Bladeless fan with double air nozzles

A bladeless fan and jet port technology, applied in jet pumps, non-variable pumps, pump devices, etc., can solve problems such as uneven wind, noise generated by blades, user interference, etc., to avoid weak wind Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

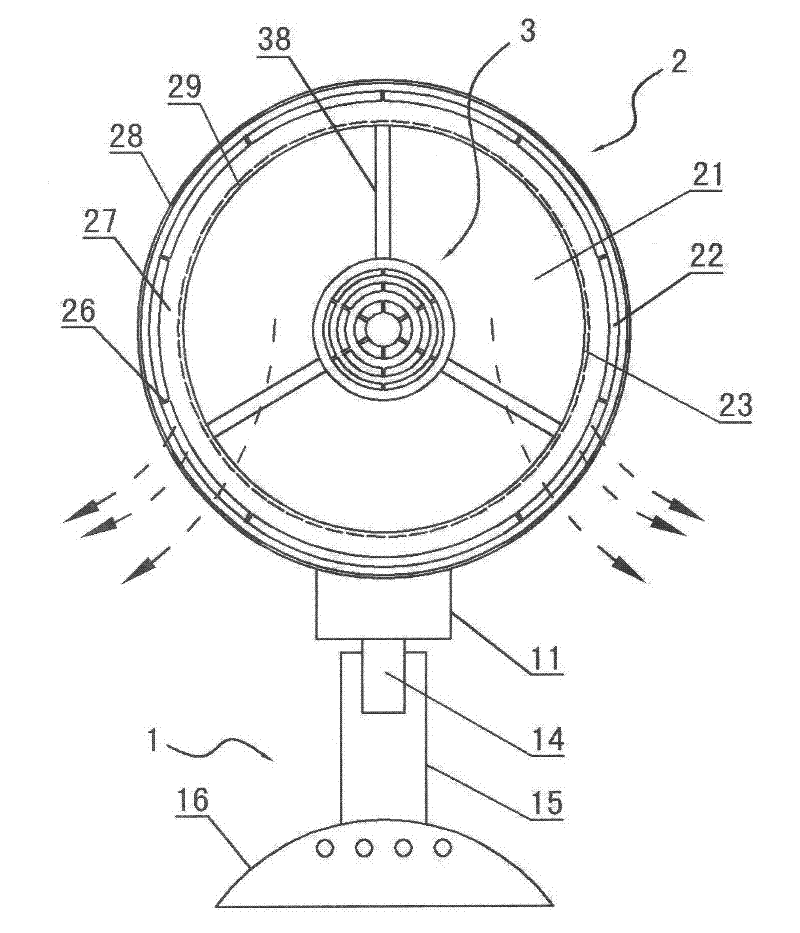

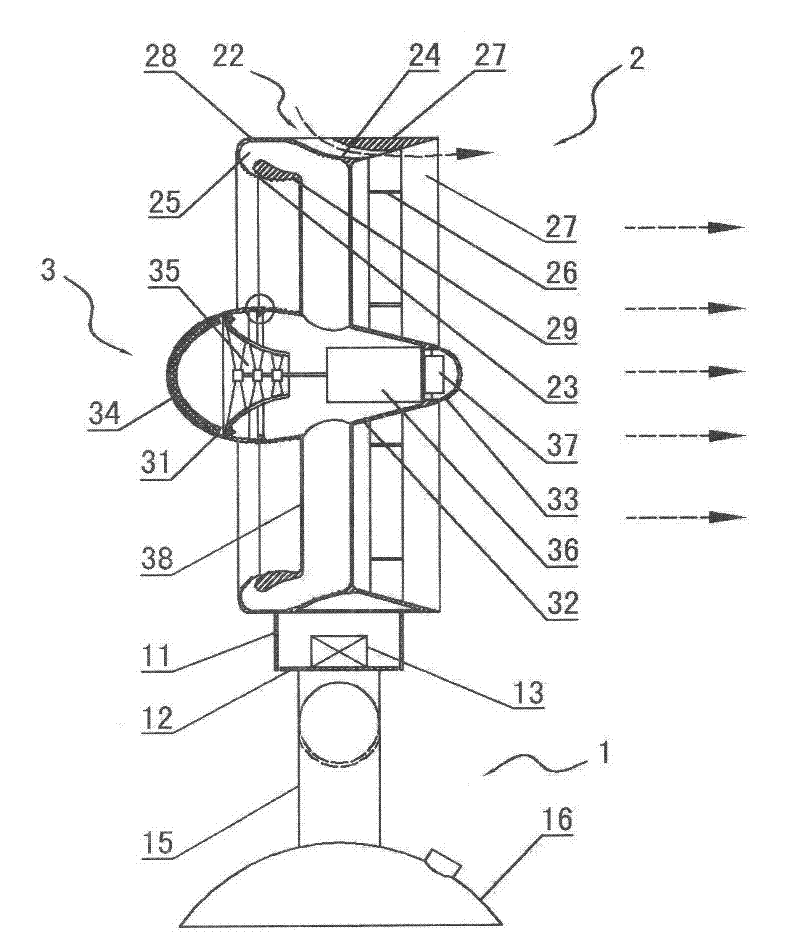

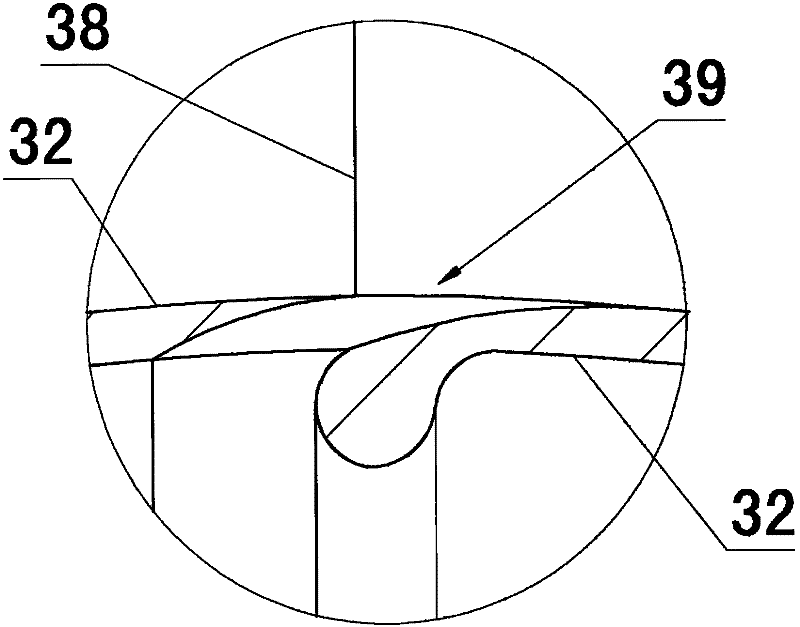

[0017] Such as figure 1 , figure 2 As shown, a bladeless fan with double air outlets is composed of a base 1, an air injection device 2 and an air booster 3. The air injection device 2 is located above the base 1 and is a hollow ring structure The middle part of the air injection device is the first air flow passage 21, and the air flow injection device 2 is provided with an annular second air flow passage 22 and an annular first air injection port 23; the air booster 3 is in the middle Large and small drop-shaped at both ends, placed in the center of the first airflow channel 21, communicated with the airway 25 of the airflow injection device 2 through the air delivery pipe 38, and a ring of first air injection ports 23 are arranged around the airway 25; The middle part of the air booster 3 is a casing 32 , one end of the casing 32 is connected with the air intake cover 31 , and the other end is connected with the dustproof cover 33 , and the casing 32 is provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com