BIM-based large refrigeration machine room digital assembly method and system

A technology for refrigerating machine room and assembly method, which is applied in the direction of cooperative operation devices, image data processing, computer parts, etc., which can solve problems affecting installation accuracy, rework, and shortening construction period, so as to improve installation accuracy, reduce material waste, and save energy. labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

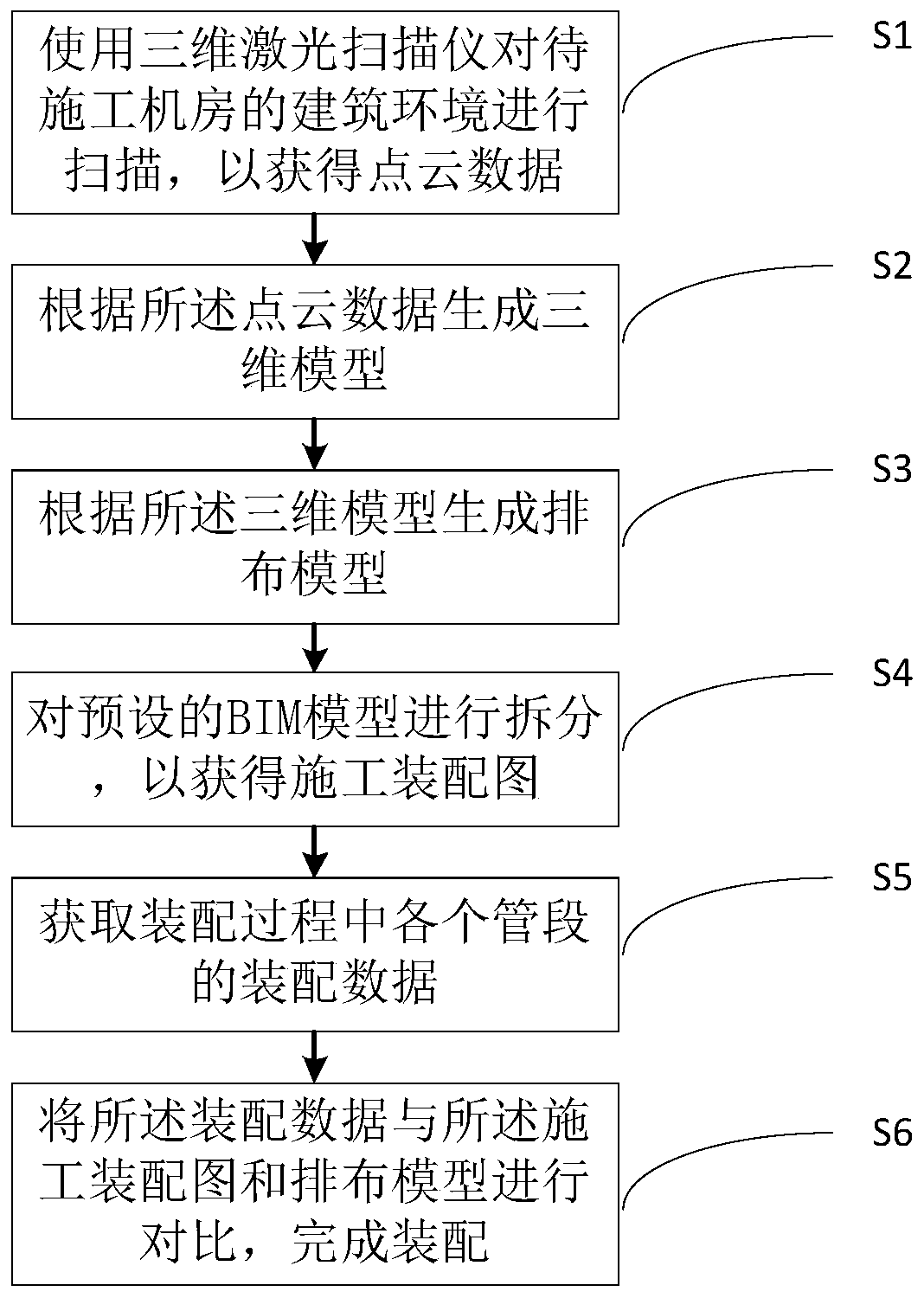

[0047] A BIM-based digital assembly method for a large refrigeration room, see figure 1 , including the following steps:

[0048] S1: Use a 3D laser scanner to scan the building environment of the machine room to be constructed to obtain point cloud data;

[0049] Specifically, the following preparatory work is required before construction: users can establish a prefabricated construction concept according to specific project conditions, form a prefabricated construction team, and formulate a feasible prefabricated construction process. Users can also build off-site and on-site prefabrication processing plants according to the volume of the prefabricated construction of the project, and realize the prefabrication, rust removal, painting, module assembly and other processes of the assembly pipeline to meet the processing needs.

[0050] After the above preparatory work is completed, first use a 3D laser scanner to scan the building environment of the machine room to be constru...

Embodiment 2

[0075] A BIM-based digital assembly system for a large refrigeration room, including:

[0076] 3D laser scanner: used to scan the building environment of the construction machine room to obtain point cloud data;

[0077] Computer: used to generate a three-dimensional model according to the point cloud data; generate an arrangement model according to the three-dimensional model; split the preset BIM model to obtain a construction assembly drawing; obtain the assembly data of each pipe section in the assembly process; The assembly data is compared with the construction assembly drawing and the layout model, and the robot is controlled to complete automatic assembly.

[0078] Preferably, the computer is specifically used for:

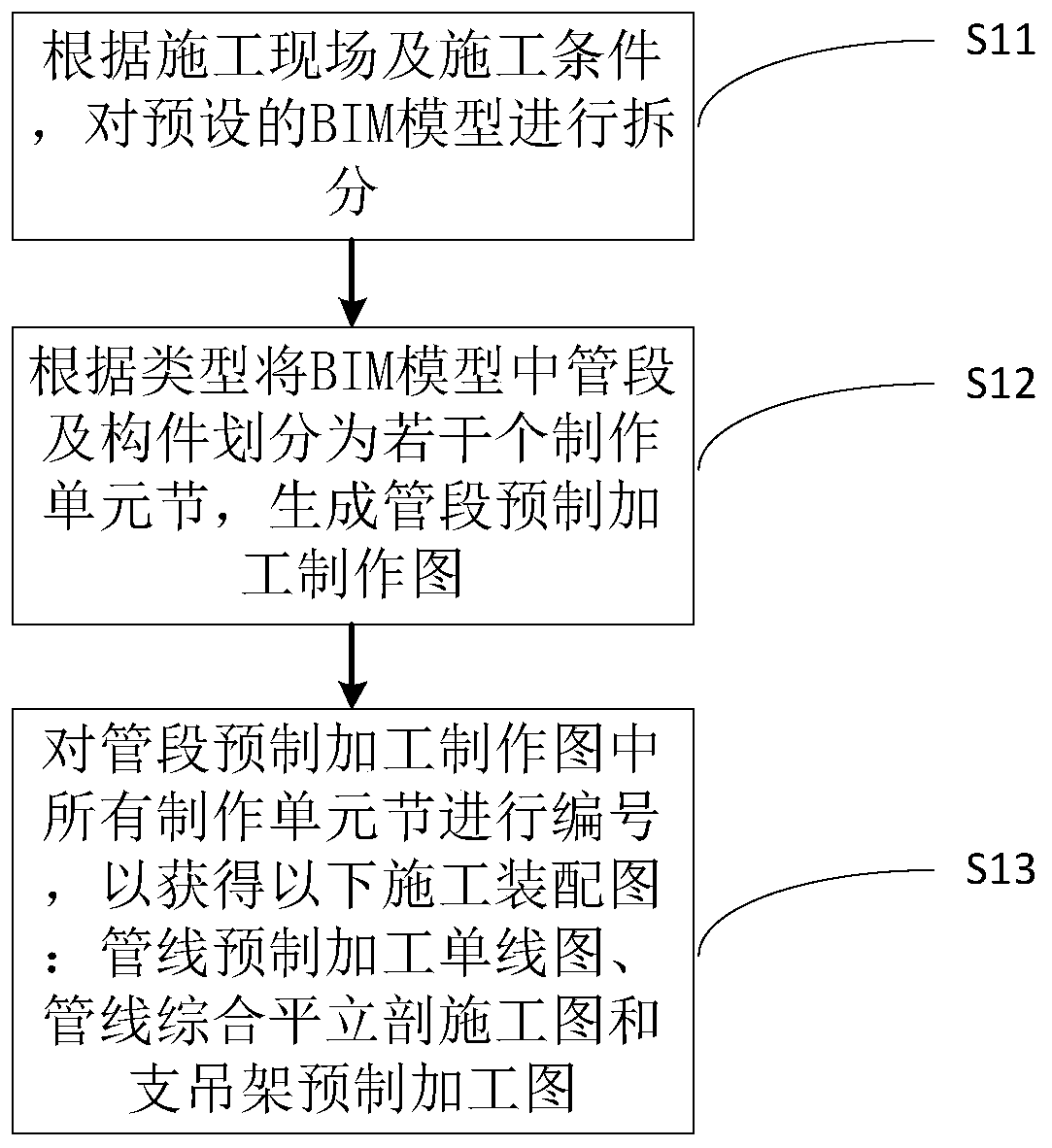

[0079] Split the preset BIM model according to the construction site and construction conditions;

[0080] Divide the pipe sections and components in the BIM model into several production unit sections according to the type, and generate the pipe section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com