PECVD rework cell processing method

A processing method and technology of work piece, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of production capacity fragmentation, many processes, large suede, etc., to save manpower and material resources, The effect of optimizing the process and simplifying the rework process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

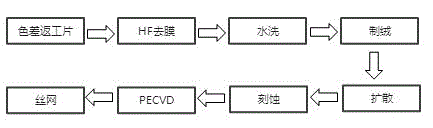

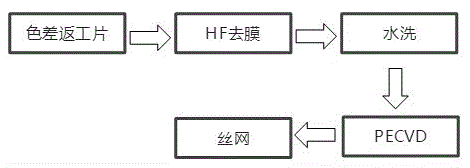

[0011] Attached below figure 2 The technical solutions provided by the present invention are further described in detail.

[0012] In the specific implementation of the present invention, two experimental schemes are adopted, namely the normal rework process and the technical scheme provided by the present invention. In the technical scheme provided by the present invention, the PECVD reworked sheet is successively processed through the pickling tank and three consecutive water washing tanks: when the reworked sheet passes through the pickling tank, the volume of HF is 32L, and the volume of H 2 The volume of O is 128L, and the time is 600S; then after the first washing tank, H 2 The volume of O is 150L, and the time is 360S; finally, it passes through the second and third washing tanks successively, and H 2 The volume of O is 150L, and the time is 300S.

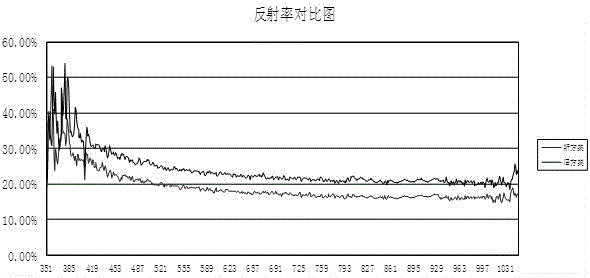

[0013] By testing the electrical properties of the solar cell sheets prepared by adopting the above two experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com