Ship outfitting process sequence automatic planning method and device, terminal and storage medium

A technology of process sequence and automatic planning, applied in the field of ship outfitting, can solve problems such as complex two-dimensional process design optimization process, difficult verification of construction process, unreasonable assembly sequence, etc., to achieve rationality and standardization, avoid interference and collision , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

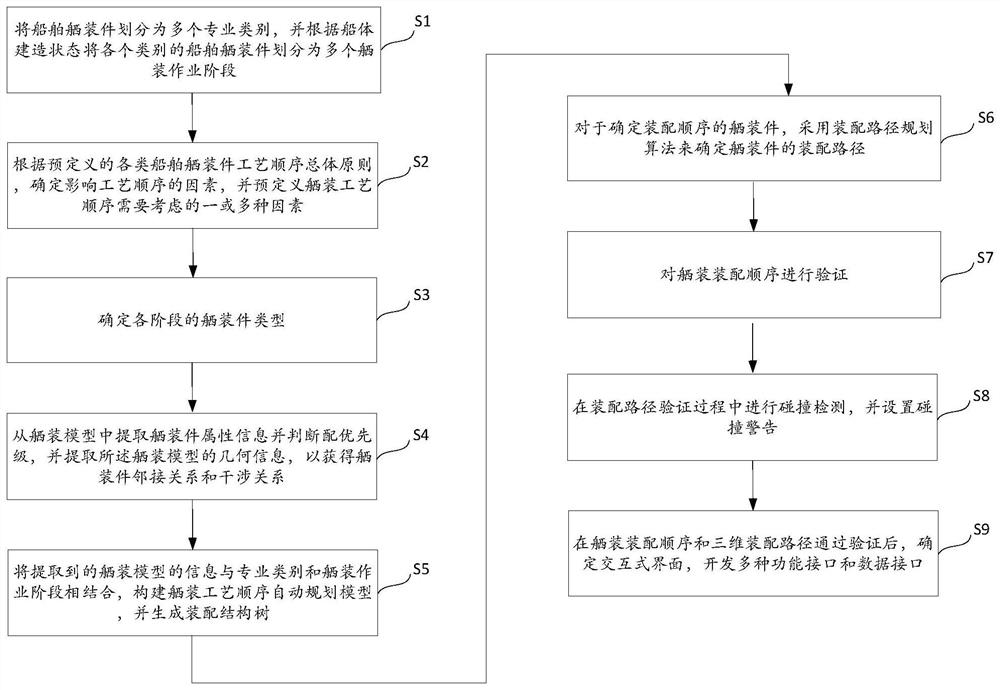

[0032] Such as figure 1 As shown in FIG. 1 , a schematic flow chart of a method for automatic planning of a ship outfitting process sequence in an embodiment of the present invention is shown. It should be noted that the automatic planning method for ship outfitting process sequence in this embodiment can be applied to controllers, such as ARM (Advanced RISC Machines), FPGA (Field Programmable Gate Array), SoC (System on Chip), DSP (Digital Signal Processing ) or MCU (Micorcontroller Unit) and other controllers; it can also be applied to personal computers such as desktop computers, notebook computers, tablet computers, smart phones, smart TVs, and personal digital assistants (Personal Digital Assistant, referred to as PDA); it can also be applied to servers, The servers may be arranged on one or more physical servers according to various factors such as functions and loads, or may be composed of distributed or centralized server clusters, which are not limited in this embodim...

Embodiment 2

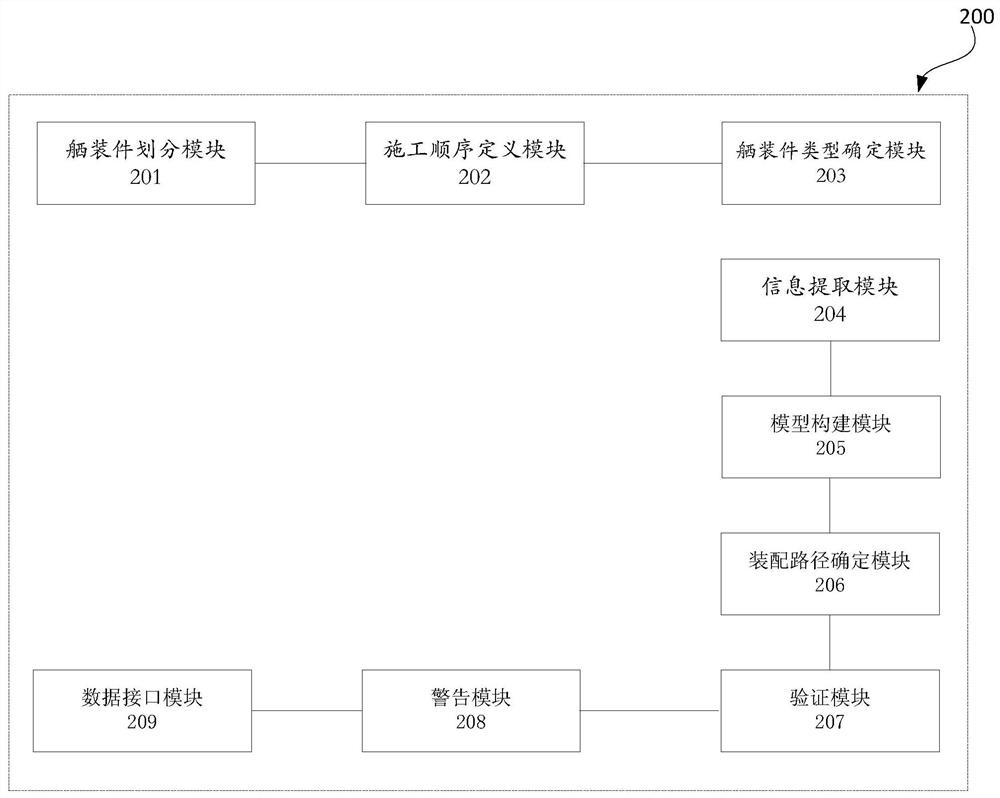

[0069] Such as figure 2 As mentioned above, a structural schematic diagram of an automatic planning device for ship outfitting process sequence in an embodiment of the present invention is shown. The ship outfitting process sequence automatic planning device 200 in this embodiment includes an outfitting division module 201, a construction sequence definition module 202, an outfitting type determination module 203, an information extraction module 204, a model construction module 205, and an assembly route determination module 206 , verification module 207, warning module 208, data interface module 209.

[0070] The outfitting division module 201 is used to divide the ship outfitting into multiple professional categories, and divide each category of ship outfitting into multiple outfitting operation stages according to the hull construction status; the construction sequence definition module 202 is used to The overall principle of the pre-defined process sequence of various s...

Embodiment 3

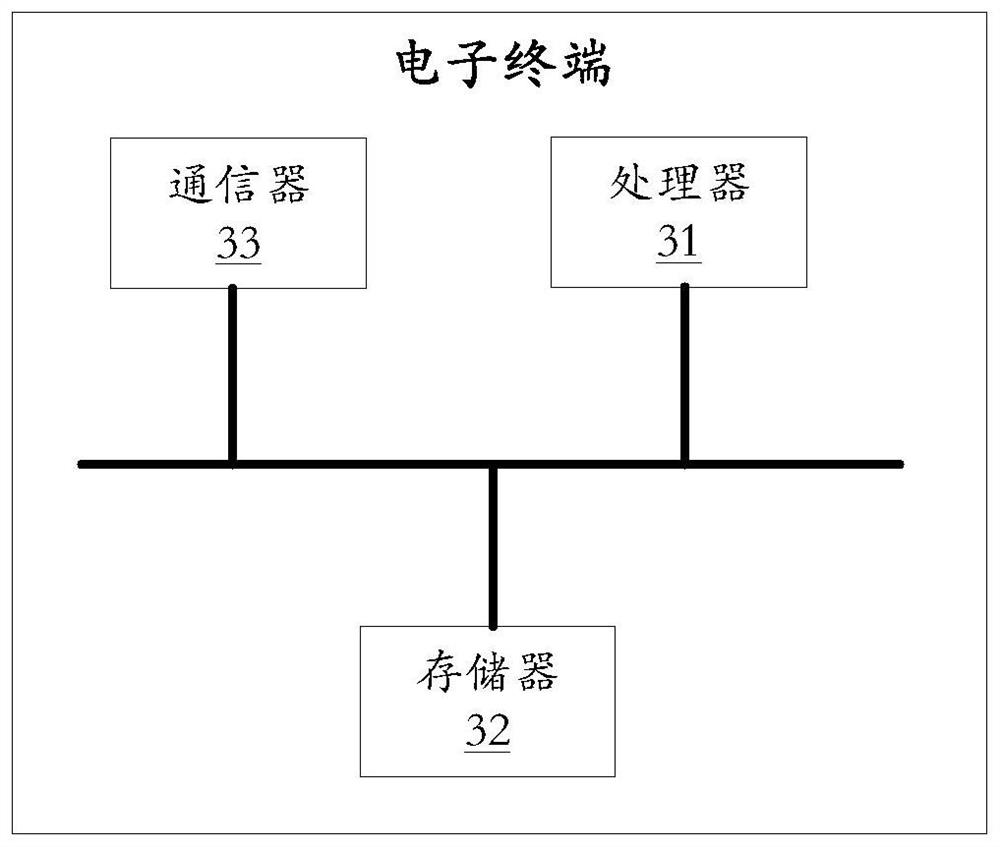

[0074] Such as image 3 As shown, a schematic structural diagram of an electronic terminal in an embodiment of the present invention is shown. The electronic terminal provided by this example includes: a processor 31, a memory 32, and a communicator 33; the memory 32 is connected to the processor 31 and the communicator 33 through a system bus and completes mutual communication, and the memory 32 is used to store computer programs and communicate The device 33 is used for communicating with other devices, and the processor 31 is used for running a computer program, so that the electronic terminal executes each step of the above-mentioned automatic planning method for ship outfitting process sequence.

[0075] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standard Architecture (EISA for short) bus or the like. The system bus can be divided into address bus, data bus, control bus and so on. For ease of rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com