Potentiometer automatic assembly machine

An automatic assembly machine and potentiometer technology, which is applied to resistors, sliding contact resistors, circuits, etc., can solve the problems of short service life, high replacement cost, and low machining accuracy of potentiometer assembly machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Attached below Figure 1-19 The present invention is described in further detail.

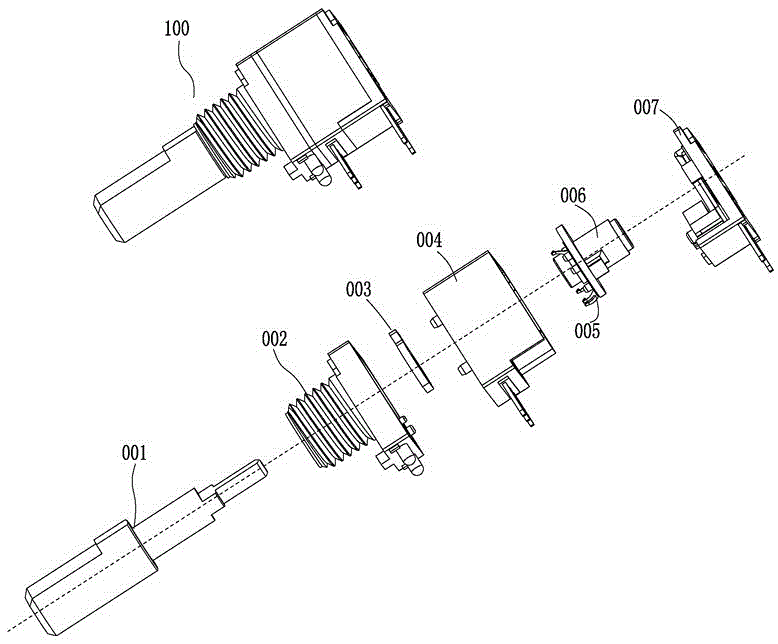

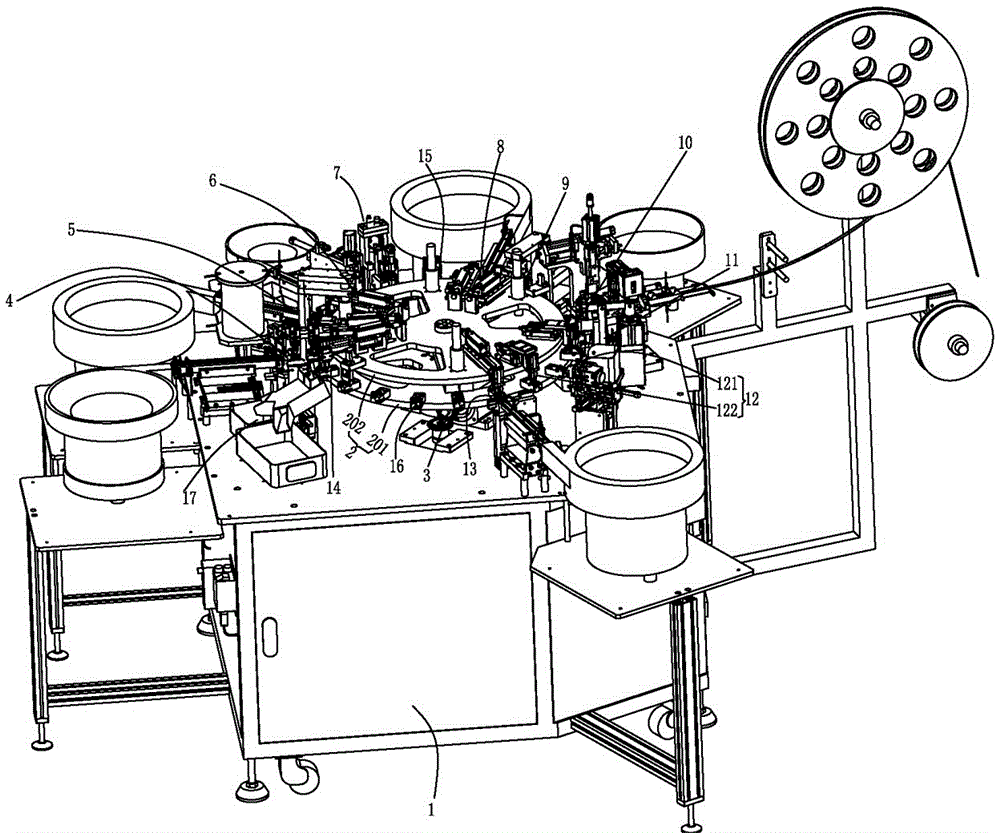

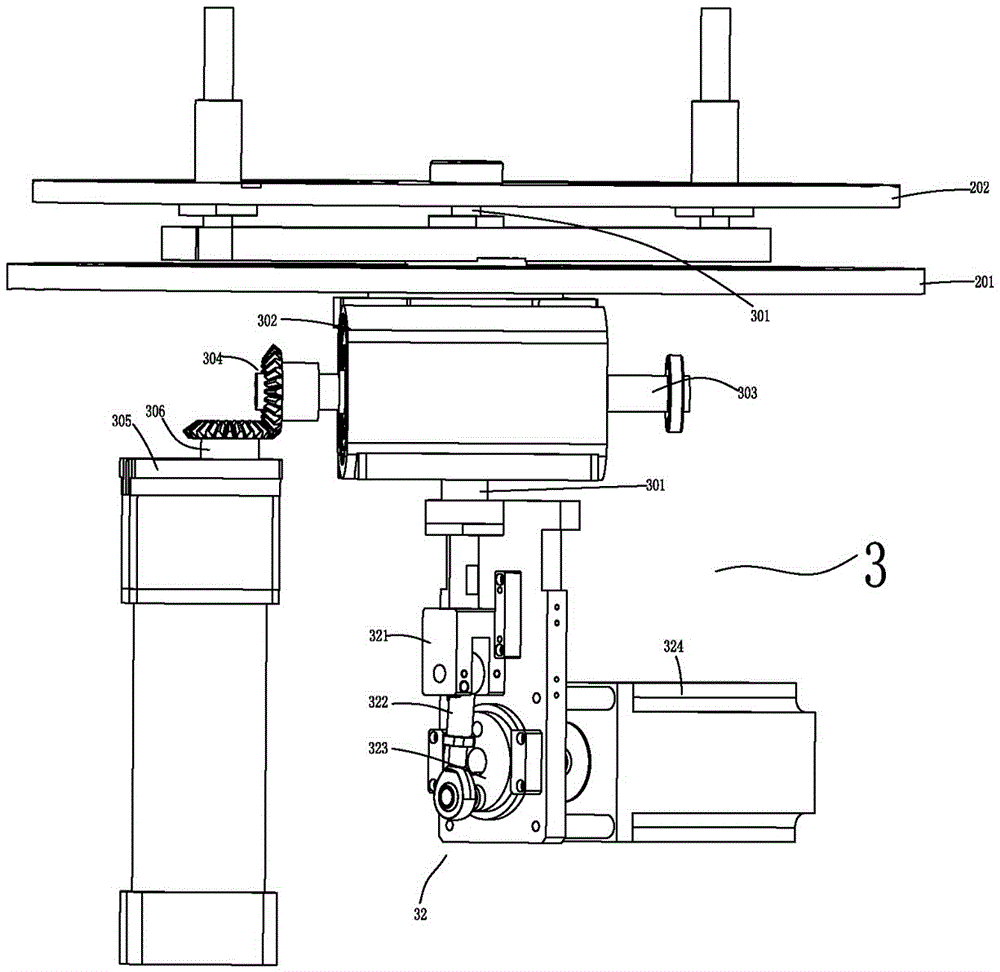

[0038] The present invention is an automatic assembly machine for potentiometers. Of course, the potentiometers assembled by the automatic assembly machine are not limited to walkie-talkies. As a specific embodiment of the application, refer to the attached Figure 1-3, the encoder automatic assembly machine of the present application includes a chassis 1. The top surface of the chassis 1 is an assembly workbench. In practice, after installing various mechanisms on the workbench, a chassis cover (not shown in the accompanying drawings) is also assembled, and a It is used to control the working controller of the automatic assembly machine, and the assembly machine is used to complete the assembly work of the potentiometer through the controller; the turntable 2 provided on the chassis 1, that is, on the workbench, includes a rotating disk 201 and a fixed disk 202. A cam divider assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com