Slim type stator, slim type motor having the stator and direct drive apparatus for drum-washing machine

A drum washing machine and drive device technology, which is applied to other washing machines, manufacturing motor generators, washing devices, etc., can solve the problems of not having an ultra-thin structure and being unable to be used as an ultra-thin motor for a built-in drum washing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

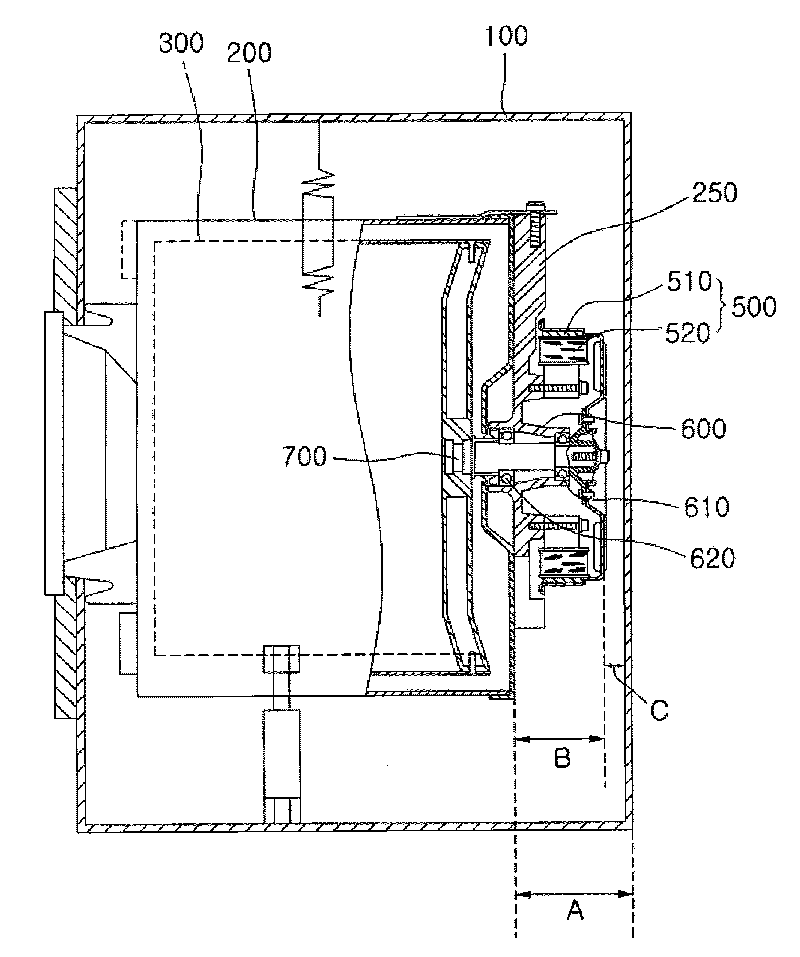

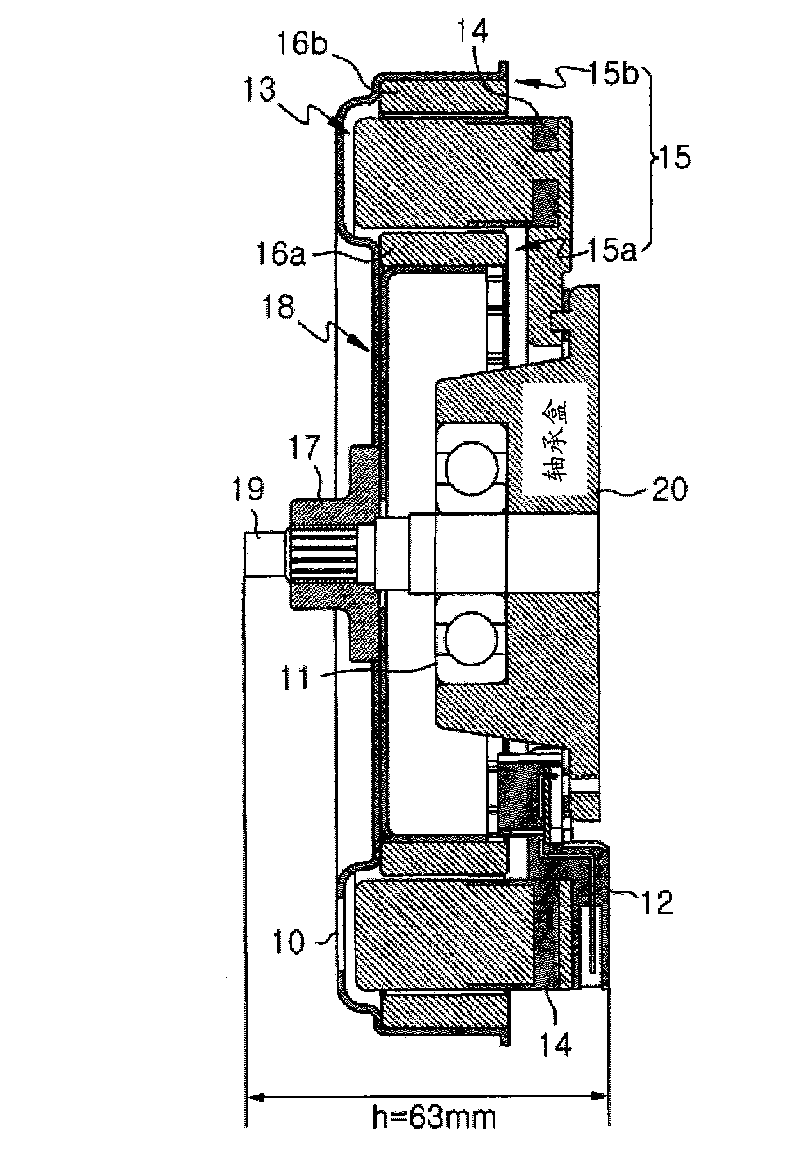

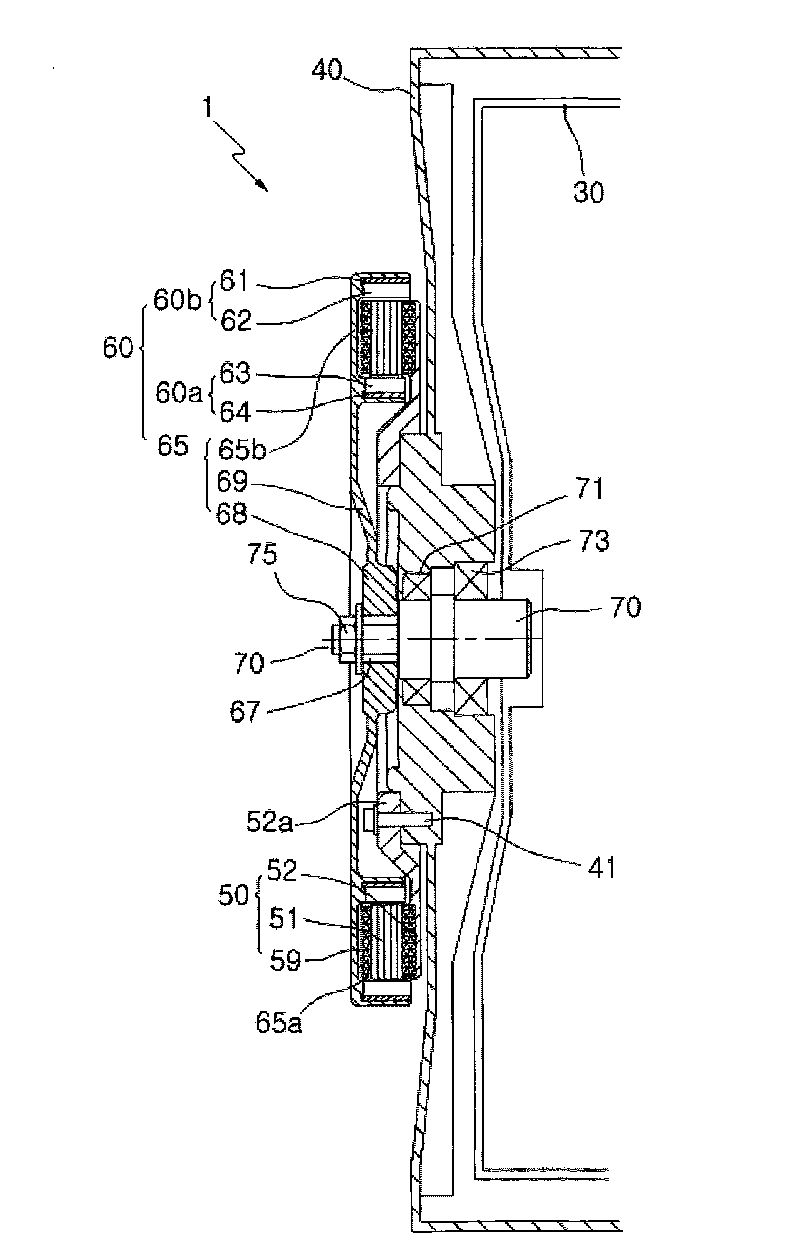

[0105] The invention relates to an ultra-thin motor with a thickness (or height) of about 25 mm or less, which is suitable for direct drive devices of built-in small and medium-sized drum washing machines, or installed in narrow motor installation spaces of other devices requiring motors.

[0106] The ultra-thin motor of the present invention is first of all an ultra-thin structure, and has a high torque suitable for the quick (Quick) flip driving mode of the drum washing machine, and in consideration of the completely split coil winding workability through the stator core, the adoption is compared with the existing one. There is a dual-rotor structure that does not reduce the size of the magnet. As a result, the magnetic circuit of the motor is defined as a dual-rotor / single stator structure that circulates "inner rotor-split core-outer rotor-adjacent split core".

[0107] In addition, in order to achieve ultra-thinning in the thickness direction of the stator, the coil windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com