Rotational flow gas outlet structure for magnetic focusing hall thruster

A Hall thruster and magnetic focusing technology, which is applied to thrust reversers, machines/engines, utilizing plasma, etc., can solve the problems of poor ionization characteristics of Hall thrusters with high specific impulse krypton working medium, and improve electron collision Chance, Lifting Effect, Thickening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

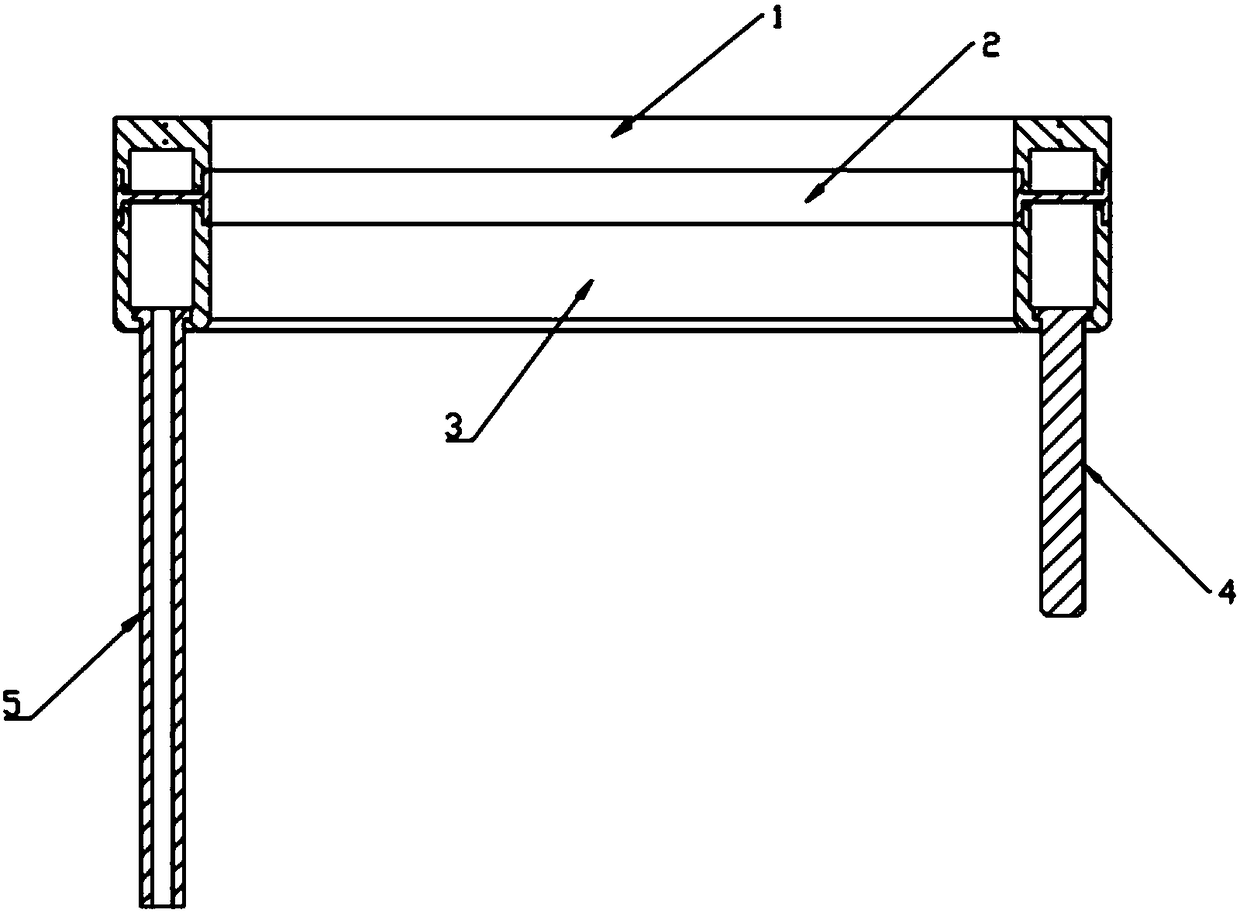

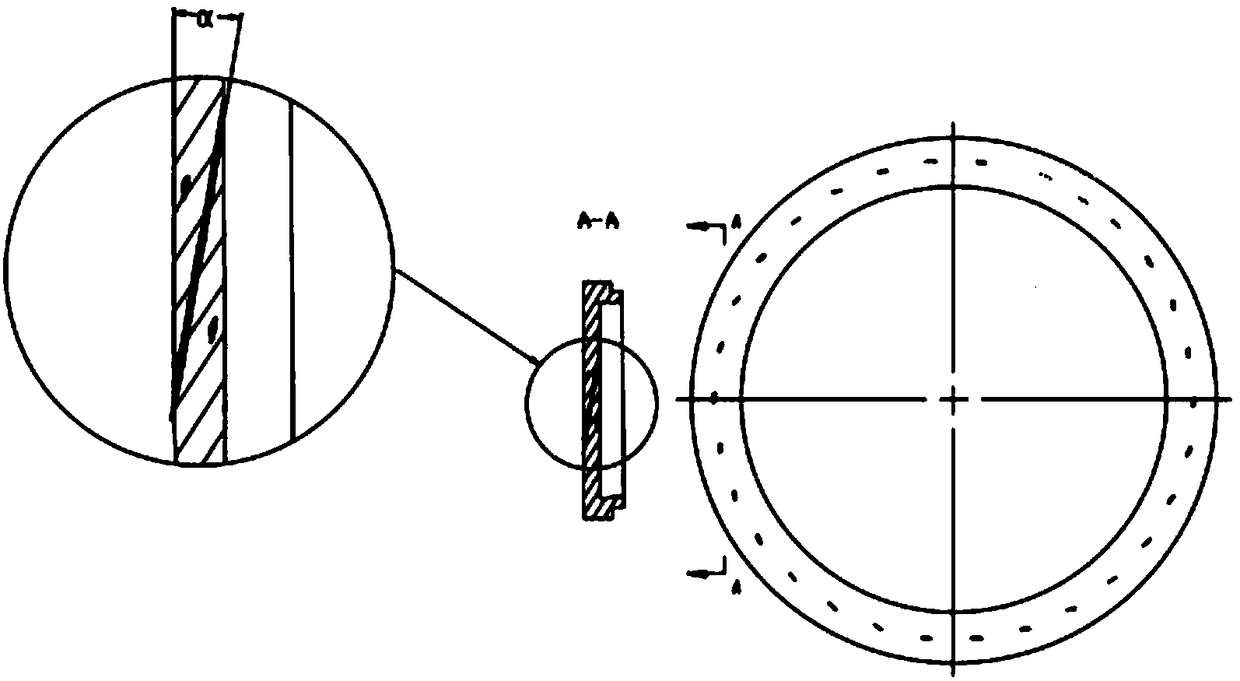

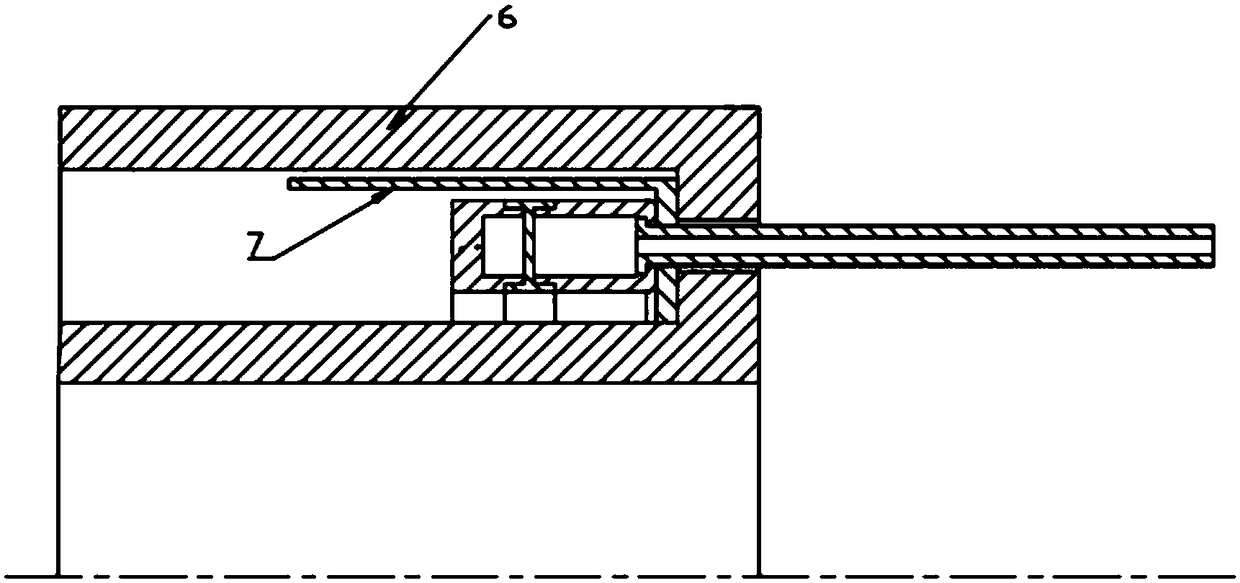

[0017] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment:

[0018] The swirling air outlet structure of a magnetic focus Hall thruster mentioned in this embodiment includes a top deflector 1, a middle deflector 2, a gas distributor base 3, a mounting pillar 4, an air guide tube 5, and a discharge channel 6 and anode 7; the top deflector 1, the middle deflector 2 and the gas distributor base 3 are arranged in parallel from top to bottom, and are fixedly connected by laser welding to form a primary buffer cavity and a secondary buffer cavity; The primary buffer cavity and the secondary buffer cavity are coaxially arranged in the discharge channel 6, and the top deflector 1 guides the neutral gas through the inclined hole to make it rotate in the discharge channel 6; the anode 7 It is arranged inside the discharge channel 6 close to the top deflector 1; the gas guide pipe 5 and the installation pillar 4 are welded on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com