Steel ladle and steel ladle building method

A ladle and masonry technology, which is applied in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of serious ladle sticking and slag, achieve less damage, avoid transverse cracks, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The particle size of the raw materials for the preparation of the aluminum-magnesium spinel castable is as follows:

[0048] Corundum powder: 200 mesh, spinel powder: 200 mesh, magnesia powder: 200 mesh, d-Al 2 o 3 Micropowder: 1200 mesh, SiO 2 Ultrafine powder: 0.1um-0.3um, 97 fused magnesia: 0-1mm, white corundum: 0-3mm, 88 super bauxite: 3-8mm.

[0049]The embodiment of the present invention uses corundum powder, spinel powder, magnesia powder, α-Al 2 o 3 Micropowder and SiO 2 Ultrafine powder is used as the matrix material. When the refractory aggregate and the matrix material are matched, the rigorous and scientific formula design is carried out. At high temperature, the matrix part reacts in situ to form MA spinel phase. The volume expansion at this time improves the thermal shock stability of the castable. At the same time, SiO 2 The liquid phase formed by the ultra-fine powder additive increases the mechanical elasticity of the castable, which can avoid c...

Embodiment 1

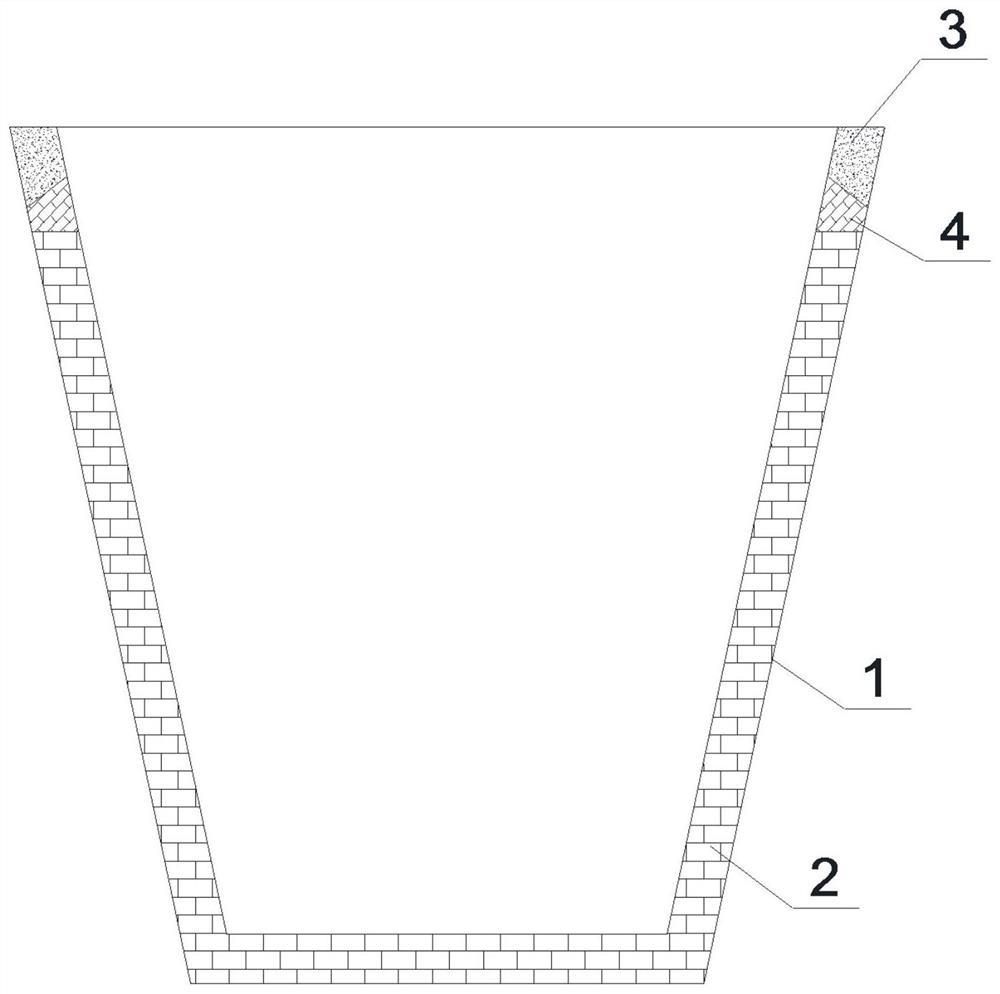

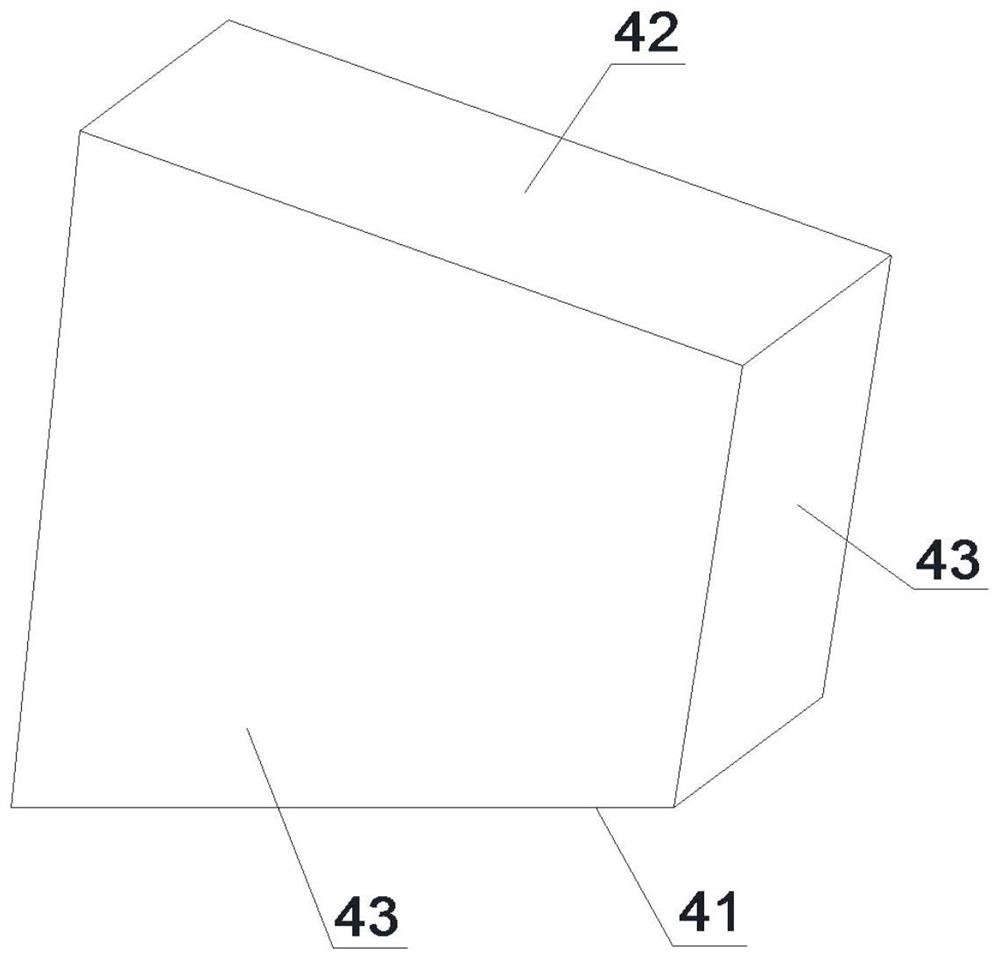

[0065] Such as figure 1 , 2 As shown, the embodiment of the present invention is a steel ladle, the middle and lower part of the inner lining of the steel ladle 1 is refractory brick 2, the upper edge of the inner lining of the steel ladle 1 is aluminum-magnesium spinel castable 3, and the refractory brick 2 The special-shaped brick 4 is used to connect with the aluminum-magnesium spinel castable 3, and the special-shaped brick 4 includes a bottom surface 41, a top surface 42 and four side surfaces 43, and the bottom surface 41 and the top surface 42 are both Rectangular surface or trapezoidal surface or fan-shaped surface, the bottom surface 41 is a horizontal surface, the top surface 42 is an inclined surface, and the height of the side 43 near the molten steel side along the vertical direction is greater than that of the side 43 near the steel shell side.

[0066] Further, the aluminum-magnesium spinel castable 3 and the steel shell of the ladle 1 are fixed by anchor hooks...

Embodiment 2

[0069] A ladle masonry method, comprising the steps of:

[0070] (1) Preparation of Al-Mg spinel castable:

[0071] Raw material preparation: corundum powder 200 mesh: 10%, spinel powder 200 mesh: 3.5%, magnesia powder 200 mesh: 5%, α-Al 2 o 3 Micropowder 1200 mesh: 3%, SiO 2 Ultrafine powder 0.1um-0.3um: 2%, other materials 4.5%, 97 fused magnesia 2%, white corundum 23%, 88 super bauxite 47%.

[0072] Among them, corundum powder: 200 mesh, spinel powder: 200 mesh, magnesia powder: 200 mesh, α-Al 2 o 3 Micropowder: 1200 mesh, SiO 2 Ultrafine powder: 0.1um-0.3um, 97 fused magnesia: 0-1mm, white corundum: 0-3mm, 88 super bauxite: 3-8mm.

[0073] Corundum powder, spinel powder, magnesia powder, α-Al 2 o 3 Micropowder and SiO 2 The superfine powder is pre-mixed for 3-5 minutes, and the mixed powder is made into the silo, and the 88 super-grade bauxite, white corundum aggregate, and fused magnesia aggregate are sequentially arranged with the automatic batching line, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com