Porous polytetrafluoroethylene film and air filter filtration material

A technology of polytetrafluoroethylene and air filter, which is applied in the field of air filter material and polytetrafluoroethylene porous membrane, which can solve the problem of falling and achieve the effect of small and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

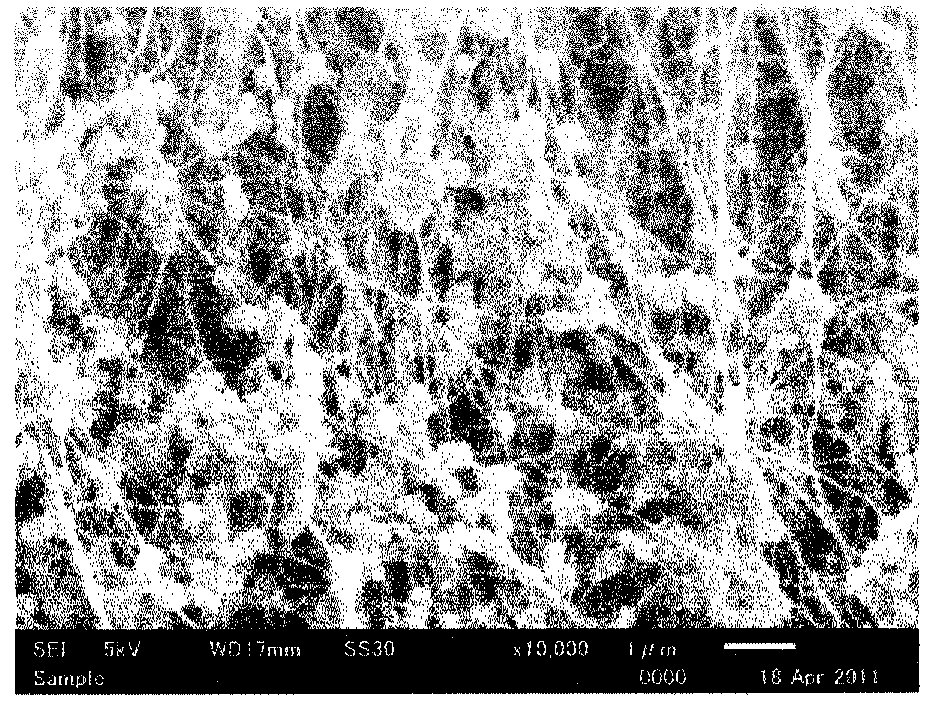

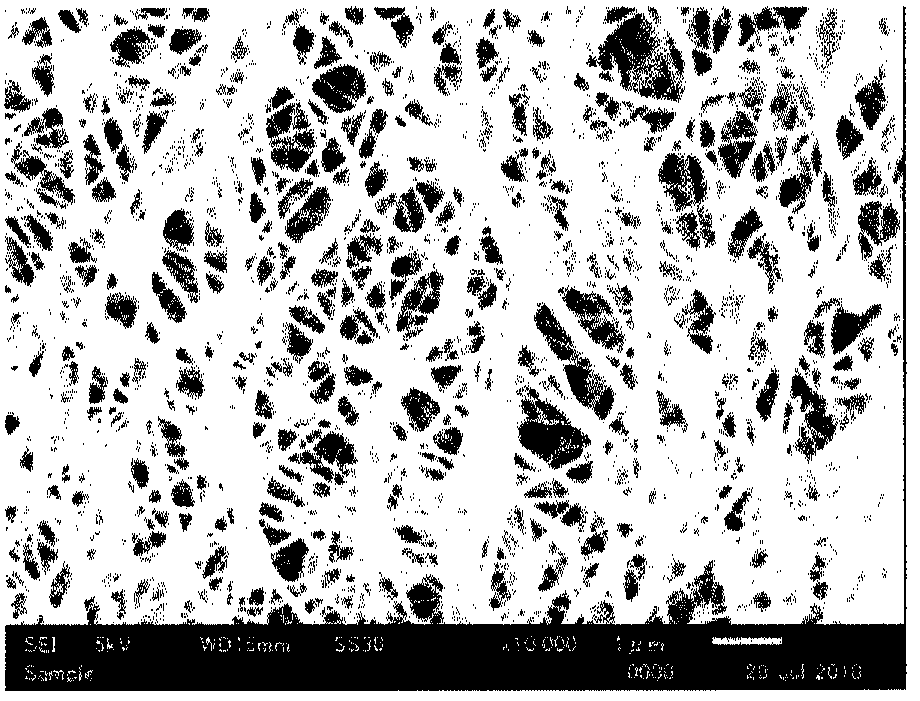

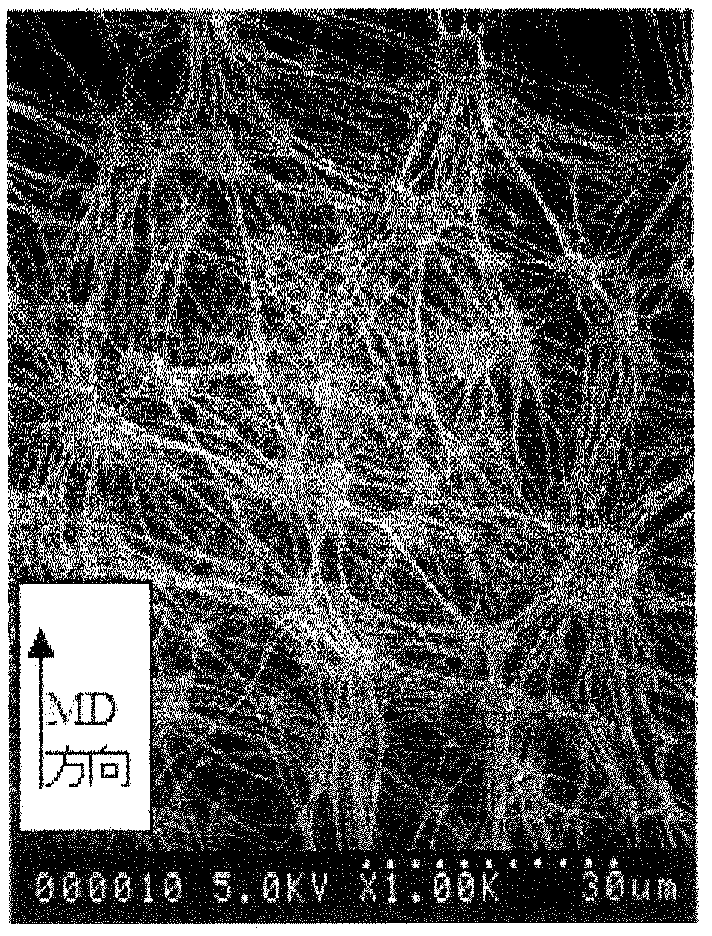

Image

Examples

Embodiment 1

[0113] 19 parts by weight of a liquid lubricant (dodecane) were uniformly mixed with 100 parts by weight of PTFE fine powder ("Polyflon F-104" manufactured by Daikin Corporation, SSG2.171) to obtain a mixture. The mixture was then extruded into sheets using an extruder equipped with a fishtail die. The extruded PTFE sheet had a thickness of 1.5 mm and a width of 20 cm.

[0114] Furthermore, the PTFE sheet was rolled by passing between a pair of metal rolling rolls. The calendering was carried out while stretching the PTFE sheet in its longitudinal direction using a roll disposed downstream of the calendering rolls so that the length of the PTFE sheet in the width direction remained unchanged before and after calendering. The thickness of the rolled PTFE sheet was 200 μm.

[0115] Next, using a tenter, the rolled PTFE sheet was stretched 4 times in the width direction while containing a liquid lubricant. Then, the stretched PTFE sheet was kept at 150° C., and the liquid lubr...

Embodiment 2

[0121] A PTFE porous membrane was produced in the same manner as in Example 1 except that the stretch ratio in the longitudinal direction of the PTFE sheet after removal of the liquid lubricant was set to 14 times. Moreover, using this PTFE porous membrane, it carried out similarly to Example 1, and produced the air filter unit.

Embodiment 3

[0123] A PTFE porous membrane was produced in the same manner as in Example 2, except that the stretching temperature when stretching the PTFE sheet from which the liquid lubricant had been removed was 60° C. in the width direction. Moreover, using this PTFE porous membrane, it carried out similarly to Example 1, and produced the air filter unit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com