Multi-stage series-connected LTD of common cavity, and trigger method thereof

A cavity and trigger pulse technology, applied in the direction of electric pulse generator circuit, energy storage element to generate pulses, etc., can solve the problems of difficult to guarantee trigger sequence, high manufacturing cost, many trigger circuits, etc., to reduce the number of trigger cables and The effect of the number of charging cables, improving reliability, and facilitating internal wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

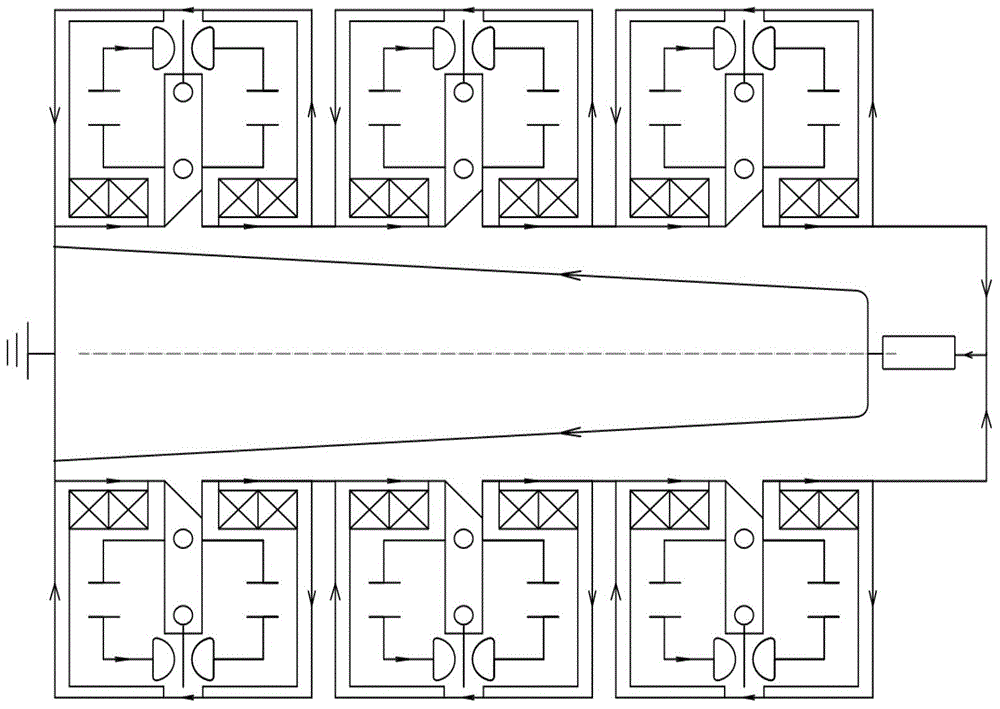

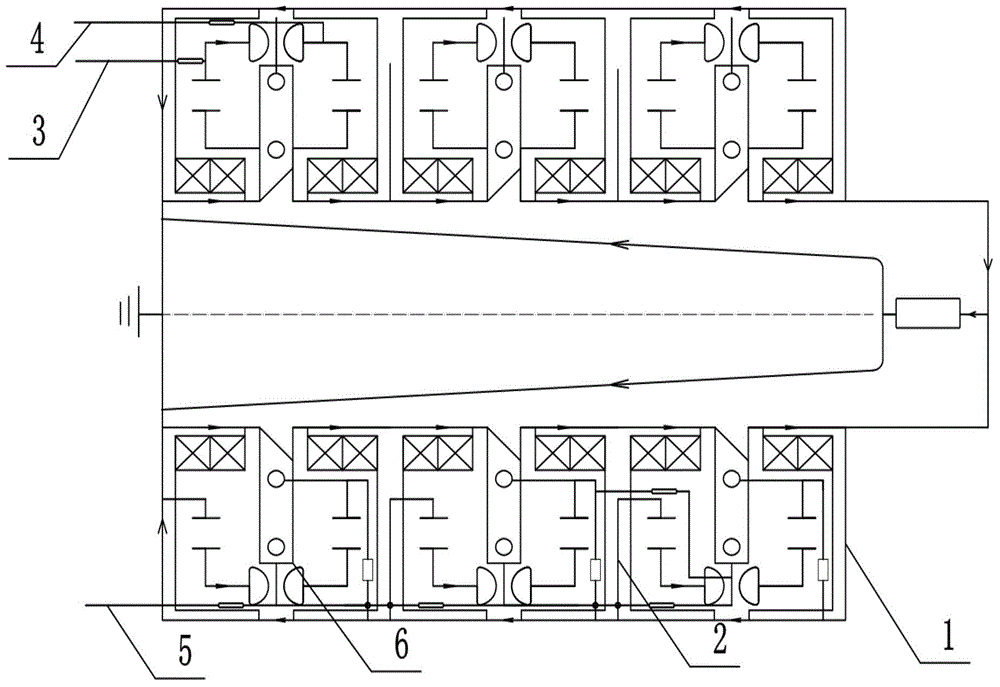

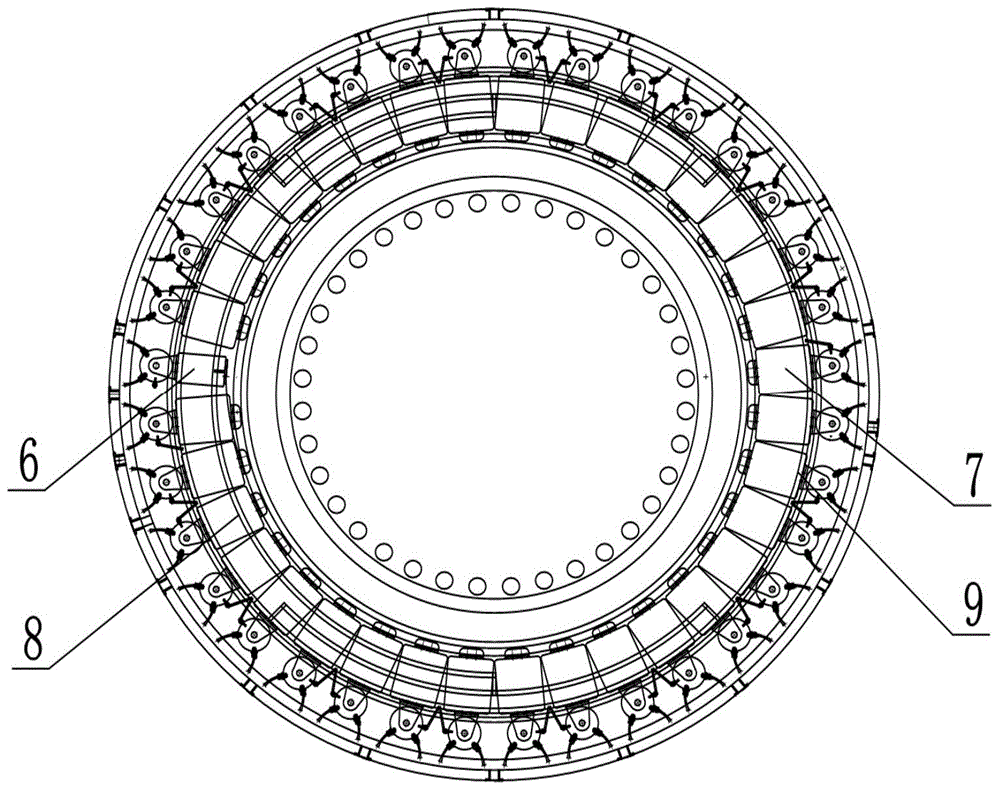

[0031] The core technical idea of the present invention is: each level of all series modules is composed of a trigger branch and a main discharge branch, and the modules of the same level use a pulse to close the switch of the trigger branch, and transmit it to the main discharge branch of the same level through the angular transmission line The switch makes the same-level modules trigger and close synchronously; the electrodes in the multi-level series modules are compressed and sealed to form a secondary outer cylinder, which constitutes the LTD movement, and is loaded into a non-magnetic metal shell (such as aluminum or stainless steel, etc.), except for the first The grounding metal cover plate of the first-level and last-level modules is integrated, and the electrode plates between the modules are combined into one and have a hollow spoke shape, which is connected to the grounding electrode plate at the end of the cavity through the metal electrode; the positive and negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com