Pipeline arrangement method based on BIM model

A pipeline layout and model technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as drawing errors, pipeline collisions, and inability to realize real-time information transmission, and achieve the goal of reducing deviation and reducing rework costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

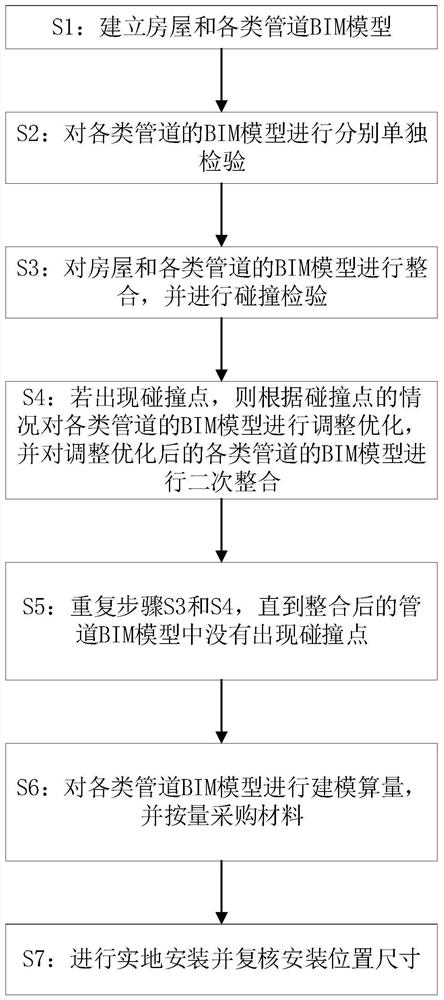

[0018] Example 1: see figure 1 The method for arranging pipelines based on a BIM model in this embodiment includes the following steps: S1: establishing BIM models of houses and various types of pipelines; S2: independently inspecting the BIM models of various types of pipelines; Integrate the BIM models of similar pipelines, and perform collision inspection; S4: If there is a collision point, adjust and optimize the BIM models of various types of pipelines according to the situation of the collision points, and carry out the adjustment and optimization of the BIM models of various types of pipelines. Secondary integration; S5: Repeat steps S3 and S4 until there is no collision point in the integrated pipeline BIM model; S6: Model and calculate various pipeline BIM models, and purchase materials according to the quantity; S7: Perform on-site installation And review the installation location size. The position of the pipeline can be pre-designed through the BIM model, problem ...

Embodiment 2

[0020] Embodiment 2: This embodiment also includes establishing a BIM model of the support and hanger, and pre-installing the support and hanger before installing the pipeline, and the support and hanger is used to fix the pipeline to the beam. It can optimize the layout of pipelines, calculate the optimal arrangement of supports and hangers in advance, and make arrangements in advance at the positions where supports and hangers need to be installed. In this embodiment, the load-bearing situation of each support and hanger and the arrangement position of each support and hanger are judged according to the BIM models of various pipelines, and then the structure of the support and hanger is designed according to the load-bearing situation and the arrangement position of the support and hanger. The structure of the installation surface at different locations is different, and the type, quantity and size of pipes at different locations are different. Therefore, it is necessary to d...

Embodiment 3

[0021] Embodiment 3: The various types of pipes in this embodiment include one or more of heating and ventilation water pipes, water supply and drainage pipes, heating and ventilation pipes, fire water pipes and smoke prevention and exhaust pipes. The drawing colors of various types of pipelines in this embodiment are different, and different pipelines are distinguished by color. In the actual construction process, a color printer is also required to print the construction drawings, which is convenient for the construction personnel to construct accurately. In step S7 of this embodiment, the installation position of the pipeline in the BIM model is corrected according to the actual construction situation, and the correction interval is ±5cm. Since the on-site construction cannot be exactly the same as the geometric dimensions given in the drawings, after construction, it is necessary to re-measure and import the actual dimensions into the BIM model for re-collision detection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com