Full-automatic drawer sliding rail assembling machine

A sliding rail assembling machine, a fully automatic technology, applied in the direction of assembling machines, drawers, furniture parts, etc., can solve the problems of high labor intensity and low assembly efficiency, and achieve high assembly production efficiency, simple operation, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

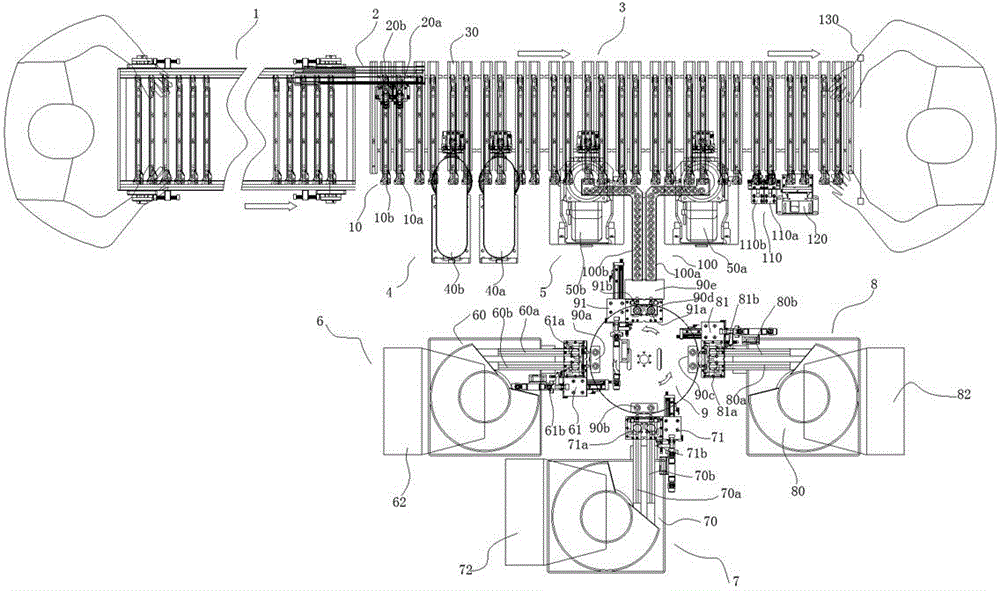

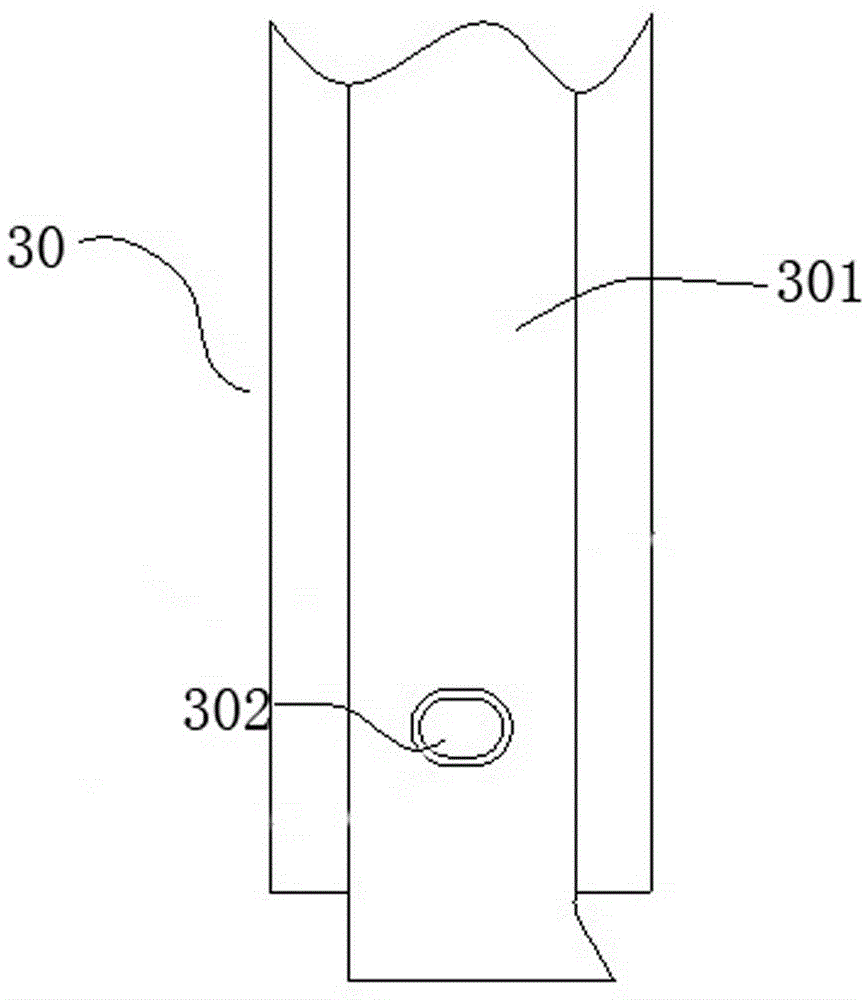

[0021] Such as figure 1 The automatic drawer slide rail assembly machine of the present invention shown in the present invention includes a slide rail main body material storage pull wire 1, a first material suction manipulator 2, a chain conveyor 3, a hole reaming device 4, a riveting device 5, a pin feeding device 6, and a roller Feeding device 7, gasket feeding device 8, turntable assembly table 9, second material suction manipulator 91, finished product roller transfer cable 100, roller axial gap detection device 110 and oiling device 120, the main body of the slide rail is stored The material backguy 1 is used for storing the slide rail main body 10 that is placed on it manually, and it is arranged on the upstream of the chain conveyor 3; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com