Double-rubber combined oil seal forming die and forming method thereof

A technology of rubber combination and forming molds, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of rising prices of rubber materials, achieve high yield, improve wear resistance and medium resistance level, and improve tear resistance The effect of crack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

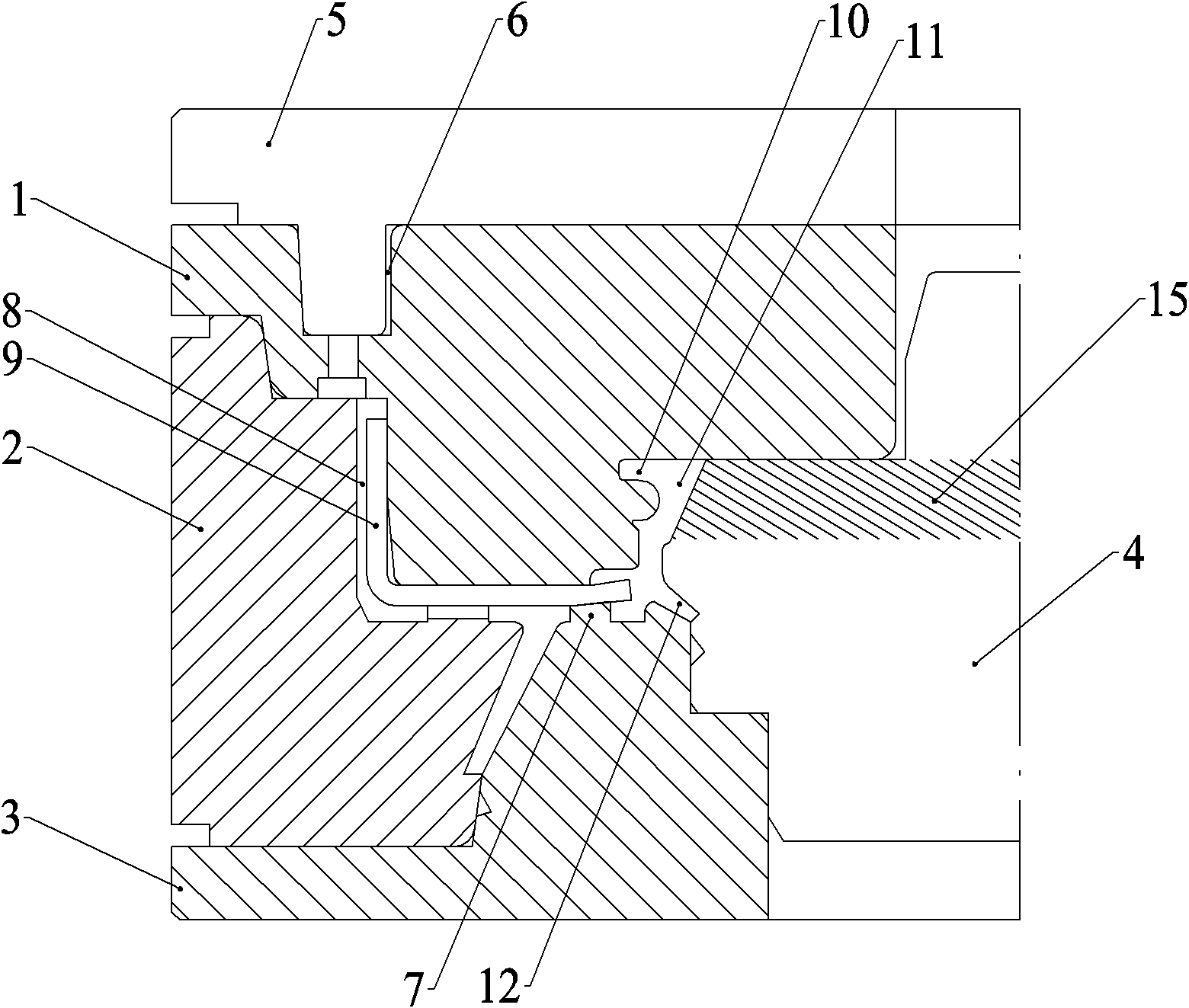

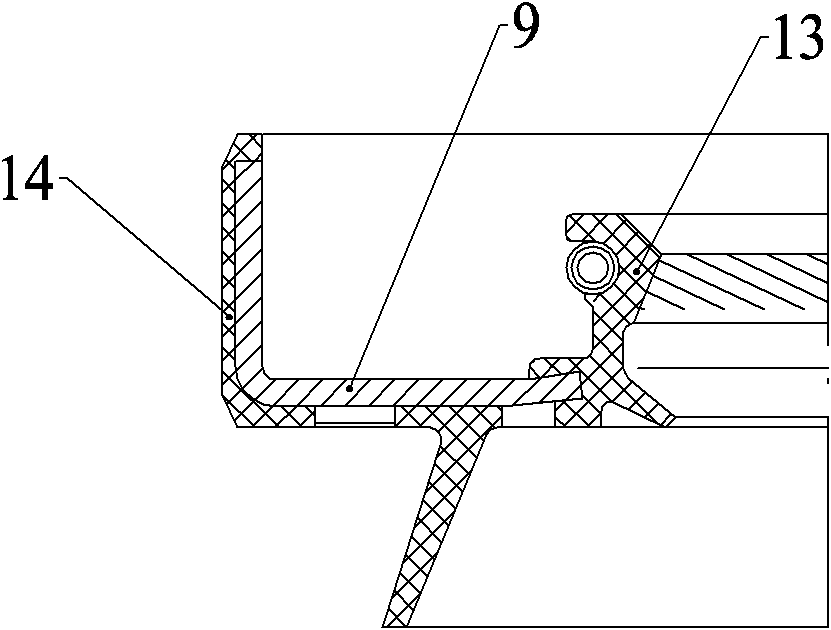

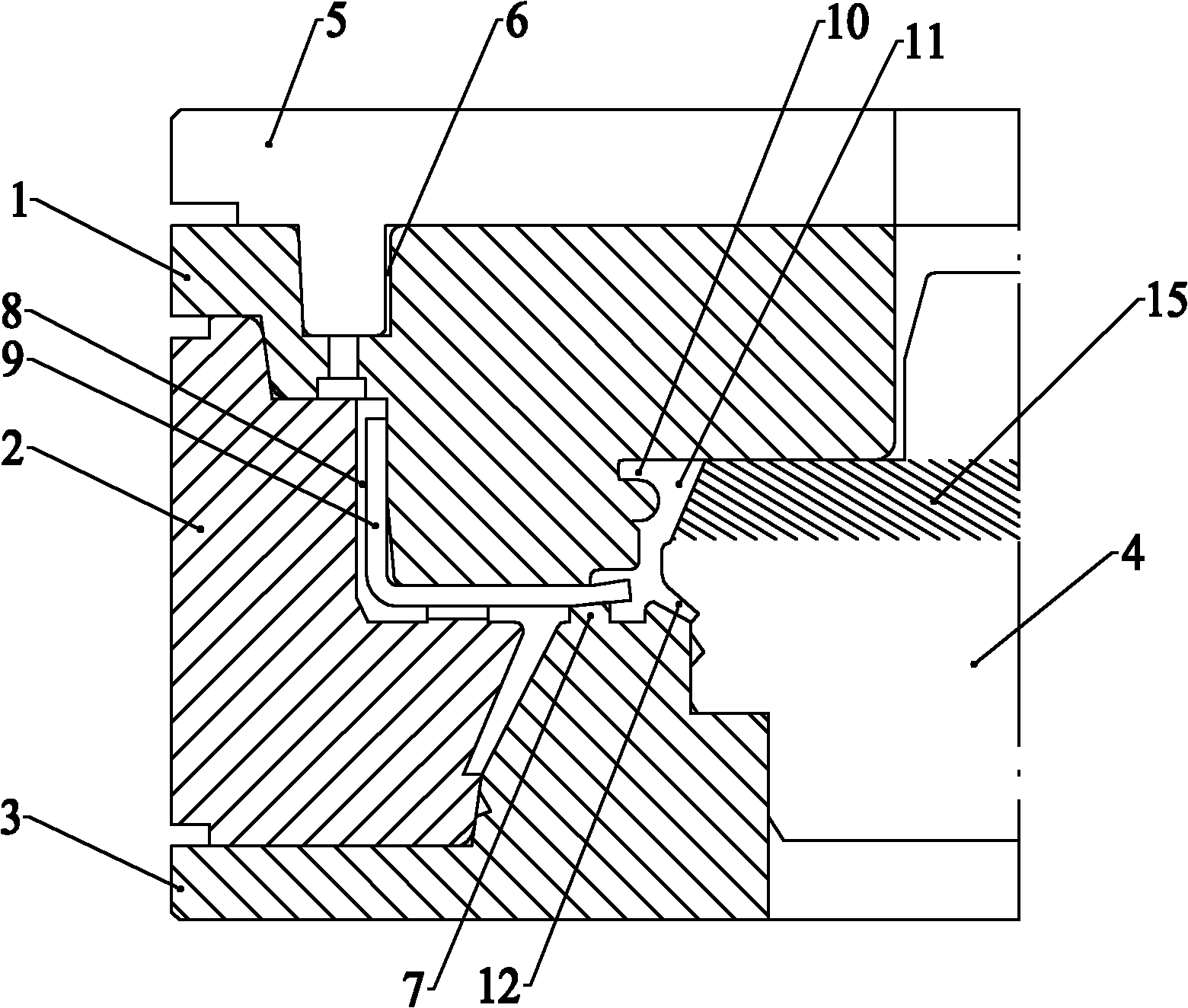

[0028] A double rubber combined oil seal molding die, refer to figure 1 , including an upper mold 1, a middle mold 2, a lower mold 3, a mold core 4 and a rubber mold 5, the upper mold is provided with a plastic injection cavity 6, the plastic pressure mold is set on the upper side of the plastic injection cavity, and the lower mold is provided with a sealing rib 7. The first rubber cavity 8 is formed by the clamping enclosure between the lower mold, the upper mold and the middle mold. The oil seal support frame 9 set in the first rubber cavity is supported and connected by the sealing ribs of the lower mold. The mold core set by the mold support and the upper mold clamping enclosure constitute the second rubber cavity 10; the second rubber cavity has the main lip cavity 11 formed by the upper end slope of the mold core and the lower end surface of the lower mold clamping enclosure , the second rubber cavity has the auxiliary lip cavity 12 formed by the upper end surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com