Test method for bending performance of fabric

A technology of bending performance and test method, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inconvenience, expensive equipment, complicated calculation of indicators, etc., and achieve the effect of convenient use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

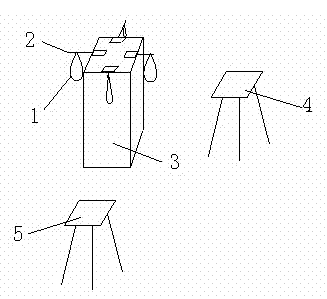

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Fabric bending property test method of the present invention comprises the following steps:

[0015] Step 1. Cut the fabric to be tested according to a certain thread direction into a rectangular sample of specified size (in this embodiment, the length is 20cm, and the width is 2.5cm). Place it under standard atmospheric conditions for 24h, and draw two marking lines parallel to the edges at a distance of 1 cm from the two edges in the length direction of the sample.

[0016] Step 2. Align the two 2.5 cm long edges of the fabric sample together, and insert 3 pins vertically and equidistantly at the position of the marked line to fix it. At this time, the fabric forms a drop-shaped sample 1 under the action of gravity.

[0017] Step 3. Prepare the remaining 3 drop-shaped samples in the same way as step 2.

[0018] Step 4. A support rod 2 is provided in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com