shaped hole Play a guiding role to the limit pin 9, the axis of the limit pin 9 is perpendicular to the axis of the shift lever 6, and the force transmission mandrel 10 can push th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com