Rotary table structure and machine tool

A technology of rotary worktable and worktable, applied in metal processing machinery parts, metal processing, manufacturing tools, etc., can solve the problems of high cost, easy deformation, difficult processing of sheet hoop, etc., and achieve high positioning accuracy and clamping. High torque, saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with principle diagrams and specific operation examples.

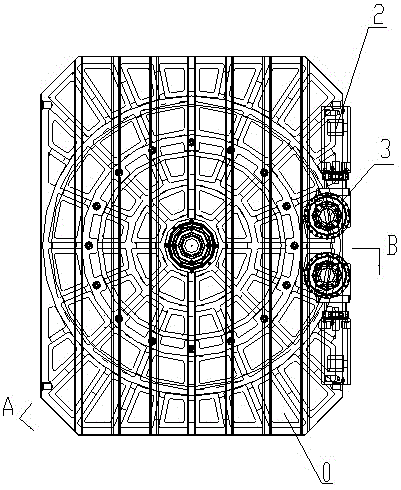

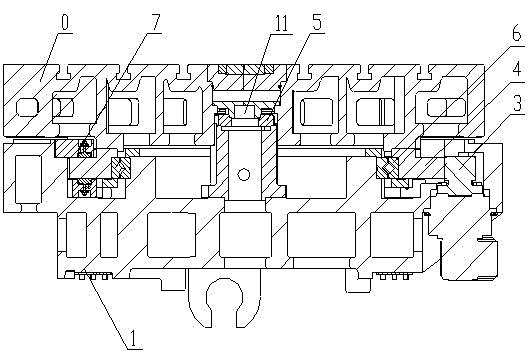

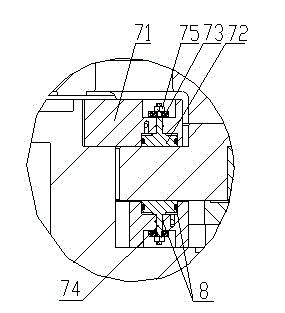

[0029] figure 1 and figure 2 Respectively show a top view of the rotary table structure according to a preferred embodiment of the present invention and a cross-sectional view along A-base circular table center-B in the top view, as shown in the figure, the rotary table structure in the embodiment of the present invention Including workbench 0 and base 1, the middle part of base 1 has base circular platform 11, the rotary workbench in the embodiment of the present invention is mainly composed of two sets of servo motors 2, two reducers, two driving gears 3, driven gear 4, piston Clamping mechanism 7, angle encoder 5 and cross roller bearing 6 are composed.

[0030] In the preferred embodiment of the present invention, the cross roller bearing 6 is used as the turning and bearing mechanism of the turning table. The characteristics of the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com