Automotive glass run

A glass run, motor vehicle technology, applied in mechanical equipment, vehicle parts, engine components, etc., can solve the problem of glass run equalization, and achieve the effect of preventing abnormal sound and door glass vibration and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

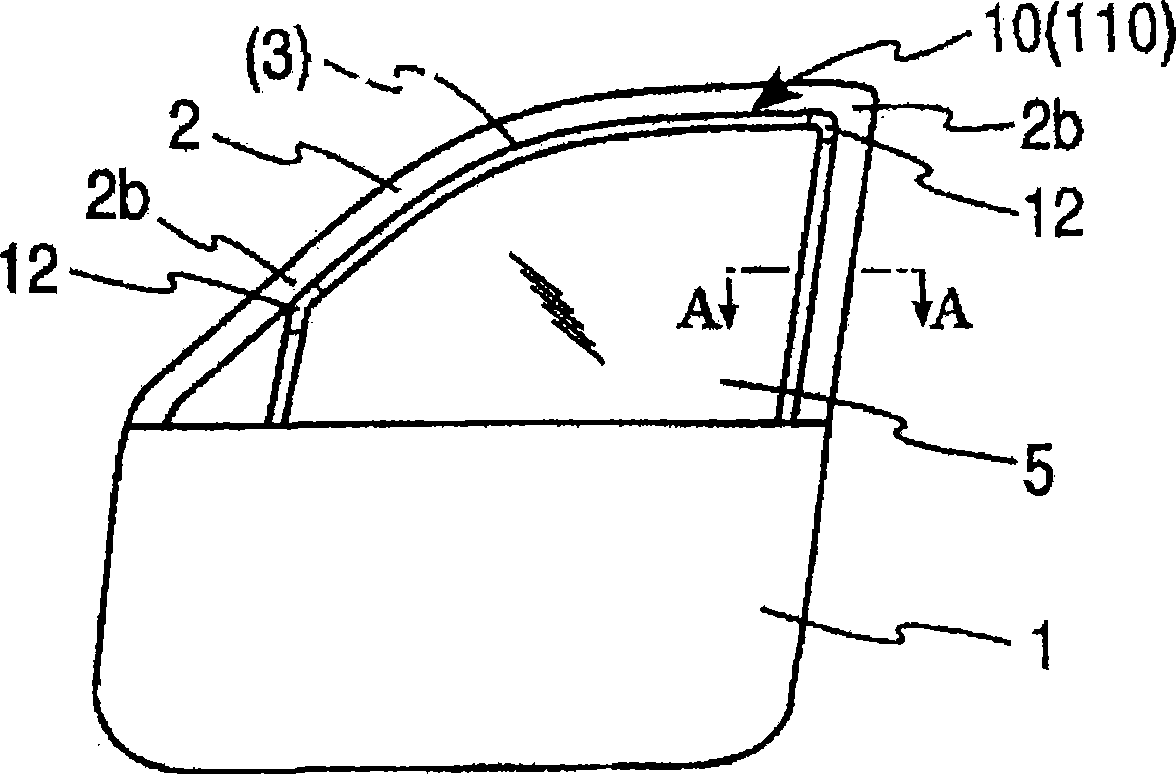

[0037] Below, refer to Figure 1 to Figure 3 Embodiments of the present invention will be described.

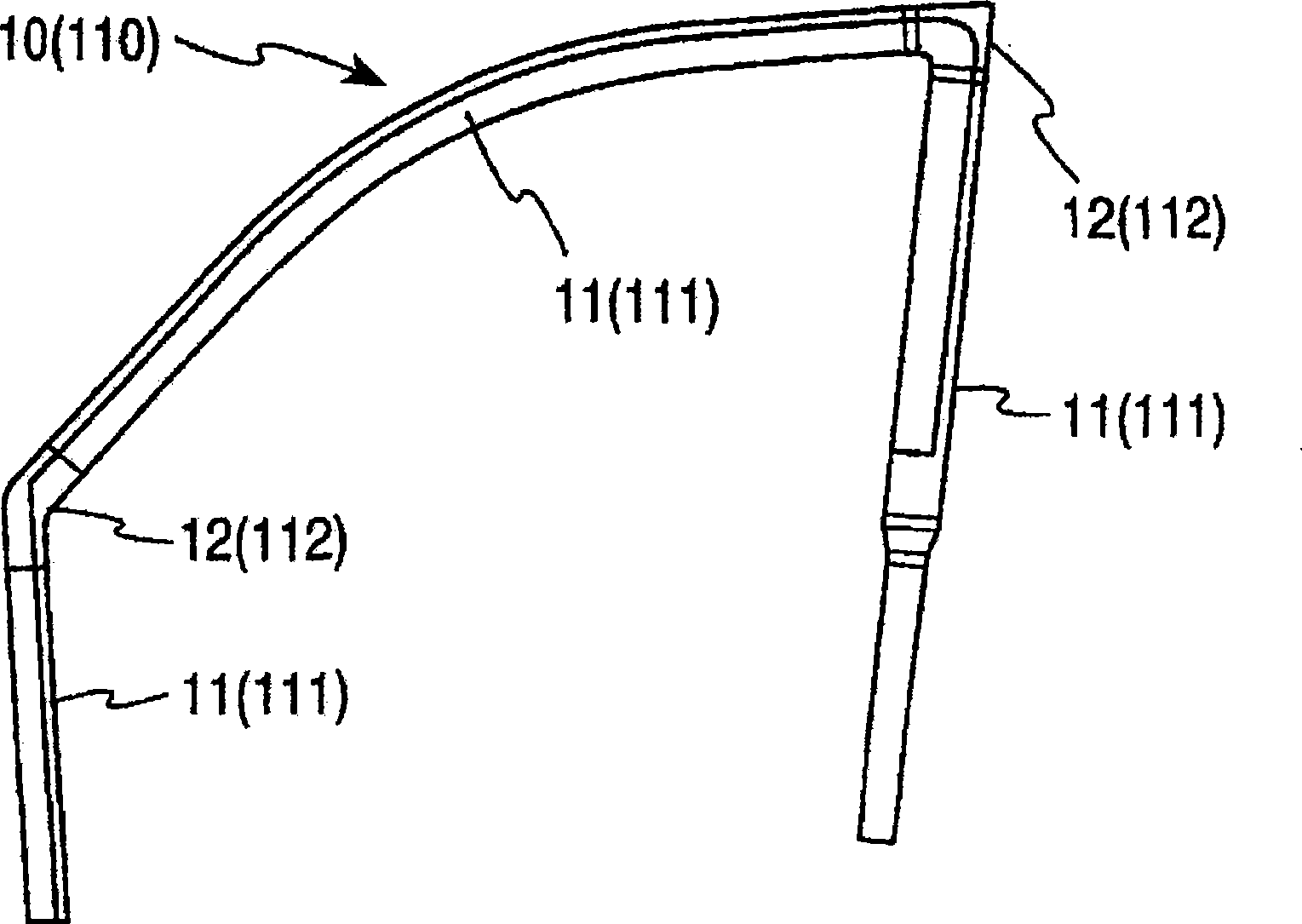

[0038] Such as figure 2 As shown, the glass run channel 10 includes: a linear portion 11 integrally formed by extrusion; and a corner portion 12 installed on the corner 2b of the door frame 2 so that the linear portions 11 are connected to each other, and the corner portion 12 passes through Formed by molding.

[0039] The corner portion 12 is molded and connected to the straight portion 11 at each front and rear corner so that the shape of the extruded portion conforms to the door frame 2 . The corner part 12 of the glass run 10 is attached to the corner 2b of the door frame 2. As shown in FIG.

[0040] The following description takes the glass run channel 10 installed on the longitudinal side of the front door 1 as an example.

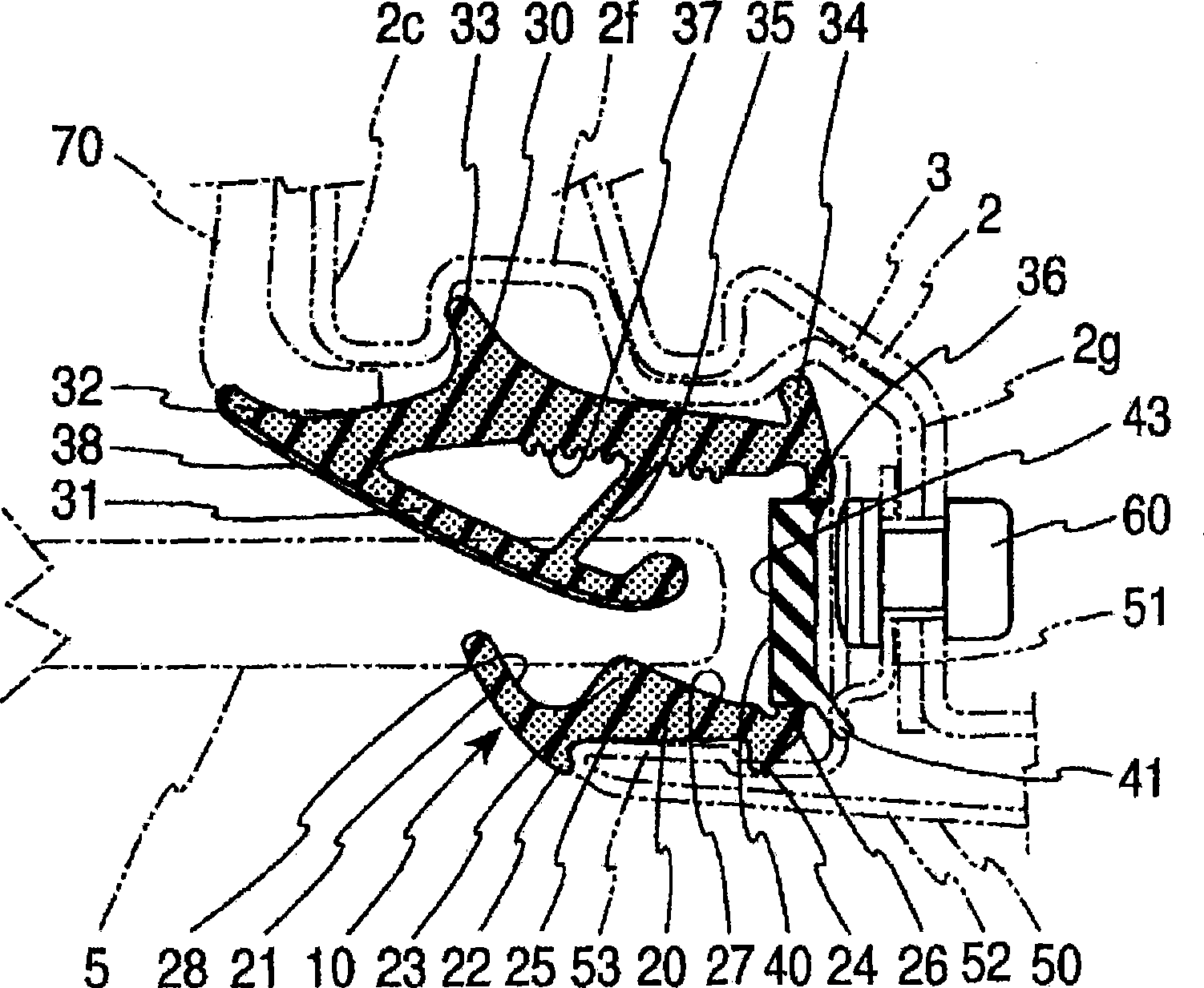

[0041] With regard to the cross-sectional profile of each linear portion 11 installed on the longitudinal side of the door frame 2 in the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com