Digital twinning workshop for general assembly of complex electronic device

A technology of electronic equipment and assembly workshops, applied in the field of digital twins, can solve the problems of high cost, uncertainty, uncoordinated production resources, etc., achieve reliable collection and transmission, reduce quality instability, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

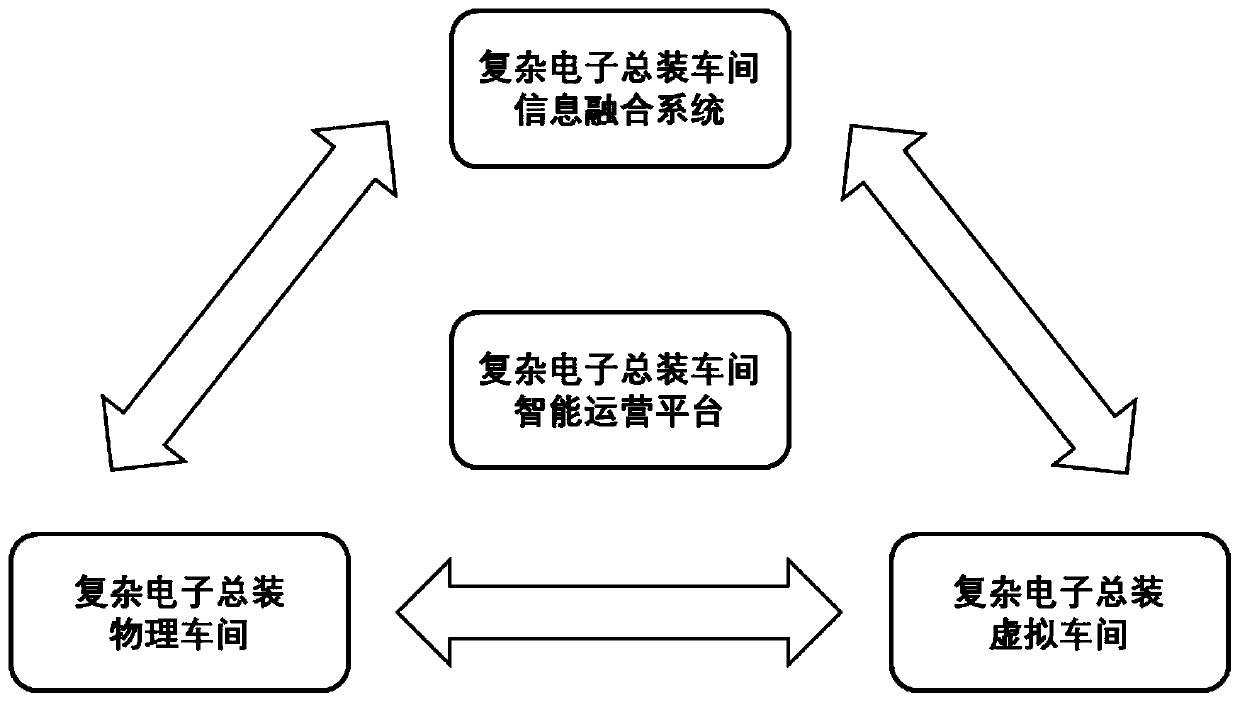

[0038] The twin workshops consist of figure 1 As shown, it includes four parts: the physical workshop of complex electronic equipment assembly, the virtual workshop of complex electronic equipment assembly, the information fusion system of complex electronic equipment assembly workshop, and the intelligent operation platform of complex electronic equipment assembly workshop.

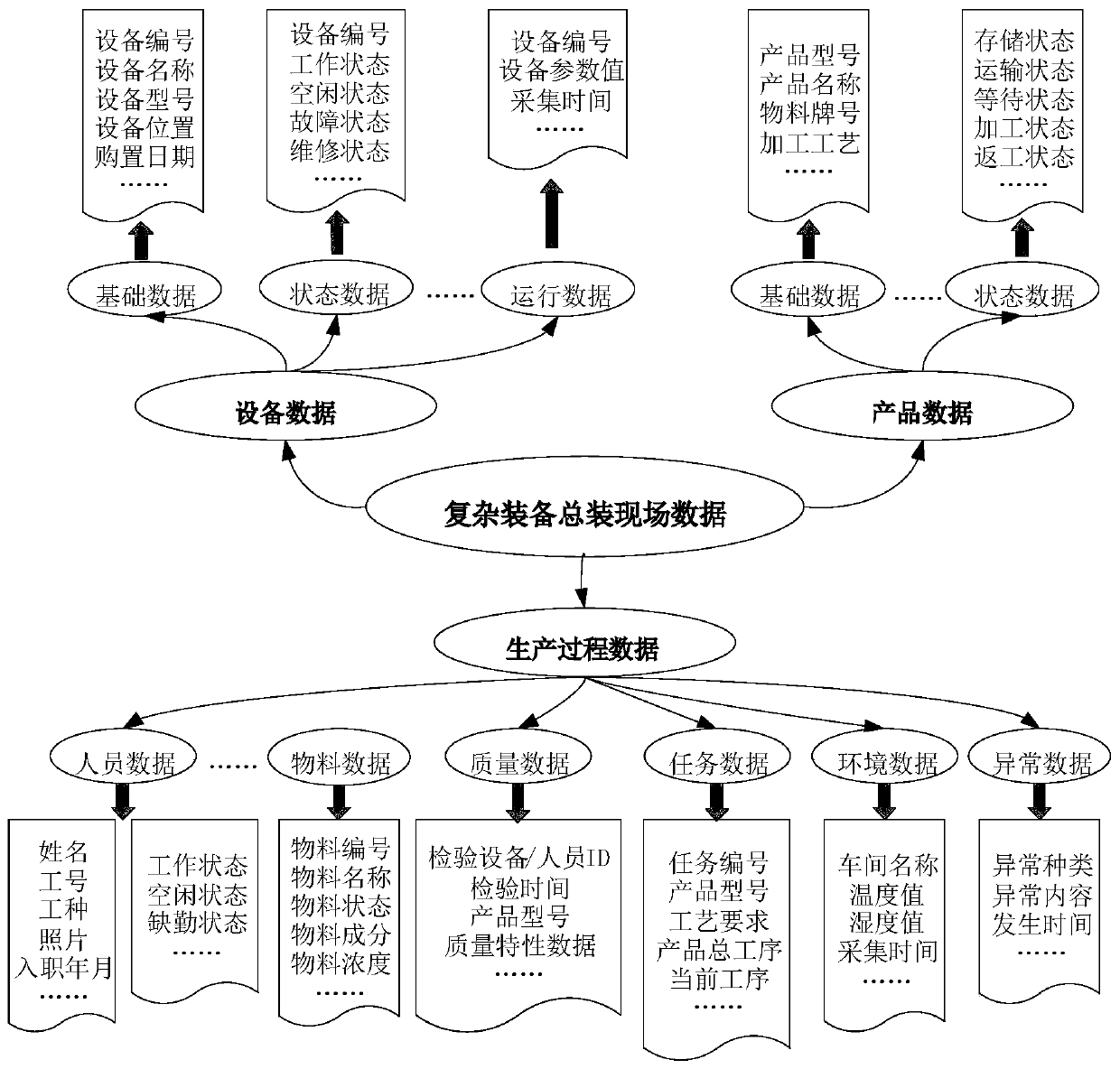

[0039] The complex electronic equipment assembly physical workshop establishes a physical workshop intelligent perception system with highly integrated information, intelligently perceives the required information in the physical environment from the four dimensions of people, machines, objects, and the environment, and realizes the full physical level in the information center. Elements are interconnected.

[0040] The key to the construction of a digital twin phy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com