Brushless DC motor and stator thereof

A DC motor and stator technology, applied in electrical components, electromechanical devices, etc., can solve the problems of high production cost, inconvenient assembly, poor axial height and poor running stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

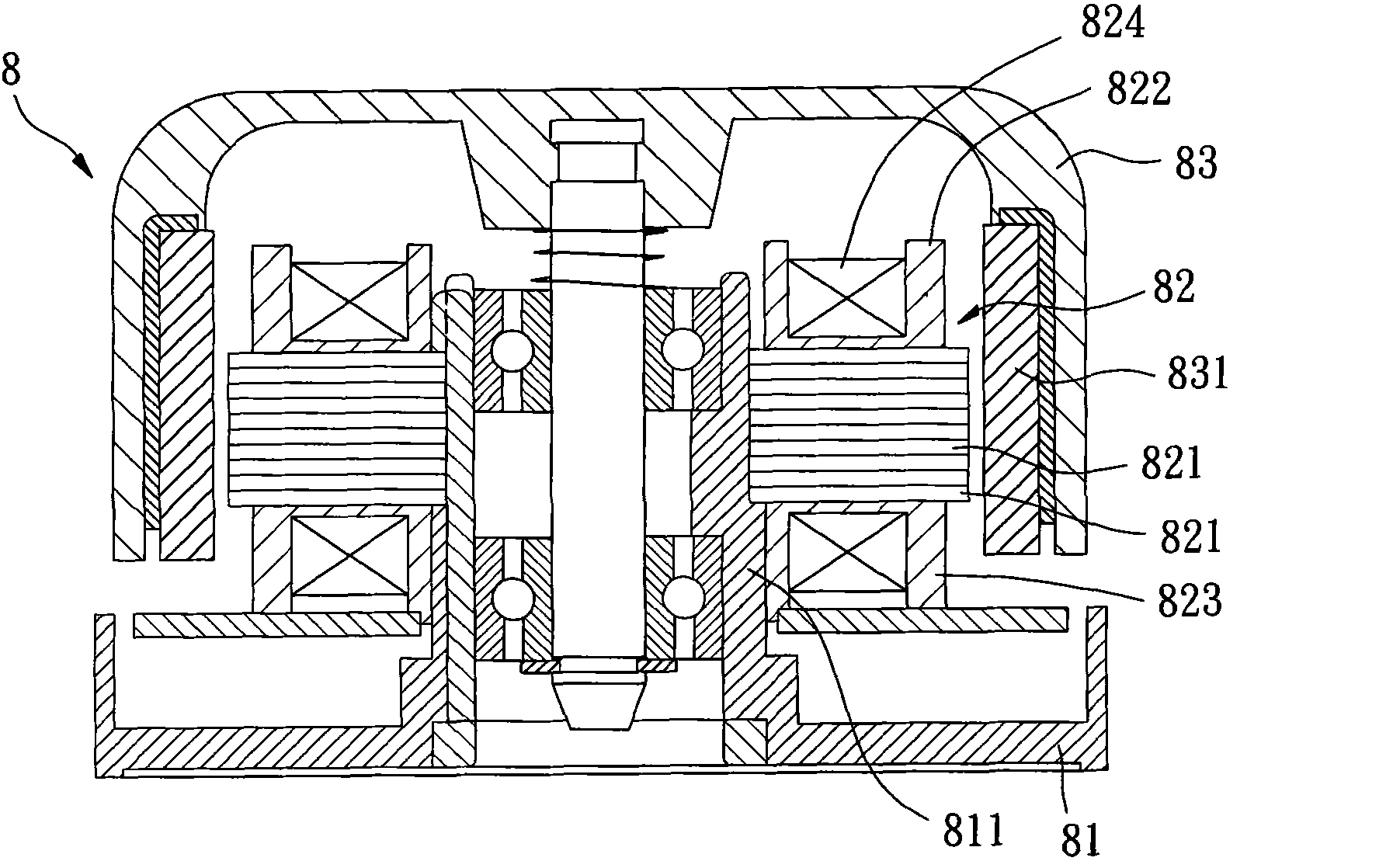

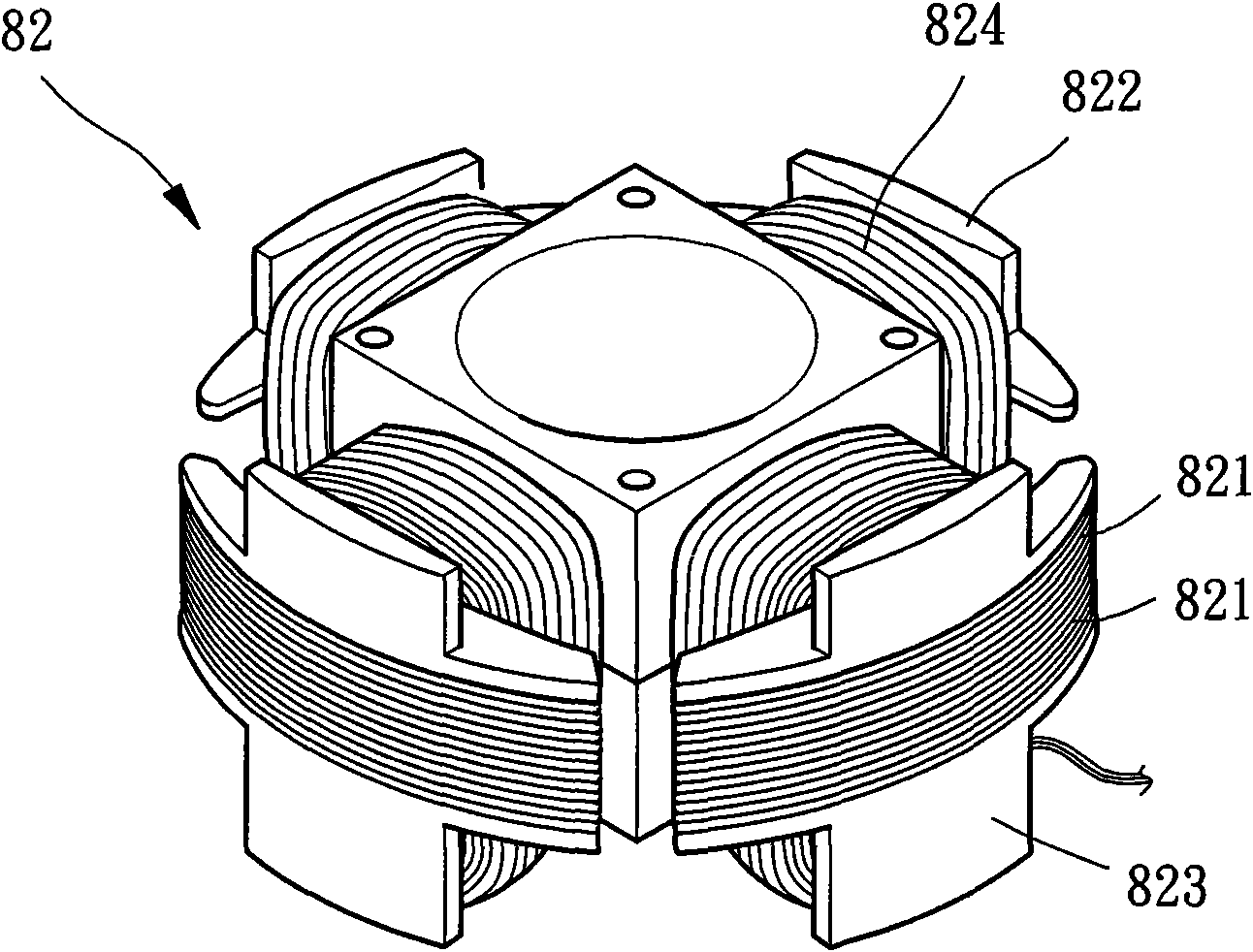

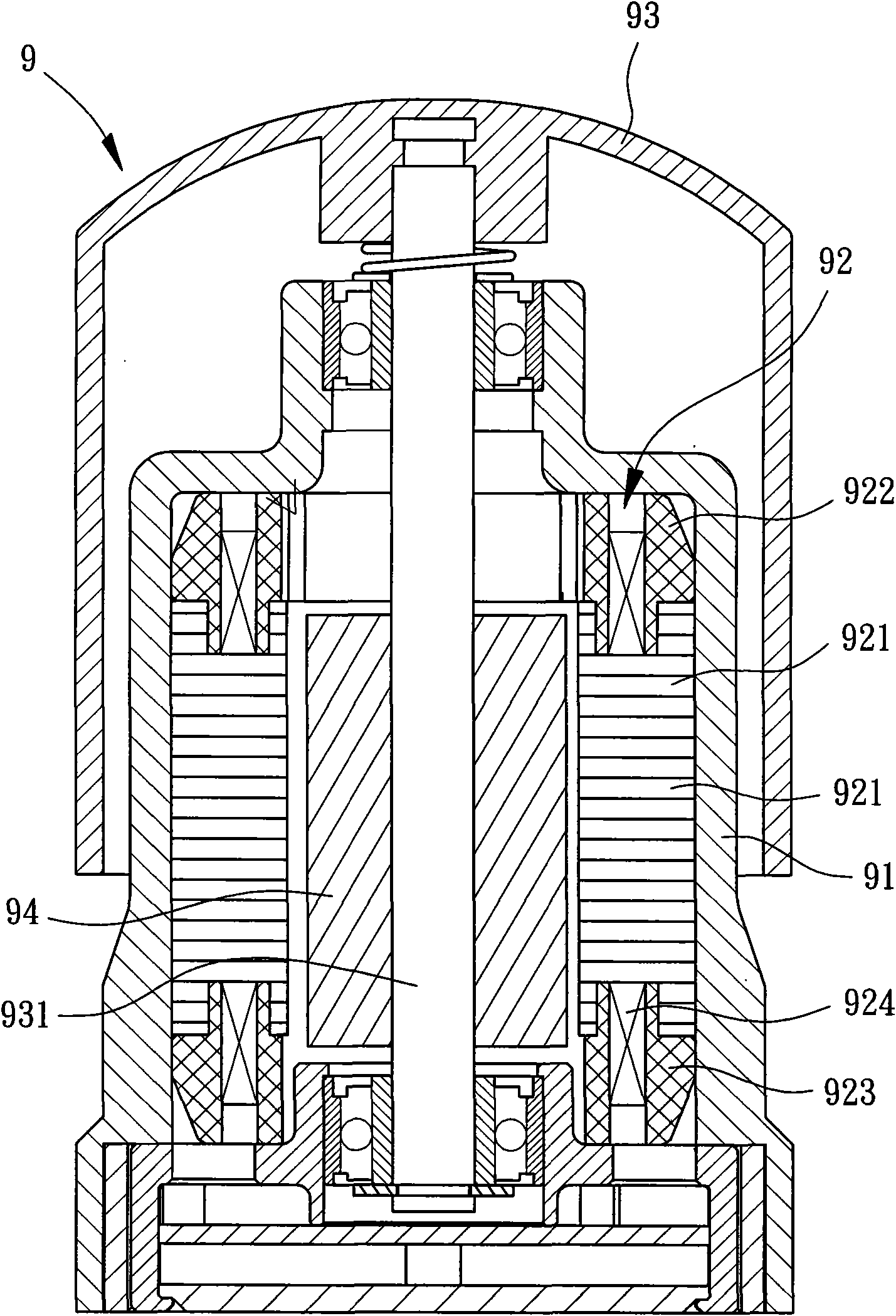

[0078] Please refer to Figure 5 and Figure 6 As shown, the brushless DC motor 1 of the first embodiment of the present invention discloses an “external rotor motor”. The brushless DC motor 1 includes a base 11 , a circuit board 12 , a stator 13 and a rotor 14 .

[0079] The base 11 has a pivot portion 111, the pivot portion 111 can be a shaft tube, a shaft seat or other structures that can be rotatably combined with the rotor 13; in the embodiment shown in the figure, the The pivoting portion 111 is a shaft tube, which can accommodate components such as the fixing ring 112 , the retaining piece 113 , the bearing 114 or the wear-resistant piece 115 , so that the rotor 14 can rotate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com