Method for preparing methane by anaerobic fermentation of corn stalks

A corn stalk and anaerobic fermentation technology, which is applied in the direction of fermentation, preparation and application of organic fertilizers, can solve the problems of large influence of fermentation temperature and pH value, low gas production rate of anaerobic digestion, poor fermentation effect, etc., and achieve improvement Utilization rate, excellent fermentation effect, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

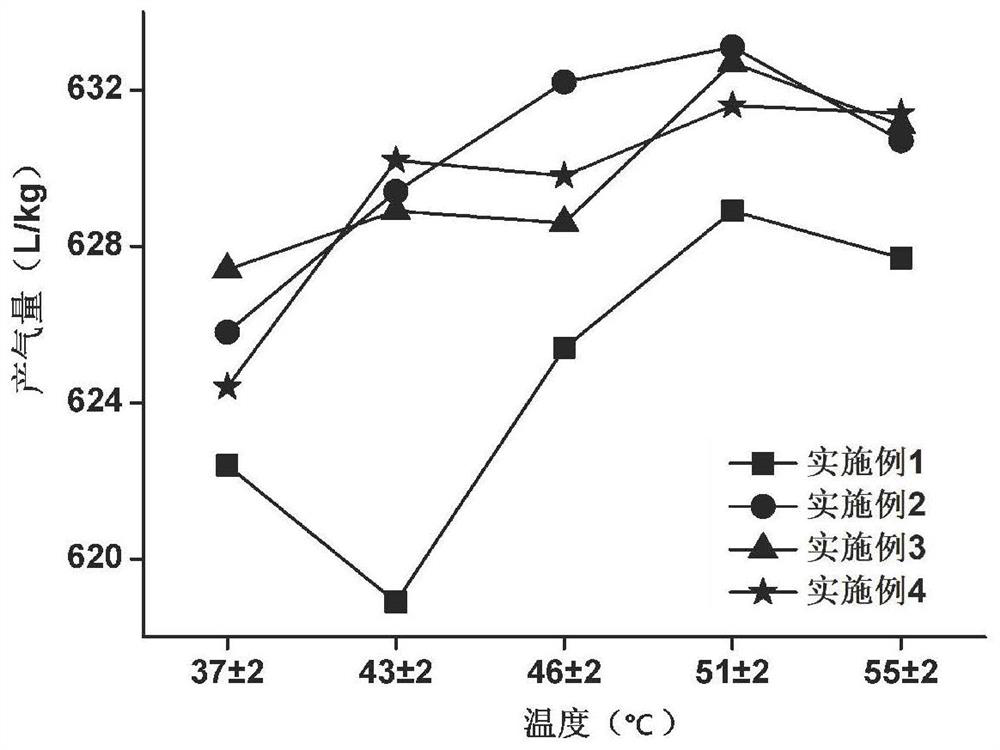

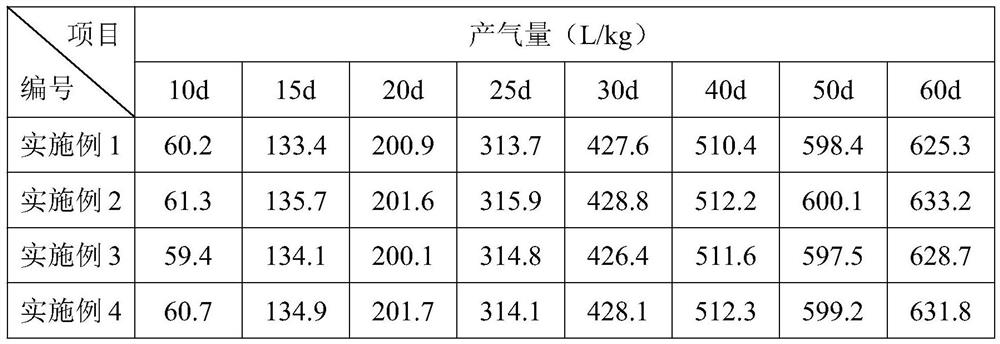

[0024] A method for producing methane by anaerobic fermentation of corn stalks, specifically comprising the following steps:

[0025] Step 1: crush the recovered corn stalks into 3cm segments, add it to the fermenter, then add water, sodium oxide and urea, and mix evenly, wherein the weight ratio of corn stalks, water, sodium oxide and urea is 110: 60:5:6.3, then adjust the temperature of the fermenter to -10°C, adjust the temperature to room temperature every 6 hours, stir, repeat this twice, and then adjust the temperature to room temperature.

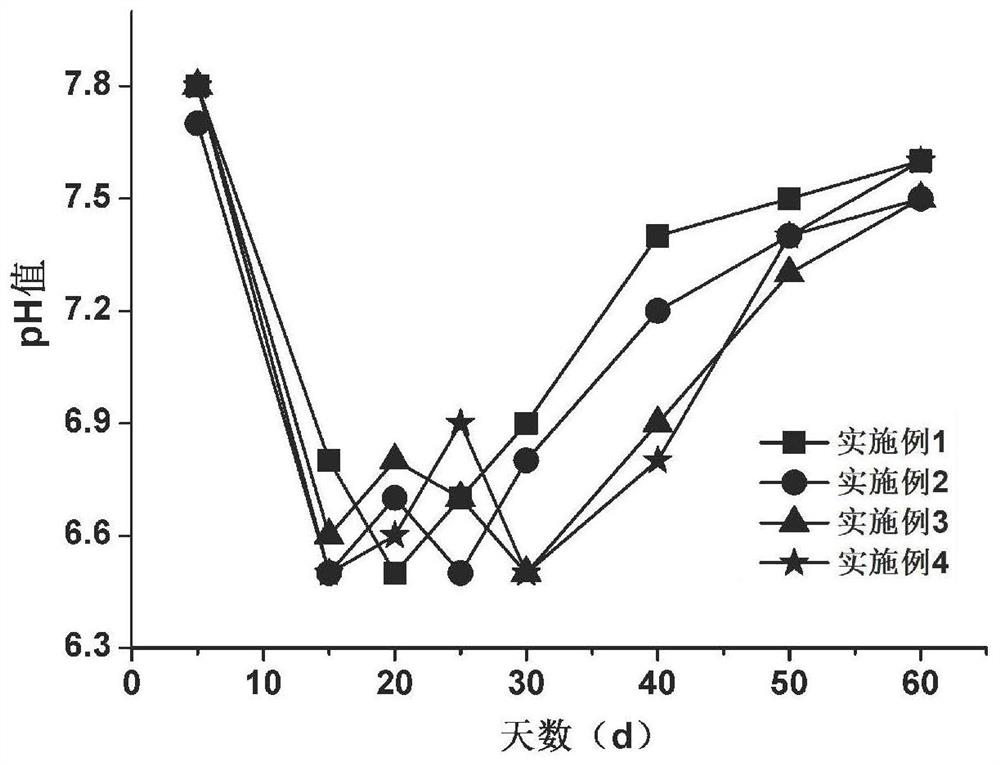

[0026] Step 2: Add livestock and poultry manure to the fermenter in step 1 to seal the fermenter, wherein the weight ratio of corn stalks to cow manure is 1:1.29, the fermentation temperature is 35°C, and the fermenter is shaken 3 times every three days , the fermentation period is 60 days.

Embodiment 2

[0028] A method for producing methane by anaerobic fermentation of corn stalks, specifically comprising the following steps:

[0029] Step 1: crush the recovered corn stalks into 7cm segments, add it to the fermenter, then add water, potassium oxide and urea, and mix evenly, wherein the weight ratio of corn stalks, water, potassium oxide and urea is 160: 85:11:10.4, then adjust the temperature of the fermenter to -15°C, adjust the temperature to room temperature every 8 hours, stir, repeat this twice, and then adjust the temperature to room temperature.

[0030] Step 2: Add livestock and poultry manure to the fermenter in step 1, and seal the fermenter, wherein the weight ratio of corn stalks to pig manure is 1.33:1.67, the fermentation temperature is 55°C, and the fermenter is shaken every three days for 3 times, the fermentation cycle is 60 days.

Embodiment 3

[0032] A method for producing methane by anaerobic fermentation of corn stalks, specifically comprising the following steps:

[0033] Step 1: crush the recovered corn stalks into 5cm segments, add it to the fermenter, then add water, calcium oxide and urea, and mix evenly, wherein the weight ratio of corn stalks, water, calcium oxide and urea is 130: 70:8:8.1, then adjust the temperature of the fermenter to -12°C, adjust the temperature to room temperature every 7 hours, stir, repeat this twice, and then adjust the temperature to room temperature.

[0034] Step 2: Add livestock and poultry manure to the fermenter in step 1, and seal the fermenter, wherein the weight ratio of corn stalks and sheep manure is 1.13:1.45, the fermentation temperature is 40°C, and the fermenter is shaken every three days for 3 times, the fermentation cycle is 60 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com